SsangYong Musso. Manual — part 252

M162 ENGINE MECHANICAL 1B1-51

Inspection

1. If the length ‘L’ of the crankshaft bearing cap bolt exceeds

63.8mm, replace it.

2. Make sure the crankshaft bearing cap is properly seated

on the cylinder block (arrows).

3. Measure and record the inner diameter of the crankshaft

bearing.

Notice

z

Measure at 2 points (1, 2).

z

Measure ‘A’,‘B’and ‘C’ as shown. If average value of ‘B’

and ‘C’is less than value ‘A’, then the average value of

‘B’ and ‘C’ is actual average value. If average value of

‘B’ and ‘C’ is more than value ‘A’is actual average value.

4. Measure and record the diameter of the crankshaft bearing

journal.

Notice

z

Record the mean value when measured at 3 points (A,

B, C).

z

Measure the inner diameter of bearing and the diameter

of journal and if it is out of the standard data, replace

the bearing shell.

1B1-52 M162 ENGINE MECHANICAL

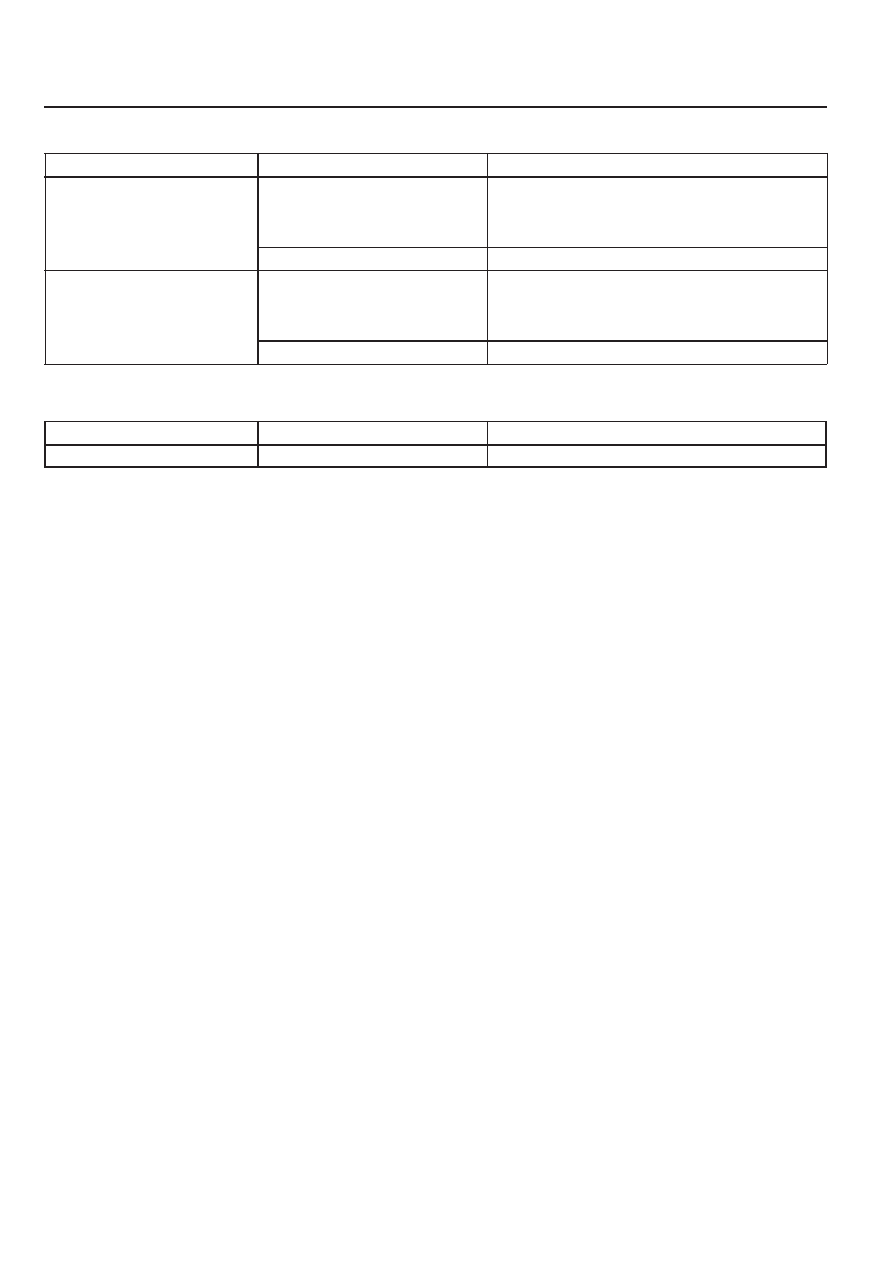

Service Data Standard (Crankshaft Main Bearing Gap)

(Connecting Rod Bearing Gap)

Item

Main Bearing Journal

( NO. 1, 5, 7)

Main Bearing Journal

( NO. 3, 4, 6)

Measuring Position

Radial

Axial

Radial

Axial

Gap (mm)

Static condition :0.015 - 0.039

Dynamic condition: 0.031 - 0.051

(Consider the expansion 0.011 - 0.016)

0.010 - 0.254

Static condition :0.011 - 0.039

Dynamic condition: 0.031 - 0.051

(Consider the expansion 0.015 - 0.022)

0.010 - 0.254

Item

Connecting Rod Bearing

Measuring Position

Radial

Gap (mm)

0.030 - 0.050

M162 ENGINE MECHANICAL 1B1-53

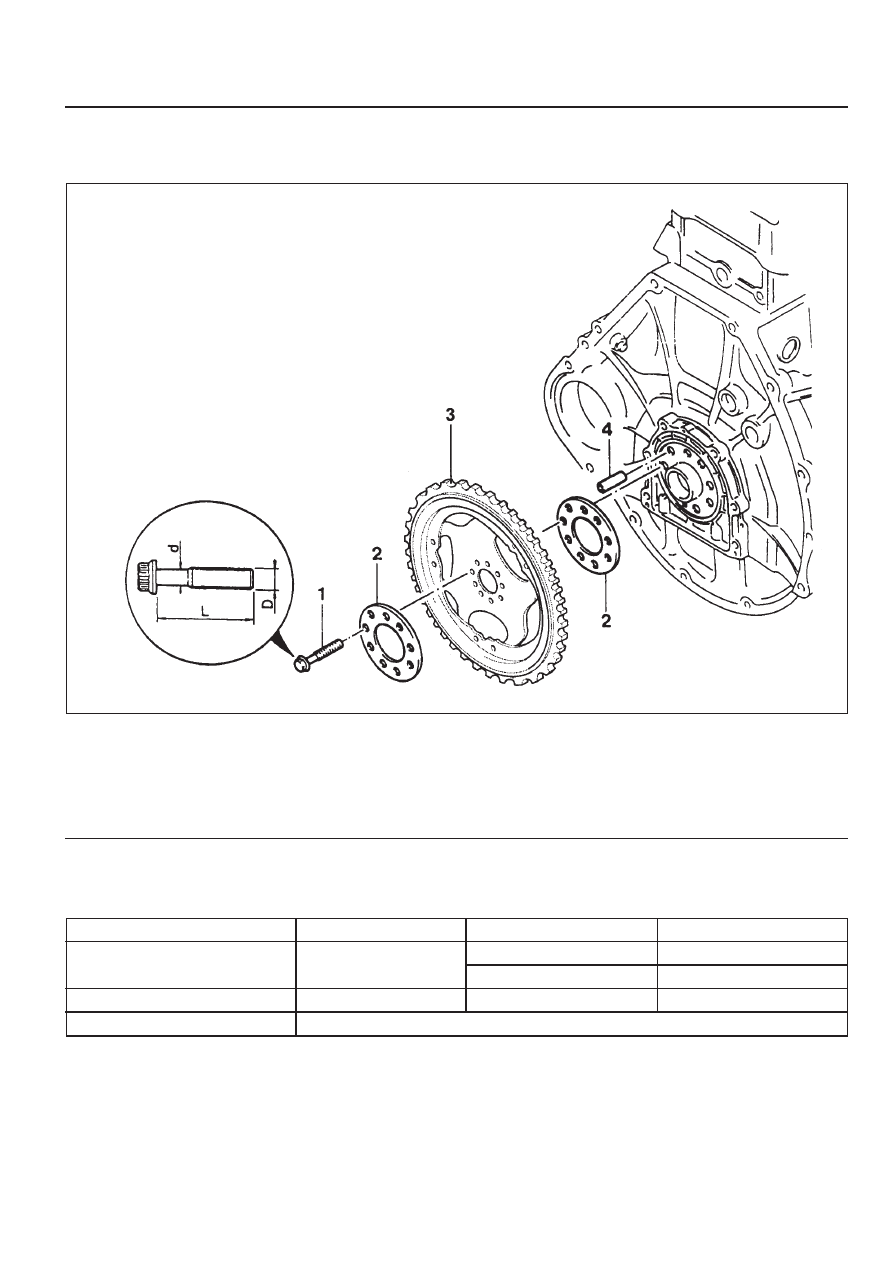

FLYWHEEL / DRIVEN PLATE

Preceding Work : Removal of manual or automatic transmission

1 Flywheel Mounting Bolt (M10 x 22, 8 pieces)

. . . . . . . . . . . ... 1st step 45+5 Nm

2nd step +90° +10°

2 Plate

3 Driven Plate (A/T)

4 Dowel Pin

Service Data Standard (Stretch Bolt)

Nominal Size

Stretch Side Diameter

Bolt Length

Tightening Torque

M x 1.5

8.5 - 0.2 mm

8.0 mm

21.8 - 22.2 mm

-

When New

Min. Diameter

When New

D

d

L

1st step 50 Nm, 2nd step 90°

1B1-54 M162 ENGINE MECHANICAL

Removal & Installation Procedure

1. Unscrew the stretch bolt.

Installation Notice

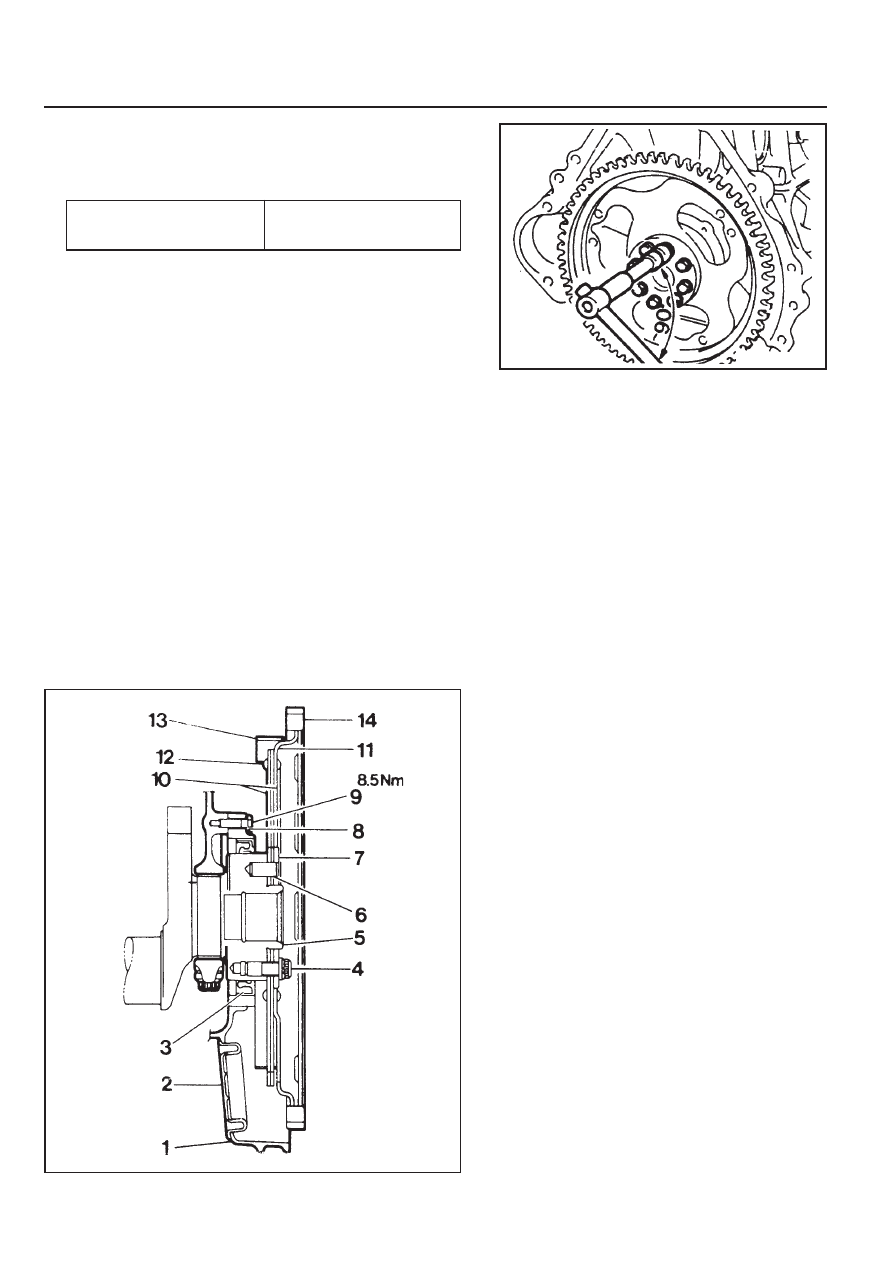

Sectional View

1 Oil Pan

2 Cover

3 Crankshaft Front Seal

4 Flywheel MTG Bolt

5 Crankshaft

6 Dowel Pin

7 Plate

8 TGCC

9 Bolt

10 Front Drive Plate

11 Rear Drive Plate

12 Rivet

13 Segment

14 Ring Gear

z

Replace the bolt when the stretch side diameter (d) of

the flywheel mounting bolt is less than 8.0mm.

z

For the stretch bolt tightening, keep the socket wrench

and Tommy-bar to be 90° and tighten as specified.

2. Remove the flywheel for manual transmission vehicles, or

the driven plate (3), and plate (2) for Auto. transmission

vehicle.

3. Installation should follow the removal procedure in the

reverse order.

Tightening Torque

1st step 45+5 Nm

2nd step 90° + 10°

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст