Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 560

6A – 78 ENGINE MECHANICAL

7. After grinding, make sure that the hot plug surfaces

are completely free of protuberances.

The hot plug surfaces must also be free of

depressions.

Once again, lightly tap the hot plug heads to make

sure that they are firmly seated.

Heat Shield Replacement

Heat Shield Removal

After removing the hot plugs, use a hammer

Q

and a

brass bar

R

to lightly tap the lower side of the heat shield

S

and drive it free.

Heat Shield Installation

Install the heat shield to the cylinder head from the nozzle

holder installation hole side. Lightly tap the heat shield

flange into place with a hammer and a brass bar.

The heat shield flange side must be facing up.

Note:

Always install a new heat shield. Never reuse the old

heat shield.

VALVE GUIDE

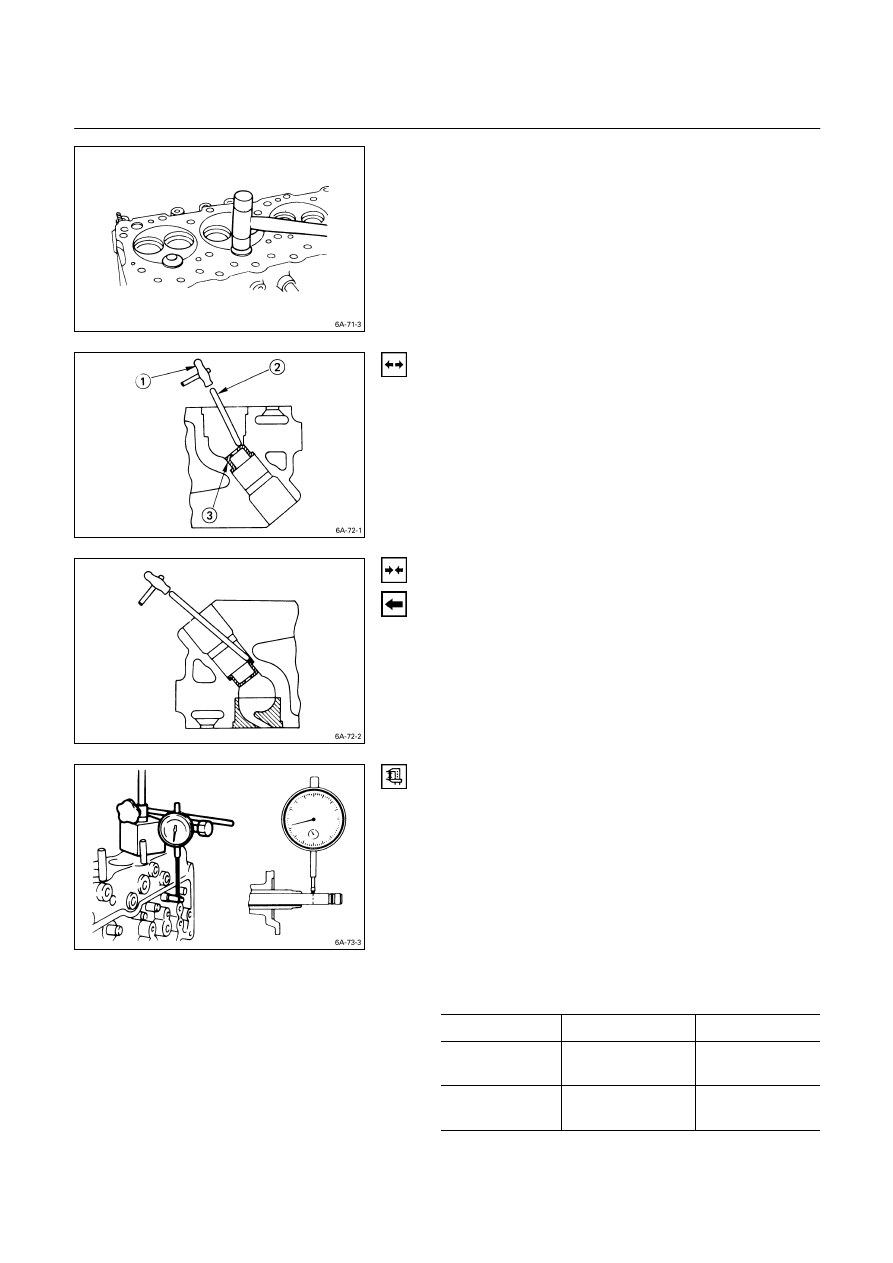

Valve Stem and Valve Guide Clearance

Measuring Method-I

1. With the valve stem inserted in the valve guide, set

the dial indicator needle to “0”.

2. Move the valve head from side to side.

Read the dial indicator.

Note the highest dial indication.

If the measured values exceed the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Clearance

mm (in)

Standard

Limit

Intake Valve

0.039 – 0.069

(0.0015 – 0.0027)

0.200

(0.008)

Exhaust Valve

0.064 – 0.093

(0.0025 – 0.0037)

0.250

(0.0098)

ENGINE MECHANICAL 6A – 79

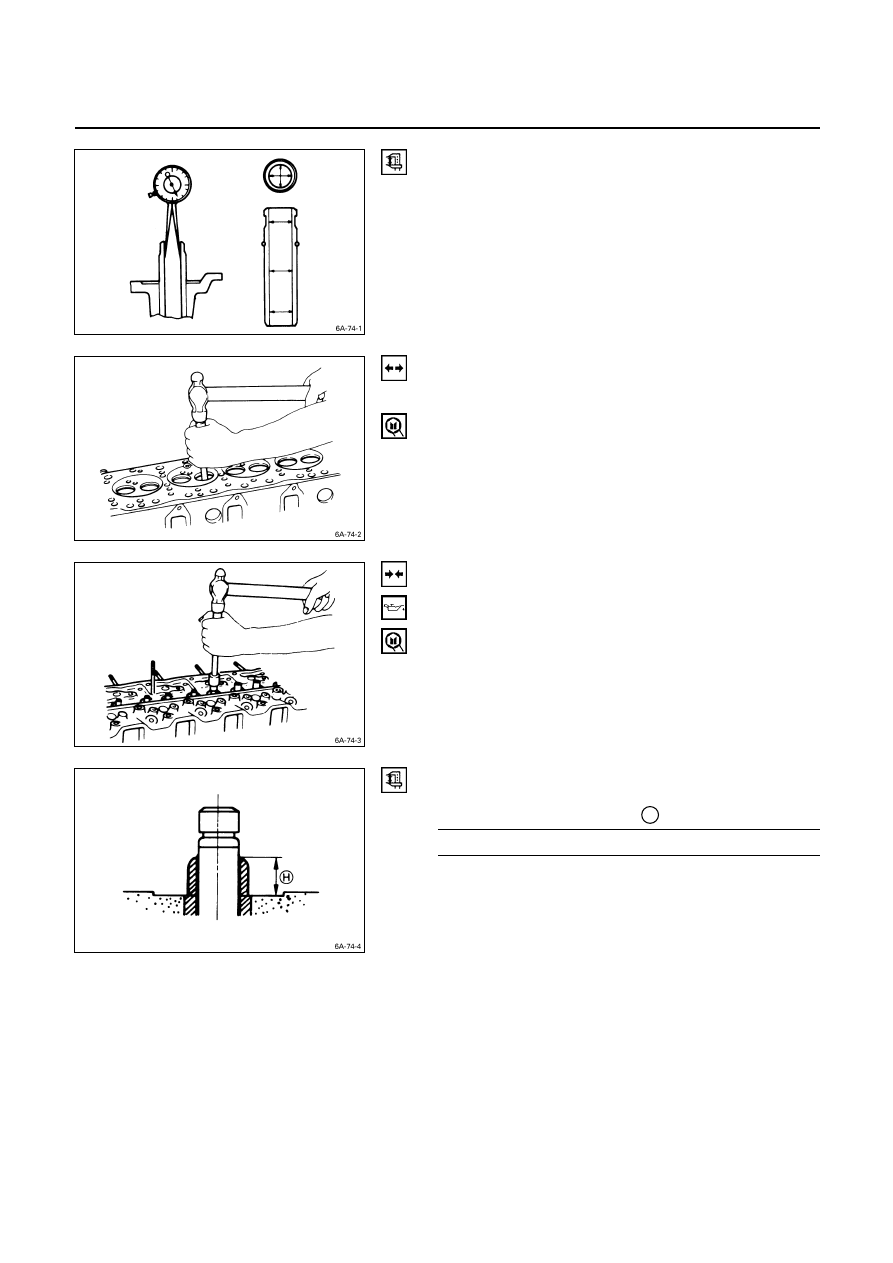

Measuring Method-II

1. Measure the valve stem outside diameter.

Refer to the Item “Valve Stem Outside Diameter”.

2. Use a caliper calibrator or a telescoping gauge to

measure the valve guide inside diameter.

Valve Guide Replacement

Valve Guide Removal

Use a hammer and the valve guide replacer to drive out

the valve guide from the cylinder head lower face.

Valve Guide Replacer: 9-8523-1212-0

Valve Guide Installation

1. Apply engine oil to the valve guide outer

circumference.

2. Attach the valve guide installer to the valve guide.

3. Use a hammer to drive the valve guide into position

from the cylinder head upper face.

Valve Guide Replacer: 9-8523-1212-0

4. Measure the height of the valve guide upper end from

the upper face of the cylinder head.

Valve Guide Upper End Height

H

(Reference) mm (in)

13 (0.51)

Note:

If the valve guide has been removed, both the valve

and the valve guide must be replaced as a set.

6A – 80 ENGINE MECHANICAL

VALVE AND VALVE SEAT INSERT

Valve Stem Outside Diameter

Measure the valve stem diameter at three points.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Valve Stem Outside Diameter

mm (in)

Standard

Limit

Intake Valve

7.946 – 7.961

(0.3128 – 0.3134)

7.880

(0.3102)

Exhaust Valve

7.921 – 7.936

(0.3119 – 0.3124)

7.850

(0.3090)

Valve Thickness

Measure the valve thickness.

If the measured value is less than the specified limit, the

valve and the valve guide must be replaced as a set.

Intake and Exhaust Valve Thickness

mm (in)

Standard

Limit

4JA1T, 4JA1, 4JB1T,

4JA1TC Engine

1.8 (0.07) 1.5 (0.06)

Inlet 1.34

(0.0528)

4JG2T Engine

Exhaust 1.38 (0.0544)

1.1 (0.043)

Inlet 1.41

(0.0555)

4JH1TC

Exhaust 1.38 (0.0543)

1.1 (0.043)

Valve Depression

1. Install

the

valve

Q

to the cylinder head

R

.

2. Use a depth gauge or a straight edge with steel rule to

measure the valve depression from the cylinder head

lower surface.

If the measured value exceeds the specified limit, the

valve seat insert must be replaced.

Valve Depression

mm (in)

Standard

Limit

Intake 0.73 (0.029) 1.28 (0.050)

4JA1T, 4JA1,

4JB1T, 4JA1TC

Engine

Exhaust 0.70 (0.028) 1.20 (0.047)

4JG2T,

4JH1TC

Engine 1.1 (0.043) 1.6 (0.063)

ENGINE MECHANICAL 6A – 81

3. Check that the rocker arm oil port is free of

obstructions.

If necessary, use compressed air to clean the rocker

arm oil port.

Rocker Arm Correction

Inspect the rocker arm valve stem contact surfaces for

step wear

Q

and scoring

R

.

If the contact surfaces have light step wear or scoring,

they may be honed with an oil stone.

If the step wear or scoring is severe, the rocker arm must

be replaced.

CYLINDER BODY

Cylinder Body Upper Face Warpage

1. Remove the cylinder body dowel.

2. Remove the cylinder liner.

Refer to “Cylinder Liner Replacement”.

3. Use a straight edge

Q

and a feeler gauge

R

to

measure the four sides and the two diagonals of the

cylinder body upper face.

If the measured values exceeds the limit, the cylinder

body must be replaced.

Cylinder Body Upper Face Warpage

mm (in)

Standard

Limit

0.05 (0.002) or less

0.20 (0.008)

Cylinder Body Height

H

(Reference)

mm (in)

Standard

4JA1, 4JA1T,

4JA1TC

244.945 – 245.055 (9.6430 – 9.6478)

4JB1T, 4JG2T,

4JH1TC

269.945 – 270.055 (10.6277 – 10.6320)

5. Reinstall the cylinder liner.

Refer to “Cylinder Liner Replacement”.

6. Reinstall the cylinder body dowel.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст