Isuzu Rodeo UE. Manual — part 351

6E2–159

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Aids

DTC P0125 set indicates a faulty ECT sensor.

Comparing the engine coolant temperature displayed on

a Tech 2 with actual coolant temperature measured with a

thermometer may isolate this condition. If the displayed

engine coolant temperature is not close to the actual

coolant temperature, replace the ECT sensor.

Check for the following conditions:

f

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

f

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

display on the Tech 2 while moving connectors and

wiring harnesses related to the sensor. A change in the

display will indicate the location of the fault.

If DTC P0125 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage wince the DTC was last set.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Comparing the engine coolant temperature displayed

on a Tech 2 with actual coolant temperature

measured with a thermometer may isolate this

condition. If the displayed engine coolant

temperature is not close to the actual coolant

temperature, replace the ECT sensor. If the

temperatures are close, the fault is intermittent;

refer to

Diagnostic Aids.

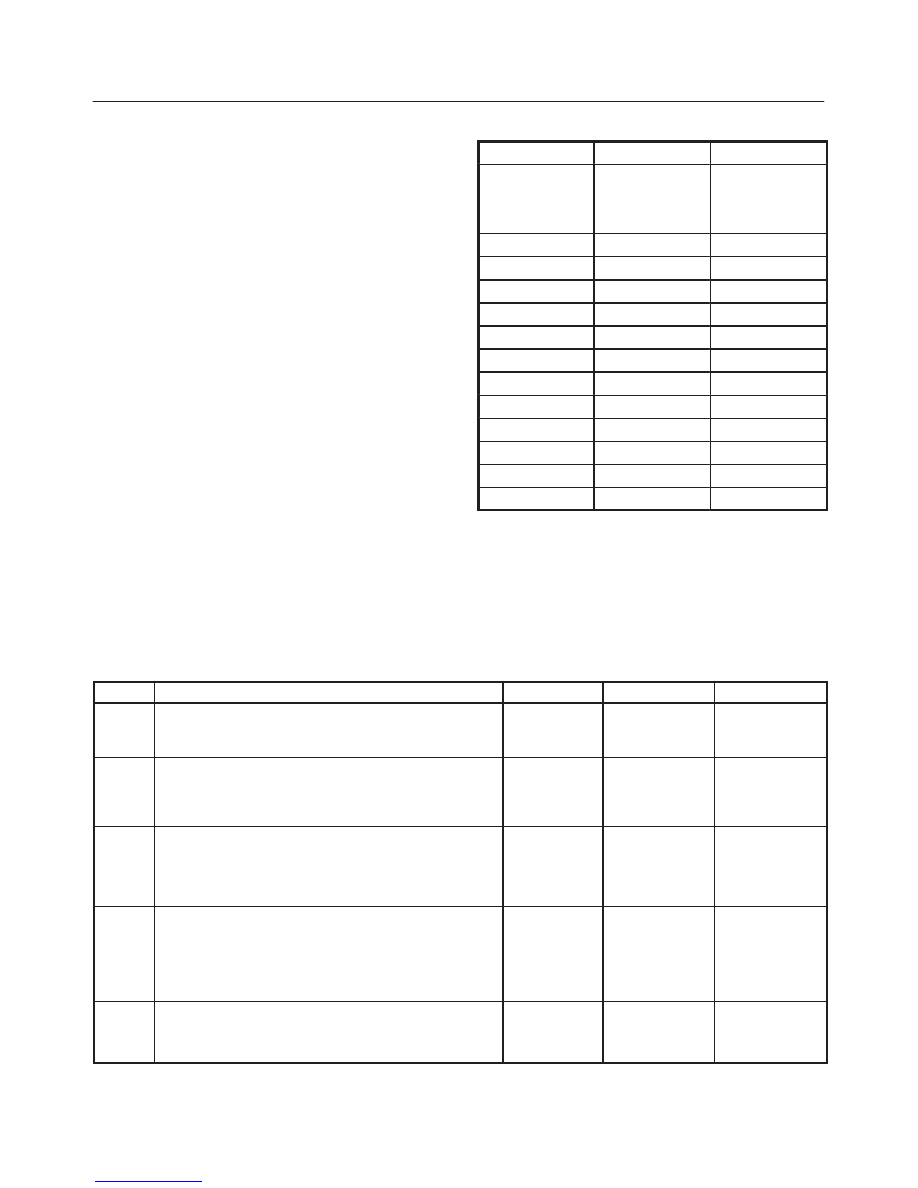

Engine Coolant Temperature

°

C

°

F

OHMS

Temperature

vs. Resistance

Values

(approximate)

100

212

177

80

176

332

60

140

667

45

113

1188

35

95

1802

25

77

2796

15

59

4450

5

41

7280

–5

23

12300

–15

5

21450

–30

–22

52700

–40

–40

100700

DTC P0125 –ECT Excessive Time to Closed Loop Fuel Control

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

Are any ECT sensor DTCs set?

—

Go to

applicable

ECT sensor

DTC chart

Go to

Step 3

3

1. Allow the engine to cool completely.

2. Check the cooling system coolant level (refer to

Cooling and Radiator).

Is the coolant level OK?

—

Go to

Step 4

Go to

Step 9

4

1. Start the engine.

2. With the engine idling, monitor “ENG COOL TEMP”

display on the Tech 2.

Does “ENG COOL TEMP” increase to above the

specified value within 2 minutes?

21

°

C (70

°

F)

Refer to

Diagnostic

Aids

Go to

Step 5

5

Check for proper operation of the thermostat (refer to

Cooling and Radiator).

Is the thermostat operating correctly?

—

Go to

Step 6

Go to

Step 9

6E2–160

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

DTC P0125 –ECT Excessive Time to Closed Loop Fuel Control

(Cont'd)

Step

No

Yes

Value(s)

Action

6

Compare engine coolant temperature displayed on the

Tech 2 to the actual coolant temperature measured

with a thermometer. (Observe normal precautions

when opening the cooling system.)

Is the Tech 2 engine coolant temperature indication

close to the measured temperature?

—

Go to

Step 9

Go to

Step 7

7

1. Ignition “OFF.”

2. Disconnect the PCM.

3. Using a DVM, measure the resistance of the ECT at

the PCM connector.

4. Compare the DVM reading with the chart in “Test

Description.”

Is the chart value approximately equal to the

thermometer reading?

—

Go to

Step 12

Go to

Step 8

8

Check for high resistance in wiring related to the ECT

sensor. Also, check for poor connections at the ECT

sensor and the PCM.

Was a problem found?

—

Go to

Step 10

Go to

Step 11

9

Refer to

Cooling and Radiator for cooling system

diagnosis and repair condition as necessary.

Is the action complete?

—

Verify repair

—

10

Replace the faulty terminal(s) or repair faulty wiring as

necessary.

Is the action complete?

—

Verify repair

—

11

Replace the ECT sensor.

Is the action complete?

—

Verify repair

—

12

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to

On-Vehicle Service in

Powertrain Control Module and Sensors for

procedures.

And also refer to latest service bulletin.

Check to see if the Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Verify repair

—

6E2–161

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

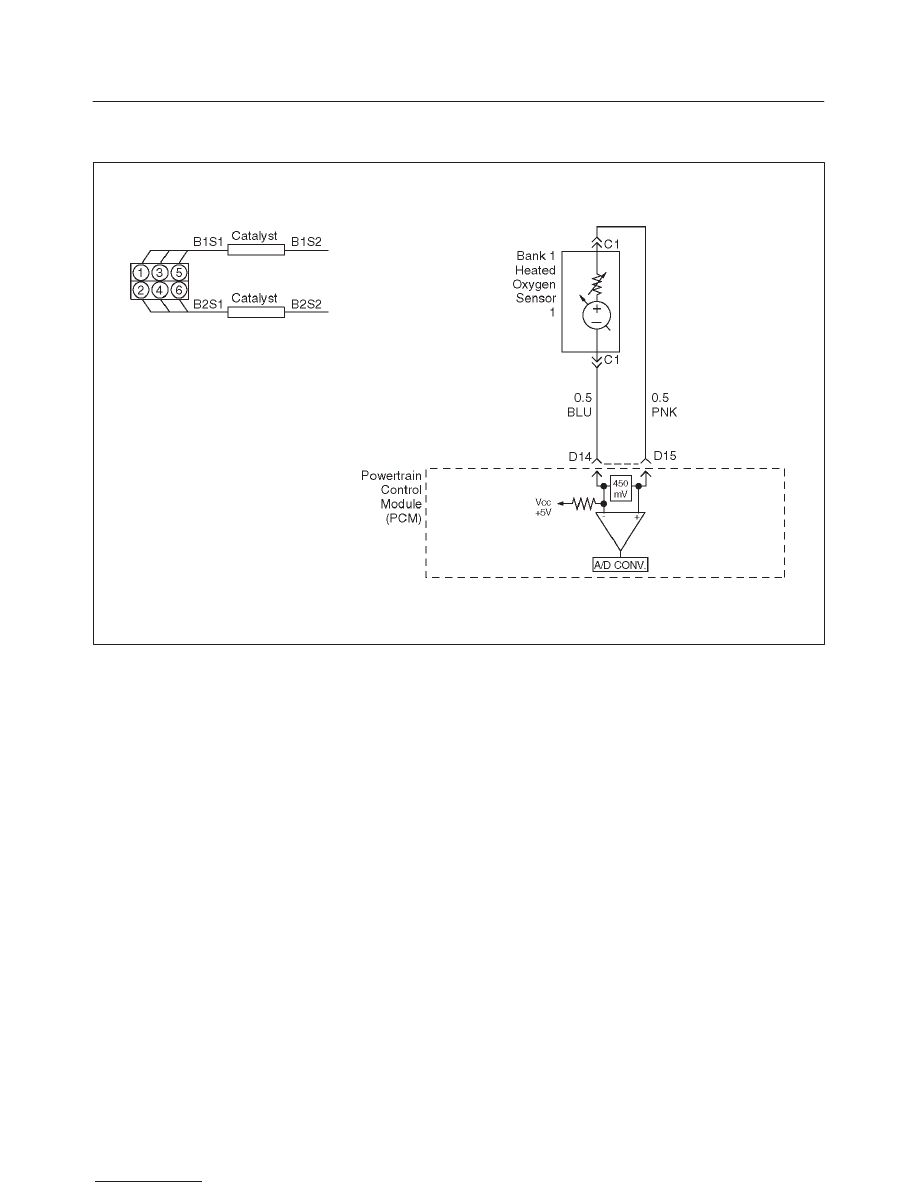

Diagnostic Trouble Code (DTC) P0131 HO2S Circuit Low Voltage Bank 1

Sensor 1

D06RW081

Circuit Description

The powertrain control module (PCM) supplies a bias

voltage of about 450 mV between the heated oxygen

sensor (HO2S) signal high and signal low circuits. When

measured with a 10 megaohm digital voltmeter, this may

display as low as 350 mV. The oxygen sensor varies the

voltage within a range of about 1000 mV when the

exhaust is rich, down through about 10 mV when exhaust

is lean. The PCM constantly monitors the HO2S signal

during “closed loop” operation and compensates for a rich

or lean condition by decreasing or increasing injector

pulse width as necessary. If the Bank 1 HO2S 1 voltage

remains excessively low for an extended period of time,

DTC P0131 will be set.

Conditions for Setting the DTC

f

No related DTCs.

f

Vehicle is operating in “closed loop.”

f

Engine coolant temperature is above 60

°

C (140

°

F)

f

“Closed loop” commanded air/fuel ratio is between

14.5 and 14.8.

f

Throttle angle is between 3% and 19%.

f

Bank 1 HO2S 1 signal voltage remains below 22 mV

during normal “closed loop” operation for a total of 77

seconds over a 90-second period of time.

Action Taken When the DTC Sets

f

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

f

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

f

“Open loop” fuel control will be in effect.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL “OFF” on the third

consecutive trip cycle during which the diagnostic has

been run and the fault condition is no longer present.

f

A history DTC P0131 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

f

DTC P0131 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

f

Heated oxygen sensor wiring – The sensor pigtail may

be routed incorrectly and contacting the exhaust

system.

f

Poor PCM to engine block grounds.

f

Fuel pressure – The system will go lean if pressure is

too low. The PCM can compensate for some

6E2–162

RODEO 6VD1 3.2L ENGINE DRIVEABILITY AND EMISSIONS

decrease. However, If fuel pressure is too low, a DTC

P0131 may be set. Refer to

Fuel System Diagnosis.

f

Lean injector(s) – Perform “Injector Balance Test.”

f

Vacuum leaks – Check for disconnected or damaged

vacuum hoses and for vacuum leaks at the intake

manifold, throttle body, EGR system, and PCV system.

f

Exhaust leaks – An exhaust leak may cause outside air

to be pulled into the exhaust gas stream past the

HO2S, causing the system to appear lean. Check for

exhaust leaks that may cause a false lean condition to

be indicated.

f

MAF sensor – The system can go lean if the MAF

sensor signal indicates an engine airflow

measurement that is not correct. Disconnect the MAF

sensor to see if the lean condition is corrected. If so,

replace the MAF sensor.

f

Fuel contamination – Water, even in small amounts,

can be delivered to the fuel injectors. The water can

cause a lean exhaust to be indicated. Excessive

alcohol in the fuel can also cause this condition. Refer

to

Fuel System Diagnosis for the procedure to check

for fuel contamination.

f

If none of the above conditions are present, replace the

affected HO2S.

Test Description

Number(s) below refer to step numbers on the diagnostic

chart.

3. DTC P0131 failing during operation may indicate a

condition described in the “Diagnostic Aids” above.

If the DTC P0131 test passes while the Failure

Records conditions are being duplicated, an

intermittent condition is indicated.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

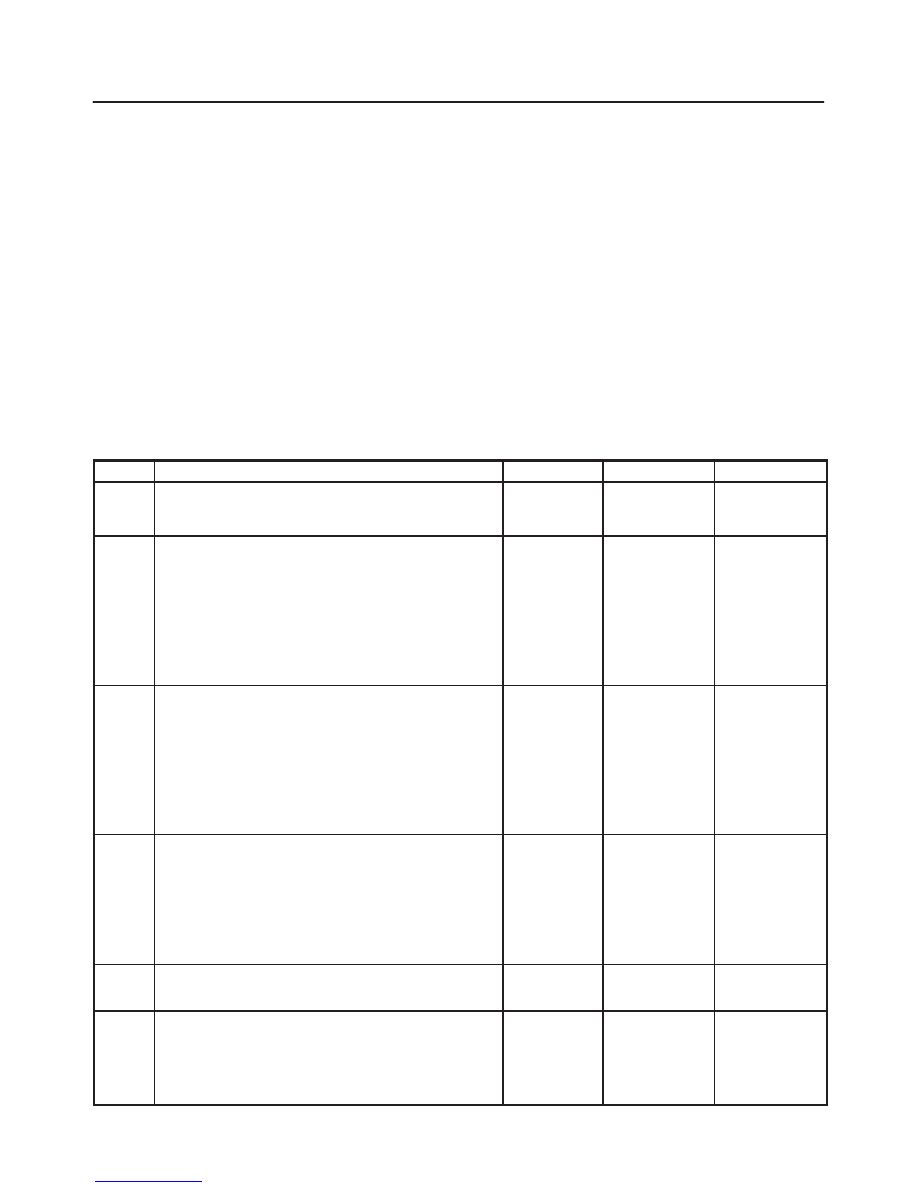

DTC P0131 –HO2S Circuit Low Voltage Bank 1 Sensor 1

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

1. Install the Tech 2.

2. Run the engine at operating temperature.

3. Operate the vehicle within the parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

4. Using a Tech 2, monitor Bank 1 HO2S 1 voltage.

Does the Bank 1 HO2S 1 voltage remain below the

specified value?

22 mV

Go to

Step 4

Go to

Step 3

3

1. Ignition “ON,” engine “OFF,” review and record Tech

2 Failure Records data and note parameters.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC” info for DTC P0131

until the DTC P0131 test runs.

Note test result.

Does Tech 2 indicate DTC P0131 failed this ignition?

—

Go to

Step 4

Refer to

Diagnostic

Aids

4

1. Turn the ignition “OFF.”

2. Disconnect the PCM.

3. Check the Bank 1 HO2S 1 high and low circuits for a

short to ground or a short to the heater ground

circuit.

Are the Bank 1 HO2S 1 signal circuits shorted to

ground?

—

Go to

Step 5

Go to

Step 6

5

Repair the Bank 1 HO2S 1 signal circuit.

Is the action complete?

—

Verify repair

—

6

1. Turn the ignition “OFF,” HO2S 1 and PCM

disconnected.

2. Check for continuity between the high and low

signal circuits.

Was there continuity between the high and low circuits?

—

Go to

Step 7

Go to

Step 8

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст