Isuzu Rodeo UE. Manual — part 412

6E2–403

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

f

EVAP purge solenoid driver circuit grounded

If any of these conditions are present, DTC P1441 will set.

Conditions for Setting the DTC

f

No TP sensor, ODM, IAT sensor, or MAP sensor DTCs

are set.

f

Intake air temperature is above 0

°

C (32

°

F).

f

Fuel tank level is between 15% and 85%.

f

A continuous open purge flow condition is detected

during the diagnostic test.

Action Taken When the DTC Sets

f

The PCM will illuminate the Malfunction Indicator lamp

(MIL) during the second key cycle trip in which the DTC

sets.

f

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL “OFF” on the third

consecutive trip cycle during which the diagnostic has

been run and the fault condition is no longer present.

f

A history DTC P1441 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

f

DTC P1441 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

f

Poor connection at PCM. Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

f

Damaged harness. Inspect the wring harness for

damage. If the harness appears to be OK, connect the

EVAP pressure/purge cart J41413 to the EVAP service

port, pressurize the EVAP system to 10 in. H

2

O and

observe the “Fuel Tank Vacuum” display on the Tech

2 while moving connectors and wiring harnesses

related to the EVAP purge solenoid. A sudden change

in the display will indicate the location of the fault.

f

Incorrect vacuum line routing. Verify that the source

vacuum line routing to the EVAP purge solenoid is

correct and that the EVAP purge and source vacuum

lines to the EVAP purge solenoid are not switched.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2.If an EVAP purge solenoid electrical fault is present,

the purge system will not operate correctly.

repairing the electrical fault will very likely correct

the condition that set DTC P1441.

3.Checks the fuel tank vacuum sensor at ambient

pressure.

4.Checks for a stuck open EVAP purge solenoid.

5.Verifies that the fuel tank pressure sensor accurately

reacts to EVAP system pressure changes.

7.If the EVAP purge and engine vacuum lines are

switched at the EVAP purge solenoid, the solenoid

valve will leak vacuum.

DTC P1441 – EVAP System Flow During Non-Purge

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Ignition “OFF.”

2. Remove the fuel filler cap.

3. Ignition “ON.” Observe “Fuel Tank Pressure” on the

Tech 2.

Is “Fuel Tank Pressure” at the specified value?

1.51 V

Go to

Step 3

Go to

P0452

or P0453

6E2–404

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P1441 – EVAP System Flow During Non-Purge

(Cont'd)

Step

No

Yes

Value(s)

Action

3

1. Re–install the fuel filler cap.

2. Using the Tech 2, command the EVAP Vent

Solenoid Valve “ON” (Closed).

3. Disconnect the canister side rubber hose end that

hose is connected between the Purge Solenoid

Valve and Canister.

IMPORTANT: Before continuing with the diagnosis,

zero the EVAP pressure and vacuum gauges on EVAP

pressure / purge cart J41413 (refer to the tool operating

instructions).

And then monitor the fuel tank inner pressure using the

Tech 2.

Does the fuel tank pressure hold the specified value?

1.52 - 1.60 V

Go to

Step 4

Go to

Step 6

4

1. Disconnect the EVAP pressure / purge cart J41413,

and then plug the hose end.

2. Disconnect the rubber hose end of engine vacuum

source side, (the hose is connected between Purge

Solenoid Valve and engine).

3. Connect a vacuum hand pump to this rubber hose

end.

4. Then apply -15 in H2O vacuum by the vacuum

pump.

5. Monitor the fuel tank inner pressure using the Tech

2.

Does the fuel tank inner pressure hold the specified

value?

1.47 - 1.51 V

Go to

Step 6

Go to

Step 5

5

Replace the Purge Solenoid Valve.

—

Verify repair

—

6

1. Check the leak, kinks or pinched hoses at the EVAP

system rubber hose line, and also check if the

rubber hoses are correctly connected or not.

2. Check for a leak from Vent Solenoid Valve and

EVAP system rubber hoses, and also check for

clogged Filter of air separator which is located near

the vent solenoid valve.

Was a problem found? Using the Vacuum Hose

Routing Diagram, repair or re-connect the rubber

hoses correctly.

—

Verify repair

Go to

Step 7

7

1. Start engine.

2. Remove the Fuel Filler Cap.

3. Using the Tech 2, command the EVAP Vent

Solenoid Valve “ON” (closed) and Purge Solenoid

Valve “OFF” (0%).

4. Replace the Fuel Filler Cap.

5. Run the engine at 2500RPM constant while

monitoring “Fuel Tank Vacuum” on the Tech 2.

Does the fuel tank vacuum remain at the specified

value while the EVAP Vent Solenoid Valve “ON”

(closed) and Purge Solenoid Valve “OFF” (o%)?

30 - 40%

Verify repair

Go to

Diagnostic

Aids

6E2–405

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1508 IAC System Low RPM

T321115

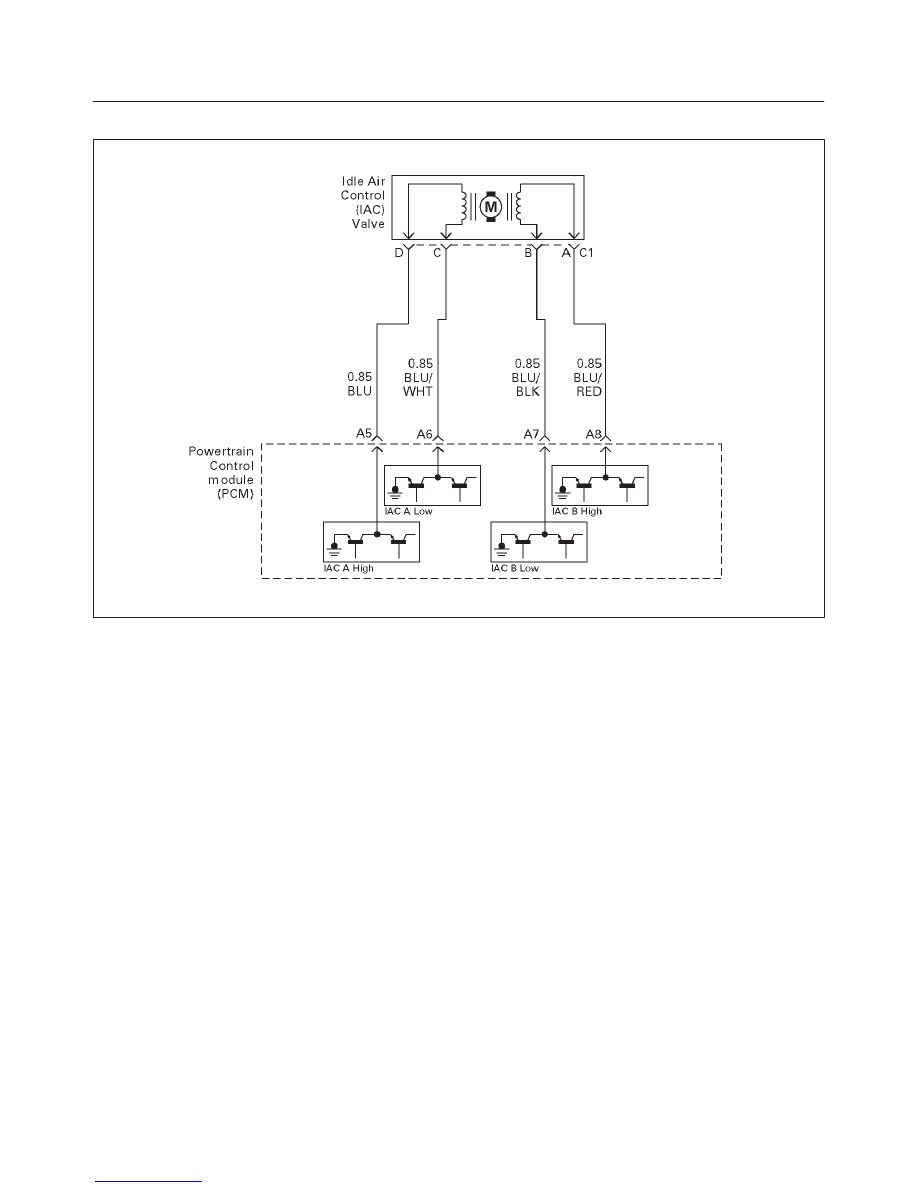

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detects a condition where too low of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1508 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

f

No Tech 2 test is being run.

f

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

f

Barometric pressure is above 75 kPa.

f

Engine coolant temperature (ECT) is above 50

°

C

(120

°

F).

f

Vehicle speed is less than 1 mph.

f

The engine has been running for at least 125 seconds.

f

Canister purge duty cycle is above 10%.

f

Ignition voltage is between 9.5 volts and 16.7 volts.

f

The throttle is closed.

f

Engine speed is lower than desired idle.

f

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

f

All of the above conditions are met for 5 seconds.

Action Taken When the DTC Sets

f

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

f

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL “OFF” on the third

consecutive trip cycle during which the diagnostic has

been run and the fault condition is no longer present.

f

A history DTC P1508 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

f

DTC P1508 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

f

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

f

Damaged harness – Inspect the wiring for damage.

6E2–406

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

f

Restricted air intake system – Check for a possible

collapsed air intake duct, restricted air filter element,

or foreign objects blocking the air intake system.

f

Throttle body – Check for objects blocking the IAC

passage or throttle bore, excessive deposits in the IAC

passage and on the IAC pintle, and excessive deposits

in the throttle bore and on the throttle plate.

f

Large vacuum leak – Check for a condition that causes

a large vacuum leak, such as an incorrectly installed or

faulty PCV valve or a disconnected brake booster

hose.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P1508 –IAC System Low RPM

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Start the engine.

2. Turn all accessories “OFF”(A/C, rear defroster,

etc).

3. Using a Tech 2, command RPM up to 1500, down to

500, and then up to 1500 while monitoring the

“Engine Speed” on the Tech 2.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does the “Engine Speed” remain within the specified

value of the “Desired Idle” for each RPM command?

±

50 RPM

No trouble

found. Go to

Diagnostic

Aids

Go to

Step 3

3

1. Disconnect the IAC.

2. Install IAC Noid Light J 37027 or equivalent.

3. With the engine running, command RPM up to

1500, down to 500, and then up to 1500 while

observing the noid light.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does each noid light cycle red and green (never

“OFF”)?

—

Go to

Step 5

Go to

Step 4

4

1. Check the following circuits for an open, short to

voltage, short ground, or poor connections at the

PCM:

f

IAC “A” Low.

f

IAC “A” High.

f

IAC “B” Low.

f

IAC “B” High.

2. If a problem is found, repair as necessary,

Was a problem found?

—

Verify repair

Go to

Step 8

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст