Isuzu KB P190. Manual — part 765

Engine Mechanical – V6

Page 6A1–283

Page 6A1–283

Crankshaft Bearing

1

Prepare a piece of cardboard or similar, numbered 1

– 4 for bearing identification.

N O T E

Main bearing journals are numbered from the

front of the engine.

2

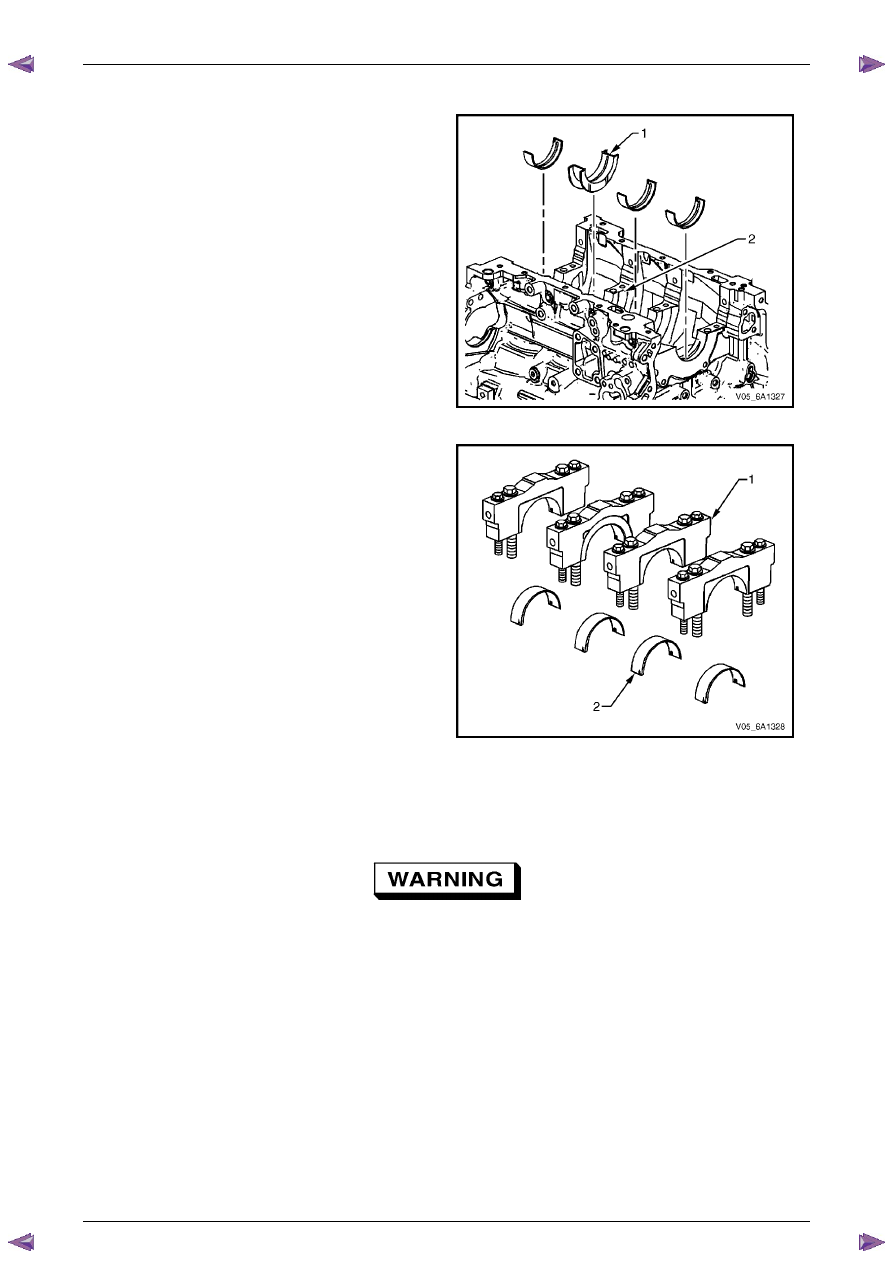

Remove the crankshaft upper bearing halves from the

cylinder block. Note the position of the thrust

bearing (1) at the number 3 journal (2).

3

Place the crankshaft upper bearing halves on the

cardboard in the correct positions.

Figure 6A1 – 504

4

Remove the crankshaft lower bearing halves (2) from

the crankshaft bearing caps (1).

5

Place the crankshaft lower bearing halves in the

correct positions on the cardboard.

Figure 6A1 – 505

Clean and Inspect

Crankshaft and Main Bearing Cleaning

Safety glasses must be worn when using

compressed air.

Clean the following components in solvent and then dry with compressed air:

•

crankshaft bearings,

•

connecting rod bearings,

•

crankshaft journals,

•

crankpin journals,

•

crankshaft oil passages, and

•

crankshaft threaded holes.

Engine Mechanical – V6

Page 6A1–284

Page 6A1–284

Crankshaft and Main Bearing Visual Inspection

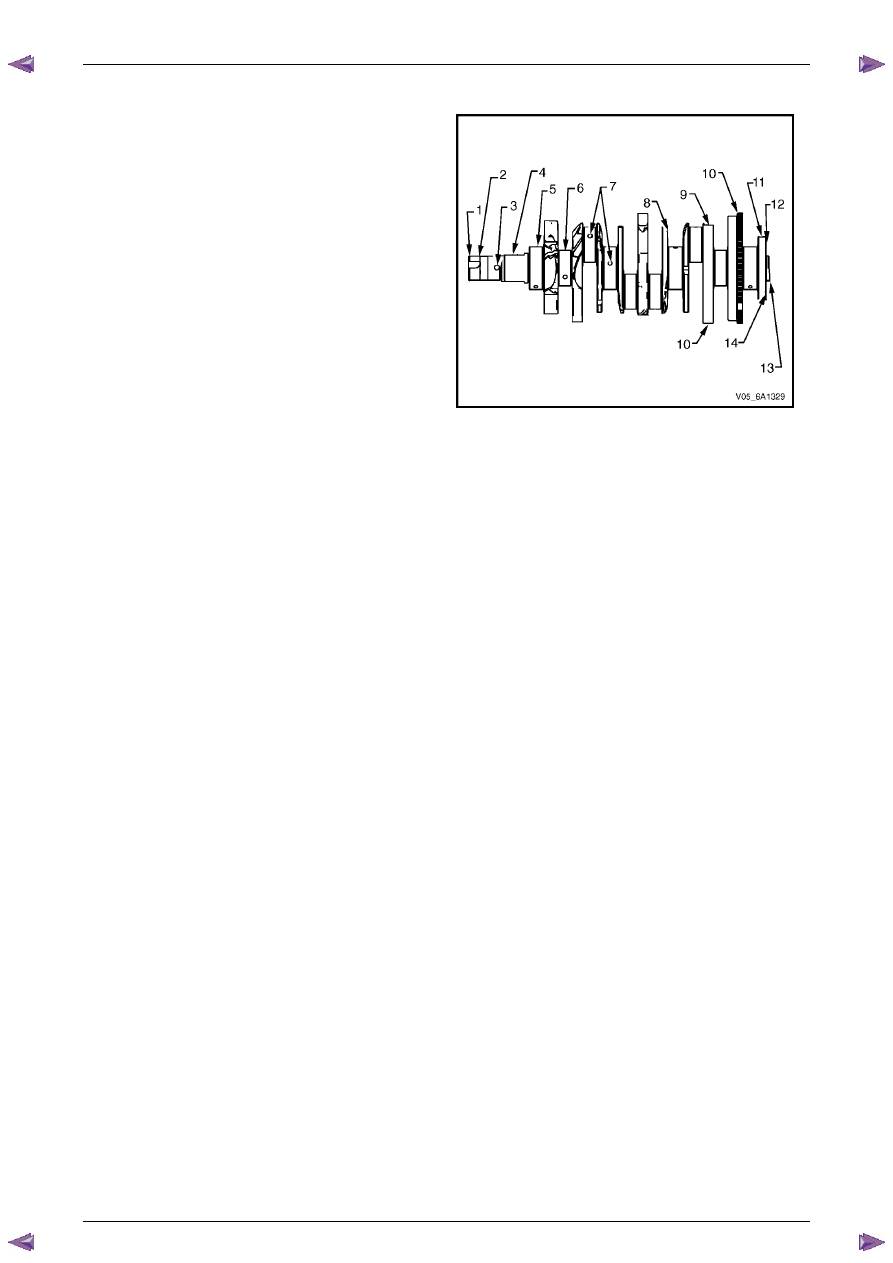

1

Perform the following visual inspections:

•

Inspect the crankshaft balancer bolt hole (1) for

thread damage.

•

Inspect the crankshaft balancer mounting

area (2) for damage.

•

Inspect the crankshaft sprocket pin hole (3) for

damage.

•

Inspect the oil pump drive flats (4) for damage.

•

Inspect the crankshaft main journals (5) for

damage.

•

Inspect the crankshaft connecting rod

journals (6) for damage.

•

Inspect the crankshaft oil passages (7) for

obstructions.

•

Inspect the crankshaft main bearing thrust wall

surfaces (8) for damage.

•

Inspect the crankshaft counterweights (9) for

damage.

•

Inspect the crankshaft reluctor ring teeth (10) for

damage.

•

Inspect the crankshaft rear main oil seal surface

(11) for damage.

•

Inspect the crankshaft engine flexplate

mounting surface (12) for damage.

•

Inspect the crankshaft pilot hole (13) for

damage.

•

Inspect the crankshaft engine flywheel bolt

holes (14) for thread damage.

2

Repair or replace the crankshaft as required.

Figure 6A1 – 506

Engine Mechanical – V6

Page 6A1–285

Page 6A1–285

Crankshaft Main Bearing Inspection

CAUTION

All connecting rod and main journal bearings

that have been used in a running engine must

be replaced. Never re-use the crankshaft or

connecting rod bearings.

N O T E

The following bearing wear conditions should be

used to diagnose engine operating conditions or

root cause of a condition.

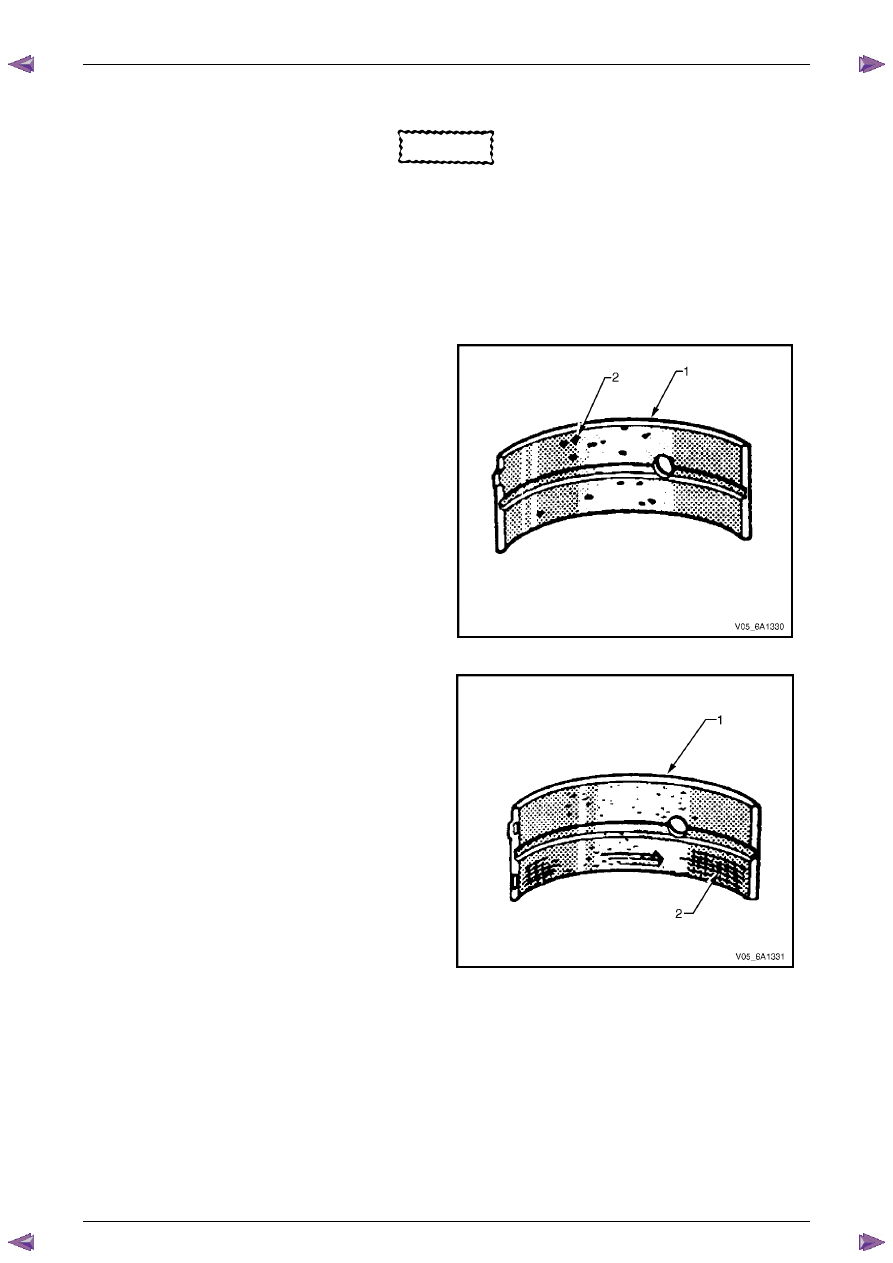

1

Inspect for fatigue indicated by craters or pockets (2).

Flattened sections on the bearing halves (1) also

indicate fatigue.

Figure 6A1 – 507

2

Inspect for excessive scoring or discoloration (2) on

both front and back of the bearing halves (1).

3

Inspect the main bearings for dirt embedded into the

bearing material.

Figure 6A1 – 508

Engine Mechanical – V6

Page 6A1–286

Page 6A1–286

4

Inspect for incorrect seating indicated by bright,

polished sections (1).

Figure 6A1 – 509

Crankshaft Measurement

1

Using a suitable fixture (1), support the crankshaft (2).

Figure 6A1 – 510

2

Using a dial indicator (1) and magnetic base (2),

rotate the crankshaft (3) carefully by hand. Measure

the crankshaft main journals for runout and compare

with the engine specifications, refer to

5 Specifications

.

Figure 6A1 – 511

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст