Isuzu Rodeo UE. Manual — part 416

6E2–419

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

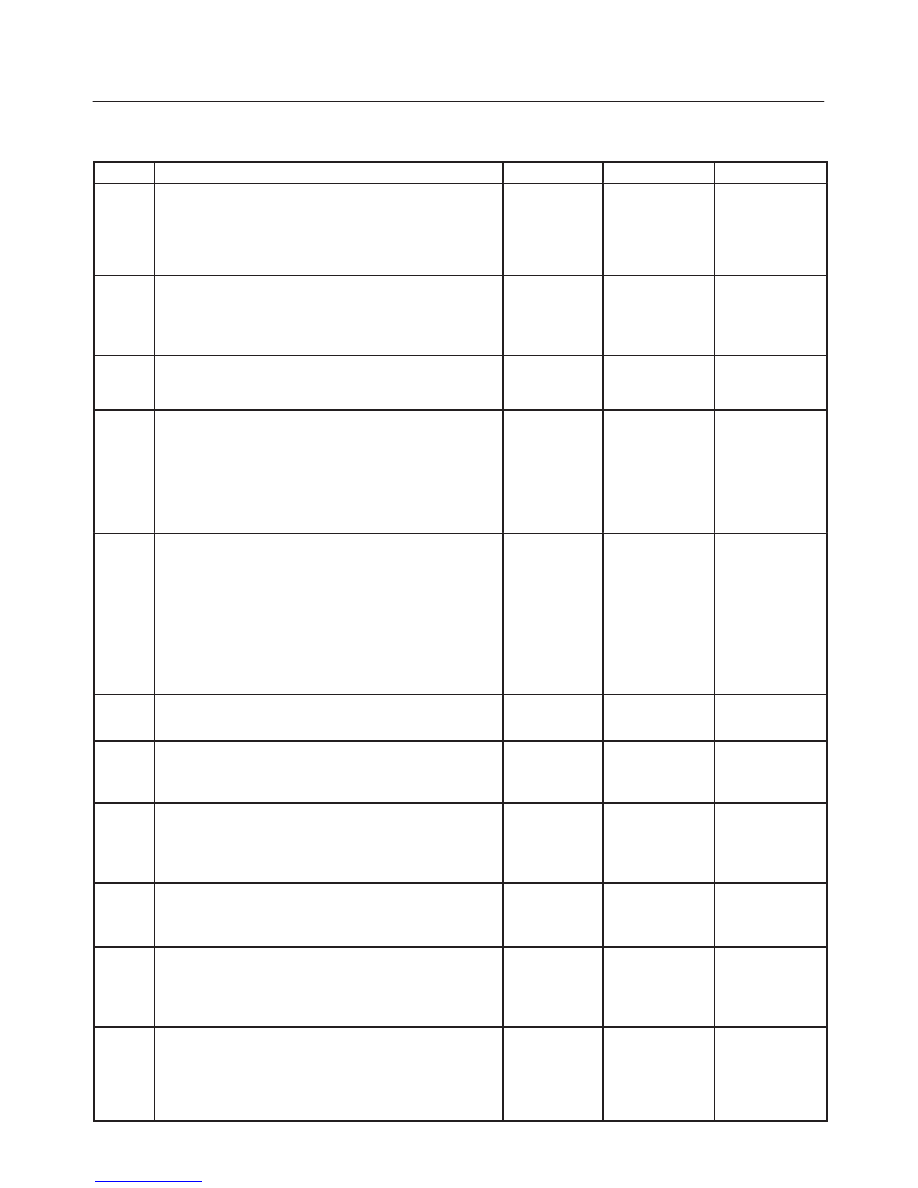

Hard Start Symptom

Step

Action

Value(s)

Yes

No

1

DEFINITION:

Engine cranks, but does not start for a long time. Does

eventually run, or may start but immediately stalls.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to

Step 3

3

Was a visual/physical check performed?

—

Go to

Step 4

Go to

Visual/Physic

al Check

4

Check engine coolant temperature (ECT) sensor for

shift in value. After 8 hours with the hood up and the

engine not running, connect the Tech 2. With the

ignition “ON” and the engine not running, compare

engine coolant temperature to intake air temperature.

Are ECT and IAT within the specified value of each

other?

±

5

°

C (

±

9

°

F)

Go to

Step 9

Go to

Step 5

5

1. Using a Tech 2, display the engine coolant

temperature and note the value.

2. Check the resistance of the engine coolant

temperature sensor.

3. Refer to

Engine Coolant Temperature Sensor

Temperature vs. Resistance chart on DTC P0118

Diagnostic Support for resistance specifications.

Is the resistance value near the resistance for the

temperature noted?

—

Go to

Step 7

Go to

Step 6

6

Replace the ECT sensor.

Is the action complete?

—

Verify repair

—

7

Locate and repair high resistance or poor connection in

the ECT signal circuit or the ECT sensor ground.

Is the action complete?

—

Verify repair

—

8

1. Check for a faulty, plugged, or incorrectly installed

PCV valve.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 9

9

1. Check for water-or alchol-contaminated fuel.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 10

10

1. Perform the procedure in

Fuel System Pressure

Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 11

11

1. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electric Ignition

System for procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 12

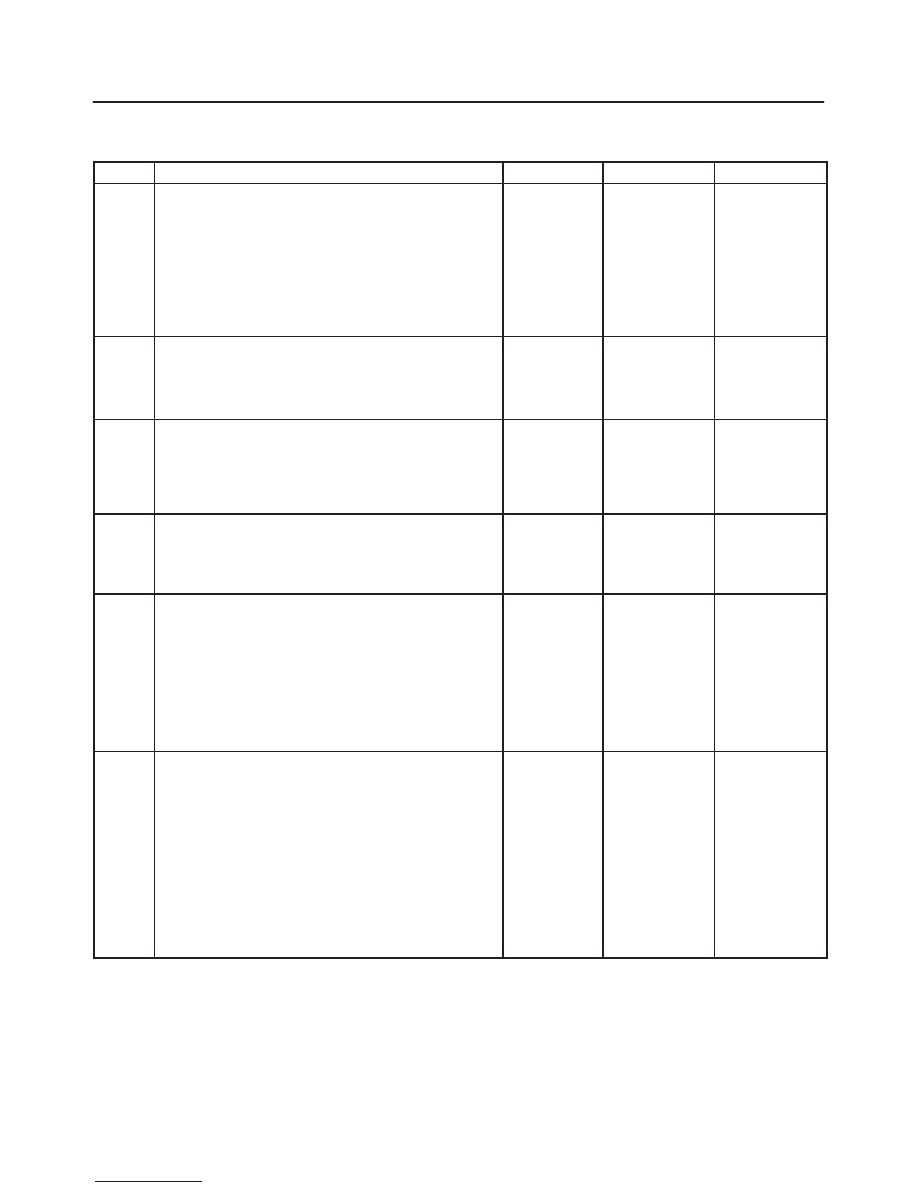

6E2–420

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Hard Start Symptom

(Cont'd)

Step

No

Yes

Value(s)

Action

12

1. Remove spark plugs. Check for wet plugs, cracks,

wear, improper gap, burned electrodes, or heavy

deposits. Refer to

Electronic Ignition System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 13

13

1. Check for a loose ignition coil ground.

Refer to

Electronic Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 14

14

1. Remove the ignition coils and check the ignition

coils for cracks or carbon tracking.

2. If a problem is found, replace affected coil(s) as

necessary.

Was a problem found?

—

Verify repair

Go to

Step 15

15

1. Check IAC operation. Perform the procedure in the

DTC P0506, Step 6 diagnostic table.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 16

16

1. Check for the following engine mechanical

problems (refer to

Engine Mechanical):

f

Low compression

f

Leaking cylinder head gaskets

f

Worn or incorrect camshaft

f

Camshaft drive belt slipped or stripped

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 17

17

1. Review all diagnostic procedures within this table.

2. If all procedures have been completed and no

malfunctions have been found, review/inspect the

following:

f

Visual/physical inspection

f

Tech 2 data

f

Freeze Frame data/Failure Records buffer

f

All electrical connections within a suspected

circuit and/or system.

3. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Contact

Technical

Assistance

6E2–421

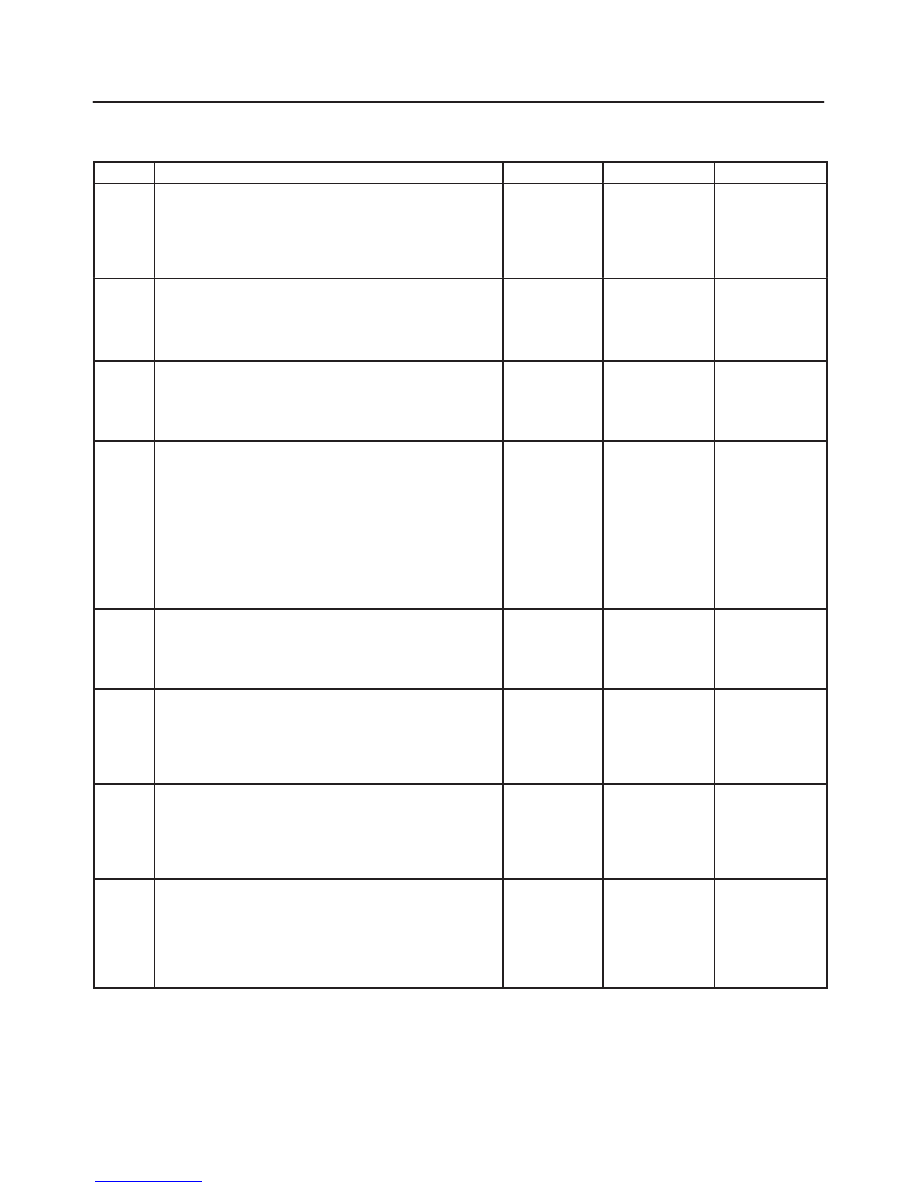

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Surges and/or Chuggles Symptom

Step

Action

Value(s)

Yes

No

1

DEFINITION:

Engine power variation under steady throttle or cruise.

Feels like the vehicle speeds up and slows down with

no change in the accelerator pedal.

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Perform a bulletin search.

2. If a bulletin that addresses the symptom is found,

correct the condition as instructed in the bulletin.

Was a bulletin found that addresses the symptom?

—

Verify repair

Go to

Step 3

3

Was a visual/physical check performed?

—

Go to

Step 4

Go to

Visual/Physic

al Check

4

Be sure that the driver understands transmission

torque converter clutch and A/C compressor operation

as explained in the owner’s manual.

Inform the customer how the TCC and the A/C clutch

operate.

Is the customer experiencing a normal condition?

—

System OK

Go to

Step 5

5

1. Check the the fuel control heated oxygen sensors

(HO2S, B1S1 and B2S1). The fuel control heated

oxygen sensors (HO2S) should respond quickly to

different throttle positions. If they don’t, check them

for silicone or other contaminants from fuel or use of

improper RTV sealant. The sensors may have a

white powdery coating.

Silicone contamination causes a high but false

HO2S signal voltage (rich exhaust indication).

The PCM will then reduce the amount of fuel

delivered to the engine, causing a severe

driveability problem. For more information, refer

to

Powertrain Control Module (PCM) and Sensors.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 6

6

1. Check the fuel pressure. Refer to

Fuel System

Pressure Test.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 7

7

Monitor the long term fuel trim on the Tech 2.

Is the long term fuel trim significantly in the negative

range (rich condition)?

—

Go to

Step 8

Go to

Step 9

8

1. Check items that can cause the engine to run rich.

Refer to

Diagnostic Aids in DTC P0172 Diagnostic

Support.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Go to

Step 10

Verify repair

9

1. Check items that can cause the engine to run lean.

Refer to

Diagnostic Aids in DTC P0171.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Go to

Step 10

Verify repair

6E2–422

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Surges and/or Chuggles Symptom

(Cont'd)

Step

No

Yes

Value(s)

Action

10

1. Check for proper ignition voltage output with spark

tester J 26792 (ST-125). Refer to

Electric Ignition

System for procedure.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 11

11

1. Check for a loose ignition coil ground.

Refer to

Electric Ignition System.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 12

12

1. Check the ignition coils for cracks or carbon

tracking.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 14

13

1. Remove the spark plugs and check for wet plugs,

cracks, wear, improper gap, burned electrodes, or

heavy deposits. Refer to

Electronic Ignition

System.

NOTE: If spark plugs are gas or oil fouled, the cause of

the fouling must be determined before replacing the

spark plugs.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 14

14

1. Check the injector connections.

2. If any of the injector connectors are connected to an

incorrect cylinder, correct as necessary.

Was a problem found?

—

Verify repair

Go to

Step 15

15

1. Check PCM grounds for the cleanliness, tightness

and proper locations. Refer to the PCM wiring

diagrams in

Electrical Diagnosis.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 16

16

1. Check MAF sensor connections.

2. If a problem is found, replace the faulty terminals as

necessary. Refer to

Electrical Diagnosis for wiring

repair procedures.

Was a problem found?

—

Verify repair

Go to

Step 17

17

1. Visually/physically check vacuum hoses for splits,

kinks, and proper connections and routing as

shown on the “Vehicle Emission Control

Information” label.

2. If a problem is found, repair as necessary.

Was a problem found?

—

Verify repair

Go to

Step 18

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст