SsangYong Actyon Sports II. Manual — part 10

02-6

Component

Size

Bolt

Quantity

Specified torque

(Nm)

Remark

(Total torque)

Glow plug

M5

4

20±2Nm

-

Vacuum pump

M6×25

3

10±1Nm

-

Timing gear case cover

M12×55

3

85±8.5Nm

-

M6×25

7

10±1Nm

-

M6×45

1

10±1Nm

-

M6×50

3

10±1Nm

-

Cylinder head cover

M6×35

21

10±1Nm

-

Oil gauge tube

M6×16

1

10±1Nm

-

Oil filter cap

1

25±2.5Nm

-

Fuel rail

M8×35SOC

2

25±2.5Nm

-

Injector clamp bolt

M6×60

2

10±1Nm,

120˚+10˚

-

High pressure pipe

(between HP pump and

fuel rail)

M17 1

30±3Nm

-

High pressure pipe

(between fuel rail and

injector)

M17 4

30±3Nm

-

Crank position sensor

M5×14

1

5±1.0Nm

-

Main wiring

M6×16

5

10±1Nm

-

Intake duct

M8x25

4

25±2.5Nm

-

Power steering pump

M8×100

3

25±2.5Nm

-

Cylinder head front cover

M6×10

5

10±1Nm

-

Ladder frame

M8×16

5

30±3Nm

-

Oil pump

M8×35

3

25±2.5Nm

-

EGR Cooler

MTG Bolt

M8×16

2

25±2.5Nm

-

M8×70

2

25±2.5Nm

-

Idle pulley/Tensioner

pulley

1

45±4.5Nm

-

02-7

0000-00

3. CHECK AND INSPECTION

1) Cylinder

(1) Compression pressure test

Specified value

▶

Compression ratio

16.5 : 1

Test condition

at normal operating temperature (80˚C)

Compression pressure

Standard

32 bar

Minimum

18 bar

Differential limit between cylinders

Maximum 3 bar

The compression pressure test is to check the conditions of internal components (piston, piston ring,

intake and exhaust vale, cylinder head gasket). This test provides current engine operating status.

Before cranking the engine, make sure that the test wiring, tools and persons are keeping away

from moving components of engine (e.g., belt and cooling fan).

Park the vehicle on the level ground and apply the parking brake.

Do not allow anybody to be in front of the vehicle.

-

-

-

Measurement

▶

Warm the engine up to normal operating temperature (80°C).

Disconnect the fuel rail pressure sensor connector to cut off the fuel injection.

Remove the air cleaner duct and glow plugs.

-

-

-

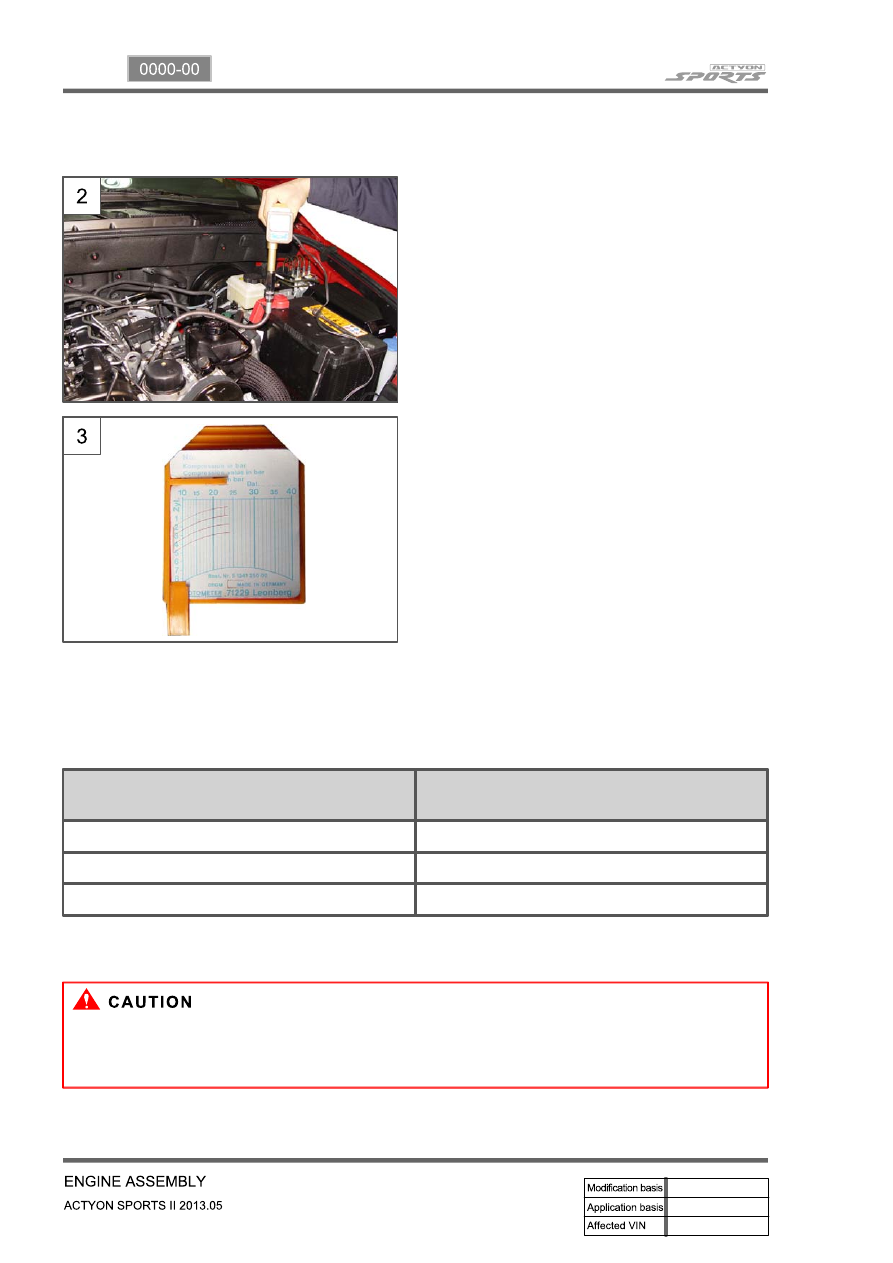

Place the diagram sheet to compression

pressure tester and install it into the plug hole.

1.

02-8

(2) Cylinder pressure leakage test

If the measured value of the compression pressure test is not within the specifications, perform the

cylinder pressure leakage test.

Specified value

▶

Perform this test in the sequence of firing order.

Do not test the cylinder pressure leakage with wet type test procedure. (do not inject the engine oil

into the combustion chamber)

-

-

Test condition: normal engine operating

temperature (80˚C)

Specified value

Whole engine

below 25%

at valve and cylinder head gasket

below 10%

at piston ring

below 20%

Crank the engine for approx. 10 seconds by

using the start motor.

2.

Record the test result and measure the

compression pressure of other cylinders with

same manner.

3.

If the measured value is out of specified

value, perform the cylinder pressure leakage

test.

4.

02-9

0000-00

Position the piston at TDC and measure the

piston protrusion from crank case mating

surface.

(3) Piston protrusion check

Specified value

0.475~0.745mm

Measure it at both ends of crankshaft.

-

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст