Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 615

EXHAUST GAS RECIRCULATION (EGR) SYSTEM 6E– 5

INSPECTION

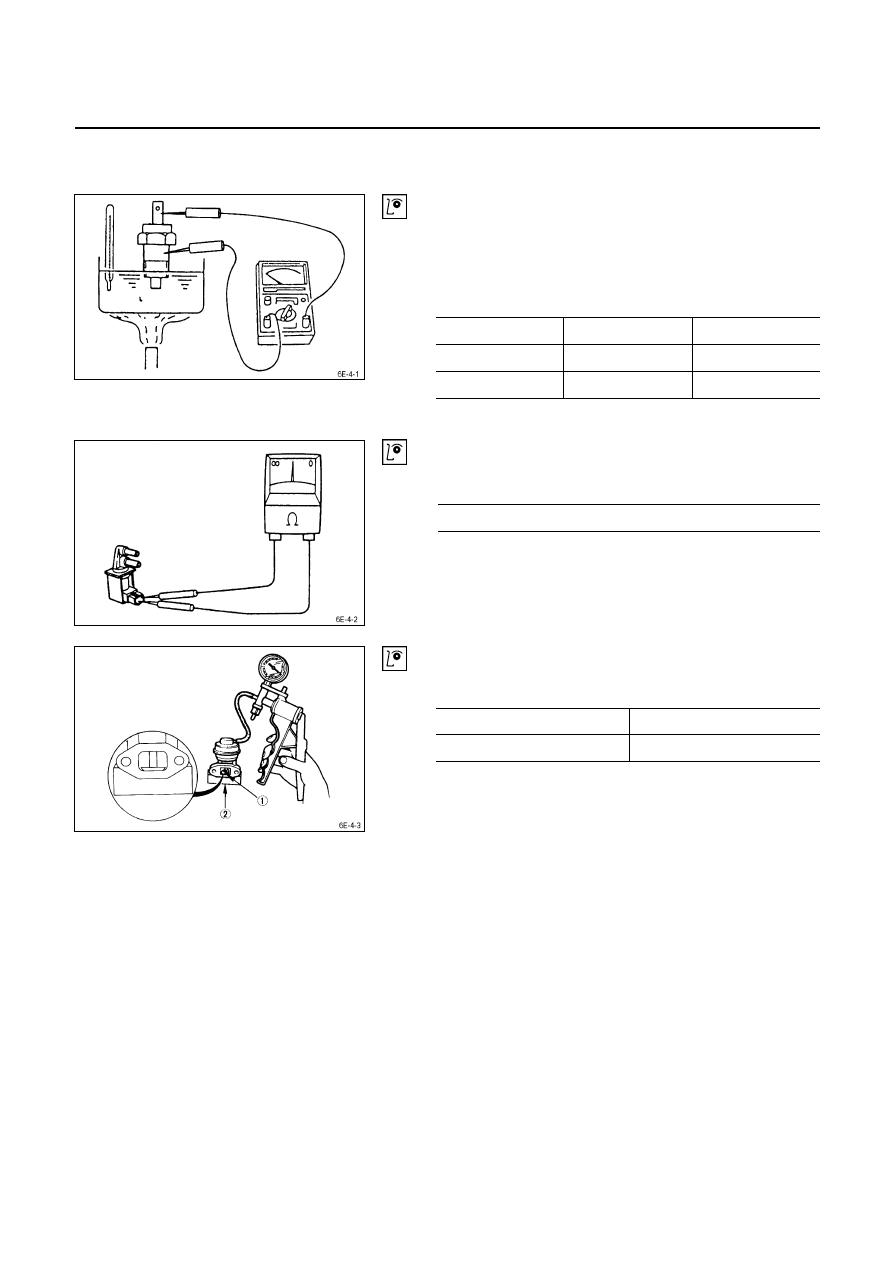

Thermo Switch

1. Submerge end of switch in water.

2. Connect circuit tester to the connector terminals.

3. Use a burner to heat the water.

4. Check the continuity test across.

Operating temperature

Thermo sw. No.2 Thermo sw. No.1

OFF

→ ON

Over 73°C

Over 30°C

ON

→ OFF

76°C ~ 84°C

36°C ~ 44°C

If there is no continuity, replace the switch.

Vacuum switch valve (VSV)

Use a circuit tester to measure the V.S.V. resistance.

V.S.V Resistance

Ω at 20°C

35 ~ 45

If the resistance is not within specification, replace it.

EGR Valve

Apply Vacuum to the EGR Valve, check to see the Valve

Apply Vacuum

Less then 120 mmHg

Not operation

More than 180 mmHg

Operation

6E – 6 EXHAUST GAS RECIRCULATION (EGR) SYSTEM

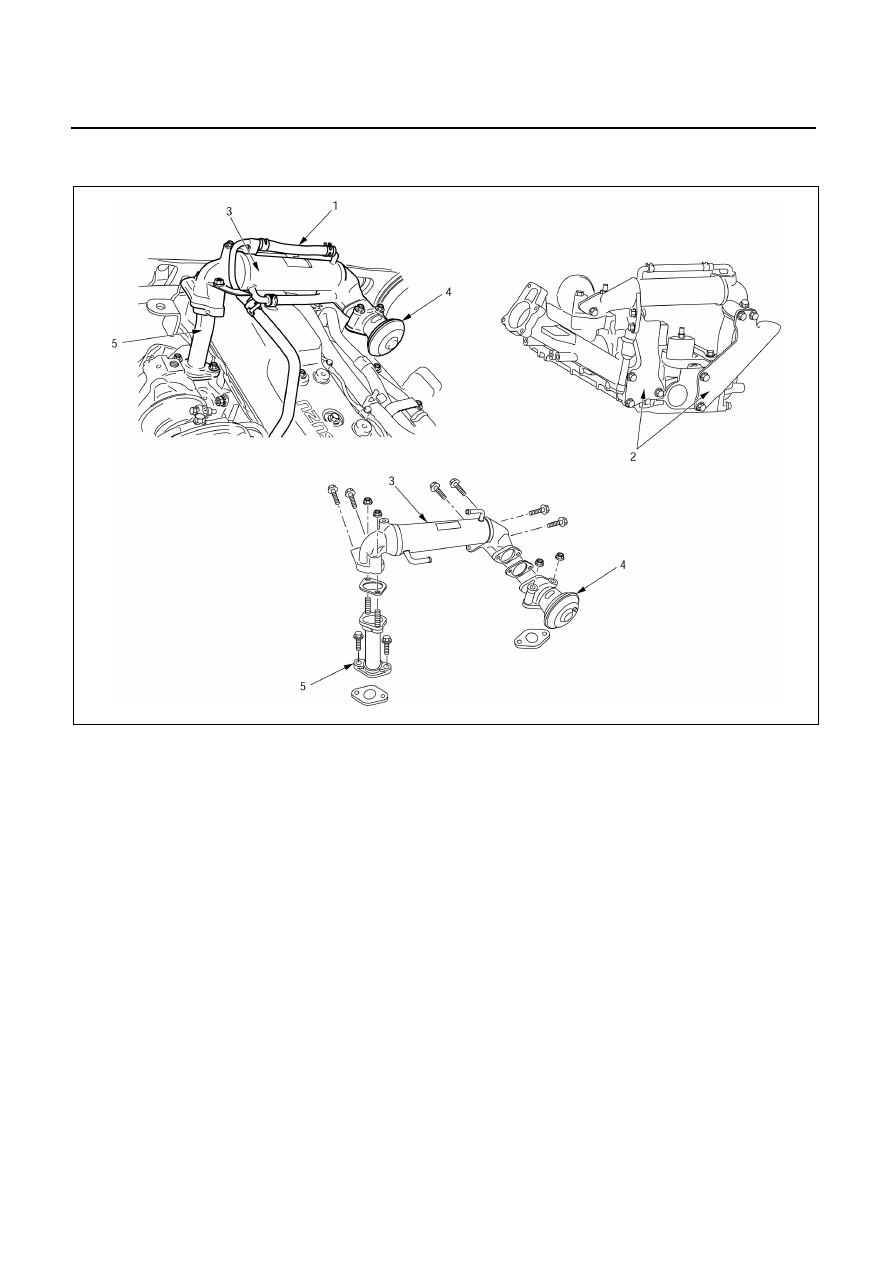

EGR COOLER (For 4JA1TC Engine)

Removal Steps

Installation Steps

Preparation:

・ Disconnect battery ground cable

To install, follow the removal procedure in

reverse order.

・ Drain coolant

J

5.

EGR pipe

・ Remove the intercooler

J

4.

EGR valve

1.

Water hose

J

3.

EGR cooler ASM

2.

EGR cooler bracket

J

2.

EGR cooler bracket

3.

EGR cooler ASM

J

1.

Water hose

4.

EGR valve

5.

EGR pipe

057L200024

EXHAUST GAS RECIRCULATION (EGR) SYSTEM 6E– 7

Installation Steps

5. EGR

Pipe

Install the EGR pipe to the Exhaust manifold and tighten

the EGR pipe bolt with EGR pipe gasket to the specified

torque.

EGR Pipe Bolt Torque

kg·m (lb·ft/N·m)

2.4

± 0.5 (17.4 ± 3.6/23.5 ± 5)

4. EGR

Valve

Install the EGR valve to the intake manifold and tighten the

EGR valve nut with EGR valve gasket to the specified

torque.

EGR Valve Nut Torque

kg·m (lb·ft/N·m)

2.4

± 0.5 (17.4 ± 3.6/23.5 ± 5)

3. EGR Cooler ASM

Temporarily install the EGR cooler assembly.

2. EGR Cooler Bracket

1) Temporarily install the EGR cooler bracket Hand-

tighten each of the bolts.

2) Fintal tighten the bolts in the order shown in the

illustration (

QRST)

.

QR

Torque kg·m

(lb·ft/N·m)

2.4

± 0.5 (17.4 ± 3.6/23.5 ± 5)

ST

Torque kg·m

(lb·ft/N·m)

1.9

± 0.5 (14 ± 3.6/19 ± 5)

1. Water

Hose

Connect the water hose to the EGR cooler ASM.

Note:

•

Take care not to scratch the installation surfaces.

•

Do not allow dirt to adhere to the installation

surfaces.

057L200022

057L200021

057L200023

EXHAUST SYSTEM 6F – 1

SECTION 6F

EXHAUST SYSTEM

TABLE OF CONTENTS

PAGE

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . ... 6F - 2

Removal and Installation. . . . . . . . . . . . . . . . . . . . . . . . ... 6F - 6

Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . ... 6F -11

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6F -12

Main Data and Specifications . . . . . . . . . . . . . . . . . . . . . ... 6F -12

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . ... 6F -13

Inspection and Repair . . . . . . . . . . . . . . . . . . . . . . . . . ... 6F -15

Special Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6F -17

IHI Service Network . . . . . . . . . . . . . . . . . . . . . . . . . . ... 6F -18

INDEX

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст