Isuzu KB P190. Manual — part 514

6A-42 ENGINE MECHANICAL (C24SE)

Installation

1. Install the fastening bolts.

2. Loosen the lower alternator fastening bolt.

3. Install the alternator, power steering and V-belts.

Cylinder Head, Disassemble and Assemble

Removal

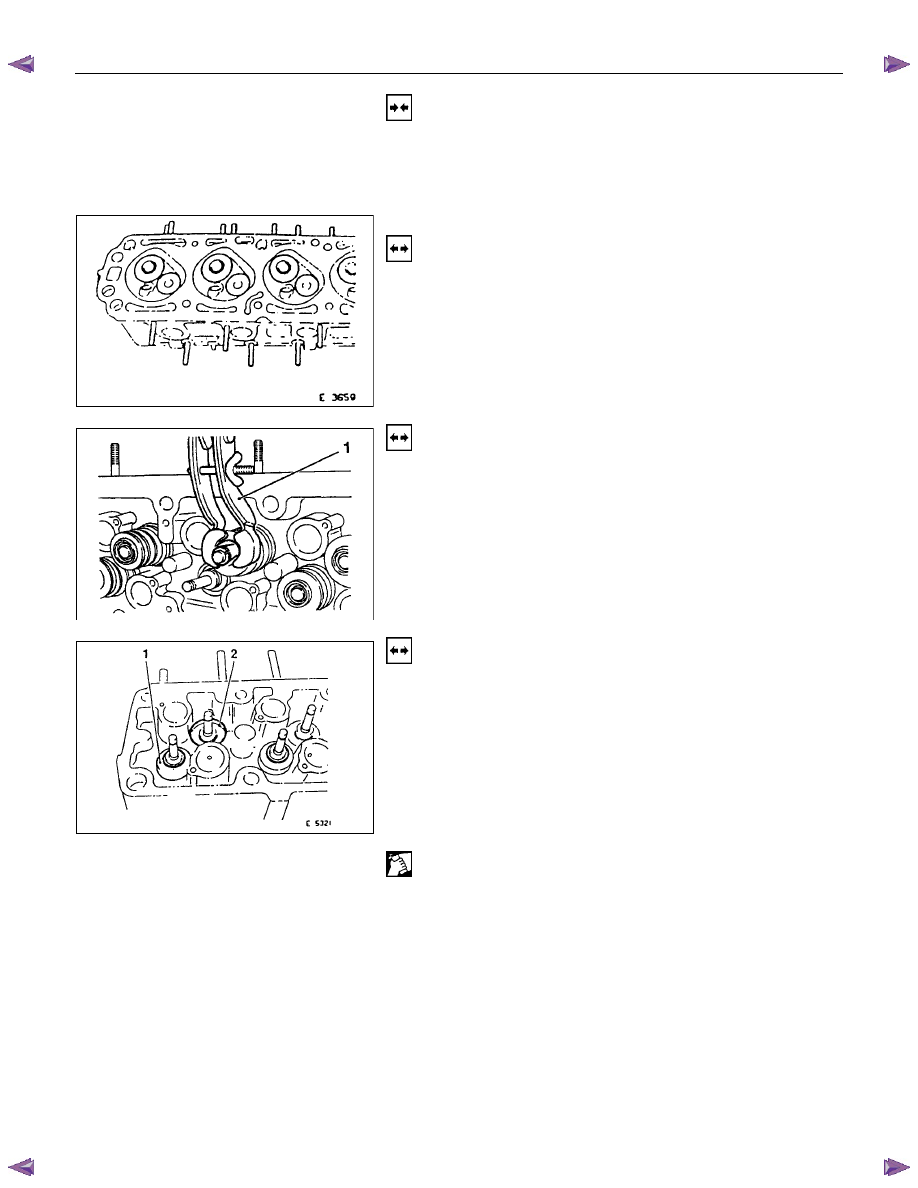

1. Remove the hydraulic valve lifters.

Lay aside in installation positions.

2. Remove the spark plugs, exhaust manifold and intake

manifold from cylinder head.

Removal

1. Mark valves.

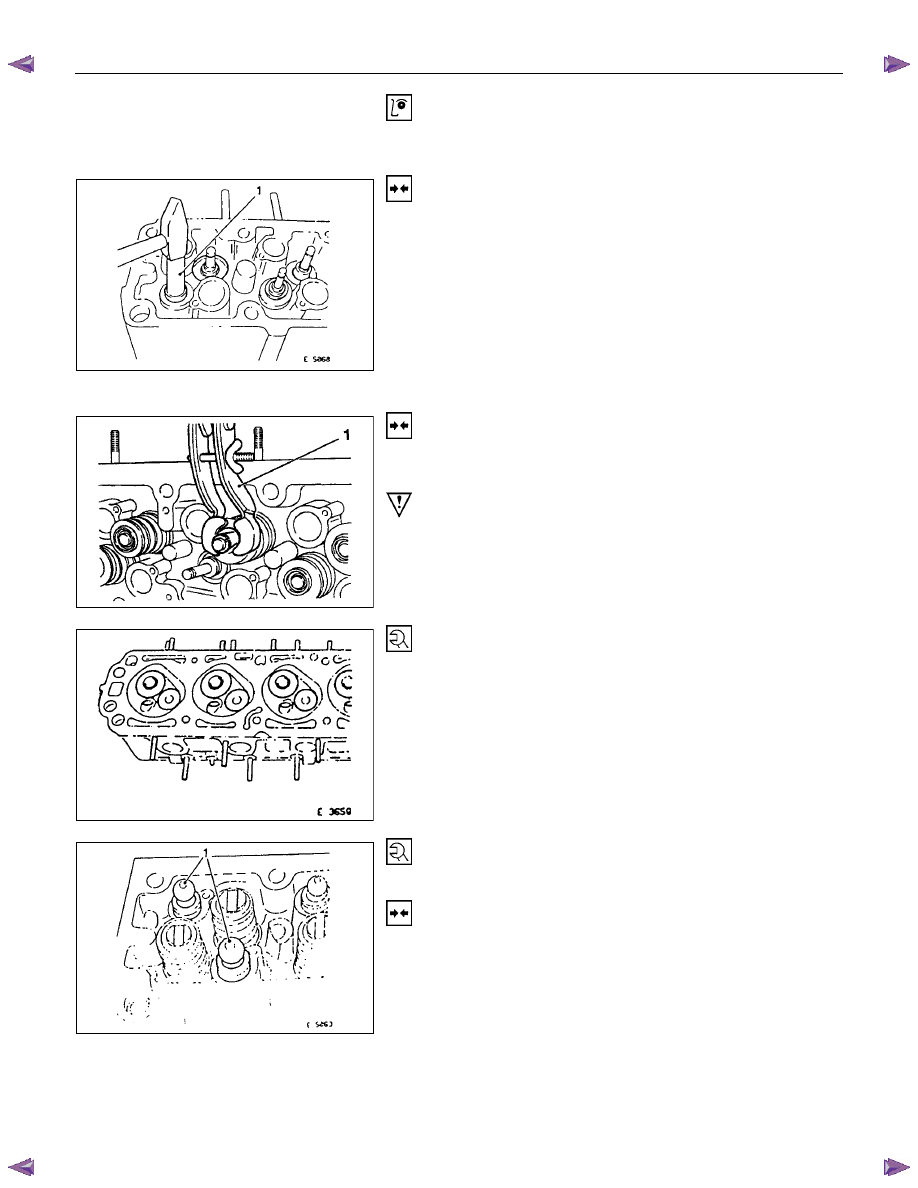

2. Remove the tension valve springs with 5-8840-2594-0

(1).

3. Remove valve keepers, valve spring cap and valve

spring.

Removal

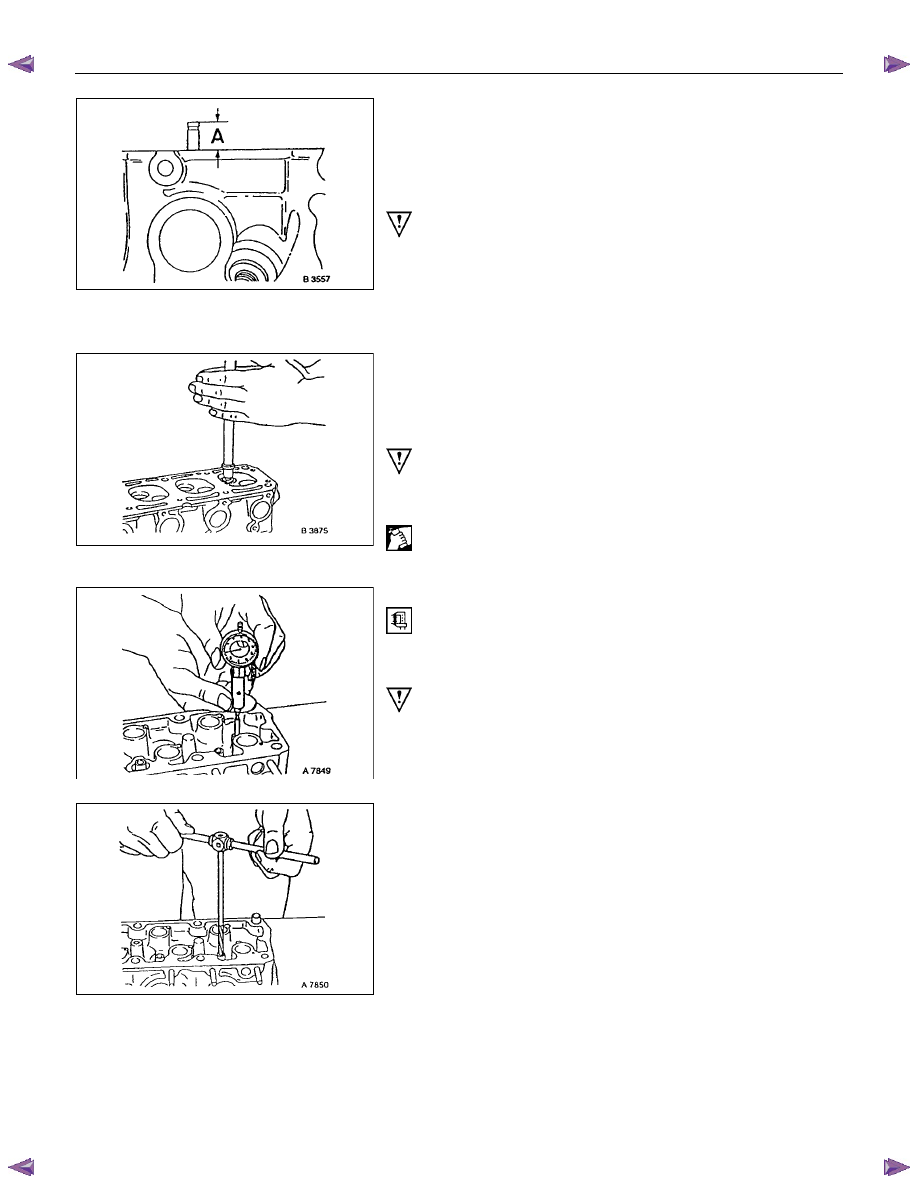

1. Remove the valve and valve stem seal.

2. Remove the valve spacer ring (1-exhaust) and valve

spring seat (2-intake).

3. Remove valve from cylinder head.

Clean

Sealing surfaces.

ENGINE MECHANICAL (C24SE) 6A-43

Inspection

Sealing surfaces for plane surface, guides, sliding and bearing

points for wear-see operation “Cylinder Head. Overhaul”.

Installation

1. Coat the valves with engine oil and insert in cylinder

head.

2. Install the valve spacer ring or valve rotator(exhaust) and

valve spring seal(intake).

3. Push the accompanying assembly sleeve onto valve

stem and coat with engine oil.

4. Insert a new valve stem seal with 5-8840-2601-0 (1).

5. Drive the valve stem seal carefully in to stop with light

hammer blow.

Installation

1. Install the valve springs and valve spring caps.

2. Install the tension valve springs with 5-8840-2594-0 (1),

valve keeper.

Important!

Note markings made on valves.

Tighten (Torque)

Exhaust manifold and intake manifold with new gaskets to

cylinder head.

Thermostat housing with new seal ring to cylinder head:

Tighten (Torque)

Spark plugs with spark plug wrench to cylinder head.

Installation

1. Coat hydraulic valves lifters (1) with oil.

2. Insert them in cylinder head.

Note installation position.

6A-44 ENGINE MECHANICAL (C24SE)

Valve, Grind

Valves can be reused once or twice after regrinding-only if

there are no crater-like burns on the valve cone.

Excessive grinding can cause the upper valve head edge to

become too thin.

Important!

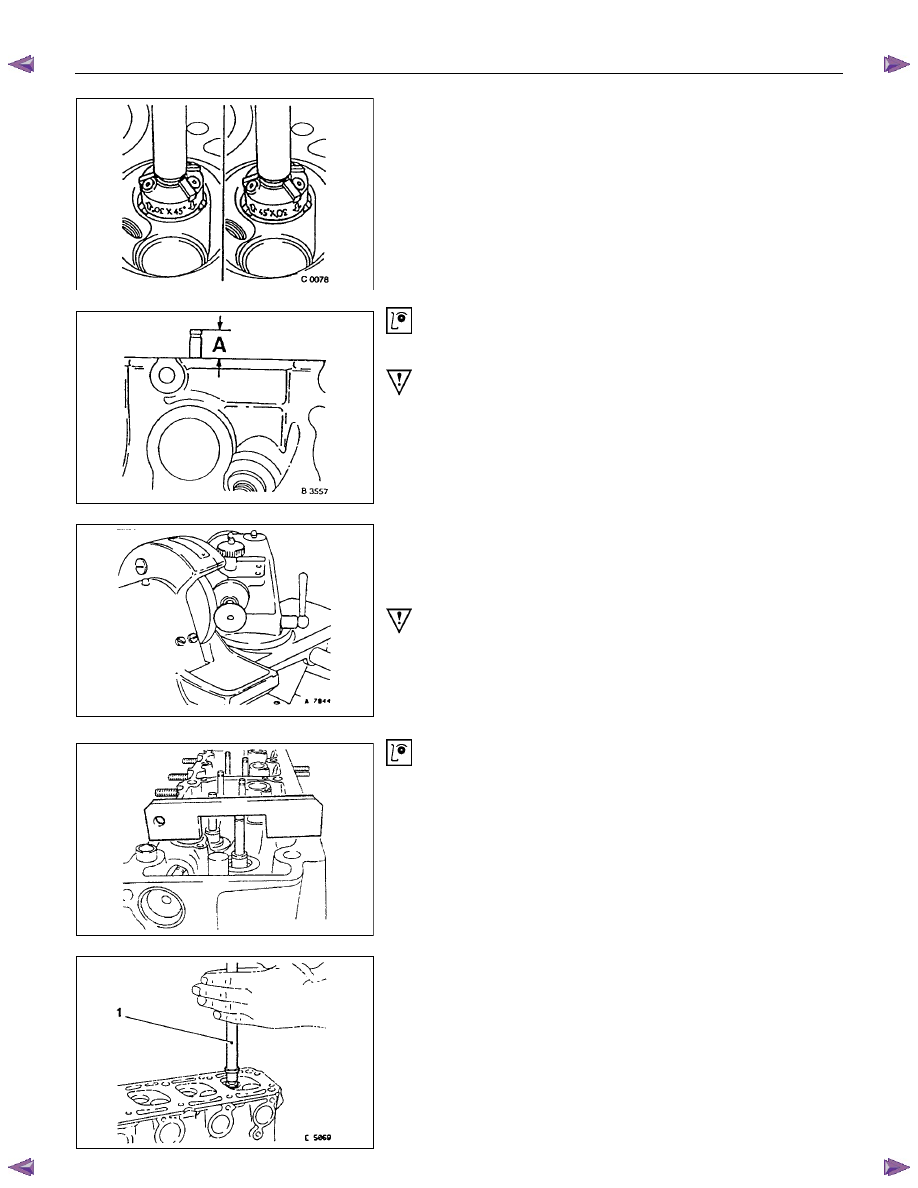

Valve stem protection must not exceed dimension “A”-use 5-

8840-2596-0.

Do not regrind valve stem ends.

For all valve reworking note that angle of valve head is 44

° and

the valve seat 45

°-see also “Technical Data”.

Valve, Grind In

Grind-In the valve to improve valve seating.

Grind-In by rhythmically lifting valves and turning uniformly.

Use commercially available grinding tool.

Important!

Use only fine-grained pastes for grinding.

Lubricate valve stem before grinding in.

Clean

After grinding, carefully clean valve and valve soat.

Valve Guide, Ream

Measure

Diameter of valve guide-dial gauge and internal measuring

instrument.

Important!

Valve oversizes are available ex-works.

Oversize identification, on the valve guide and on the valve

stem end with the following specified identificaton

flgures/letters-see also “Technical Data”.

Identification Mark

Size Production

Customer

Service

Reamer

Normal none

K

0.075 mm

1

K1

0.150mm 2

K2

Ream valve guide from the upper side of the cylinder head to

the next oversize (use 5-8840-2599-0).

After reaming, cross out identification mark and stamp in new

identification mark.

ENGINE MECHANICAL (C24SE) 6A-45

Valve Seating, Mill

Place cylinder head on block of wood.

Inlet and exhaust, Guide Drift and Valve Seat Cutter 5-8840-

2593-0.

Valve seat-45

°, side face, upper correction-30°, side face

(arrows on cutter).

Valve seat width:

Inlet-1.0 to 1.5 mm/0.04 to 0.06 in.

Exhaust-1.7 to 2.2 mm/0.072 to 0.088 in.

Inspection

Valve stem projection-use 5-8840-2596-0.

Important!

If dimension “A” is exceeded, use new valves.

Check valve stem projection again. If dimension “A” is

exceeded, replace cylinder head.

Cylinder Head, Overhaul

Cylinder head disassembled.

Valve, Grind

Important!

Ensure that there are no crater-like burns on the valve cone.

Regrinding possible once or twice.

Grinding of valve stem end is not permitted.

Angle at valve head-44

°

Inspection

Check valve stem projection as shown 5-8840-2596-0.

Valve, Grind in

Lubricate valve stem, use fine-graining grinding paste.

Lift up valve from seat rythmically using valve grinding tool (1)

for distribution of grinding paste.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст