Isuzu D-Max / Isuzu Rodeo (TFR/TFS). Manual — part 1763

DIAGNOSIS 7A2-103

Step

Action

Yes

No

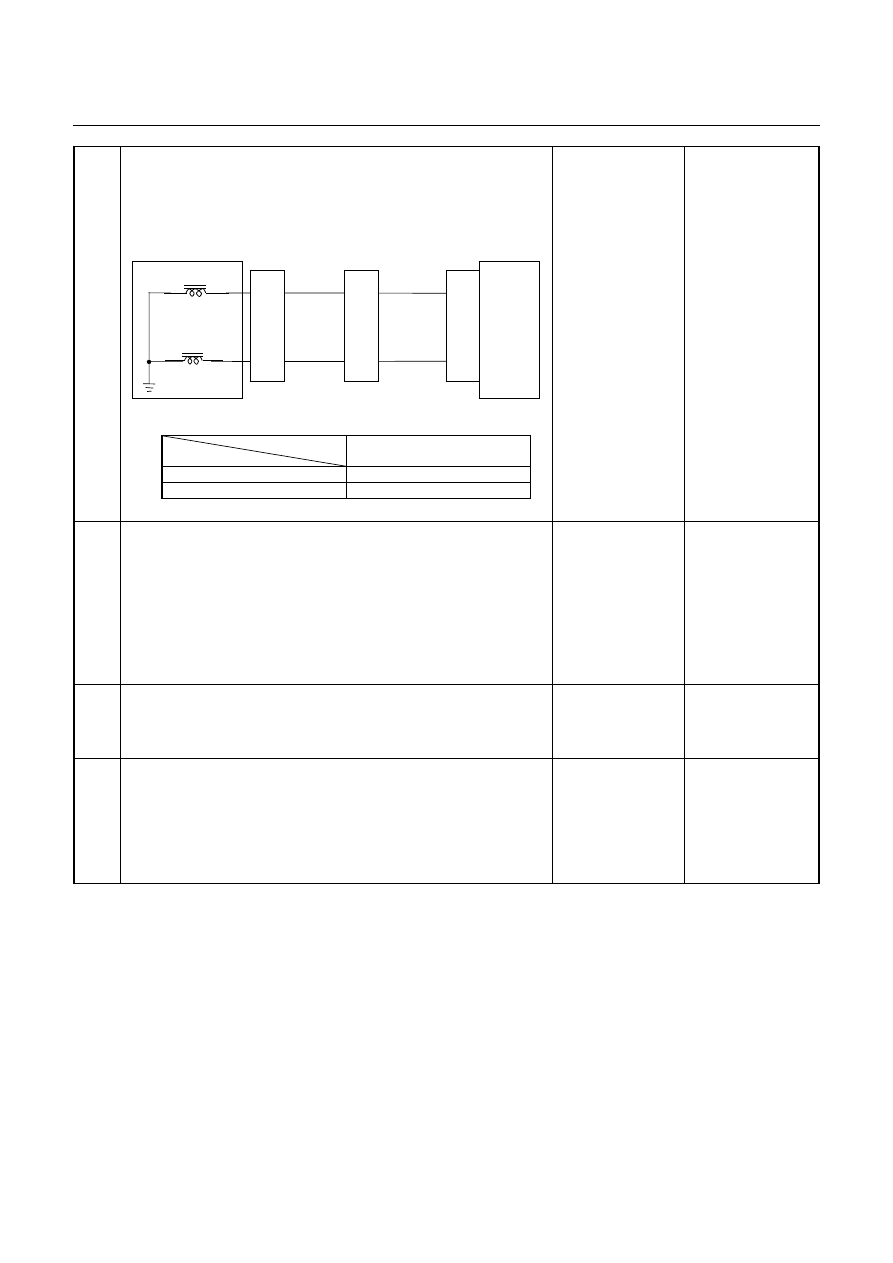

6

Inspect the output voltage and throttle opening signal of the

throttle position sensor using a Tech 2 or circuit tester.

Is a voltage value in proportion to the throttle opening output?

TPS

TCM

A16

C56

(28)

C94

(16)

RED/WHT

C56

(49)

(38)

(57)

(69)

ECM

A47 (GND)

A35 (Output)

A26

A55 (+5V)

A69 (Idle SW)

Go to Step 7

Repair the defect or

replace.

7

Check of power supply to and earth of TCM.

Are the power supply and earth proper?

TCM

A1 (+B)

B5

B15

H23

(15)

C95

(5)

(15)

BLK/YEL

BLK

BLK

Battery

C94

(1)

BLK

Go to Step 8

Check the power

source harness and

earth harness (bolt

tightening to the

body).

8

Is the stall revolution correct in D, 3, 2 and L range? Refer the

STALL TEST section in this manual.

Go to Step 9

Repair the defect or

replace.

9

Is the line pressure correct? Refer the LINE PRESSURE TEST

section in this manual.

Trouble in the AT

assembly or control

valve.

Repair the defect or

replace.

7A2-104 DIAGNOSIS

No. B4: Large Shock When Shift Lever is Changed to N to D

Range or N to R Range

Description:

•

Large shock is felt when selecting D or R range from N range during the idling after warming up.

Diagnosis Hints:

•

Check the entire condition of the vehicle for unusual other than AT including faulty engine mount, exhaust

hanger, etc.

•

When the fail-safe operation, select shock may grow worse. In such a case, check for the DTC. If no DTC is

issued, shock due to faulty operation of the control valve or burnt clutch is considered.

Possible Cause:

•

High

engine

idling.

•

Dislocated select lever, improper inhibitor switch adjusting point.

•

Faulty or insufficient tightening of engine mount, exhaust mount.

•

Play of suspension.

•

Burnt

clutch.

•

Too low or high line pressure.

•

Faulty input signal system.

•

Faulty control valve. (faulty operation or sticking of accumulator)

DIAGNOSIS 7A2-105

No. B5: Engine Stalls When Selecting From N Range to

R, D, 3, 2 or L Range

Description:

•

The engine stalls when selecting from N or P range to a run range during the engine idling.

Diagnosis Hints:

•

As causes attributable to the engine, faulty idle up, insufficient engine output, etc. are considered.

•

As a cause of the AT system, faulty lockup piston system (lockup engine stall) is considered.

•

If the oil through resistance increases remarkably due to clogged oil cooler or some other reason, or if the ATF

level decreases, the lock-up piston works causing the engine stall.

Possible Cause:

•

Disordered idling speed, faulty idle up, faulty engine output, shortage output.

•

Insufficient ATF quantity (dropped level).

•

Clogged oil cooler (foreign substance mixed in).

•

Faulty lock-up piston (clogged oil passage of solenoid drive circuit, faulty operation).

Step

Action

Yes

No

1

Gear ratio trouble diagnosis.

Travel in the following sequence for about 7 seconds or more in

each range: Start in the L range (1st) to 2 range (2nd) to 3 range

(3rd) to D range (4th) (to detect the gear ratio trouble exactly, this

process should be carried out)

Go to Step 2

Go to Step 2

2

Are any DTCs stored?

Go to DTC Chart

Go to Step 3

3

Are the quantity, contamination and smell normal?

If the ATF level is

low, replenish up to

the specified level.

Go to Step 4

If ATF is extremely

black and

contaminated and

smells burnt, slip of

the clutch is

supposed.

Overhaul the AT

unit.

4

Check of engine idle up speed

Does the idle speed increase when the air conditioning or other

electric load is turned on?

Go to Step 5

Repair the defect or

replace.

7A2-106 DIAGNOSIS

Step

Action

Yes

No

5

Inspection of electrical or mechanical fault

When the D range is selected from D at idling speed, is the signal

to the lock-up solenoid turned off using the Tech 2 or circuit

tester?

Control Valve

TCM

B17

B23

BLK

Lock-up Solenoid

Terminal

Assembly

VIO

Line Pressure Solenoid

E54

(4)

(6)

H23

(14)

(6)

C95

(17)

(23)

BLK

VIO

TCM terminal

Lock-up

B17

At lock-up

Approx. 7.2 V (AC range)

At unlock-up

Approx. 4.0V (AC range)

Go to Step 6

Find a cause to turn

on the lockup

solenoid

6

Check of clogging of oil cooler

When blowing the oil cooler outlet with air, does some foreign

substance come out?

Clean or replace the

oil cooler.

Go to Step 7

Clogged lock-up

solenoid oil

passage. Faulty

operation of lock-up

piston.

Faulty control valve.

7

Is the stall revolution correct in D, 3, 2 and L range? Refer the

STALL TEST section in this manual.

Go to Step 8

Repair the defect or

replace.

8

Is the line pressure correct? Refer the LINE PRESSURE TEST

section in this manual.

Trouble in the AT

assembly or control

valve.

Repair the defect or

replace.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст