Isuzu Rodeo UE. Manual — part 192

6E1–139

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

f

Faulty Throttle Position sensor – With the ignition key

ON engine OFF observe the TP sensor display on the

Tech 2 while slowly depressing the accelerator to wide

open throttle. If a voltage over 4.88 volts is seen at any

point in normal accelerator travel, replace the TP

sensor.

If Diagnostic Trouble Code P0123 cannot be duplicated,

the information included in the Failure Records data can

be useful in determining vehicle mileage since the

Diagnostic Trouble Code was last set. If it is determined

that the Diagnostic Trouble Code occurs intermittently,

performing theDiagnostic Trouble Code P1121

Diagnostic Chart may isolate the cause of the fault.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

7. Components that share the TP sensor 5 volt

reference circuit include the following devices:

f

EGR valve

f

Fuel Tank Pressure sensor

f

MAP sensor

Disconnect the component while observing the

Throttle Position sensor display on the Tech 2. If

the reading changes drastically when this

component is disconnected, replace the

component that affected the reading.

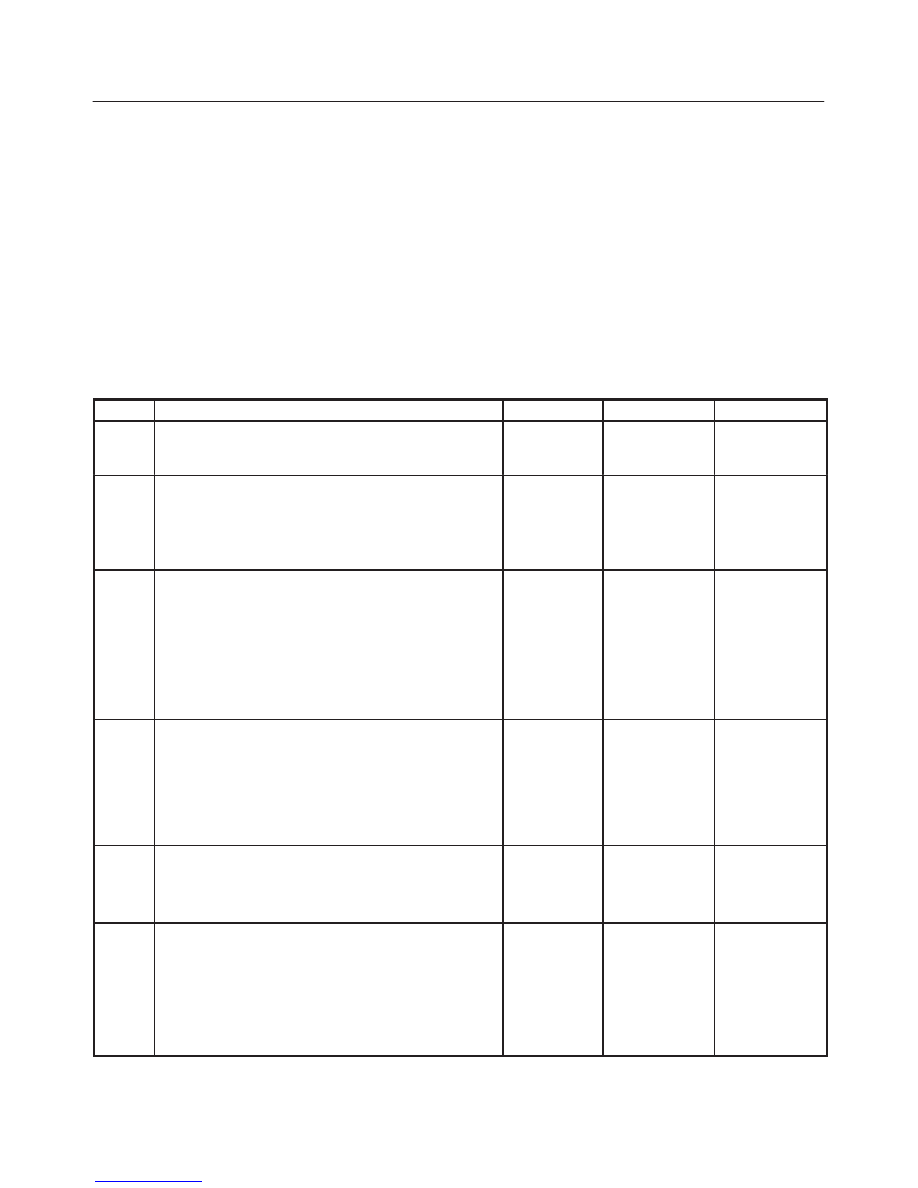

DTC P0123 – TP Sensor Circuit High Input

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

1. Ignition ON, engine OFF.

2. With the throttle closed, observe the ”Throttle

Position Sensor” display on the Tech 2.

Is the ”Throttle Position Sensor” above the specified

value?

4.78 V

Go to Step 4

Go to Step 3

3

1. Ignition ON, engine OFF.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “Diagnostic Trouble Code”

info for Diagnostic Trouble Code P0123.

Does the Tech 2 indicate Diagnostic Trouble Code

P0123 failed.

—

Go to Step 4

Refer to

Diagnostic

Aids

4

1. Disconnect the Throttle Position sensor electrical

connector.

2. Observe the ”Throttle Position Sensor” display on

the Tech 2.

Is the ”Throttle Position Sensor” near the specified

value? (if no, start with the diagnosis chart for other

sensors in the circuit and see if 5V returns.)

0 V

Go to Step 5

Go to Step 6

5

Probe the sensor ground circuit at the Throttle Position

sensor harness connector with a test light connected to

B+.

Is the test light ON?

—

Go to Step 7

Go to Step

10

6

1. Ignition OFF disconnect the PCM.

2. Ignition ON engine OFF.

3. Check for a short to voltage on the TP sensor signal

circuit.

4. If the TP sensor signal circuit is shorted, repair it as

necessary.

Was the TP sensor signal circuit shorted?

—

Verify repair

Go to Step

12

6E1–140

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

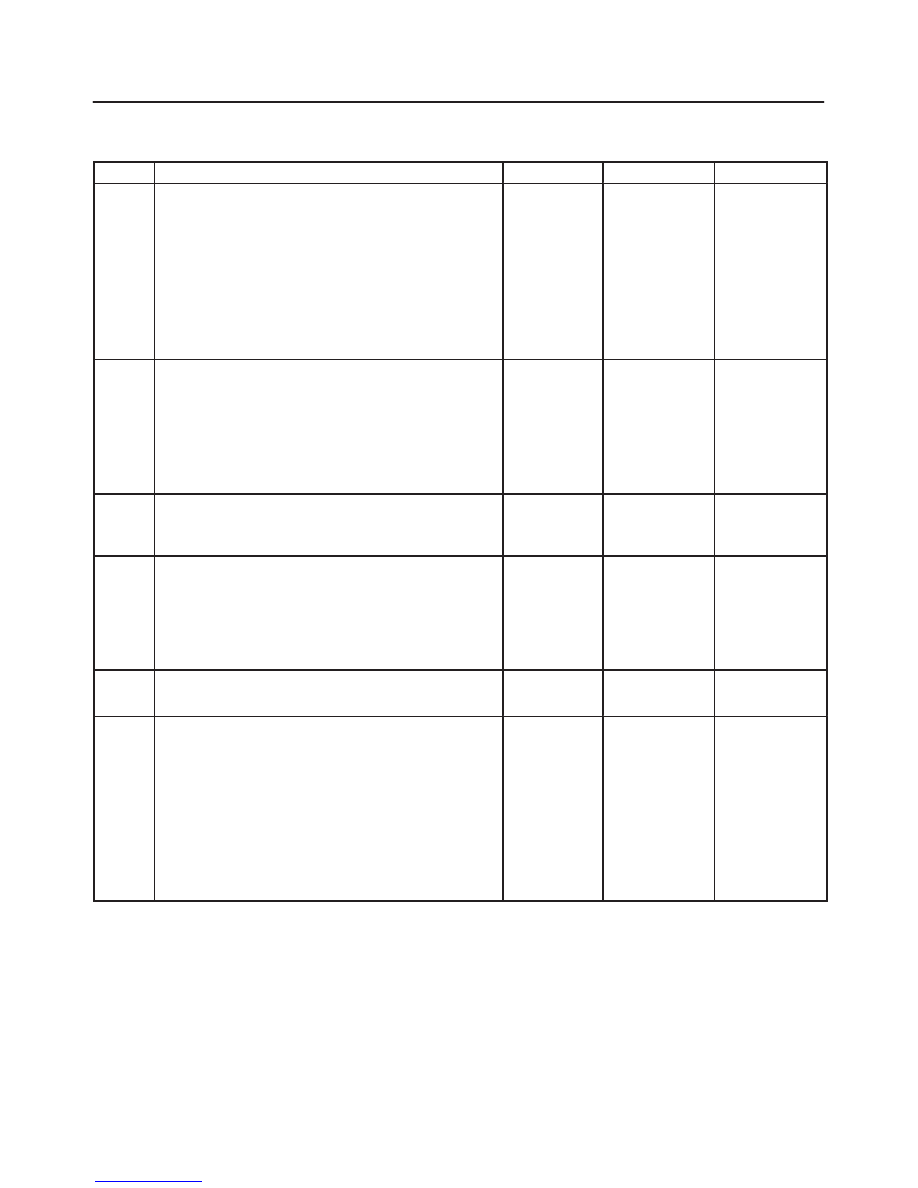

DTC P0123 – TP Sensor Circuit High Input

(Cont'd)

Step

No

Yes

Value(s)

Action

7

1. Ignition ON.

2. Monitor the ”Throttle Position Sensor” Tech 2

display while disconnecting each of the

components that share the 5 volt reference circuit

(one at a time).

3. If the ”Throttle Position Sensor” Tech 2 display

changes, service the component(s) that caused the

display to change when disconnected.

Does disconnecting any of these components cause

the ”Throttle Position Sensor” display to change?

—

Verify repair

Go to Step 8

8

1. Ignition OFF disconnect the PCM.

2. Ignition ON, engine OFF.

3. Check for a short to B+ on the 5 volt reference

circuit.

4. If the 5 volt reference circuit is shorted, repair it as

necessary.

Was the 5 volt reference circuit shorted?

—

Verify repair

Go to Step 9

9

Check for poor electrical connections at the Throttle

Position sensor and replace terminals if necessary.

Did any terminals require replacement?

—

Verify repair

Go to Step

11

10

1. Ignition OFF.

2. Disconnect the PCM, and check for an open sensor

ground circuit to the Throttle Position sensor.

3. If a problem is found, repair it as necessary.

Was the sensor ground circuit to the Throttle Position

sensor open?

—

Verify repair

Go to Step

12

11

Replace the Throttle Position sensor.

Is the action complete?

—

Verify repair

—

12

Replace the PCM.

IMPORTANT: The replacement PCM must be

programmed. Refer to On–Vehicle Service in

Powertrain Control Module and Sensors for

procedures.

And also refer to latest Service Bulletin.

Check to see if the Latest software is released or not.

And then Down Load the LATEST PROGRAMMED

SOFTWARE to the replacement PCM.

Is the action complete?

—

Verify repair

—

6E1–141

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

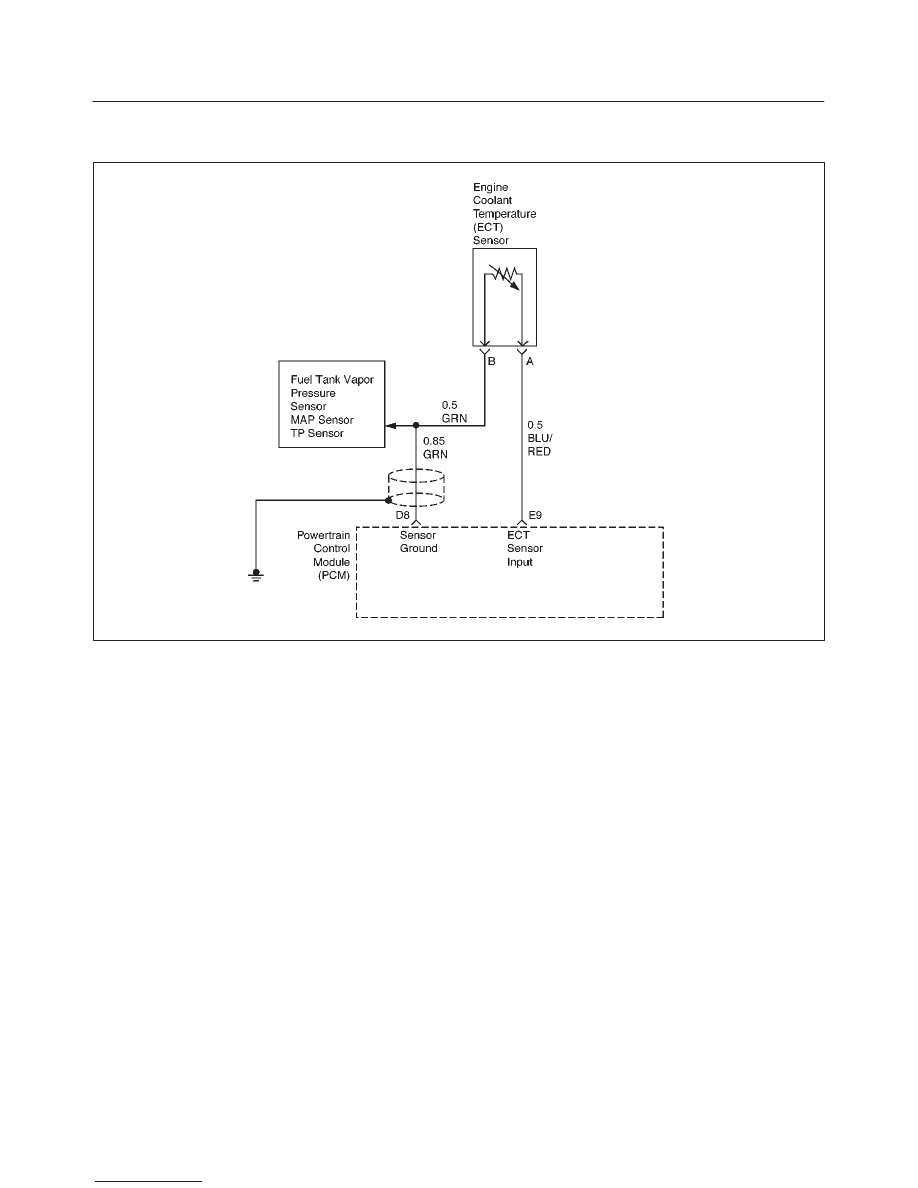

DIAGNOSTIC TROUBLE CODE (DTC) P0125 INSUFFICIENT COOLANT TEM-

PERATURE FOR CLOSED LOOP FUEL CONTROL

D06RX044

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a ”Closed Loop”

air/fuel metering system is used. When the vehicle is first

started, the powertrain control module (PCM) controls

fuel delivery in ”Open Loop” ignoring the heated oxygen

sensor (HO2S) signals and calculating air/fuel ratio based

on inputs from the engine coolant temperature, throttle

position, and mass air flow sensors.

If the PCM detects that the ECT sensor has not reached a

sufficient reading to achieve ”Closed Loop” within a

specified amount of time, DTC P0125 will set. DTC

P0125 is a type B code.

Conditions for Setting the DTC

f

No MAP, IAT, ECT, TP, Misfire, Injector, or VSS DTC

codes set.

All the above mentioned conditions are true and any

combination of the following three tests fail three times in

two consecutive ignition cycles (for a total of six failures):

Warm Case Test

f

Start–up ECT value is less than 29

°

C (84

°

F).

f

IAT is greater than 10

°

C (50

°

F).

f

Accumulated airflow is greater than 1500 grams.

f

Engine run time is greater than 90 seconds.

f

Time for coolant to reach stabilized ”Closed Loop”

value is less than 120 seconds.

Cold Case Test

f

IAT is between –7

°

C (20

°

F) and 10

°

C (50

°

F)

f

Accumulated airflow is greater than 2000 grams.

f

Engine run time is less than 225 seconds.

f

Time for coolant to reach stabilized ”Closed Loop”

value is less than 300 seconds.

Other Case Test

f

IAT is between –30

°

C (–22

°

F) and –7

°

C (20

°

F).

f

Accumulated airflow is greater than 3600 grams.

f

Engine run time is less than 450 seconds.

f

Time for coolant to reach stabilized ”Closed Loop”

value is less than 600 seconds.

Action Taken When the DTC Sets

f

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

f

The PCM will store conditions which were present

when the Diagnostic Trouble Code was set as Freeze

Frame and in the Failure Records data.

Conditions for Clearing the MIL/DTC

f

The PCM will turn the MIL OFF on the third consecutive

trip cycle during which the diagnostic has been run and

the fault condition is no longer present.

6E1–142

RODEO X22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

f

A history Diagnostic Trouble Code P0125 will clear

after 40 consecutive warm–up cycles have occurred

without a fault.

f

Diagnostic Trouble Code P0125 can be cleared by

using the Scan Tool’s ”Clear Info” function.

Diagnostic Aids

DTC P0125 set indicates a faulty ECT sensor. Comparing

the engine coolant temperature displayed on a Tech 2

with actual coolant temperature measured with a

thermometer may isolate this condition. If the displayed

engine coolant temperature is not close to the actual

coolant temperature, replace the ECT sensor.

Check for the following conditions:

f

Poor connection at PCM – Inspect harness connectors

for back–out terminals, improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal–to–wire connection.

f

Damaged Harness – Inspect the wiring harness for

damage; open circuits, shorts to ground, or shorts to

voltage. If the harness appears to be OK, observe the

display on the Tech 2 while moving connectors and

wiring harnesses related to the sensor. A change in the

display will indicate the location of the fault.

If DTC P0125 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

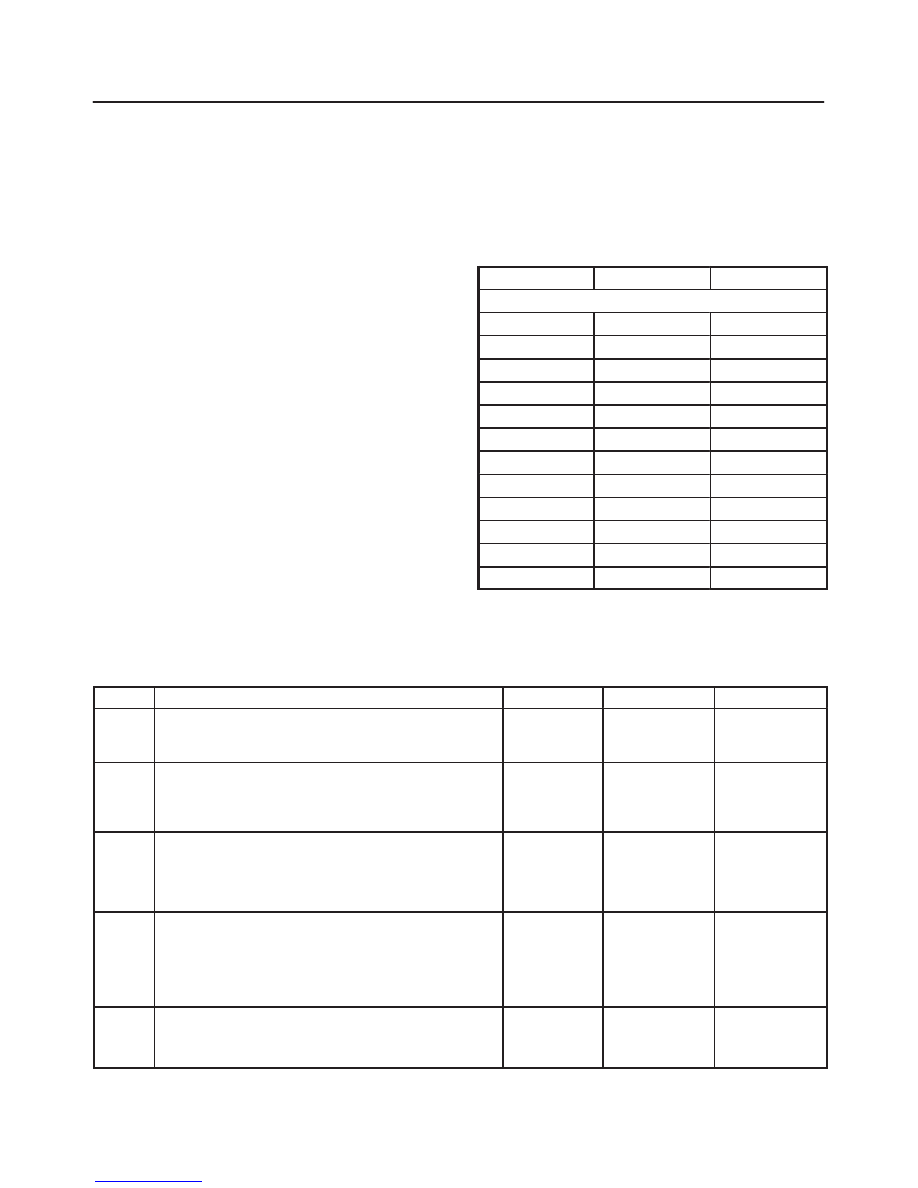

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Comparing the engine coolant temperature

displayed on a Tech 2 with actual coolant

temperature measured with a thermometer may

isolate this condition. If the displayed engine coolant

temperature is not close to the actual coolant

temperature, replace the ECT sensor. If the

temperatures are closed, the fault is intermittent;

refer to Diagnostic Aids.

7. Engine Coolant Temperature

°

C

°

F

OHMS

Temperature vs. Resistance Values (approximate)

100

212

177

80

176

332

60

140

667

45

113

1188

35

95

1802

25

77

2796

15

59

4450

5

41

7280

–5

23

12300

–15

5

21450

–30

–22

52700

–40

–40

100700

DTC P0125 Insufficient Coolant Temperature for Closed Loop Fuel Control

Step

Action

Value(s)

Yes

No

1

Was the ”On–Board Diagnostic (OBD) System Check”

performed?

—

Go to Step 2

Go to OBD

System

Check

2

Are any ECT sensor DTC’s set?

—

Go to

applicable

ECT sensor

DTC chart

Go to Step 3

3

1. Allow the engine to cool completely.

2. Check the cooling system coolant level (refer to

Cooling and Radiator).

Is the coolant level OK?

—

Go to Step 4

Go to Step 9

4

1. Start the engine.

2. With the engine idling, monitor ”ENG COOL TEMP”

display on the Tech 2.

Does ”ENG COOL TEMP” increase to above the

specified value within 2 minutes?

21

°

C (70

°

F)

Refer to

Diagnsotic

Aids

Go to Step 5

5

Check for proper operation of the thermostat (refer to

Cooling and Radiator).

Is the thermostat operating correctly?

—

Go to Step 6

Go to Step 9

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст