Isuzu KB P190. Manual — part 638

Engine Mechanical – V6

Page 6A1–73

7

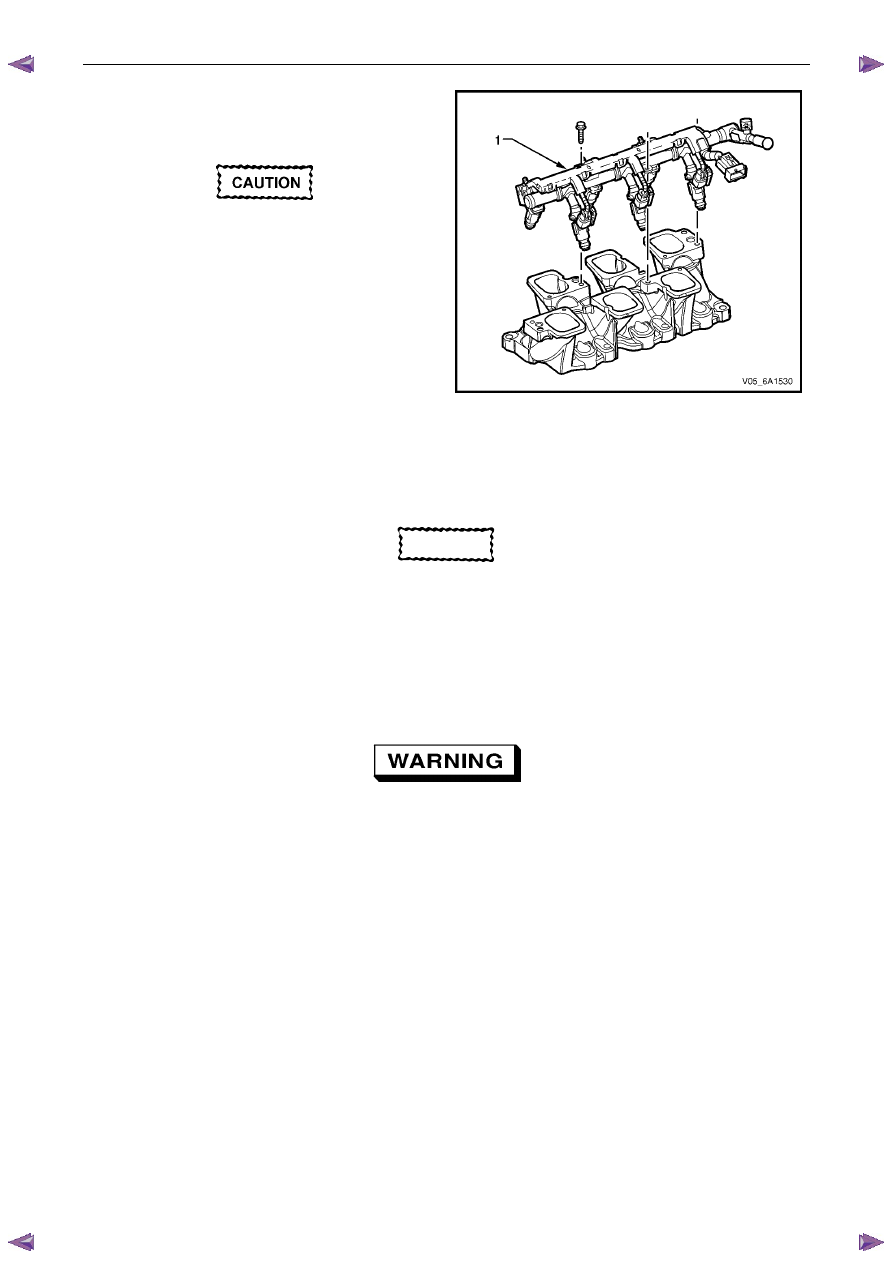

Remove the fuel rail and injector assembly. Refer to

6C1-3 Engine Management – V6 – Service

Operations.

The following precautions must be followed

when removing the fuel rail and injector

assembly:

•

Care must be taken when removing the

fuel rail and injector assembly to

prevent damage to the injector spray

tips and injector harness connector

terminals.

•

Support the fuel rail and injector

assembly after removal.

•

Plug all fuel line and manifold openings

after removal to prevent dirt and other

contaminants from entering the fuel

system.

Figure 6A1 – 53

Clean

CAUTION

Due to the aluminium alloy construction of

the intake manifold, wire brushes and steel

scrapers must not be used during the

cleaning process, as damage to sealing

surfaces may occur. Use of a wooden or

plastic scraper is preferred.

1

Clean mating surfaces ensuring any gasket material is removed.

2

Clean the manifold using a suitable solvent

Safety glasses must be worn when using

compressed air.

3

Dry the timing components with compressed air.

Inspect

1

Inspect the intake manifold for the following fault conditions:

•

Damaged sealing and mating surfaces.

•

Damaged lower intake manifold gasket.

•

Damage or excessive debris on the threaded and through holes.

•

Cracks or damage to the intake manifold body.

Engine Mechanical – V6

Page 6A1–74

N O T E

If the lower intake manifold is cracked or

damaged, it must be replaced. No welding or

patching of the intake manifold should be

performed.

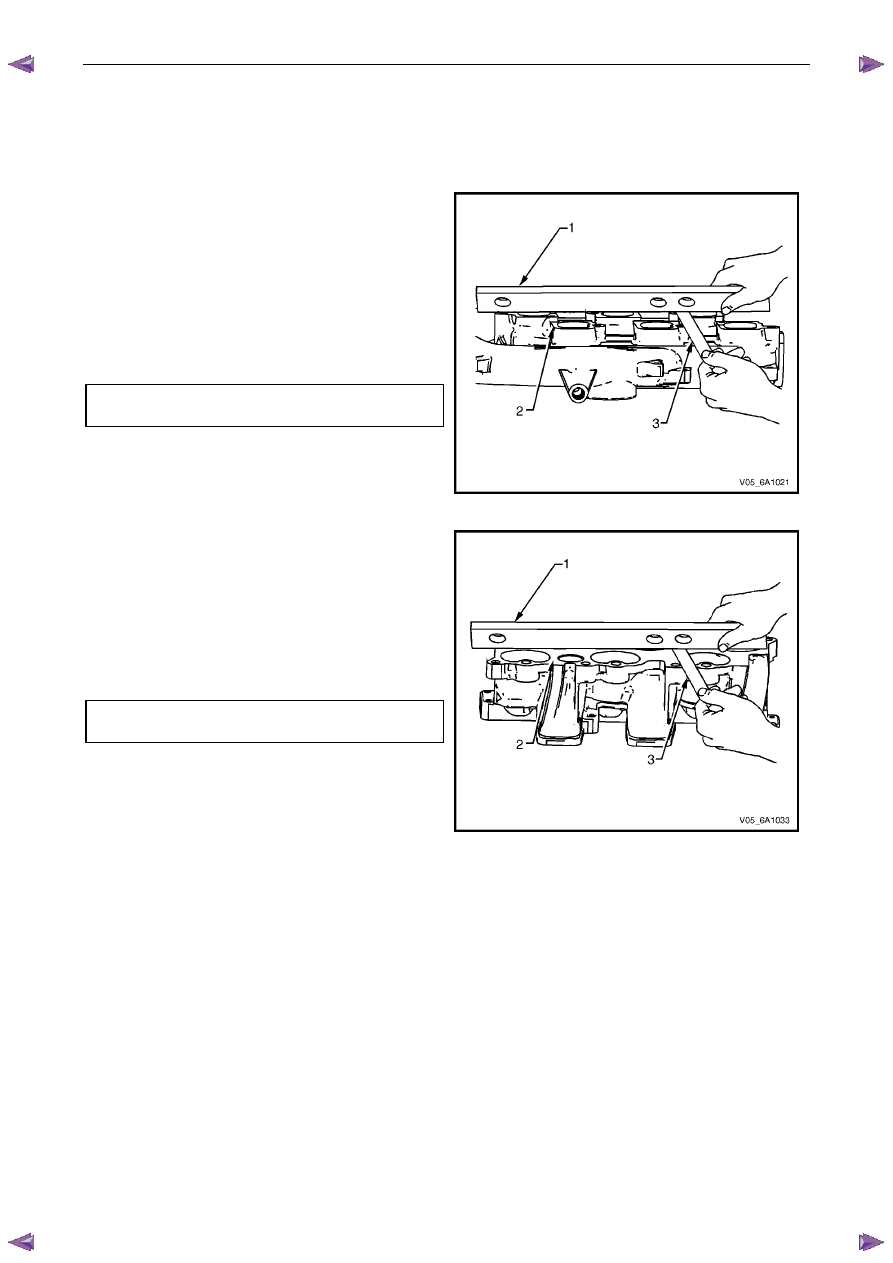

2

Place a straight edge (1) across the upper intake

manifold sealing surface (2).

3

Using a feeler gauge (3), measure the clearance

between the manifold and the straight edge.

4

If the clearance between the upper intake manifold

sealing surface and the straight edge exceeds the

specified maximum warpage, replace the manifold.

Upper manifold maximum

warpage . . . . . . . . . . . . . . . 0.05 mm

Figure 6A1 – 54

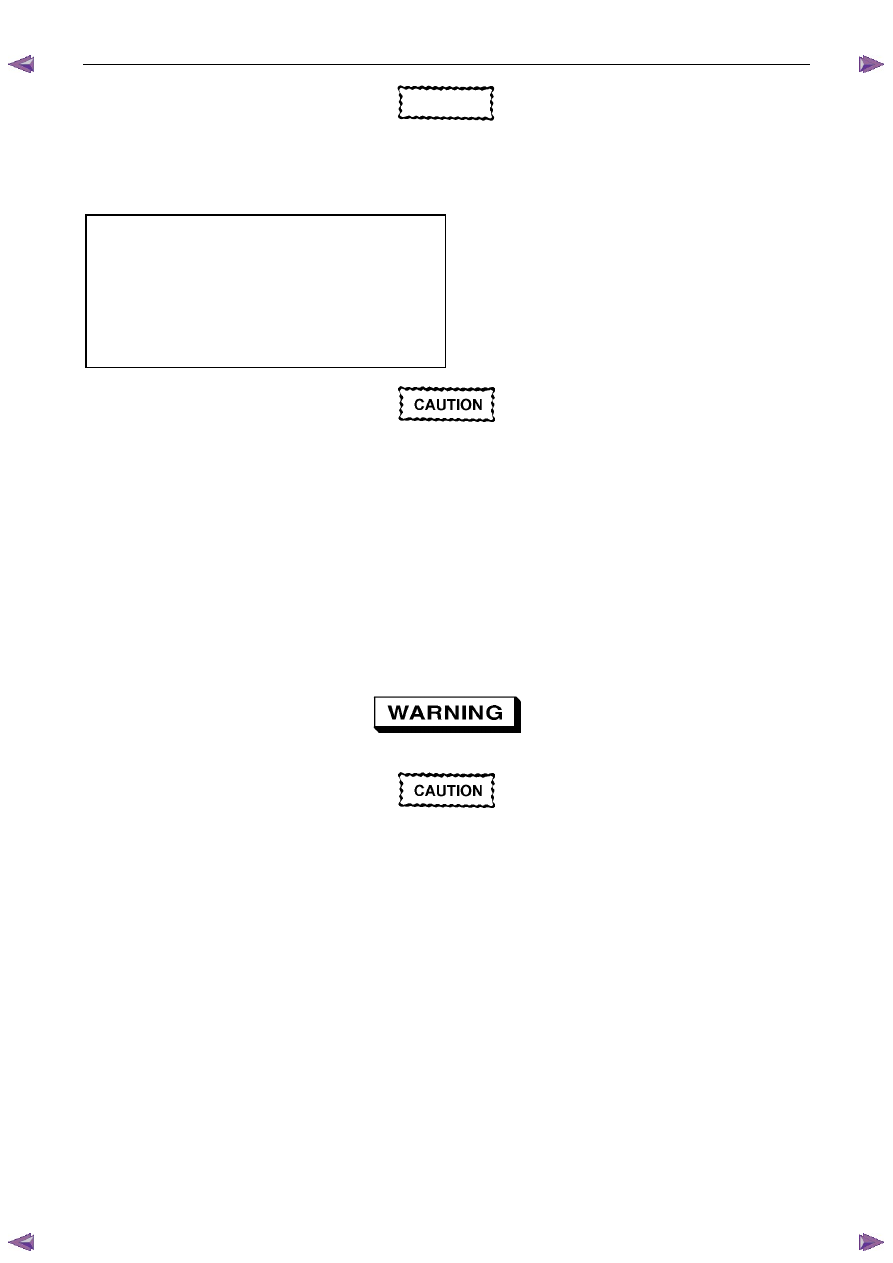

5

Place a straight edge (1) across the lower intake

manifold sealing surface (2).

6

Using a feeler gauge (3), measure the clearance

between the manifold and the straight edge.

7

If the clearance between the lower intake manifold

sealing surface and the straight edge exceeds the

specified maximum warpage, replace the manifold.

Lower manifold maximum

warpage . . . . . . . . . . . . . . . 0.05 mm

Figure 6A1 – 55

Reassemble

Reassembly of the upper to lower intake manifold is the reverse of the disassembly procedure noting the following:

1

Ensure that both the manifolds have been cleaned and inspected.

2

Ensure that the warpage of the mating surfaces is within tolerances.

3

New upper to lower intake manifold gaskets must be used.

4

Do not tighten the intake manifold to lower intake manifold attaching bolt at this stage. The intake manifold

attaching bolts must be tightened at the specified sequence during the reinstallation procedure.

Reinstall

Reinstallation of the upper intake manifold and the upper and lower intake manifold assembly is the reverse of the

removal procedure, noting the following:

1

Install the EVAP hose to the clip attached to the lower intake manifold.

2

Only new gaskets are to be fitted between the upper and lower intake manifolds.

3

If undamaged, the lower intake manifold to cylinder head gasket may be re-used, however its replacement is

strongly recommended.

Engine Mechanical – V6

Page 6A1–75

CAUTION

Tighten the intake manifold bolts in a circular

pattern starting at the centre bolt and moving

outward.

4

Ensure that all fasteners are tightened to the correct torque specification.

Upper intake manifold to lower intake

manifold attaching bolt torque specification . ...23.0 Nm

Upper intake manifold to cylinder

head attaching bolt torque specification. . . .23.0 Nm

Lower intake manifold to cylinder

head attaching bolt torque specification. . . .23.0 Nm

Fuel injector wiring harness bracket

attaching bolt torque specification. . . . . . 9.0 Nm

Incorrect wiring connector installation may

cause component malfunction or component

damage.

5

Ensure all wiring connectors are fully engaged and if applicable, locked in place.

6

Ensure all wiring harnesses are correctly routed and attached securely in their retaining clips.

7

Ensure that all hoses and pipes are routed correctly and that any retaining clips are correctly installed.

8

After installation pull on any quick connect fittings to check that each is correctly installed.

9

Start and run the engine to check for correct operation.

3.11 Exhaust Manifold Assembly

Remove

Allow the engine to cool before commencing.

Disconnection of the battery affects certain

vehicle electronic systems, refer to 1.1

WARNING, CAUTION and NOTES before

disconnecting the battery.

1

Disconnect the battery negative terminal.

Engine Mechanical – V6

Page 6A1–76

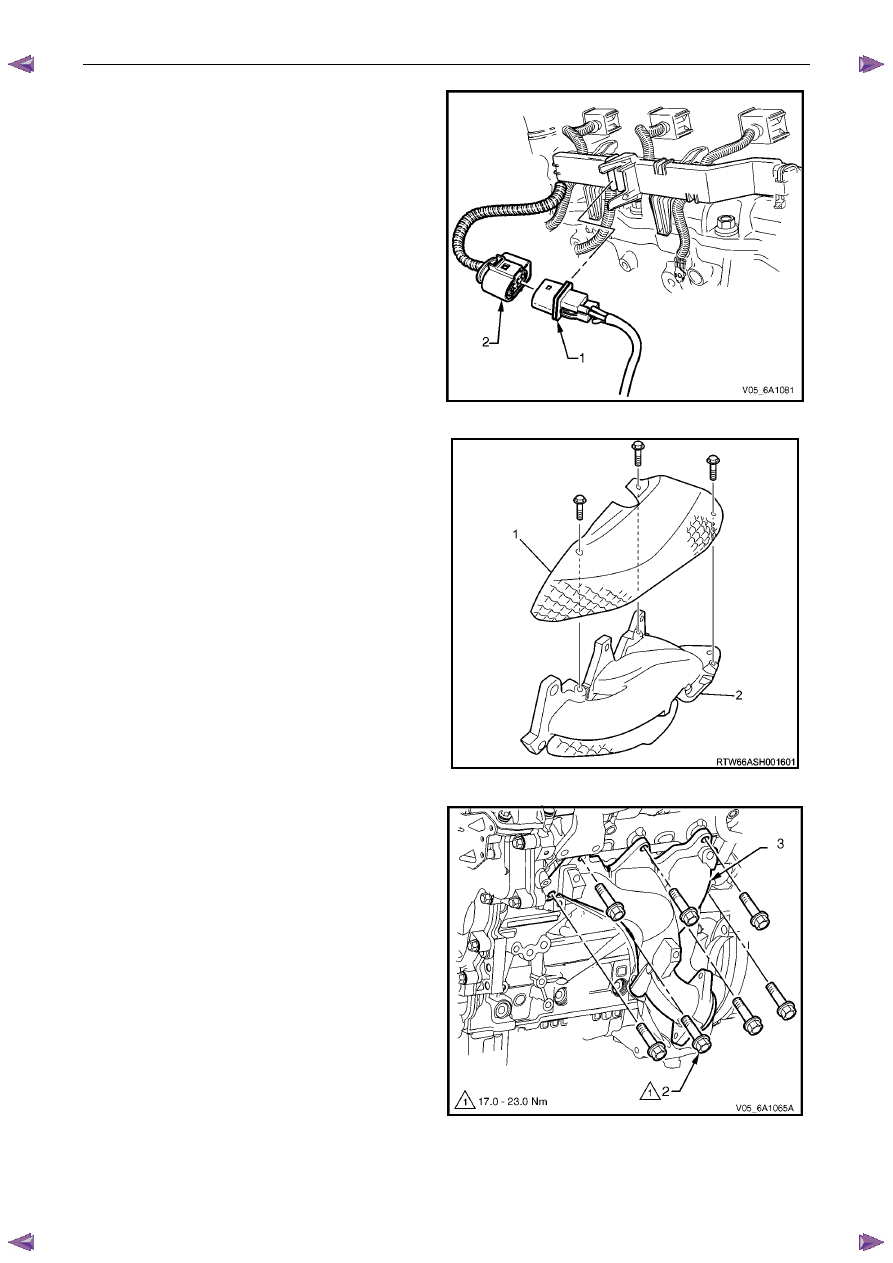

2

Remove the oxygen sensor harness connector (1)

from the retaining bracket.

3

Disconnect the oxygen sensor wiring harness

connector from the engine wiring harness connector

(2).

4

Unclip the oxygen sensor wiring harness retaining clip

and move aside.

5

For the left-hand side:

Remove the oil level indicator tube.

6

Raise the front of the vehicle and place on stands,

refer to 0A General Information.

7

Working from under the vehicle, remove the two

exhaust manifold to exhaust pipe flange nuts, refer to

6F Exhaust System - V6 - V6.

Figure 6A1 – 56

8

Remove the three bolts attaching the exhaust

manifold outer heat shield (1) to the exhaust manifold

(2).

Figure 6A1 – 57

9

Progressively loosen the seven exhaust manifold

attaching bolts (2), working from the outside to the

centre and then remove the bolts.

10

Manoeuvre the exhaust manifold (3), away from the

cylinder head.

11

Remove and discard the exhaust manifold to cylinder

head gasket.

Figure 6A1 – 58

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст