Isuzu KB P190. Manual — part 207

ENGINE MECHANICAL 6A – 23

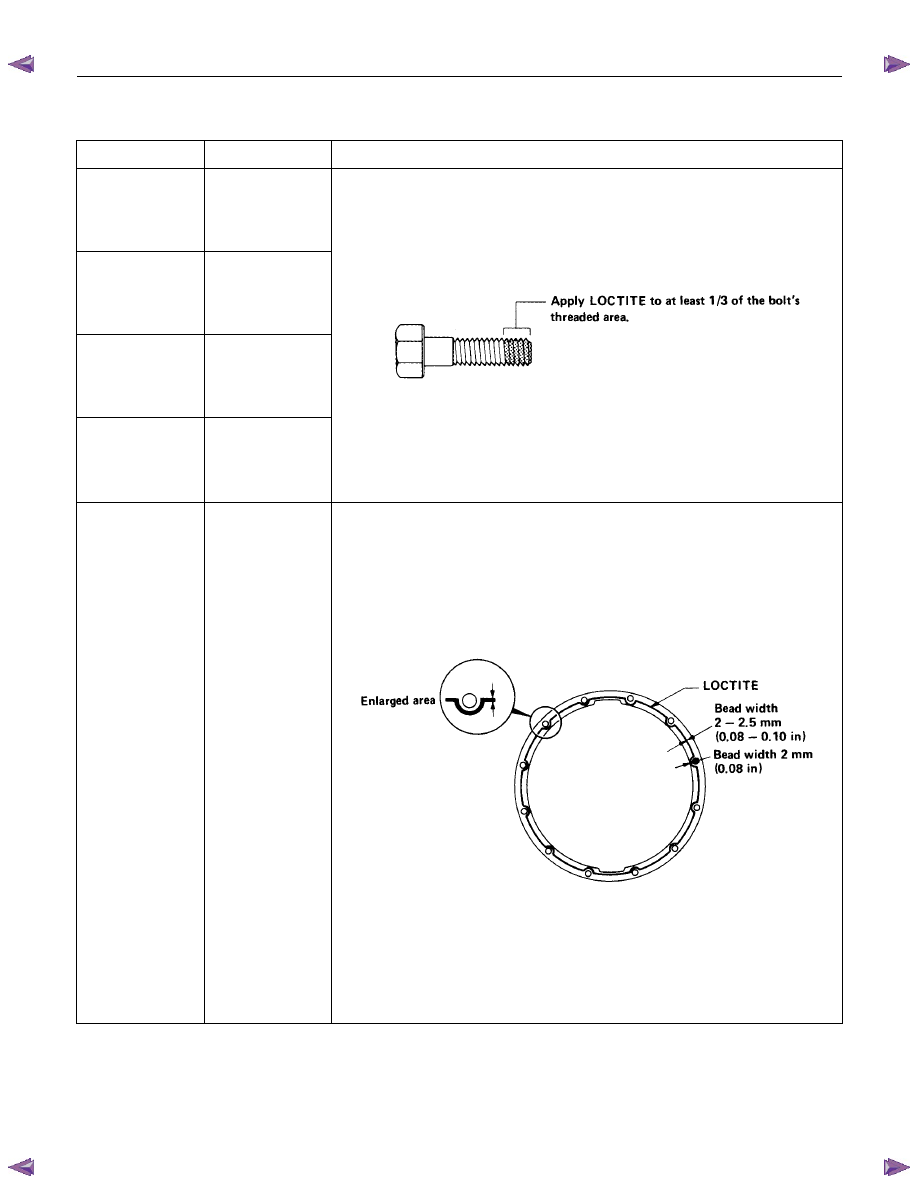

LOCTITE APPLICATION PROCEDURE

LOCTITE Type

LOCTITE Color

Application Steps

LOCTITE 242

Blue

LOCTITE 262

Red

LOCTITE 270

Green

LOCTITE 271

Red

1.

Completely remove all lubricant and moisture from the bolts and the

female threaded surfaces of the parts to be joined.

The surfaces must be perfectly dry.

2.

Apply LOCTITE to the bolts.

3.

Tighten the bolts to the specified torque.

4.

Wait at least one hour before continuing the installation procedure.

LOCTITE 515

Violet

1.

Completely remove lubricant and moisture from the connecting

surfaces.

The surfaces must be perfectly dry.

2.

Apply a 2.0 – 2.5 mm bead of LOCTITE to one of the connecting

surfaces.

There must be no gaps in the bead.

3.

Tighten the bolts to the specified torque.

4.

Let the joined parts set for at least thirty minutes.

6A – 24 ENGINE MECHANICAL

SERVICING

Servicing refers to general maintenance procedures to be performed by qualified service personnel.

RTW36ASH000401

MODEL IDENTIFICATION

Engine Serial Number

The engine number is stamped on the rear left hand side

of the cylinder body.

The engine number is stamped in the plate in front of the

engine room as well.

AIR CLEANER

Element cleaning procedures will vary according to the

condition of the element.

Dust Fouled Element (Except wet type element)

Rotate the element with your hand while applying

compressed air to the inside of the element. This will blow

the dust free.

Compressed air pressure kPa (kg/cm

2

/psi)

392 – 490 (4 – 5/57 – 71)

LUBRICATING SYSTEM

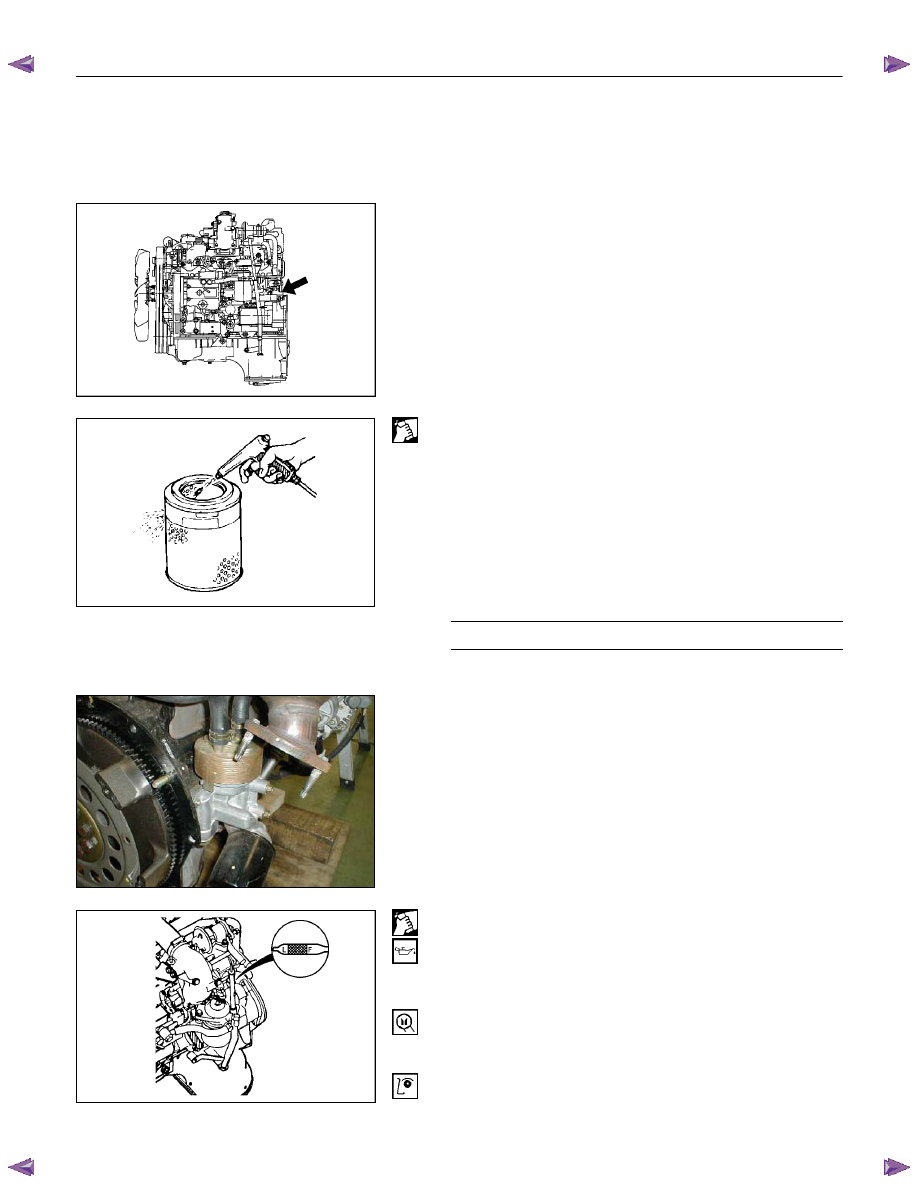

Main Oil Filter (Cartridge Type Paper Element)

Replacement Procedure

1. Drain the engine oil.

2. Retighten the drain plug.

3. Loosen the used oil filter by turning it counterclockwise

with a filter wrench.

Filter Wrench: 5-8840-0200-0

RTW36ASH000101

4. Clean the oil cooler fitting face. This will allow the new

oil filter to seat properly.

5. Apply a light coat of engine oil to the filter O-ring.

6. Turn in the new oil filter until the filter O-ring is fitted

against the sealing face.

7. Use the filter wrench to turn in the filter an additional

2/3 turns.

Filter Wrench: 5-8840-0200-0

8. Check the engine oil level and replenish to the

specified level if required.

130RY00003

6A-6

ENGINE MECHANICAL 6A – 25

Replenished Engine Oil

MAX lit (US/UK gal)

Condition

Model

Engine Dry

With oil filter

replacement

Without oil

filter

replacement

4

× 2

4

× 4

(4JA1L/TC)

6.2 (1.64/1.36)

5.2

∼ 4.2

(1.37

∼ 1.11

/ 1.14

∼ 0.92)

4.5

∼ 3.5

(1.19

∼ 0.93

/ 0.99

∼ 0.77)

4

× 2

(4JH1TC)

6.2 (1.64/1.36)

5.2

∼ 4.2

(1.37

∼ 1.11

/ 1.14

∼ 0.92)

4.5

∼ 3.5

(1.19

∼ 0.93

/ 0.99

∼ 0.77)

4

× 4

(4JH1TC)

7.0 (1.85/1.54)

6.2

∼ 5.2

(1.64

∼ 1.37

/ 1.36

∼ 1.14)

5.3

∼ 4.3

(1.72

∼ 1.14

/ 1.17

∼ 0.95)

9. Start the engine and check for oil leakage from the

main oil filter.

RTW66ASH003201

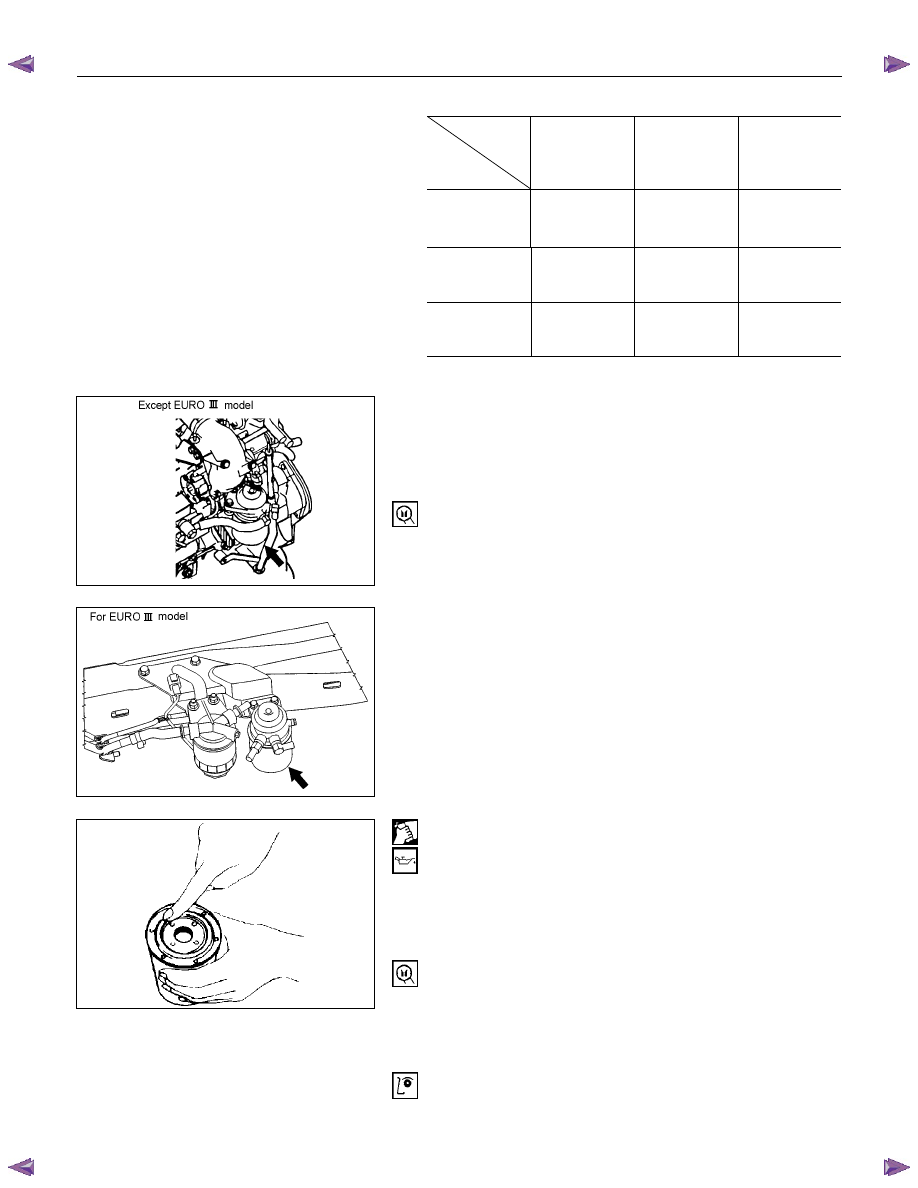

FUEL SYSTEM

Fuel Filter Replacement Procedure

1. Remove the fuel filter by turning it counterclockwise

with a filter wrench.

Filter Wrench: 5-8840-0253-0 (J-22700)

Note:

Be careful not to spill the fuel in the filter cartridge.

RTW66ASH003301

2. Clean the fuel filter cartridge fitting faces.

This will allow the new fuel filter to seat properly

3. Apply a light coat of engine oil to the O-ring.

4. Turn in the fuel filter until the sealing face comes in

contact with the O-ring.

5. Turn in the fuel filter an additional 2/3 of a turn with a

filter wrench.

Filter Wrench : 5-8840-0253-0 (J-22700)

6. Operate the priming pump until the air discharged

completely from fuel system.

7. Start the engine and check for fuel leakage.

Note:

The use of an ISUZU genuine fuel filter is strongly

recommended.

041RY00009

6A – 26 ENGINE MECHANICAL

041RY00011

Draining Procedure

The indicator light will come on when the water level in the

water separator exceeds the specified level.

Drain the water and foreign material from the water

separator (inside chassis frame) with the following

procedure.

1. Place the drain pan under the drain plug.

2. Loosen the drain plug and drain water.

3. After draining the water, tighten the drain plug.

4. Operate the priming pump on the fuel filter several

times and check for fuel leakage.

5. Check the water separator indicator light. It should be

off.

Except EURO III model

RTW46ASH002901

For EURO III model

RTW46ASH000501

Air Bleeding

1. Operate the priming pump until strong resistance is

felt.

2. Wait 1 minute, and operate the priming pump until

strong resistance is felt.

3. Once more wait, and operate the priming pump until

strong resistance is felt.

4. Turn the ignition switch to the "ON" position. Wait until

the glow indicator lamp turns off.

5. Turn the ignition switch to the "START" position and

crank the engine until it starts.

6. If the engine does not start, repeat Step 3 - 5.

7. Allow the engine to idle for 3 minutes to bleed air

completely form the fuel system and check for fuel

leakage.

Note:

Insufficient air bleeding may cause the Diagnostic

Trouble Code (DTC) store or improper engine

performance.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст