SsangYong Musso. Manual — part 412

1E3-6 OM600 ENGINE ELECTRICAL

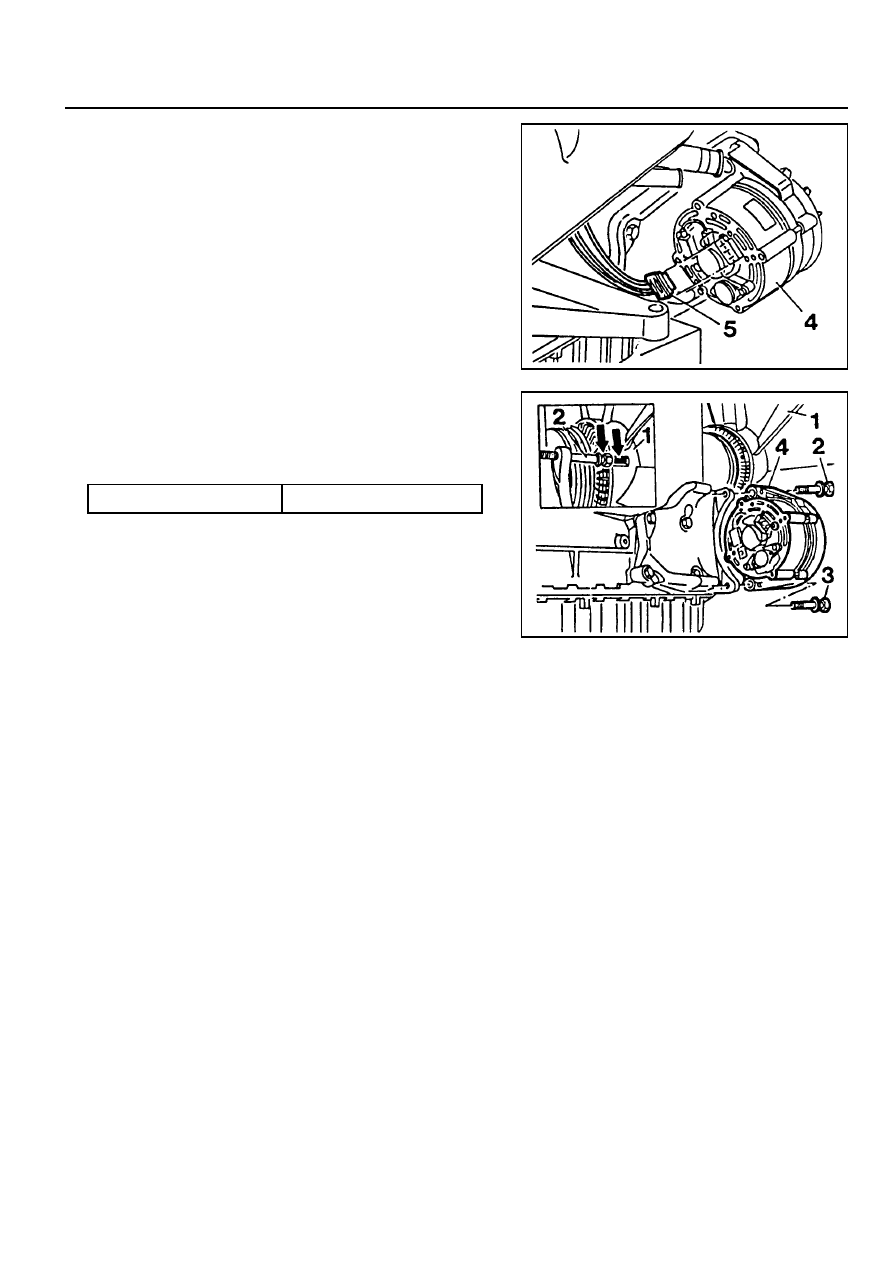

ALTERNATOR

Preceding Work : Removal of poly V-belt

1 Cooling Fan

2 Bolt . . . . . . . . . . . . . . . 45Nm

3 Bolt . . . . . . . . . . . . . . . 45Nm

4 Alternator

5 Plug Connection

OM600 ENGINE ELECTRICAL 1E3-7

Removal & Installation Procedure

1. Disconnect the negative terminal of the battery.

2. Disconnect the plug connection (5).

3. OM 662 Engine

Align the groove of cooling fan with bolt (2) (arrow).

4. Remove the bolts (2, 3) and take out the alternator.

5. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

45 Nm

1E3-8 OM600 ENGINE ELECTRICAL

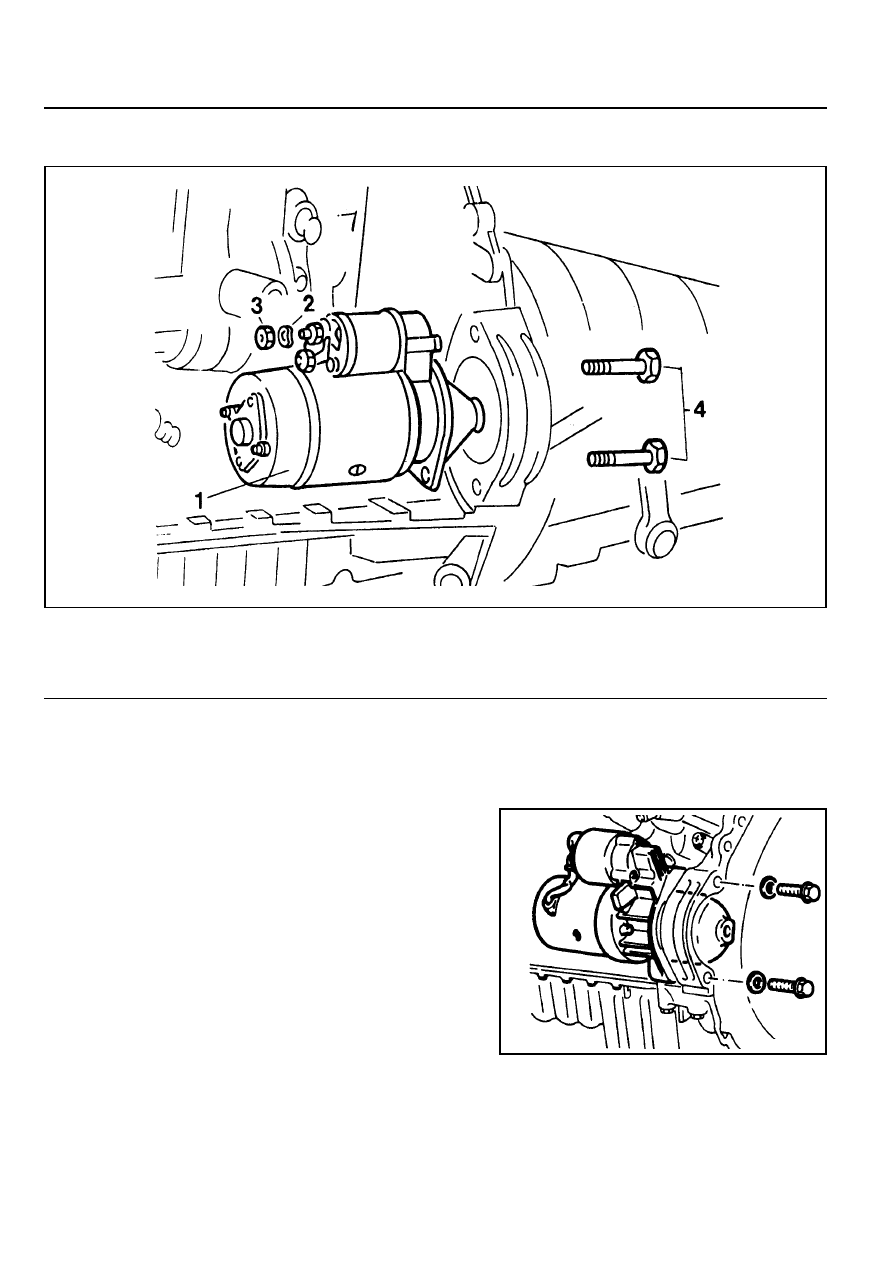

STARTER MOTOR

1 Starter Motor

2 Washer

3 Nut . . . . . . . . . . . . . . . . 15Nm

4 Bolt . . . . . . . . . . . . . . . 48Nm

Removal & Installation Procedure

1. Disconnect the battery terminals.

2. Disconnect the starter motor cable harnesses.

3. Remove the bolts and then remove the starter motor.

4. Installation should follow the removal procedure in the

reverse order.

SECTION 1F3

OM600 ENGINE CONTROLS

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1F3-1

Fastener Tightening Specifications . . . . . . . . 1F3-1

Maintenance and Repair . . . . . . . . . . . . . . 1F3-2

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-2

Fuel Injection Pump Coding . . . . . . . . . . . . . 1F3-3

Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-4

Vacuum Control System Test . . . . . . . . . . . . 1F3-5

Vacuum Pump(Sectional View) . . . . . . . . . . 1F3-10

Vacuum Pump Test . . . . . . . . . . . . . . . . . . . 1F3-11

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . 1F3-13

Vacuum Unit Replacement . . . . . . . . . . . . . 1F3-15

Idle Speed Adjustment . . . . . . . . . . . . . . . . 1F3-16

Fuel Pump Test . . . . . . . . . . . . . . . . . . . . . . 1F3-18

Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . . . 1F3-21

Injection Nozzle Test . . . . . . . . . . . . . . . . . . 1F3-22

Injection Nozzles . . . . . . . . . . . . . . . . . . . . . 1F3-25

Injection Nozzle Repair . . . . . . . . . . . . . . . . 1F3-27

Removal and Installation of

Injection Timing Device . . . . . . . . . . . . . . 1F3-30

Injection Timing Device . . . . . . . . . . . . . . . . 1F3-35

Start of Delivery Test

(Position Sensor, RIV Method) . . . . . . . . . 1F3-37

Fuel Injection Pump . . . . . . . . . . . . . . . . . . 1F3-46

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application

Fuel Tank Mounting Nut

Fuel Pump Pressure Line

Fuel Injection Nozzle

Fuel Injection Pipe

Nozzle Tensioning Nut

Screw Plug

Left-Hand Thread Bolt

N·m

28 - 47

13

35 - 40

18

80

30

46

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст