SsangYong Korando II (1996-2006 year). Manual — part 324

AUTOMATIC TRANSMISSION 5A-199

SSANGYONG MY2002

1. Measure the projection of the front servo push rod

from the transmission case dimension ‘A’.

a. Apply air at 650/700 kPa to the front servo apply

area (B1 outer)

b. Measure the travel of the push rod and subtract

3 mm to find the shim size required.

c. Release the air.

Notice: A minimum of one shim is required at all times

- minimum shim size is 1 mm. The thickness of

available shims are listed in the table below.

FRONT AND REAR BAND ADJUSTMENT

Front Band Setting Procedure

2. Fit the selected shim(s) to the shank of the anchor

strut as follows:

a. Inspect the shim(s) for damage, wear or corro-

sion. Replace as necessary.

b. The shim(s) are to be installed between the case

abutment face and the anchor strut flange.

c. The shim(s) are to be fitted by hand and under

no circumstances to be hammered or forced.

d. Shim(s) are to be pressed on by hand until an

audible click is heard. The click indicates that

the shim is clipped home correctly.

3. Re-check that the push rod travel. (3 mm ± 0.25

mm)

KAA5A2E0

Thickness (mm)

Part Number

0.95/1.05

0574-037017

1.15/1.25

0574-037018

1.44/1.56

0574-037019

1.73/1.87

0574-037020

1.93/2.07

0574-037021

2.12/2.28

0574-037022

2.42/2.58

0574-037023

2.61/2.79

0574-037024

5A-200 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

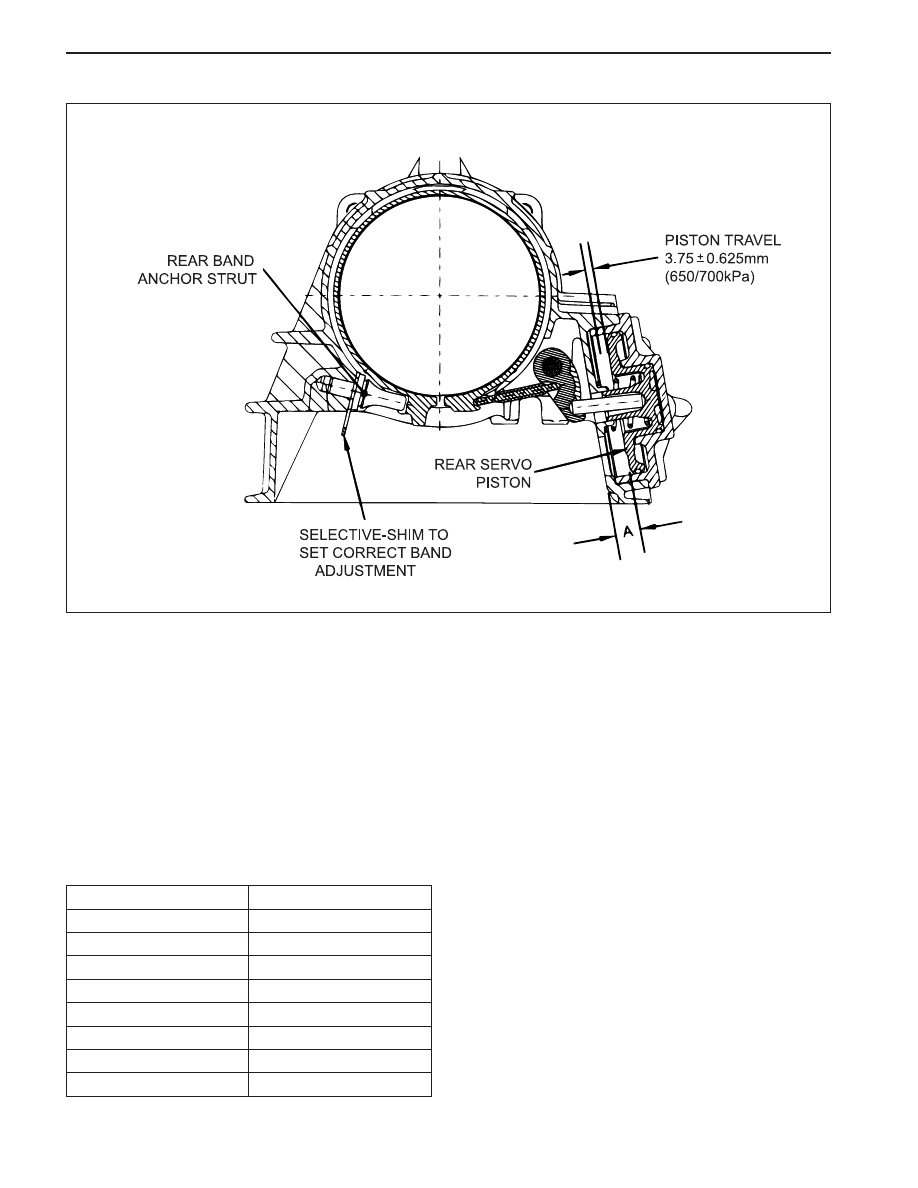

1. Measure distance‘A’ from the rear servo piston to

the inner face of the transmission case using vernier

calipers.

a. Apply air at 650/700 kPa to the rear servo apply

area (B2 outer)

b. Measure the travel of the piston, subtract 3.75

mm and divide the remainder by 2.5 to find shim

size.

c. Release the air.

Notice: A minimum of one shim is required at all times

- minimum shim size is 1 mm. The thickness of

available shims are listed in the table below.

Rear Band Setting Procedure

2. Fit the selected shim(s) to the shank of the anchor

strut as follows.

a. Inspect the shim(s) for damage, wear or

corrosion and replace as necessary. The shim(s)

are to be installed between the case abutment

face and the anchor strut flange.

b. The shim(s) are to be fitted by hand and under

no circumstances to be hammered or forced

c. The shim(s) are to be pressed on by hand until

an audible click is heard. The click indicates

that the shim is clipped home correctly.

3. Re-check that the piston travel.

(3.75 mm ± 0.625 mm)

KAA5A2F0

Thickness (mm)

Part Number

0.0.95/1.05

0574-037017

1.15/1.25

0574-037018

1.44/1.56

0574-037019

1.73/1.87

0574-037020

1.93/2.07

0574-037021

2.12/2.28

0574-037022

2.42/2.58

0574-037023

2.61/2.79

0574-037024

AUTOMATIC TRANSMISSION 5A-201

SSANGYONG MY2002

KAA5A2G0

5A-202 AUTOMATIC TRANSMISSION

SSANGYONG MY2002

KICKDOWN SWITCH

1. Separate the Kickdown Switch from the Kickdown

Switch bracket by pushing the lock.

2. Disconnect the Kickdown Switch connector.

3. Installation should follow the removal procedure in

the reverse order.

KAA5A5S0

GEAR SHIFT CONTROL LEVER

Disassembly and Assembly Procedure

1. Disconnect the negative battery cable.

2. Remove the gear shift control lever assembly.

Refer to Section 9G, interior Trim.

3. Remove the gear shift control lever knob.

4. Separate the upper and middle housing from the

gear shift control lever assembly by unlocking the

lock.

5. Remove the upper housing.

6. Disconnect the P position lamp by turning it from

the middle housing.

7. Remove the P position switches assembly bolts.

8. Remove the middle housing with the mode

selector switch wiring harness from the gear shift

control lever assembly.

9. Separate the P position switches assembly with

the P position lamp wiring harness from the gear

shift control lever assembly.

Notice: Adjust the brake transmission shift interlock

ease the operation well.

10. Remove the clips supporting the springs and

bushes from the pin of the pin of the gear shift

control lever.

11. Remover the spring and bushes from the pin of

the gear shift control lever.

12. Remove the gear shift control lever by pushing

the pin.

13. Installation should follow the removal procedure

in the reverse order.

KAA5A5P0

KAA5A5Q0

KAA5A5R0

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст