SsangYong Korando II (1996-2006 year). Manual — part 344

SSANGYONG MY2002

5D1-4 TRANSFER CASE

COMPONENTS OF THE TOD

TRANSFER CASE SYSTEM

Shift Motor

It locates backside transfer case, which drives rotary

helical cam. When mode select switch changes to 4L,

shift fork is on position for 2.48 : 1 by rotation of helical

cam.

Rear Speed Sensor

A hall effect speed sensor which produces a square

wave. 0 to 5 volts direct current signal in response to

a rotating 30-tooth wheel coupled to the rear propeller

shaft inside the transfer case. Each rotation of the rear

propeller shaft will result in 30 speed sensor pulse.

Front Speed Sensor

A hall effect speed sensor which produces a square

wave. 0 to 5 volts direct current signal in response to

a rotating 30-tooth wheel coupled to the front propeller

shaft inside the transfer case. Each rotation of the front

propeller shaft will result in 30 speed sensor pulse.

Electro-Magnetic Clutch

An electromagnetic clutch used to control the amount

of torque applied to the front propeller shaft.

Position Encoder

A set of 4 gray code switches which provide feedback

to the TCCU indicating the position of the shift motor.

Clutch Pedal Position Switch

A switch on vehicles equipped with a manual transmis-

sion which indicates that the clutch pedal is depressed

Park/Neutral Position Switch

A switch on vehicles equipped with an automatic trans-

mission which indicates that the transmission is in neu-

tral.

4H/4L Switch

A switch selects the desired gear ratio.

DEFINITION OF TERMINOLOGY

Shift Inhibit Speed

The vehicle speed limit, which transfer case shifts, is

disallowed. Vehicle speed is indicated by propeller

shaft speed measurement.

Duty Cycle

Duty cycle is the time the electromagnetic clutch is on

divided by the period in which it is being modulated.

Touch-off

A minimum amount of duty cycle applied to the electro

magnetic clutch.

Front Overrun

A condition where the front propeller shaft is turning at

a rate which is faster than the rear propeller shaft.

Rear Overrun

A condition where the rear propeller shaft is turning at

a rate which is faster than the front propeller shaft.

High Range

The highest (numerically lowest = 1 : 1) gear ratio be-

tween the input and outputs of the transfer case.

Low Range

The lowest (numerically highest = 2.48 : 1) gear ratio

between the input and outputs of the transfer case.

OPERATION OF THE TOD

TRANSFER CASE SYSTEM

Initial Operation of TOD Control Unit

When ignition switch is turned to ON, 4WD LOW and

4WD CHECK lamp illuminates for 0.6 second to check

bulb in instrument panel, then perform diagnosis of

system. Refer to “Self-Diagnosis Test” in this section.

Electric Shift System Operation

The electric shift system is responsible for changing

the transfer case gear ratio by controlling the electric

shift motor. The TCCU monitors the 4H/4L switch, park/

neutral position switch, speed sensors, position

encoder, and ignition switch.

A range change is initiated when:

•

The 4H/4L switch is changed from 4H to 4L or from

4L to 4H.

•

The motor position (as indicated by the position

encoder) does not match the 4H/4L switch

immediately after the ignition is turned on.

Shift Criteria

When a range change is initiated a diagnostic test will

be completed on the motor, speed sensors, and

position encoder. If the diagnostic test fails, the shift

will not be attempted. If all components are operating

properly, the TCCU will attempt a range change after

the following shift criteria are met:

•

The transmission is in neutral for 2 seconds after

the shift is requested.

•

Both propeller shaft speeds are below 87 rpm (2580

pulses/minute). If the transmission is taken out of

neutral before 2 seconds has passed, or either

propeller shaft speed increases above the limit, the

shift will be suspended and the 4L indicator will

continue to blink until the criteria are met again or

the 4H/4L switch is returned to the original position.

Range Change

When the shift criteria are met, the motor is rotated in

the appropriate direction (as determined by the selector

switch) until one of the following occurs:

TRANSFER CASE 5D1-5

SSANGYONG MY2002

•

The motor reaches its destination.

•

The motor is on for 5 seconds without reaching its

destination. The shift has failed and the TCCU will

respond as default mode.

•

A fault occurs with either the motor or position

encoder. Refer to the diagnosis requirement.

When the motor is energized, the Ignition, 4H/4L

switch, propeller shaft speeds, and transmission

neutral inputs are ignored.

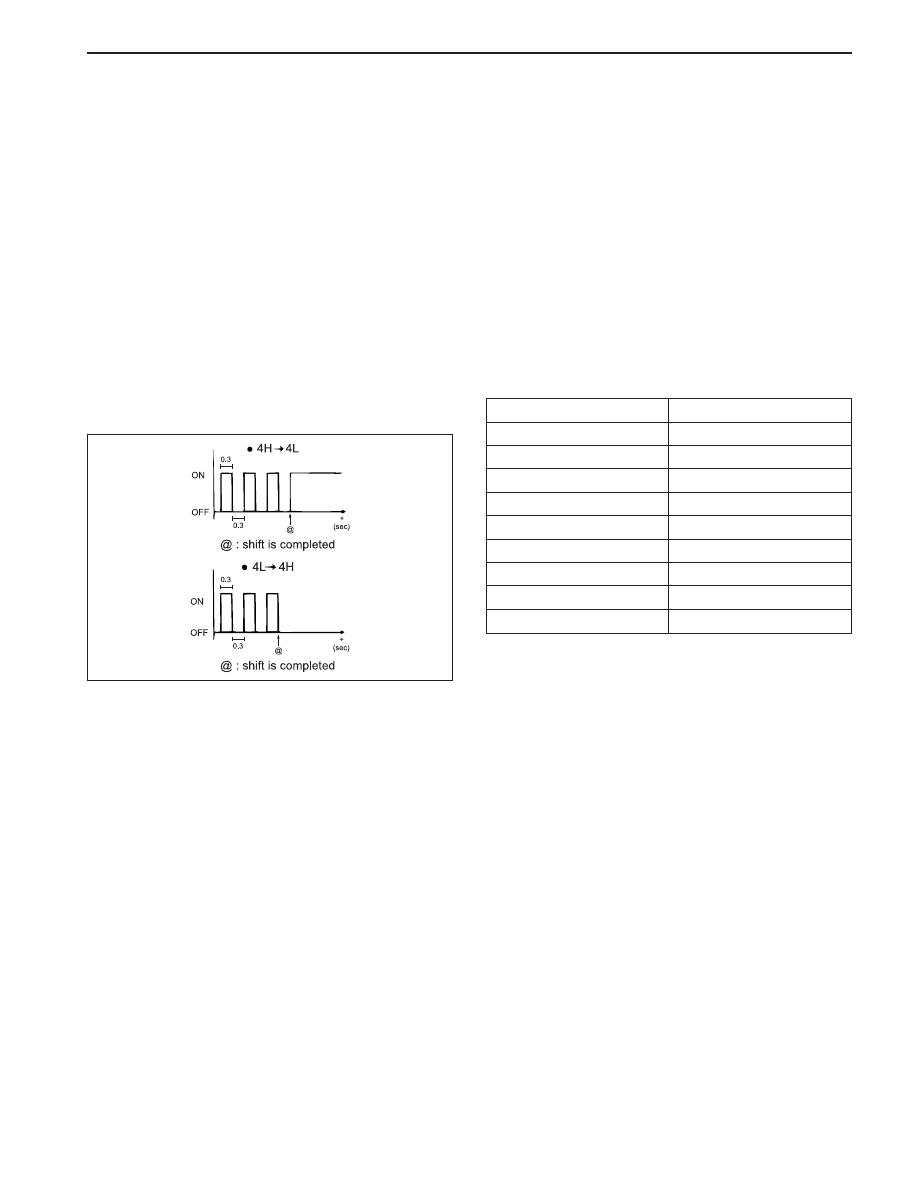

Indicator Function

Once a range change has been initiated the 4WD LOW

indicator will begin to blink at a rate of 0.3 seconds

on, 0.3 seconds off until the shift is completed or

canceled. If a successful shift has been completed,

the 4WD LOW indicator will be illuminated if the motor

is in low range and it will be turned off if the motor is in

high range.

4WD LOW indicator illuminates as below figure.

KAA5D000

TOD

TM

System Operation

The TOD

TM

System is responsible for distributing torque

between the front and rear axles. The TCCU monitors

the propeller shaft speeds, operating range (high/low),

and ABS activity and then applies a calculated amount

of torque to the front axle by pulse width modulating

(PWM) the current applied to the electromagnetic clutch

(EMC).

Touch-off Torque

The minimum EMC duty cycle is based on the vehicle

speed and throttle position. The TCCU receives the

throttle position (TP) sensor signal from the engine con

trol module (ECM) through CAN bus line.

Wheel Slip Detection and Control

The TCCU continuously monitors the front and rear pro-

peller shaft speeds to detect wheel slip.

When wheel slip is detected the TCCU controls the

EMC duty cycles as necessary until the wheel slip is

reduced below the allowable limit. The EMC duty cycle

will then be reduced to the touch-off value.

Brake/ABS Strategy

When the ABS System is active, the EMC duty cycle

is set to a fixed duty cycle (30%) to aid in braking

without counteracting the ABS System.

4L Strategy

When the system is operating in 4WD low range, the

TCCU continues TOD

TM

operation provided that the pro

peller shaft speed is below 175 rpm (5220 pulses/min-

ute). When the speed increases above 175 rpm, the

EMC duty cycle is set to the maximum value (88 %)

which applies the maximum available torque to the front

axle.

Position Encoder

The position encoder is used by the TCCU to determine

the position of the shift motor. Each motor position is

identified by a position code as shown.

Motor Position

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop

Position code 1/2/3/4

1111

1010

0010

0000

1110

1001

0001

0101

0100

Notice:

•

All other position codes are invalid

•

Position input : open circuit (> 4.5V) = 1

•

Position input : Shorted to speed/position return

(< 0.5V) = 0

Position Sensor Interpretation

1. When the module powers up, it will read the position

sensor and the 4H/4L switch input and respond to

the possible codes as following tables.

2. A command to shift will only be acted upon if the

TCCU is reading a valid code at the time the com-

mand to shift is made.

3. After a shift has started, the TCCU will power the

shift motor until the code for the requested position

is read. If an invalid code is read, the TCCU will go

into a default mode.

4. During a shift attempt, the shift motor will be ener-

gized for a maximum of 5 second

SSANGYONG MY2002

5D1-6 TRANSFER CASE

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

4H

Left Stop

Left of High

High

Right of High

Zone 1

Neutral

Zone 2

Low

Right Stop

Left Stop

Left of High

High

Right to High

Zone 1

Neutral

Zone 2

Low

Right stop

No action required. 4WD LOW indicator off.

Blink 4WD LOW indicator.

After the shift conditions are input, attempt a shift to 4H mode if follow-

ing conditions are maintained for 2 seconds conditions are maintained

for 2 seconds.

•

Shift lever position is in neutral.

•

The speed of front and rear propeller shaft is below 87 rpm.

After successfully shifting into 4L mode, stop blinking 4WD LOW indicator.

Blink 4WD LOW indicator.

After the shift conditions are input, attempt a shift to 4L mode if following

conditions are maintained for 2 conditions are maintained for 2 seconds.

•

Shift lever position is in neutral.

•

The speed of front and rear propeller shaft is below 87 rpm.

After successfully shifting into 4L mode, stop blinking 4WD LOW indicator.

No action required. 4WD LOW indicator on.

4H/4L Switch

Input

Action

Motor Position

TRANSFER CASE 5D1-7

SSANGYONG MY2002

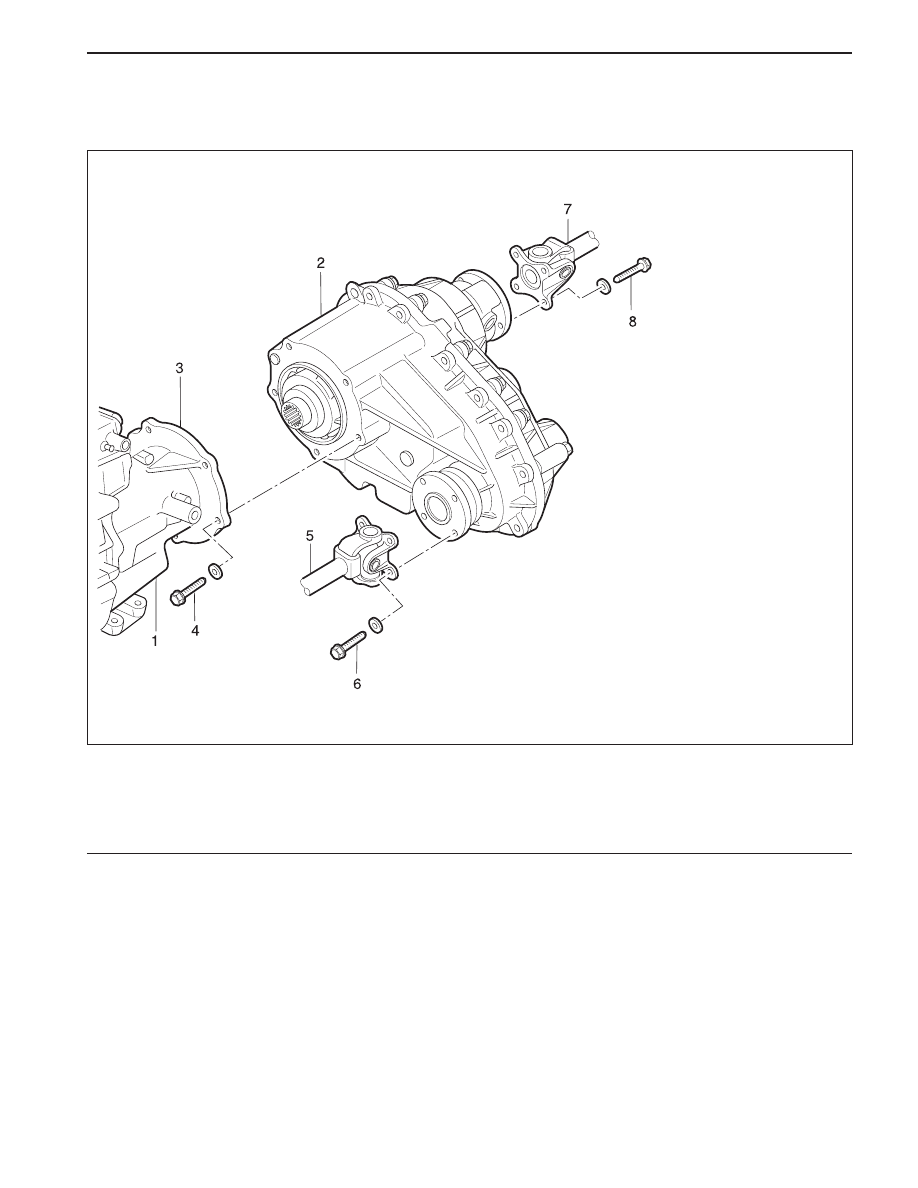

COMPONENT LOCATOR

TORQUE ON DEMAND (TOD) TYPE TRANSFER CASE

KAA5D010

1 Transmission

2 Transfer Case

3 Rear Propeller Shaft

4 Bolt

5 Bolt

6 Front Propeller Shaft

7 Bolt

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст