Isuzu Rodeo UE. Manual — part 239

6E1–327

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

4. When the engine is idling or at steady cruise, the

HO2S voltage should vary from between

approximately 100 mV to 900 mV. During ”power

enrichment” mode, more fuel is needed and the

HO2S voltage should rise above 447 mV. This step

checks to see if the HO2S is operating properly.

5. Wrap a shop towel around the fuel pressure

connector to absorb any small amount of fuel

leakage that may occur when installing the gauge.

Ignition ON, pump pressure should be 235–320

kPa.

7. Add Caution: Use correct pliers so damage to fuel

lines will not occur.

6E1–328

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

DTC P1171 – Fuel System Lean During Acceleration

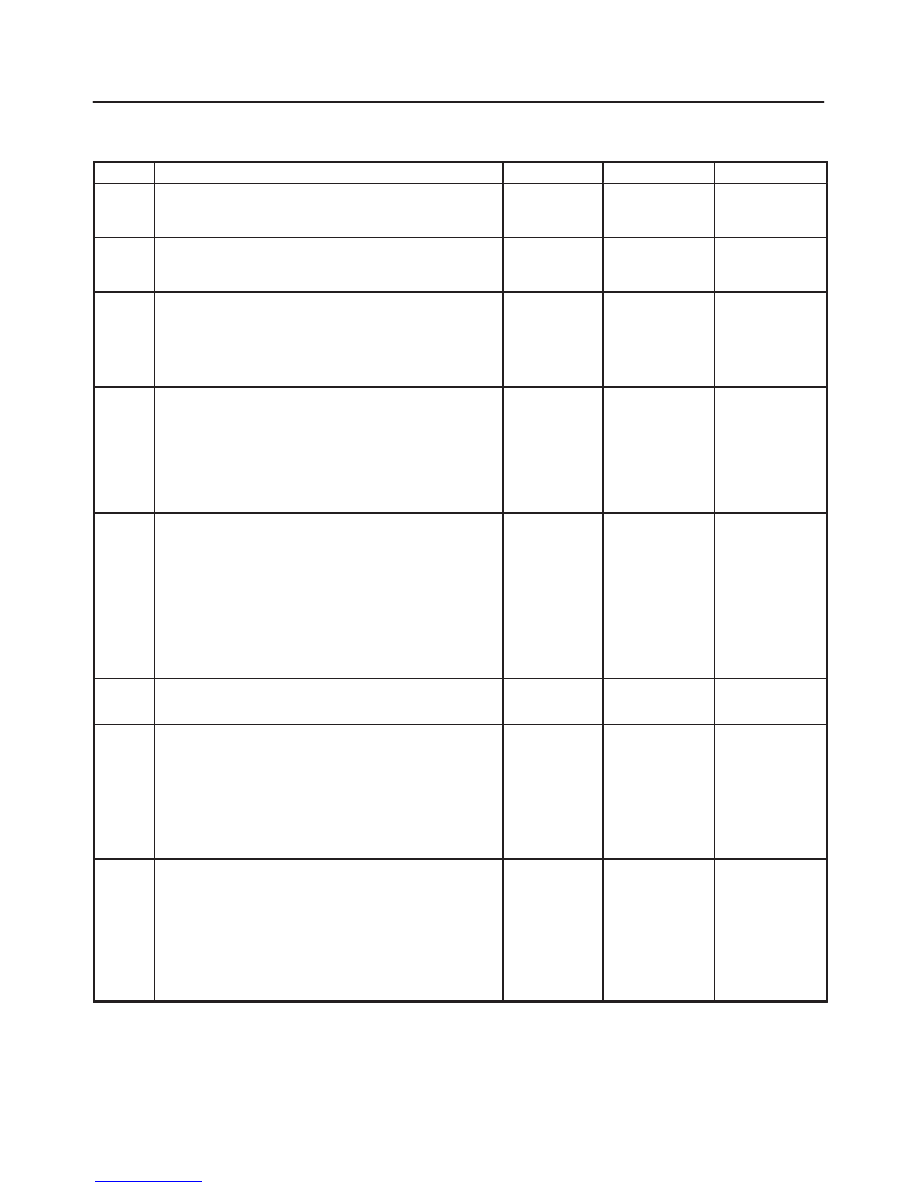

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

Are any component–related Diagnostic Trouble Codes

set?

—

Go to

component

DTC charts

Go to Step 3

3

1. Check the vehicle’s fuel tank for an adequate

amount of fuel.

2. Add fuel to the vehicle’s fuel tank if the tank is almost

empty.

Was fuel added to the vehicle’s fuel tank?

—

Go to Step 4

Go to Step 5

4

1. Using a Tech 2, observe HO2S 1 voltage while

running warm engine(75

°

C–95

°

C [167

°

F–203

°

F])

at 1200 RPM.

2. HO2S 1 voltage should vary within the specified

range.

Does the voltage toggle back and forth within the

specified range?

100– 900 mV

Go to

Diagnostic

Aids

Go to Step 5

5

1. Disconnect the fuel pump relay and crank the

engine to relieve the fuel pressure.

2. Install the fuel pressure gauge.

3. Start the engine and idle at normal operating

temperature.

4. Disconnect the vacuum line going to the fuel

pressure regulator.

With the engine running, is the fuel pressure within the

specified range?

284– 325 kPa

Go to OBD

System

Check

Go to Step 6

6

Check for restricted fuel lines or restricted in–line filter.

Was a problem found?

—

Verify repair

Go to Step 7

7

1. Ignition OFF.

2. Ignition ON, engine OFF.

3. Using a Tech 2, enable the fuel pump to operate.

4. Using pliers, slowly close the return line (do not

exceed the first specified value).

Using the pliers, can the fuel pressure be manipulated

to exceed the second specified value?

414 kPa 325

kPa

Go to

Diagnostic

Aids

Go to Step 8

8

Check for:

f

Faulty fuel pump

f

Restricted fuel pump strainer (sock)

f

Incorrect fuel pump

f

Incorrect fuel being used

f

Hot fuel

—

Verify repair

—

6E1–329

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

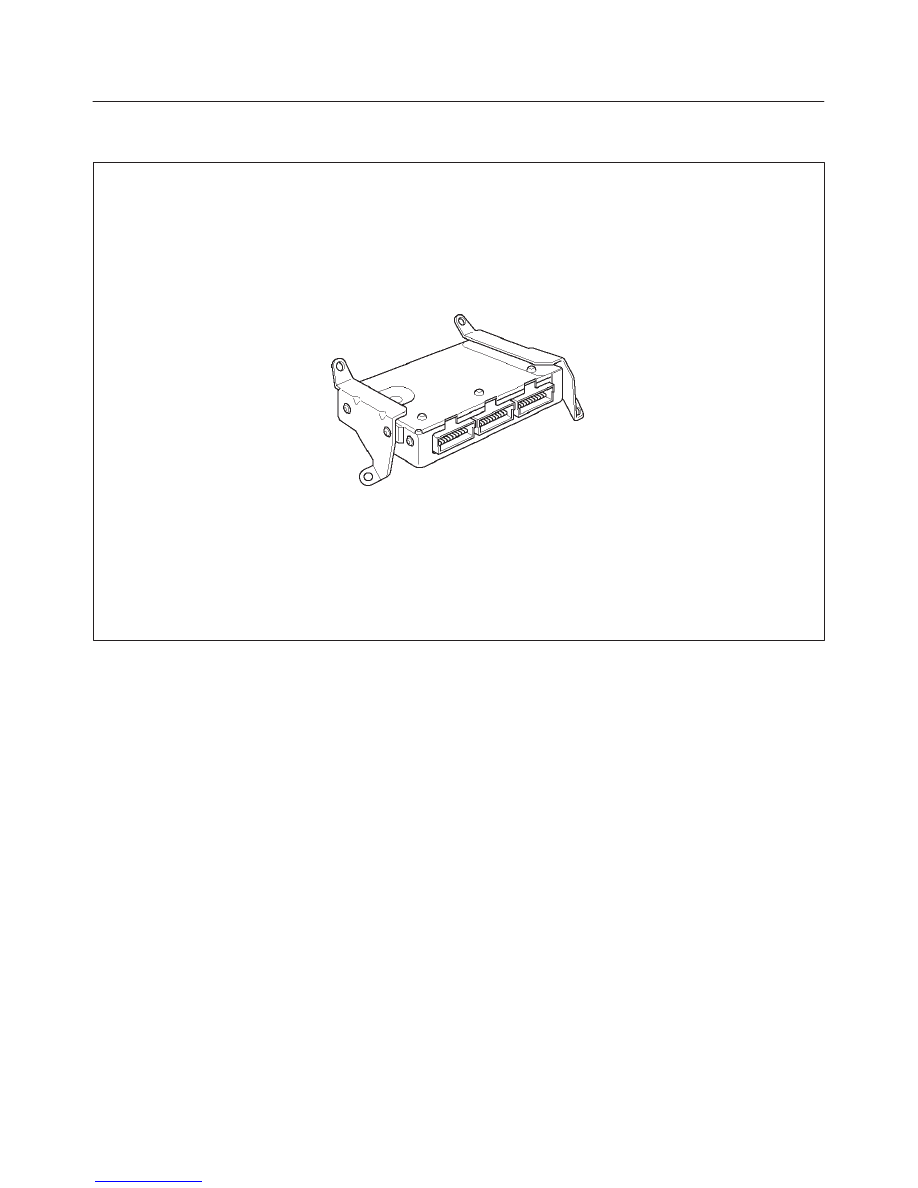

DIAGNOSTIC TROUBLE CODE (DTC) P1336 CRANKSHAFT POSITION

SENSOR (CKP) SYSTEM VARIATION NOT LEARNED

014RX002

Circuit Description

In order to detect engine misfire at higher engine speeds,

the Powertrain Control Module (PCM) must know of any

variation between the crankshaft sensor pulse. Most

variations are due to the machining of the crankshaft

reluctor wheel, however, other sources of variation are

also possible. A Crankshaft Position Sensor Tooth Error

Correction (TEC) procedure must be performed any time

a change is made to the crankshaft sensor, crankshaft, or

if the PCM measures the variations and then calculates

compensation factors needed to enable the PCM to

accurately detect engine misfire at all speeds and loads.

The Tech 2 must be used to command the PCM to learn

these variations. If for any reason the PCM is unable to

learn these variations or they are out of an acceptable

range, the PCM will set a DTC P1336. A PCM that has not

had the Crankshaft Position Sensor Tooth Error

Correction (TEC) Procedure performed due to

replacement or reprogramming will also set a DTC

P1336. DTC P1336 is a type A code.

Conditions for Setting the DTC

f

No ECT, Knock, CKP, CMP or injector sensor DTCs.

f

PCM has not successfully learned crankshaft position

Tooth Error Correction(TEC) within 5 attempts or 5 Km

(3 miles).

Action Taken When the DTC Sets

f

The Malfunction Indicator Lamp (MIL) will illuminate

the first time the error is detected.

f

The PCM will record operating conditions at the time

the diagnostic fails. This information will be stored in

the Freeze Frame and Failure Records buffers.

f

A history DTC is stored.

Conditions for Clearing the MIL/DTC

f

The MIL will turn OFF after three consecutive ignition

cycles in which the diagnostic runs without a fault.

f

A history DTC will clear after 40 consecutive warm up

cycles without a fault.

f

DTC(s) can be cleared by using the Tech 2.

Diagnostic Aids

f

Refer to ”TEC Learn Procedure”

CAUTION: When performing the Crankshaft

Position Sensor Tooth Error Correction (TEC)

Procedure always set the vehicle parking brake and

block the drive wheels. Release the throttle

immediately when the engine starts to decelerate.

Once the learn procedure is completed, engine

control will be returned to the operator and the

engine will respond to throttle position.

DTC P1336 will only set if the PCM has not learned the

crankshaft position sensor Tooth Error Correction (TEC).

The PCM only needs to learn this variation once per life

6E1–330

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

cycle of the vehicle unless the crank sensor to crankshaft

relationship is disturbed. Removing a part for inspection

and then reinstalling the same part is considered a

disturbance. A fully warmed up engine is critical to

learning the variation correctly. If a valid learn occurs, no

other learns can be completed that ignition cycle. If the

engine cuts out before the specified learn procedure

engine speed or at normal fuel cut–off RPM. The PCM is

not in the learn procedure mode. Review the Crankshaft

Position Sensor Tooth Error Correction (TEC) Procedure

and re–enable the learn procedure. Verify that the Tech 2

says ”Test in Progress.”

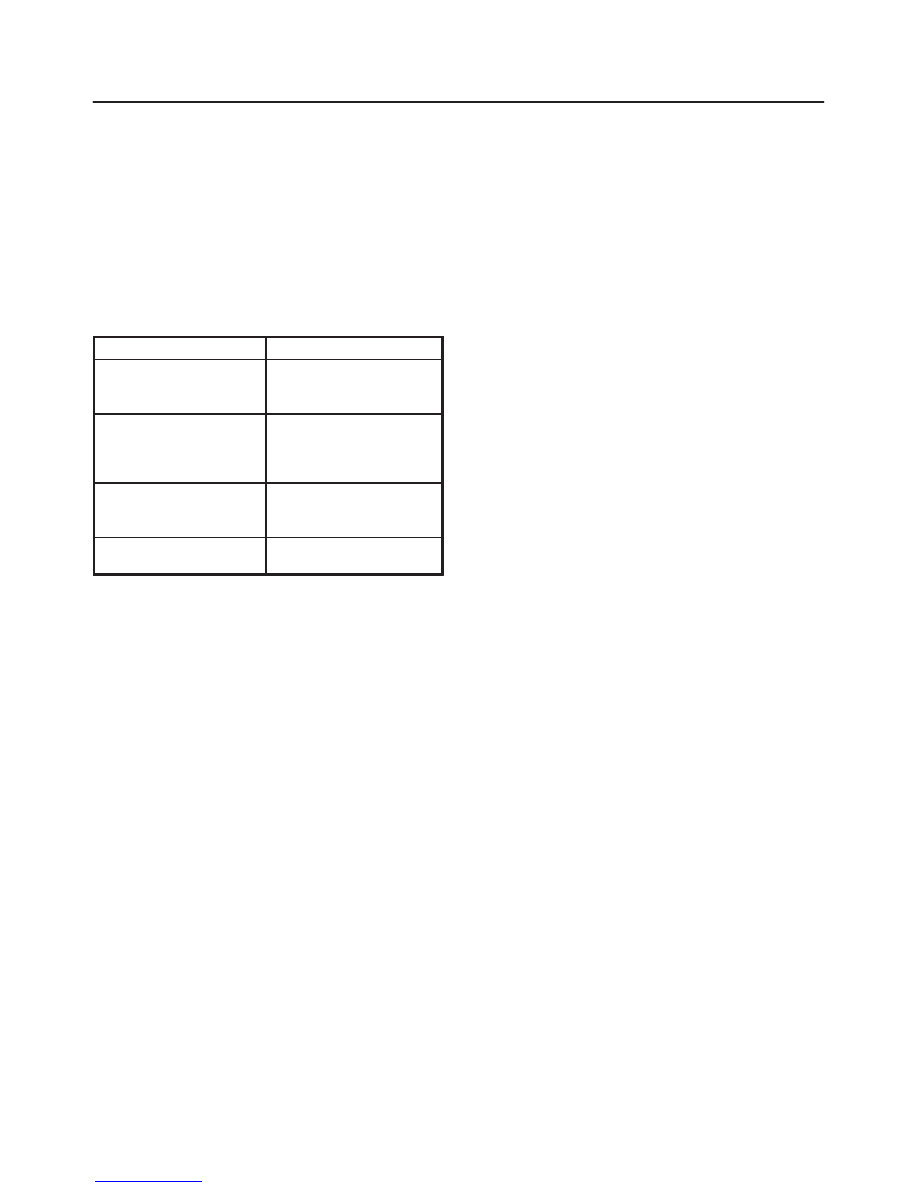

Excessive Crankshaft Variation Symptom

Tech 2 Display

Possible Causes

Factors out of range

Reluctor wheel–matching

quality, run out, incorrect

air gap

Opposing factors out of

range

Disturbance–noise on

crank sensor circuit,

reattempt the Learn

procedure

Sum out of range

Engine too cold,

reattempt the Learn

Procedure

Crank pulse count error

Crank or Cam sensor

DTCs set–Repair first

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

1. The Powertrain OBD System Check prompts the

technician to complete some basic checks and store

the freeze frame and failure records data on the

Tech 2 if applicable. This created an electronic copy

of the data taken when the fault occurred. The

information is then stored on the Tech 2 for later

reference.

2. Engine temperature if critical to properly learn the

Crankshaft Position Sensor Tooth Error Correction

(TEC). Failure to properly warm the engine before

performing this procedure will result in an inaccurate

measurement of the Crankshaft Position Sensor

Tooth Error Correction (TEC). The PCM learns this

variation as the engine is decelerating and then

allows engine control to be returned to the operator.

All accessories must be turned OFF when learning

the Crankshaft Position System angle variation. If

the A/C is not disabled when the learn procedure is

enable, the PCM will disable the A/C. When the

PCM is ready to allow the learn procedure to run,

the Tech 2 will display ”Test in Progress.”

3. If after the specified number attempts the PCM

cannot learn the crankshaft position Sensor Tooth

Error Correction (TEC) then the variation is too

large and no variation problem is corrected.

4. Being unable to learn the Crankshaft Position

Sensor Tooth Error Correction (TEC) indicates that

the variation is out of range. Using the Excessive

Crankshaft Variation Trouble shooting will help to

diagnose the area where the problem lies.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст