Isuzu Rodeo UE. Manual — part 439

6E2–511

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

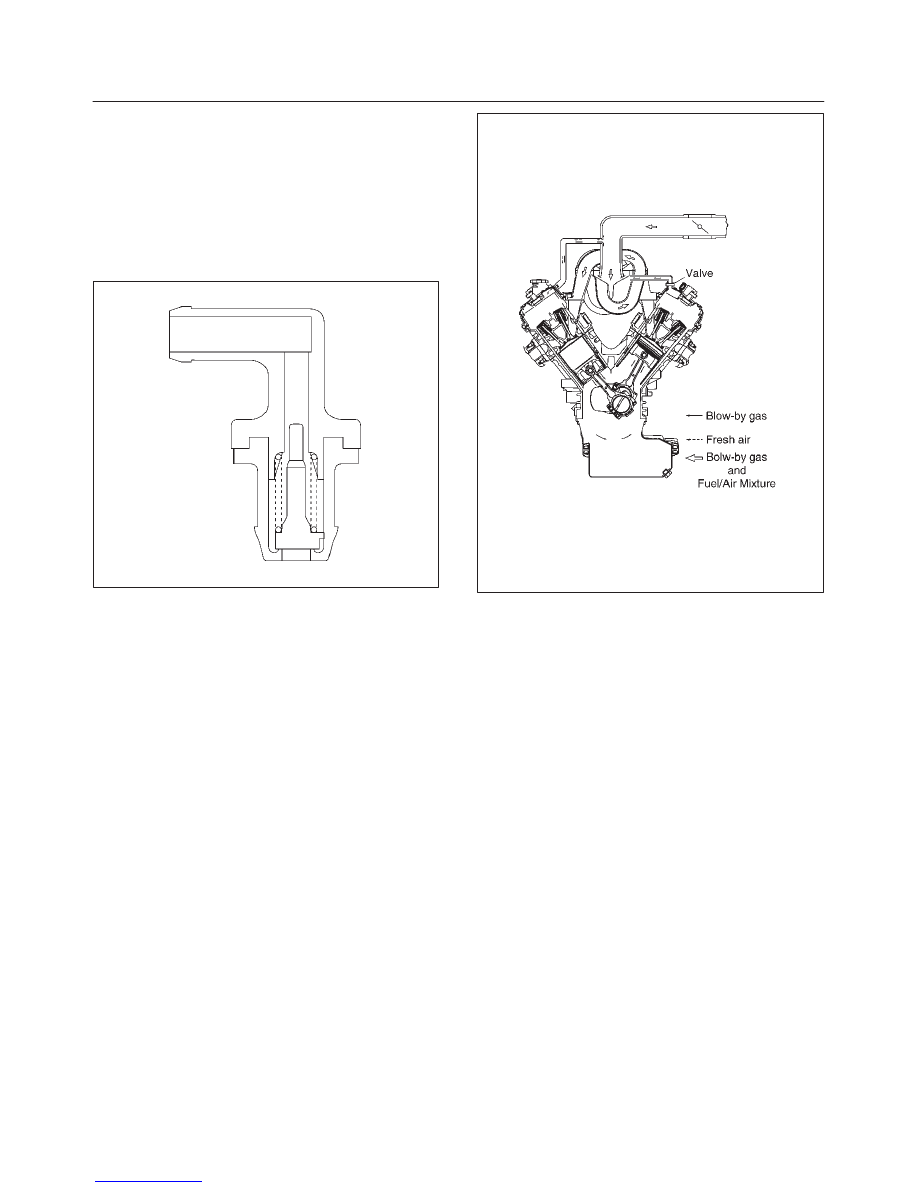

positive crankcase ventilation (PCV) valve into the

common chamber.

Crankcase Ventilation System Operation

The primary control is through the positive crankcase

ventilation (PCV) valve. The PCV valve meters the flow at

a rate that depends on the intake vacuum. The PCV valve

restricts the flow when the inlet vacuum is highest. In

addition, the PCV valve can seal the common chamber

off in case of sudden high pressure in the crankcase.

028RV002

While the engine is running, exhaust fuses and small

amounts of the fuel/air mixture escape past the piston

rings and enter the crankcase. These gases are mixed

with clean air entering through a tube from the air intake

duct.

028RW002

During normal, part-throttle operation, the system is

designed to allow crankcase gases to flow through the

PCV valve into the throttle body to be consumed by

normal combustion.

A plugged valve or PCV hose may cause the following

conditions:

f

Rough idle.

f

Stalling of slow idle speed.

f

Oil leaks.

f

Sludge in the engine.

A leaking PCV hose would cause:

f

Rough idle.

f

Stalling.

f

High idle speed.

6E2–512

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Special Tools

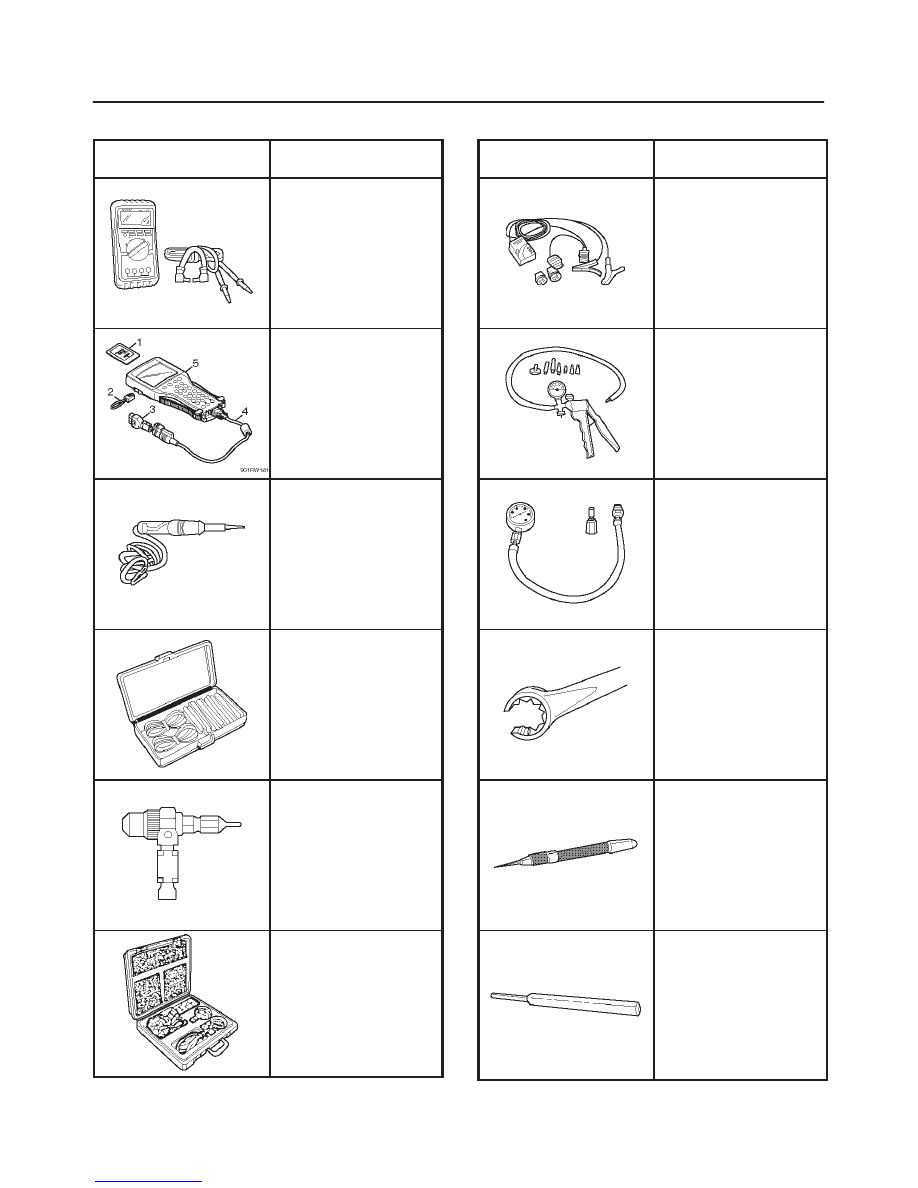

ILLUSTRATION

TOOL NO.

TOOL NAME

J 39200

High Impedance

Multimeter (Digital

Voltmeter – DVM)

(1) PCMCIA Card

(2) RS232 Loop Back

Connector

(3) SAE 16/19 Adapter

(4) DLC Cable

(5) TECH–2

J 34142-B

Unpowered Test Light

Connector Test Adapter

Kit J 35616-A/BT-8637

J 26792/BT-7220-1

Spark Tester

J 34730-E

Port Fuel Injection

Diagnostic Kit

ILLUSTRATION

TOOL NO.

TOOL NAME

J 37027-A

IAC Motor Analyzer

J 23738-A

Vacuum Pump with

Gauge

BT-8515/8515V

Exhaust Back Pressure

Tester

J 39194-B

Heated Oxygen Sensor

Wrench

J 35689-A

Terminal Remover

J 28742-A

Weather Pack II

Terminal Remover

6E2–513

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

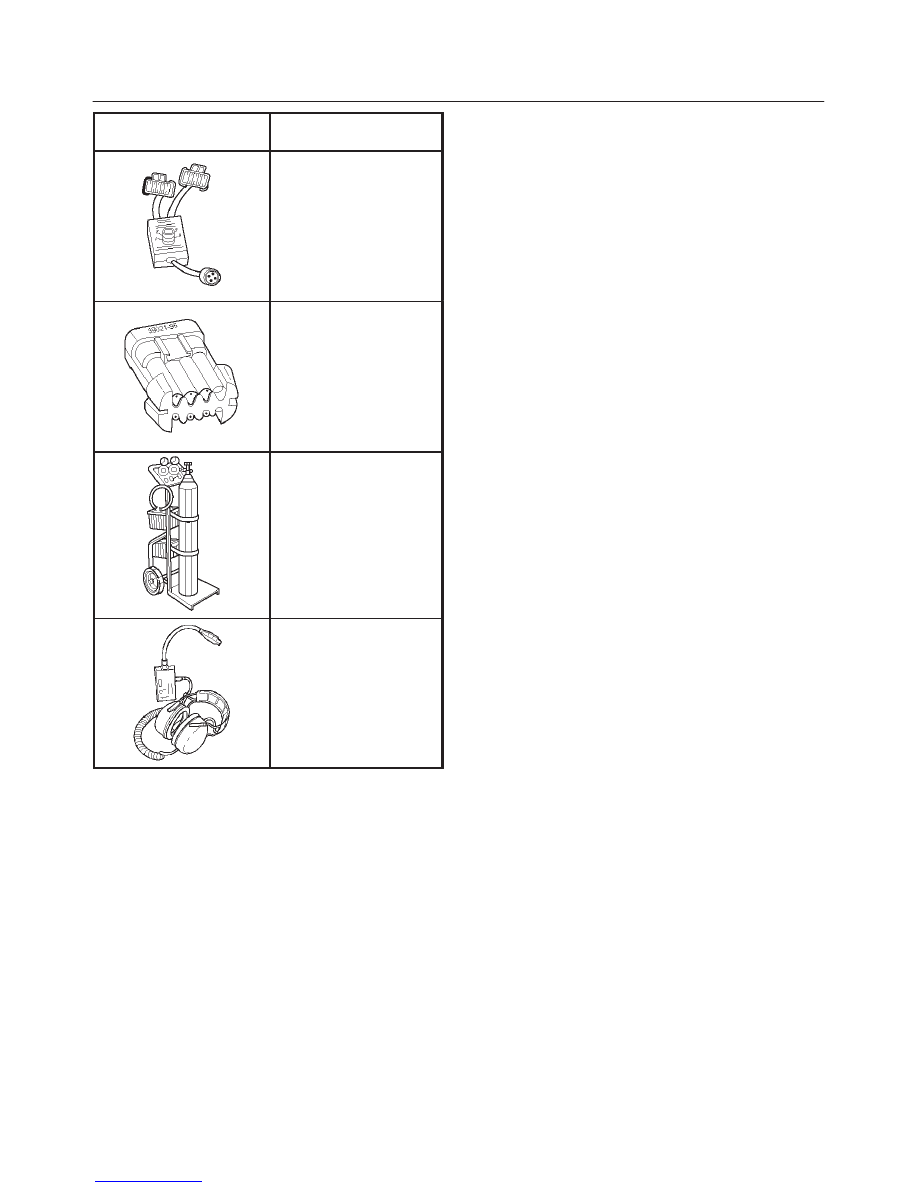

ILLUSTRATION

TOOL NO.

TOOL NAME

J 39021-90

Injector Switch Box

J 39021-65

Injector Test Light

J 41413

!

EVAP Pressure/Purge

Diagnostic Station

J 41416

@

Ultrasonic Leak Detector

1. J 41413 EVAP Pressure/Purge Diagnostic Station is

a multipurpose tool which is used to perform several

diagnostic procedures for enhanced emission

testing. The station will accommodate a nitrogen gas

filled cylinder which is used to pressurize the vehicle

EVAP system for a leakdown test and leak location

test when a vehicle is repaired for leakage in the

enhanced evaporative emission control system. It

also has two additional gauges (inches of mercury

and inches of water) which are used to measure both

source vacuum and EVAP canister purge vacuum to

verify correct operation and vapor flow within the

canister purge circuit.

2. J 41416 Ultrasonic Leak Detector is a

microprocessor-based device used to detect leaks in

the enhanced evaporative emission control system.

The evaporative system is pressurized to 30 inches of

water using the J 41413 EVAP Pressure/Purge

Diagnostic System. Small leaks in the EVAP system

will emit sound at a high frequency undetectable by a

human ear but detectable with the J 41416. The

technician traces along the evaporative system and

can pinpoint leaks due to corroded lines, cracked

hoses, or a damaged EVAP component. The

detector includes a high quality set of headphones to

block out surrounding shop noise and the LED

sensitivity meter allows a visual reference for locating

leaks in conjunction with the audio output heard

through the headphones. Powered by (1) nine volt

battery.

6F–1

ENGINE EXHAUST (6VD1 3.2L)

RODEO

ENGINE

ENGINE EXHAUST (6VD1 3.2L)

CONTENTS

Service Precaution

6F–1

. . . . . . . . . . . . . . . . . . . . . .

General Description

6F–2

. . . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter RH and

Forked Exhaust Pipe

6F–3

. . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter RH and

Forked Exhaust Pipe and Associated Parts

6F–3

Removal

6F–3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

6F–3

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter LH and

Forked Exhaust Pipe

6F–4

. . . . . . . . . . . . . . . . . . . .

Three Way Catalytic Converter LH and

Forked Exhaust Pipe and Associated Parts

6F–4

Removal

6F–4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

6F–4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forked Exhaust Pipe

6F–5

. . . . . . . . . . . . . . . . . . . .

Forked Exhaust Pipe and Associated Parts

6F–5

Removal

6F–5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

6F–5

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Silencer

6F–6

. . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Silencer and Associated Parts

6F–6

. . .

Removal

6F–6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

6F–6

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe

6F–7

. . . . . . . . . . . . . . . . . . . . . . .

Rear Exhaust pipe and Associated Parts

6F–7

.

Removal

6F–7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

6F–7

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications

6F–8

. . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст