Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1865

7A2-76 DIAGNOSIS

Step

Action

Yes

No

8

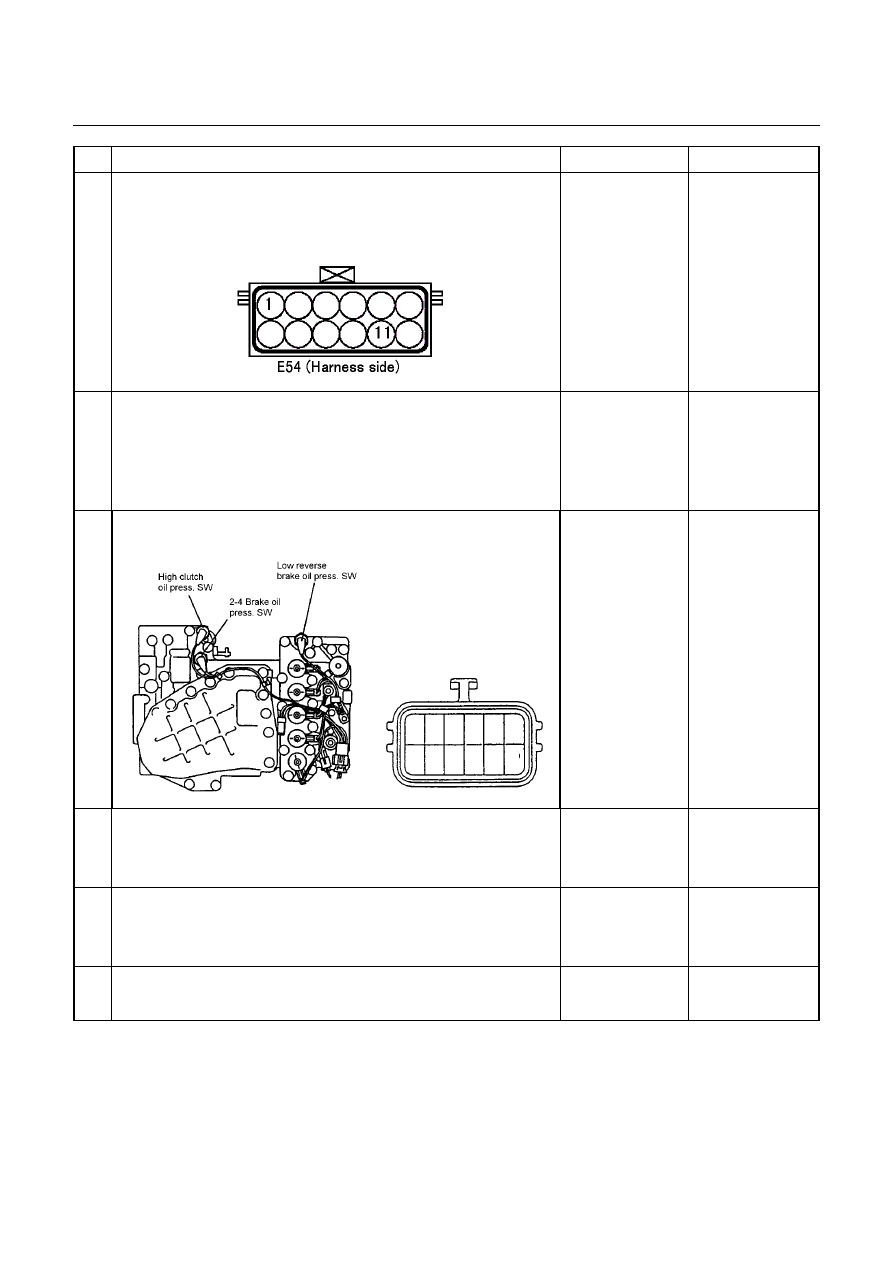

Connect the Tech 2, and with the key switch in OFF position, short

the terminals 11 and 1 on the vehicle harness side. Does the

indication of the high clutch pressure switch on the Tech 2 turn on

when the key switch is turned on?

Go to Step 9

Repair the harness

or connector.

Go to Step 12

9

Check if the trouble is caused by a poor connection of terminal

assembly connector.

With the key switch in OFF position, is the connection condition of

the connector and harness correct?

Go to Step 10

Repair the harness

or connector. Go to

Step 12

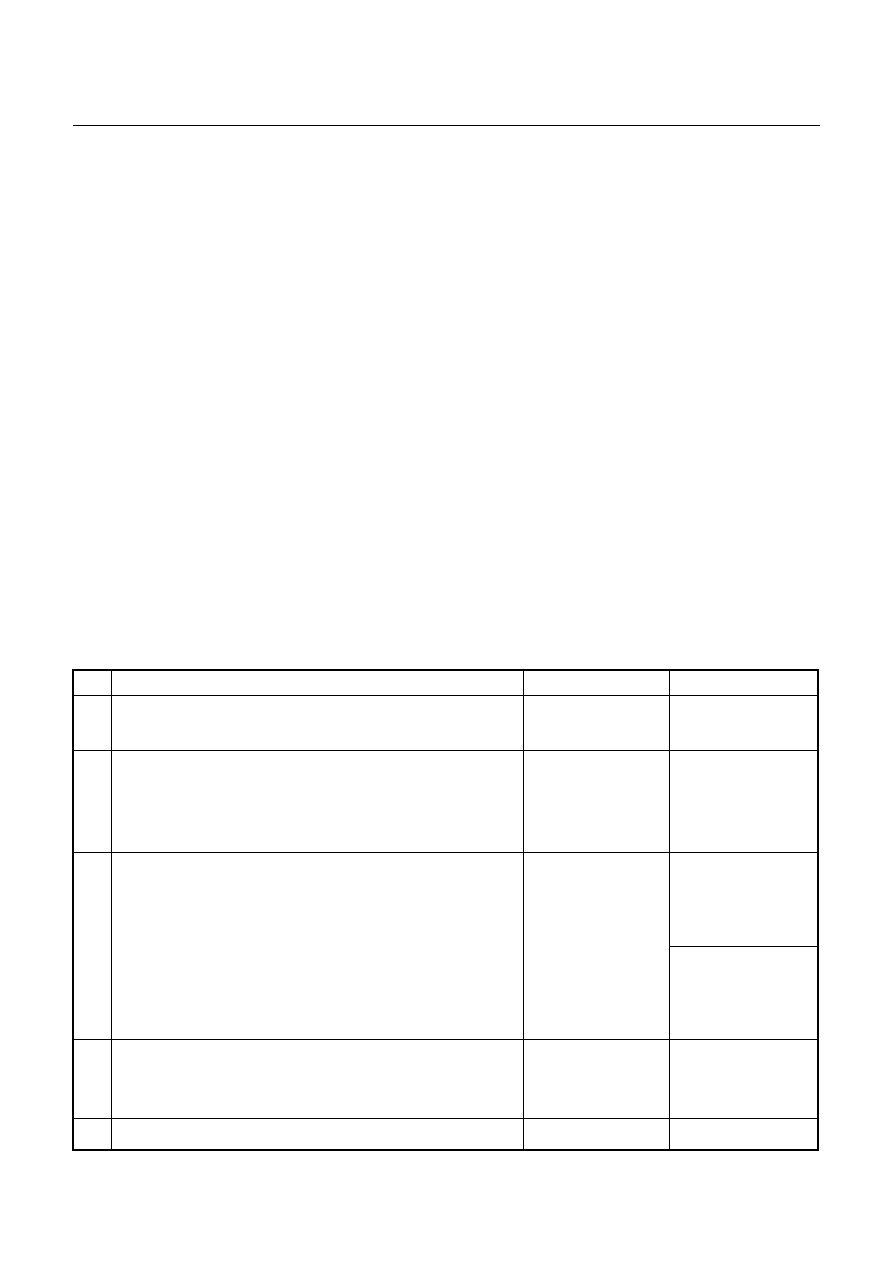

10 Remove the oil pan. Is the continuity correct between terminal

assembly teminal 1 and high clutch pressure switch connector?

1

Go to Step 11

Repair the harness

or connector.

Go to Step 12

11 Is the result OK when the oil pan is removed and the high clutch

pressure switch is checked?

Repair the control

valve.

Go to Step 12

Replace pressure

switch.

Go to Step 12

12 Clear the DTC from the memory and perform the work after repair.

Is the same DTC code outputted again in the subsequent DTC

check?

Replace the TCM

Go to Step 13

13 Are the other DTCs outputted?

Go to Other DTC

Section

Action is completed

DIAGNOSIS 7A2-77

DTC P0731 (Flash Code 41) 1st Gear Ratio Error

DTC P0732 (Flash Code 42) 2nd Gear Ratio Error

DTC P0733 (Flash Code 43) 3rd Gear Ratio Error

DTC P0734 (Flash Code 44) 4th Gear Ratio Error

Pre-setting Condition:

•

No

other

DTCs.

•

2 seconds elapsed after D, 3, 2, or 1 range was selected.

•

Vehicle is running at the vehicle speed over 10 km/h with the turbine speed over 1000 rpm.

•

Except at the gear shifting.

•

ATF temperature more than 60

°

C.

•

No fail safe valve malfunction.

Setting Condition:

In the case pre-setting conditions are met, the TCM calculates the turbine speed that corresponds to the gear ratio

of the outputted solenoid pattern in about 7 seconds after each gear shift has completed, and when the output shaft

speed against the turbine speed exceeds 500 rpm.

Fail Safe:

•

No fail safe function

Possible Cause:

•

Turbine sensor or speed sensor malfunction.

•

Shift

solenoid

malfunction.

•

Clutch

slipping.

Step

Action

Yes

No

1

Turn the key switch on and check the DTC. Are the DTC other

than gear ratio error outputted?

Go to Other DTC

Section

Go to Step 2

2

Clear the DTC from the memory. Turn the key switch off once,

and then start the engine. Does the CHECK TRANS blink

when the gear shift is repeated 3 times from 1st to 4th in the D

range?

Go to Other DTC

Section

Go to Step 3

3

Check again the DTC. Are all codes indicating gear ratio error

outputted?

Even if one of DTC

indicating gear ratio

error is outputted

Go to step 5

Go to Step 4

DTC indicating gear

ratio error are not

outputted at all.

Go to step 9

4

Check the turbine sensor and the speed sensor for function. Is

the result OK?

Go to Step 9

Replace turbine speed

sensor.

Go to Step 9

5

Are the color and smell of ATF normal?

Go to Step 6

Go to Step 9

7A2-78 DIAGNOSIS

Step

Action

Yes

No

6

Is the quantity of ATF correct?

Go to Step 7

Correct the quantity of

ATF.

Go to Step 9

7

Connect the Tech 2 and test the solenoids of respective

solenoids for low & reverse brake, 2-4 brake, high clutch and

low clutch. Is operation sound heard from each solenoid?

Go to Step 8

Replace the solenoid

that does not generate

the operation sound.

Go to Step 9

8

Check the line pressure during the idling and at the engine stall

speed. Is the line pressure correct?

Go to Step 10

Either control valve, oil

pump or power train

parts (clutch, brake)

will be faulty. Replace

or overhaul the

transmission unit.

Go to step 10

9

Run the vehicle, and is the gear shifted from 1st to 4th

correctly?

Go to Step 10

Either control valve, oil

pump or power train

parts (clutch, brake)

will be faulty. Replace

or overhaul the

transmission unit.

Go to step 10

10 Clear the DTC from the memory and perform the work after

repair. Is the same DTC code outputted again in the

subsequent DTC check?

Replace the TCM

Go to Step 11

11 Are the other DTCs outputted?

Go to Other DTC

Section

Action is completed

DIAGNOSIS 7A2-79

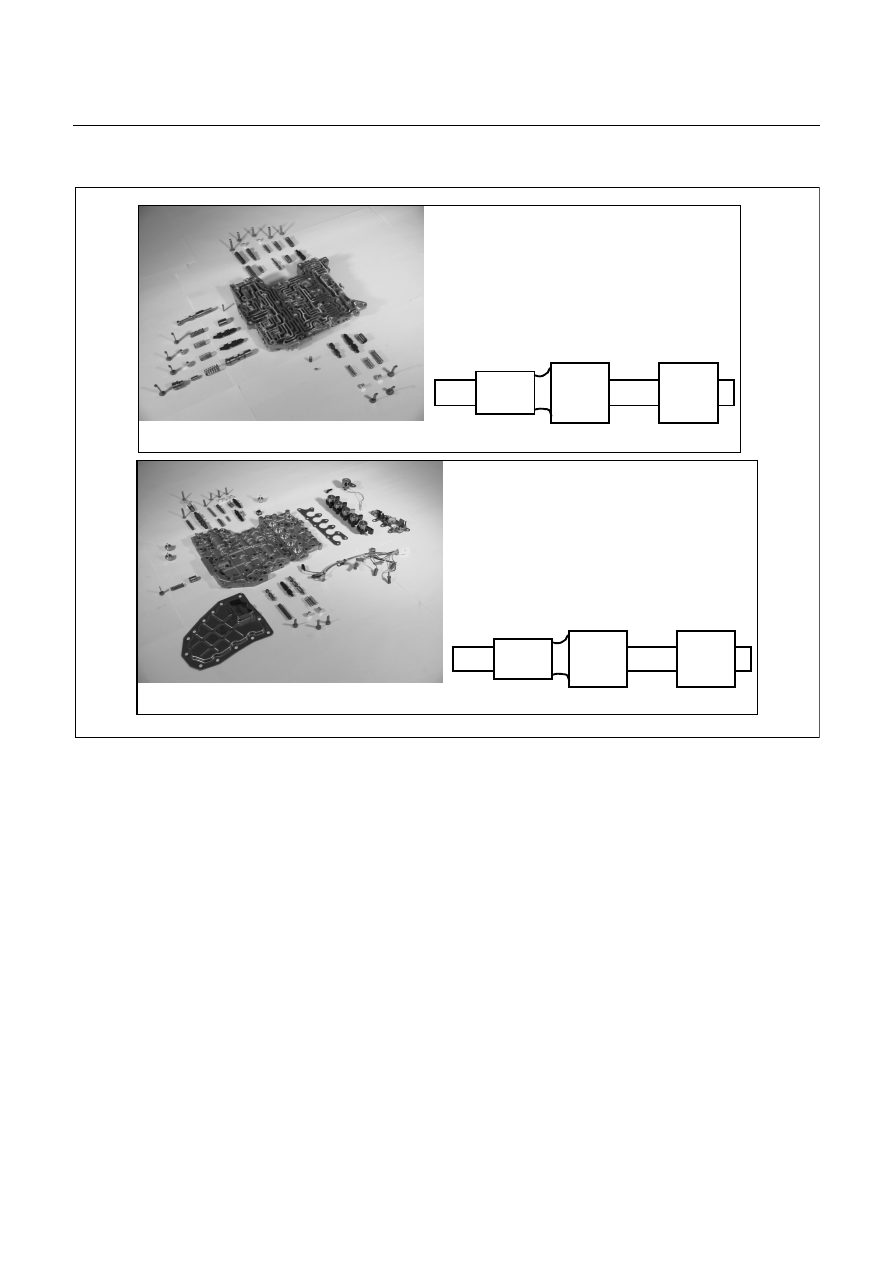

DTC P1750 (Flash Code 51) Low & Reverse Brake Fail-safe Valve Failure

Low & Reverse Brake Fail Valve (B)

Control Valve Upper Body

Low & Reverse Brake Fail Valve (A)

Control Valve Lower Body

Setting Condition:

•

When the oil pressure generated and low & reverse brake pressure switch operates off/on twice, the TCM

detected an operation failure of the low & reverse brake fail-safe valve in D, 3, 2, L range.

Fail Safe:

•

When the vehicle is running, the gear position selected at the trouble detection is held and the lock-up is

inhibited.

•

After the vehicle stopped, all solenoid operations stop (OFF) and the gear is fixed to the 3rd.

Possible Cause:

•

Stick of low & reverse brake fail-safe valve.

•

Low & reverse brake pressure switch does not turn on.

•

Short circuit to ground of harness low & reverse brake pressure switch.

•

Poor connection of each connector of harness in low & reverse brake pressure switch.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст