Isuzu KB P190. Manual — part 815

Engine Management – V6 – General Information

Page 6C1-1–18

3.12 Immobiliser

System

The vehicle incorporates an immobiliser system. After the ignition switch is turned to the ON position, and the powertrain

interface module (PIM) has authenticated the immobiliser control unit (ICU), the PIM sends an encrypted security code to

the engine control module (ECM). The ECM compares the received security code with its own security code, and if it is

valid, the ECM enables the vehicle to be started. For further information and diagnosis of the immobiliser system, refer to

11A Immobiliser.

For further information on the PIM, refer to 6E1 Powertrain Interface Module – V6.

Engine Management – V6 – General Information

Page 6C1-1–19

4

Component Description and

Operation

4.1

A/C Refrigerant Pressure Sensor

The engine control module (ECM) applies a positive 5 V reference voltage and ground to the air-conditioner (A/C)

refrigerant pressure sensor. The A/C refrigerant pressure sensor provides signal voltage to the ECM that is proportional

to the A/C refrigerant pressure. The ECM monitors the A/C refrigerant pressure sensor signal voltage to determine the

refrigerant pressure.

•

The A/C refrigerant pressure sensor voltage increases as the refrigerant pressure increases.

•

When the ECM detects the refrigerant pressure exceeds a predetermined value, the ECM activates the cooling

fans to reduce the refrigerant pressure.

•

When the ECM detects the refrigerant pressure is too high or too low, the ECM disables the A/C clutch to protect

the A/C compressor from damage.

4.2

Brake Pedal Switch Assembly

Stop Lamp and Initial Brake Apply Switch

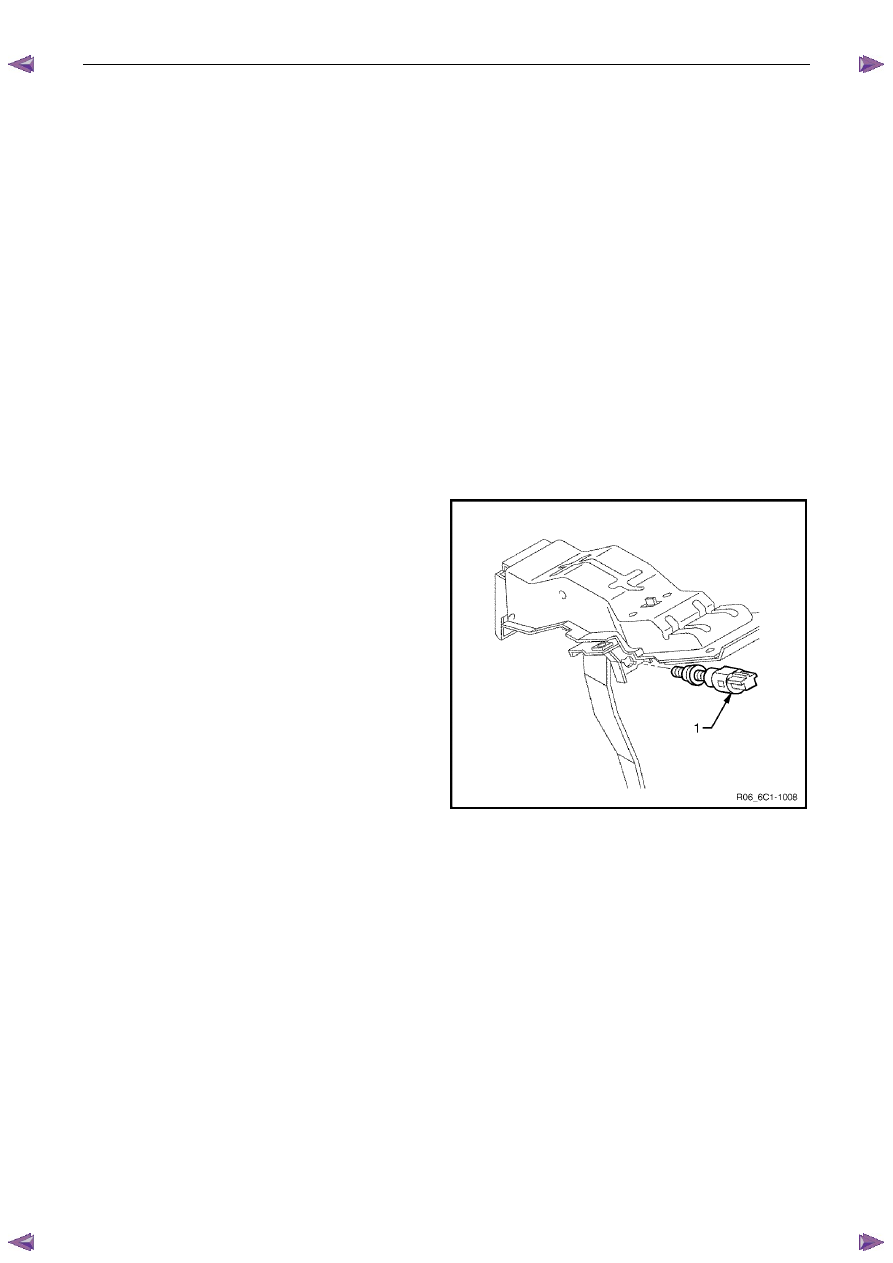

The stop lamp and initial brake apply switch assembly (1) is

located on the brake pedal support.

The engine control module (ECM) uses the brake pedal

switch inputs to determine when the brake pedal is

depressed.

The ECM uses the two break pedal switch inputs for:-

•

Enabling cruise control,

•

Brake torque management,

•

Cross referencing the stop lamp switch against the

initial brake apply switch for correct operation.

For further information on brake torque management,

refer to 3.7

Brake Torque

Management.

For further information on the cruise control system, refer to

3.6

Cruise Control System.

Figure 6C1-1 – 13

Stop Lamp Switch

The stop lamp switch contacts are normally open with the brake pedal at rest and closed when the brake pedal is

depressed.

Initial Brake Apply Switch

The initial brake apply switch contacts are normally closed with the brake pedal at rest and open when the brake pedal is

depressed.

Engine Management – V6 – General Information

Page 6C1-1–20

4.3

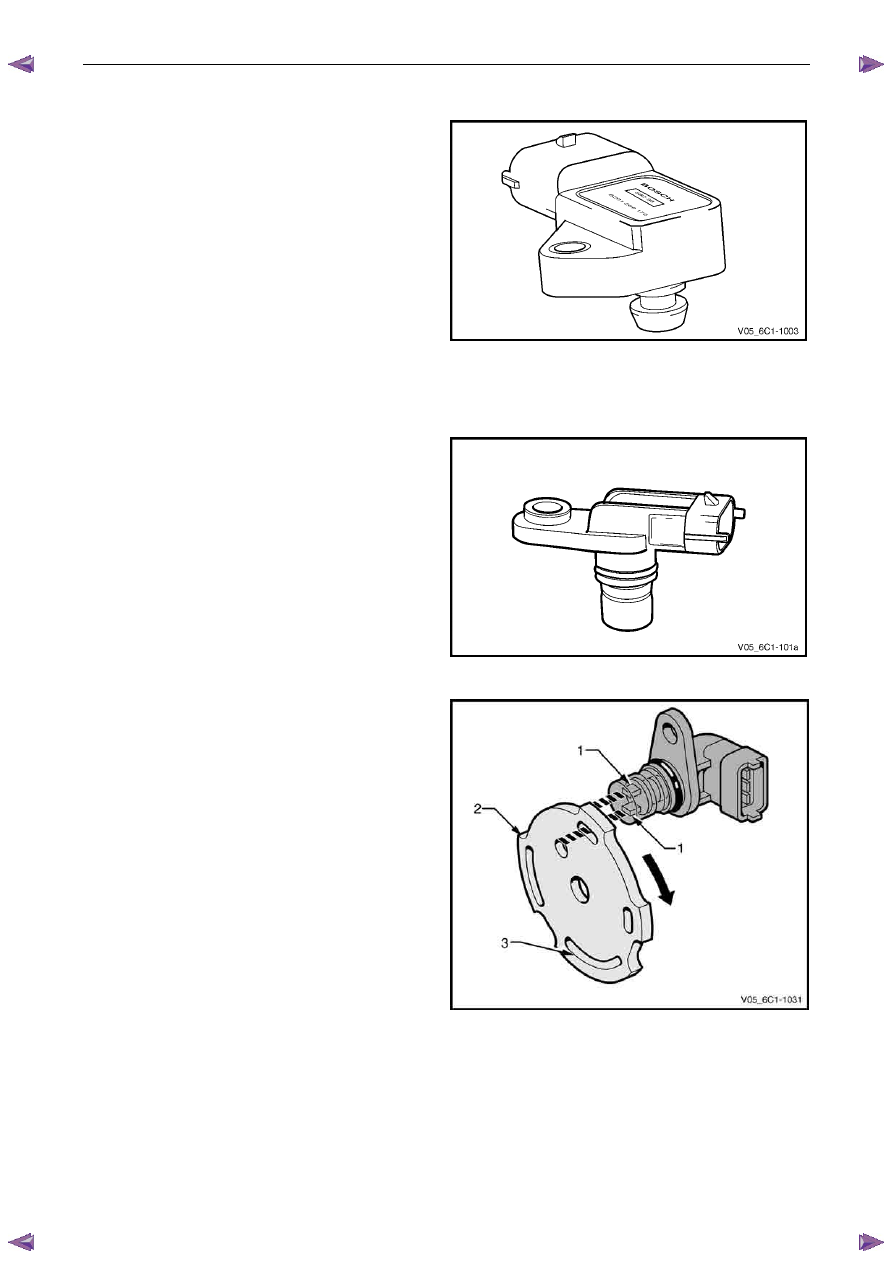

Barometric Pressure Sensor

The barometric pressure (BARO) sensor measures

barometric (atmospheric) pressure. The ECM uses this

signal to make corrections to the operating parameters of

the system based on changes in air density, since the

oxygen content of atmospheric air varies proportionally to air

density (barometric / atmospheric pressure). Barometric

pressure is affected mainly by altitude and climate.

The BARO sensor provides a voltage signal to the ECM that

is a function of barometric pressure. It does this through a

series of deformation resistors, which change resistance

when a mechanical force is applied. This force is applied to

the resistors by a diaphragm on which the atmospheric

pressure acts.

The ECM supplies the BARO sensor with a 5 V reference

and a ground circuit.

Figure 6C1-1 – 14

4.4

Camshaft Position Sensor

The HFV6 engine is fitted with an inlet camshaft position

(CMP) sensor.

The CMP sensor is used by the ECM to determine the

position of the camshafts. In conjunction with the crankshaft

position sensor, the CMP enables the ECM to determine

engine rotational position.

Figure 6C1-1 – 15

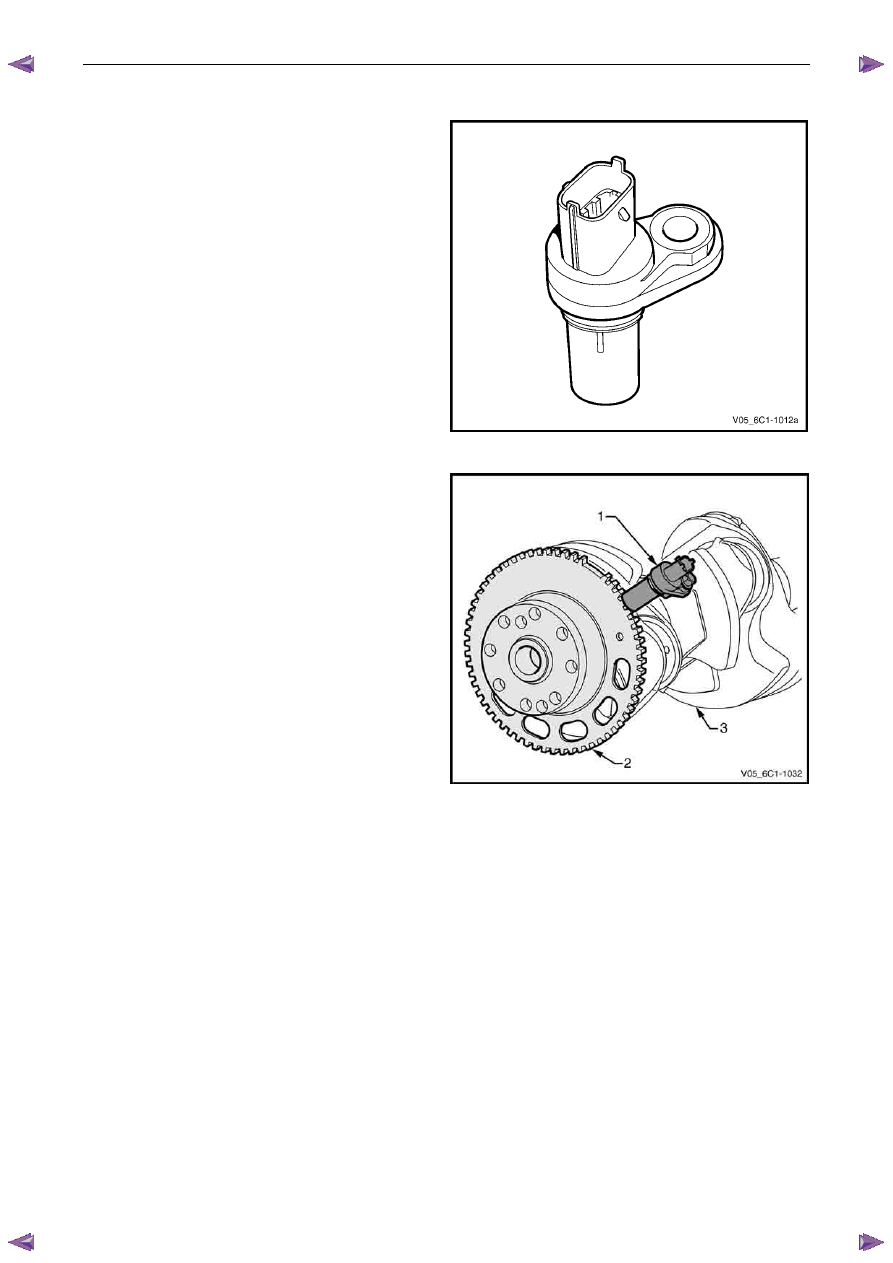

The CMP sensor operates on the dual-Hall sensing

principle. The sensor contains two hall elements (1) which

operate in conjunction with a two-track trigger wheel (2)

mounted on the camshaft.

As the tracks (3) on the trigger wheel pass the elements,

magnetic flux affects a voltage in the Hall elements. The

integrated circuit inside the sensor conditions the signal

generated by the Hall elements to provide a rectangular

wave on / off signal to the ECM.

The ECM supplies the CMP sensors with a 5 V reference

and ground circuit.

Figure 6C1-1 – 16

Engine Management – V6 – General Information

Page 6C1-1–21

4.5

Crankshaft Position Sensor

In conjunction with the camshaft position sensor, the

crankshaft position (CKP) sensor enables the ECM to

determine engine rotational position. The CKP is also used

to determine engine speed (rpm).

Figure 6C1-1 – 17

The CKP sensor (1) operates on the variable reluctance

(pulse generator) sensing principle. It contains a magnet

and pickup coil and is used in conjunction with a 58 tooth

ferromagnetic reluctor wheel (2) attached to the

crankshaft (3).

As the crankshaft rotates, the reluctor wheel revolves past

the CKP, causing fluctuations in the magnetic field inside

the sensor. This action creates an AC voltage across the

pickup coil which is processed by the ECM. An increase in

engine speed will increase the output voltage and

frequency.

The reluctor wheel teeth are placed six degrees apart.

Having only 58 teeth leaves a 12 degree open span, which

creates a signature pattern that enables the ECM to

determine the crankshaft position. The ECM determines

which two cylinders are approaching the top dead centre

based on the crankshaft position sensor signal. The CMP

sensor signals are used by the ECM to determine which

cylinder is on the firing stroke.

Figure 6C1-1 – 18

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст