SsangYong Musso. Manual — part 359

GENERAL ENGINE INFORMATION 1A3-13

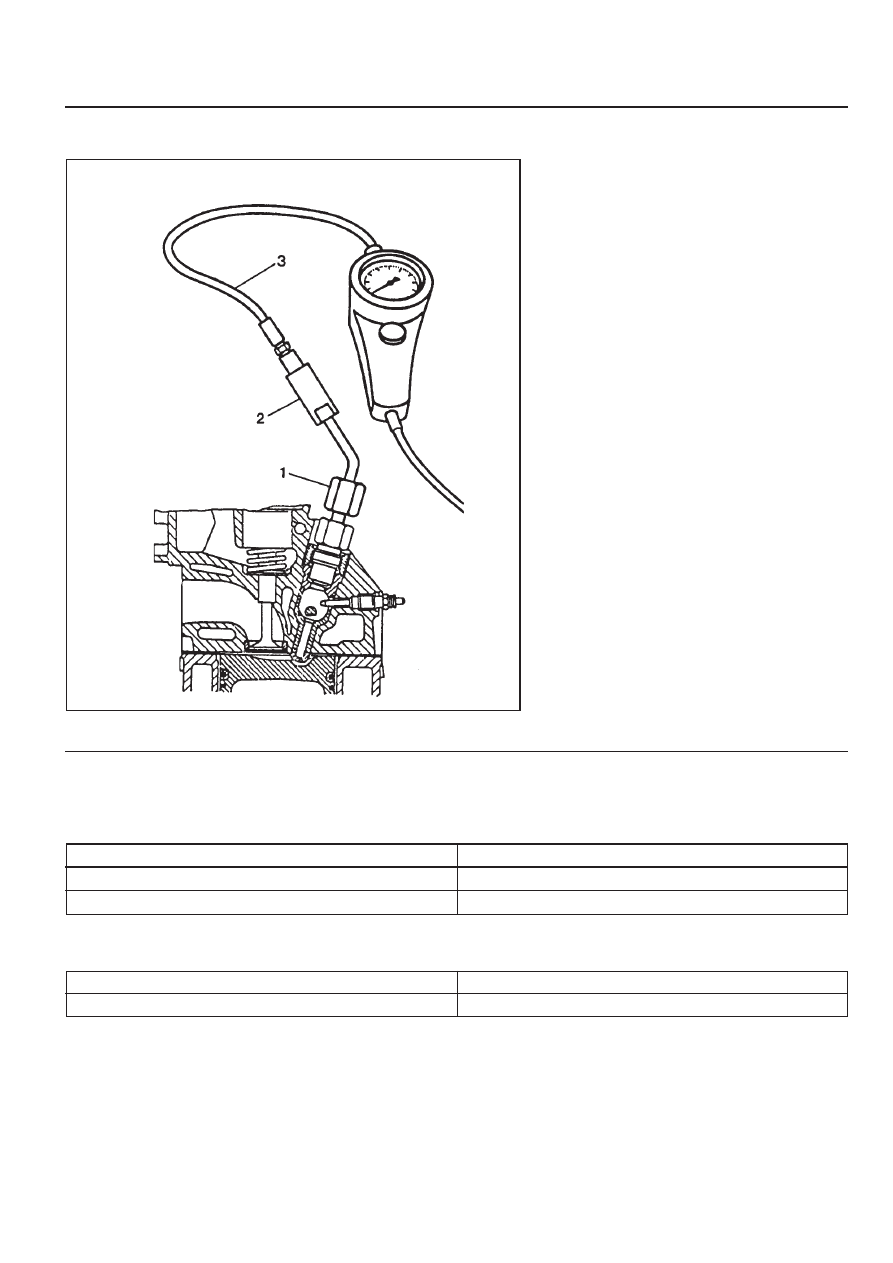

Cylinder Pressure Leakage tester

Connection Piece

CYLINDER PRESSURE LEAKAGE TEST

1 Connector

2 Connection Piece

3 Connection Hose

Permissible Pressure Leakage (Engine at Normal Operating Temperature of 80°C)

At Whole Engine

At Valve and Cylinder Head Gasket

At Piston and Piston Ring

Max. 25 %

Max. 10 %

Max. 20 %

Commercial Tools

BOSCH, EFAW 210 A or SUN CLT 228

BOSCH order no. 1 687 010 016

1A3-14 GENERAL ENGINE INFORMATION

Leakage Test

1. Run the engine to be the coolant temperature 80°C.

2. Remove the fuel injection nozzle.

3. Open the coolant subtank cap.

4. Check the coolant level and replenish if necessary.

5. Open the oil filler cap.

6. Remove the air cleaner cover and element.

7. Position the piston at TDC.

8. Install the connector (1) and connection piece (2).

9. Calibrate the tester and connect the connection hose

(3)

10. Pressurize with compressed air and compare the

pressure changes with permissible pressure leakage.

11. If permissible pressure leakage is out of standard, check

followings :

- Intake and exhaust lines.

- Sounds in oil filler area.

- Air bubbles in radiator coolant.

12. Do pressure leakage test for the remaining cylinders

according to the firing order.

z

OM 662LA Engine : 1-2-4-5-3

z

OM 661LA Engine : 1-3-4-2

13. Remove the tester.

14. Close the coolant pressure cap and oil filler cap.

15. Install the air cleaner element and cover.

16. Install the fuel injection nozzle.

GENERAL ENGINE INFORMATION 1A3-15

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths

of an inch. When any internal engine parts are

serviced, care and cleanliness are important. A liberal

coating of enigne oil should be applied to friction areas

during assembly, to protect and lubricate the surfaces

on initial operation. Proper cleaning and protection

of machined surfaces and friction areas is part fo the

repair procedure. This is considered standard shop

practice even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same

mating surfaces, as when they were removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable

before removing or installing any electrical unit,

or when a tool or equipment could easily come in

contact with exposed electrical terminals.

Disconnecting this cable will help prevent

personal injury and damage to the vehicle. The

ignition must also be in LOCK unless otherwise

noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

SECTION 1B3

OM600 ENGINE MECHANICAL

CAUTION: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Specifications . . . . . . . . . . . . . . . . . . . . . . . 1B3-2

Fastener Tightening Specifications . . . . . . . . 1B3-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . 1B3-4

Special Tools Table . . . . . . . . . . . . . . . . . . . . 1B3-4

Maintenance and Repair . . . . . . . . . . . . . 1B3-12

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . 1B3-12

Engine Assembly . . . . . . . . . . . . . . . . . . . . 1B3-12

Poly V-Belt . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-21

Tensioning Device. . . . . . . . . . . . . . . . . . . . 1B3-23

Poly V-Belt Alignment & Inspection . . . . . . . 1B3-26

Prechamber . . . . . . . . . . . . . . . . . . . . . . . . 1B3-29

Milling of Prechamber Sealing Surface . . . . 1B3-32

TDC (TDC Sensor Bracket) Setting . . . . . . 1B3-35

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . 1B3-37

Timing Case Cover . . . . . . . . . . . . . . . . . . . 1B3-63

Crankshaft End Cover . . . . . . . . . . . . . . . . 1B3-71

Vibration Damper and Hub . . . . . . . . . . . . . 1B3-74

Crankshaft Front Radial Seal . . . . . . . . . . . 1B3-80

Crankshaft Ball Bearing . . . . . . . . . . . . . . . 1B3-82

Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-83

Flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-93

Machining of Flywheel . . . . . . . . . . . . . . . . 1B3-97

Flywheel Ring Gear . . . . . . . . . . . . . . . . . . 1B3-98

Hydraulic Valve Clearance Compensation

Element Check . . . . . . . . . . . . . . . . . . . . 1B3-101

Valve Tappets . . . . . . . . . . . . . . . . . . . . . . 1B3-103

Valve Spring Check . . . . . . . . . . . . . . . . . 1B3-105

Valve Springs (Cylinder Head Removed) . 1B3-106

TABLE OF CONTENTS

Valve Springs (Cylinder Head Installed) . . 1B3-109

Valve Stem Seals . . . . . . . . . . . . . . . . . . . 1B3-112

Check and Replacement of

Valve Guides . . . . . . . . . . . . . . . . . . . . . 1B3-116

Valve Seat Rings . . . . . . . . . . . . . . . . . . . 1B3-122

Check and Machining of Valves . . . . . . . . 1B3-127

Machining of Valve Seat . . . . . . . . . . . . . . 1B3-132

Camshaft Timing Test . . . . . . . . . . . . . . . . 1B3-137

Camshaft . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-139

Chain Tensioner . . . . . . . . . . . . . . . . . . . . 1B3-145

Timing Chain. . . . . . . . . . . . . . . . . . . . . . . 1B3-147

Tensioning Rail . . . . . . . . . . . . . . . . . . . . . 1B3-151

Cylinder Head Guide Rail . . . . . . . . . . . . . 1B3-152

Timing Case Cover Guide Rail . . . . . . . . . 1B3-156

Crankshaft Sprocket . . . . . . . . . . . . . . . . . 1B3-158

Piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-163

Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-169

Oil Pan . . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-171

Oil Spray Nozzle . . . . . . . . . . . . . . . . . . . . 1B3-174

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . 1B3-175

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 1B3-177

Cylinder Head Pressure Leakage Test . . . 1B3-177

Facing Cylinder Head Mating Surface. . . . 1B3-178

Replacement of Crankcase Core Plug . . . 1B3-180

Facing Crankcase Contacting Surface . . . 1B3-182

Oil Gallery Steel Ball . . . . . . . . . . . . . . . . . 1B3-183

Cylinder Bore Measurement . . . . . . . . . . . 1B3-187

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст