Isuzu Rodeo UE. Manual — part 151

6C–11

ENGINE FUEL (X22SE 2.2L)

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connection or leakage. For the fuel system

diagnosis, see Section “Driveability and Emission”.

1. Disconnect battery ground cable.

2. Loosen fuel filler cap.

3. Support underneath of the fuel tank protector (15)

with a lifter.

4. Disconnect evaporative fuel hose (3) at the canister.

5. Disconnect fuel feed hose (17) and fuel return hose

(18) near the fuel filter.

NOTE: Plug both ends of the fuel hoses to prevent fuel

leakage.

6. Disconnect air breather hose (4) and fuel filler hose

(5) at the fuel filler neck.

NOTE: Cover fuel hose to prevent any dust entering.

7. Remove the four fuel tank assembly fixing bolts (14)

at four corners of the tank.

8. Let down the tank and disconnect the wiring

connectors (8,9) and the emission hose at the

emission port on the fuel pump and sending assembly

(10).

9. Remove fuel tank assembly along with protectors

(15,19) .

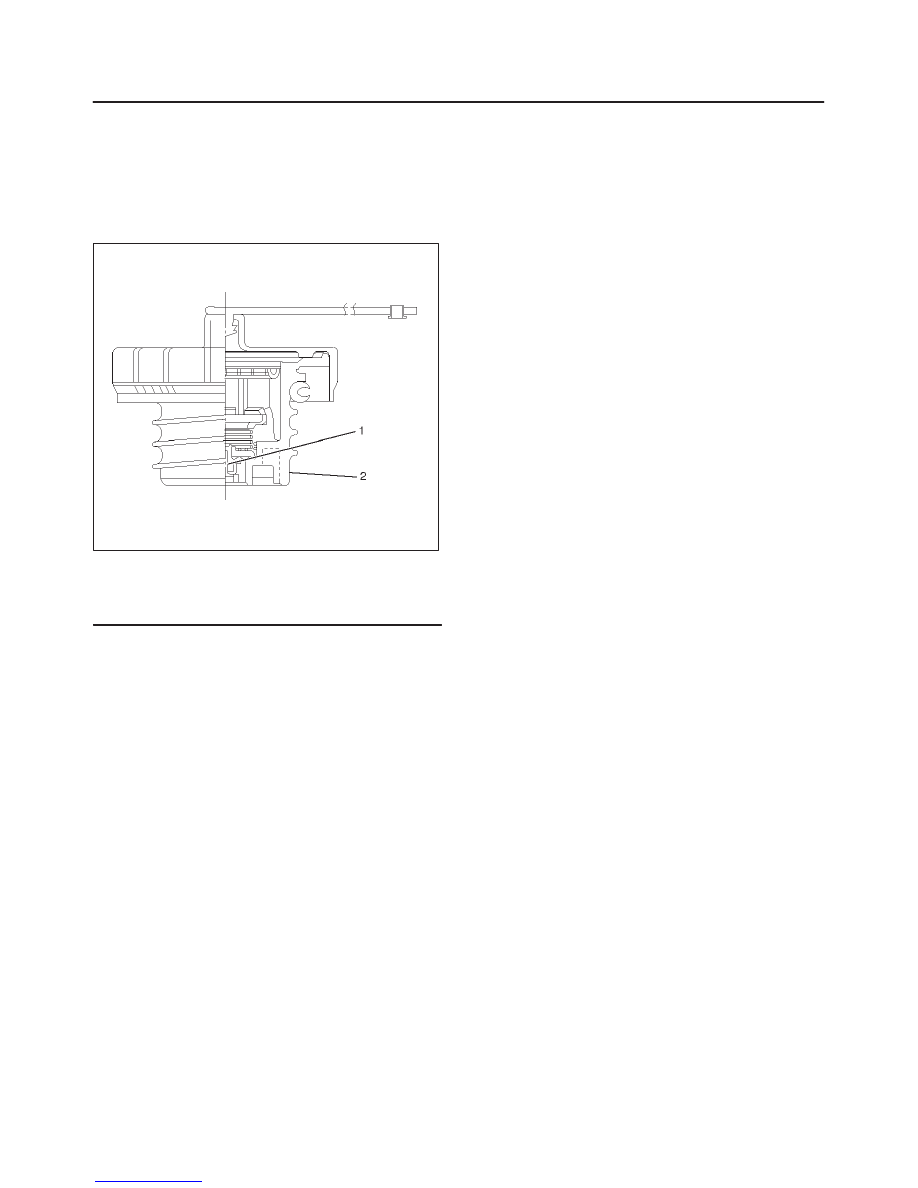

10. Remove retaining cover (2) and roll over&float valve

(1) along with the evaporative fuel hose and pipe (3).

11. Remove Fuel Tube/Quick Connector (12).

NOTE: Handling of fuel tube sure to refer “Fuel

Tube/Quick Connector Fittings” in this section.

12. Remove fuel pump and sender assembly (10) by

removing the snap ring (7) along with the fuel hoses

(17,18).

13. Remove protectors (15,19) by removing the six fixing

bolts (6).

Installation

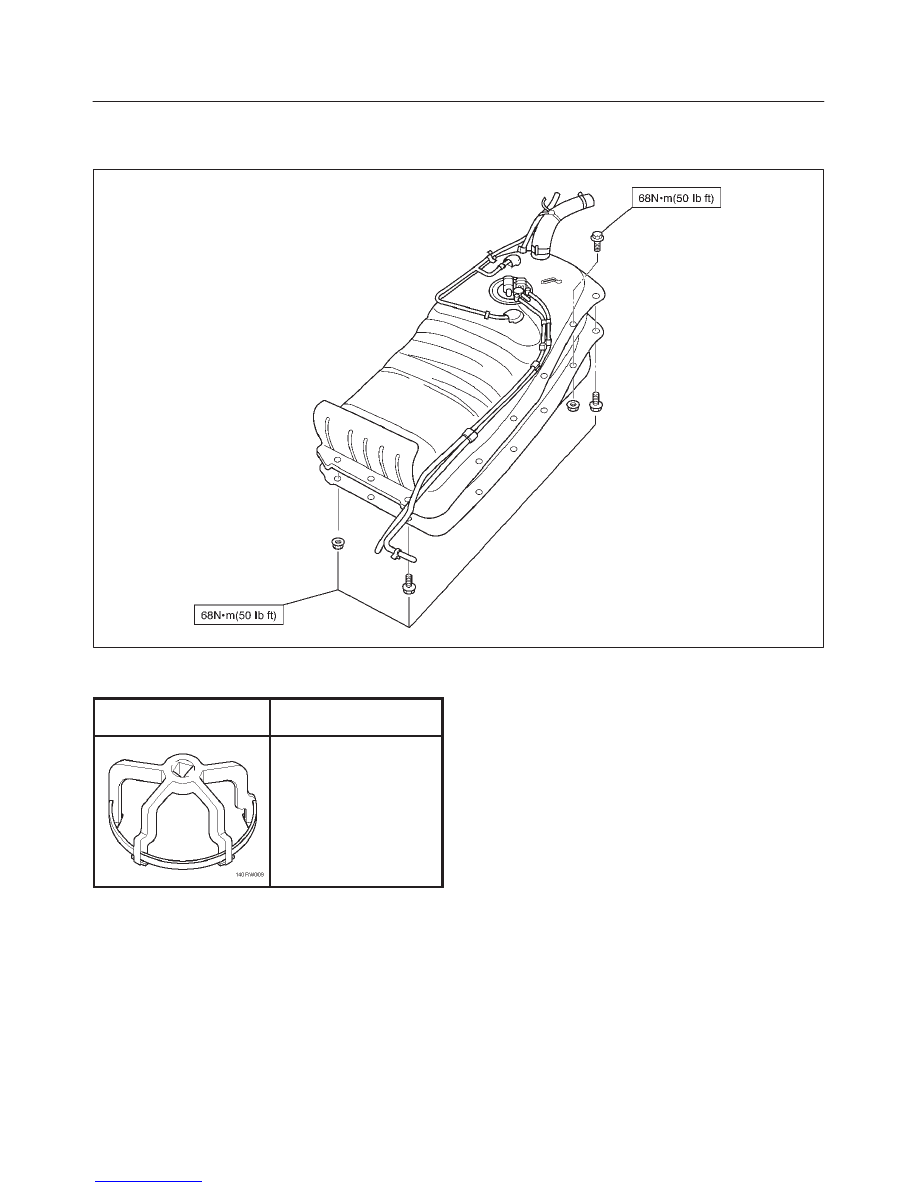

1. Install protectors (15,19) and tighten the six fixing

bolts to the specified torque.

Torque: 68 N·m (50 lb ft)

2. Install fuel pump and sender assembly by fitting in the

snap ring (7).

3. Install Fuel Tube/Quick Connector (12).

NOTE: Handling of fuel tube sure to refer “Fuel

Tube/Quick Connector Fittings” in this section.

4. Install roll over&float valve (1) by fitting in the retaining

cover (2).

5. Lift up fuel tank assembly and connect the emission

hose to the emission port and the wiring connectors

(8,9) on the fuel pump and sending assembly (10).

6. Install fuel tank assembly along with protectors and

tighten the four fixing bolts to the specified torque.

Torque: 68 N·m (50 lb ft)

7. Connect fuel filler hose (5) and air breather hose (4),

and clip them firmly.

8. Connect fuel feed hose (17) and fuel return hose (18),

and clip them firmly.

9. Connect evaporative fuel hose (3).

10. Tighten fuel filler cap.

11. Connect battery ground cable.

Fuel Gage Unit

Removal and Installation

As for removal and installation of the Fuel Gauge Unit,

refer to “Fuel Tank” of this section 6C as the fuel gauge

unit is combined with the fuel pump and sender assembly.

6C–12

ENGINE FUEL (X22SE 2.2L)

Fuel Filler Cap

General Description

Fuel filler cap includes vacuum valve.

In case any high vacuum happen in tank, the valve works

to adjust the pressure to prevent the tank from being

damaged.

140RW014

Legend

(1) Vacuum Valve

(2) Fuel Filler Cap

Inspection

Check the seal ring in the filler cap for presence of any

abnormality and for seal condition.

Replace the filler cap, if abnormal.

CAUTION:

The fuel filler cap valve has characteristics.

A defective valve, no valve at all or a valve with the

wrong characteristics will do a lot of harm to engine

operating characteristics; be sure to use the same

fuel filler cap as installed in this vehicle.

6C–13

ENGINE FUEL (X22SE 2.2L)

Main Data and Specifications

Torque Specification

140RX009

Special Tool

ILLUSTRATION

TOOL NO.

TOOL NAME

J–39763

Remover; fuel pump

lock

(For S/W)

6D1–1

ENGINE ELECTRICAL (X22SE 2.2L)

RODEO

ENGINE

ENGINE ELECTRICAL (X22SE 2.2L)

CONTENTS

Service Precaution

6D1–1

. . . . . . . . . . . . . . . . . . . . . .

Battery

6D1–2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description

6D1–2

. . . . . . . . . . . . . . . . . . . .

Diagnosis

6D1–2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Charging

6D1–3

. . . . . . . . . . . . . . . . . . . . . .

Jump Starting

6D1–3

. . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal

6D1–4

. . . . . . . . . . . . . . . . . . . . . .

Battery Installation

6D1–4

. . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications

6D1–5

. . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст