Isuzu KB P190. Manual — part 954

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–30

•

records the operating condition at the time the diagnostic fails and stores this information in the Freeze Frame/

Failure Record.

Type B – Emission Related DTCs

The TCM takes the following actions when a Type B DTC runs and fails.

•

On the first time a Type B DTC fails:

•

sets a current Type B DTC that represents the fault condition, and

•

records the operating conditions at the time the fault sets and stores this information in the Failure Records.

•

On the second consecutive ignition cycle that a Type B DTC fails:

•

illuminates the MIL, and

•

records the operating condition at the time the diagnostic fails and stores this information in the Freeze

Frame/ Failure Record.

Conditions for Clearing Type A or Type B DTCs

•

The current DTC clears when there is no fault condition in the current TCM self-diagnostics.

•

If there are no DTCs logged after six consecutive ignition cycles, the TCM deactivates the MIL.

•

Type A or Type B History DTC clears when there is no fault condition after 40 consecutive warm-up cycles.

•

Use of Tech 2 to clear DTCs.

Type C – Non-emission Related DTCs

The TCM takes the following action when a Type C DTC runs and fails:

•

sets a current Type C DTC that represents the fault condition,

•

records the operating conditions at the time the DTC is logged and stores this information in the Failure Record,

and

N O T E

The MIL does not illuminate when a Type C DTC

sets.

Conditions for Clearing Type C DTCs

•

The current DTC clears when there is no fault condition in the current TCM self-diagnostics.

•

Type C History DTC clears when there is no fault condition after 40 consecutive warm-up cycles.

•

Use of Tech 2 to clear DTCs.

Current DTCs

A DTC is a Current DTC if the fault condition that triggers the DTC is present during the last TCM self-diagnostics.

History DTCs

A DTC is a History DTC if the fault condition that triggers the DTC is not present during the last TCM self-diagnostics.

4.7

Diagnostic System Check

Description

This section procedure is organised in a logical structure that begins with the diagnostic system check. The diagnostic

system check directs you in a logical direction to the appropriate Section or diagnostic procedure.

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–31

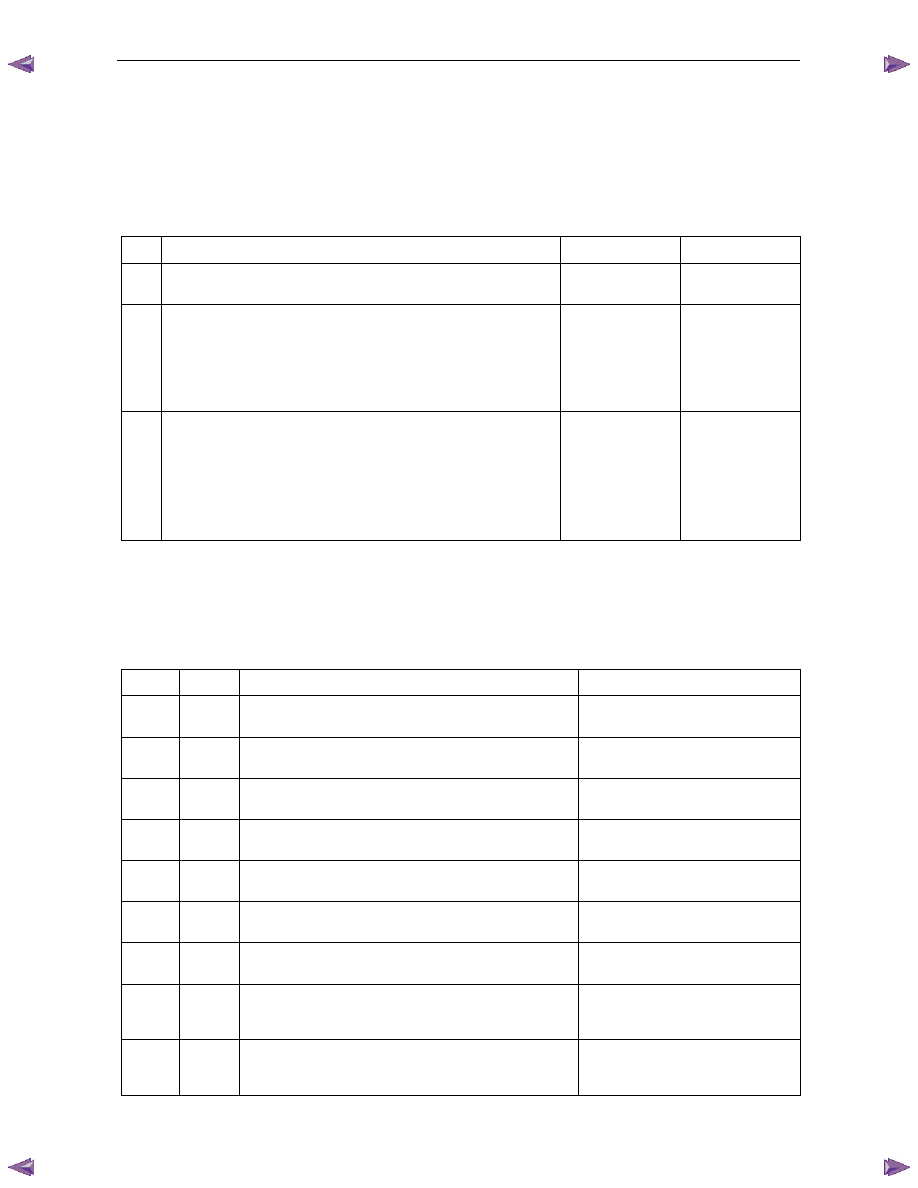

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1

Within this document there are a number of requirements that must be met before you can start diagnosis. Refer to

4.2 Basic Knowledge Required, 4.3

Diagnostic Precautions and 4.4

Preliminary Checks.

2

Checks if there is data communication between Tech 2 and the TCM.

3

Checks if the TCM has set any DTCs. If no DTCs have set, the functional test must be performed, which diagnoses

the hydro-mechanical functions of the transmission.

Step Action

Yes

No

1

Have you read the Basic Diagnostic Requirements, Diagnostic

Precautions and Preliminary Checks?

Go to Step 3

Refer to Note 1

2

1

Connect Tech 2 to the DLC.

2

On Tech 2 select:

Transmission / Automatic Transmission

and follow the instruction on Tech 2.

Does Tech 2 display the TCM specifications?

Go to Step 4

Refer to 6E1

Powertrain Interface

Module

3

On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information

Does Tech 2 display any DTCs?

Go to

4.8 Diagnostic

Trouble Code List

Perform the

Functional Test,

refer to 7C3

Automatic

Transmission –

4L60E – Hydraulic

and Mechanical

Diagnosis

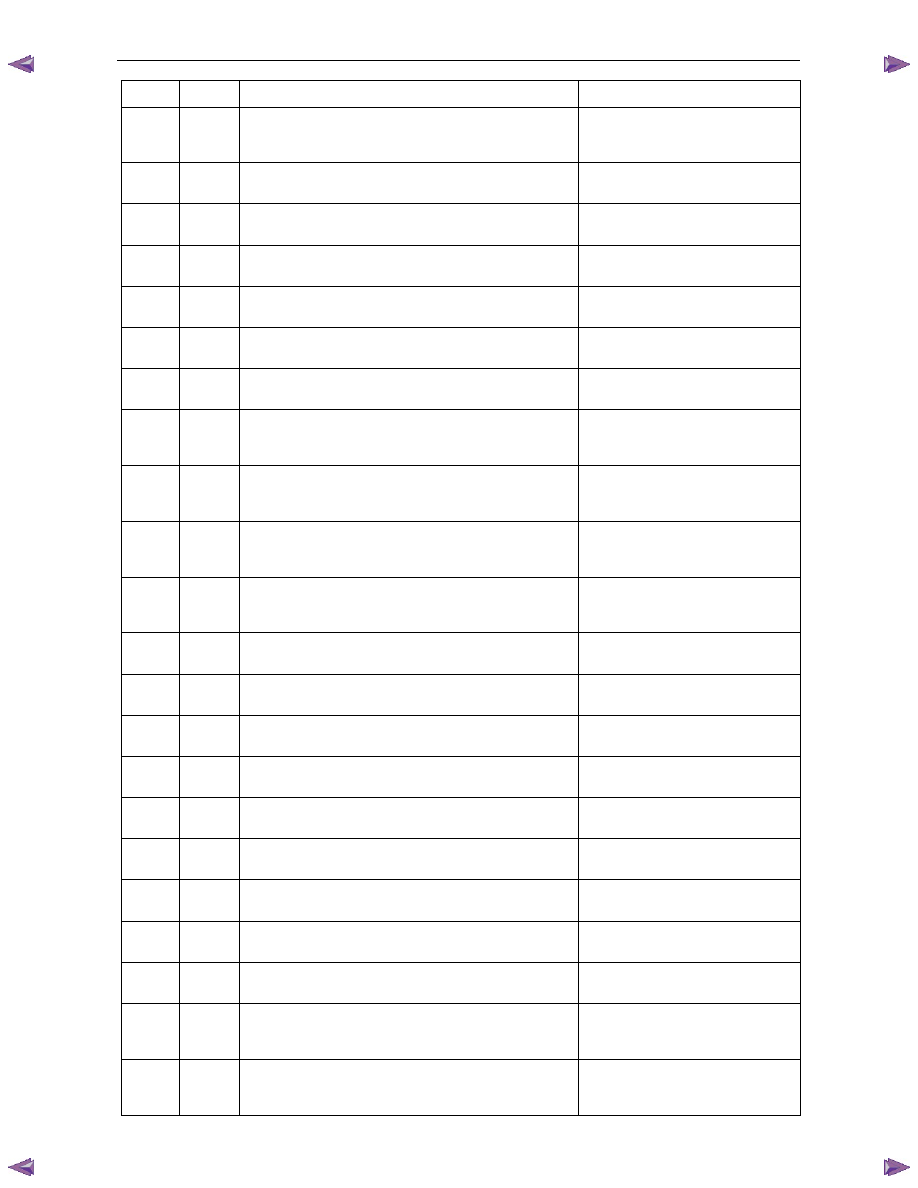

4.8

Diagnostic Trouble Code List

N O T E

If the DTC listed on Tech 2 is not contained in

this list, refer to OD Vehicle Diagnostics.

DTC Type

Description

Diagnostic

Table

P0218 C

Transmission Fluid Overtemperature

4.9

DTC P0218 – Transmission

Fluid Overtemperature

P0562 C

System Voltage Low

4.10

DTC P0562 – System

Voltage Low

P0563 C

System Voltage High

4.11

DTC P0563 – System

Voltage High

P0601 A

Transmission Control Module (TCM) Read Only Memory

(ROM)

4.12

DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0602 A

Transmission Control Module (TCM) Not Programmed

4.12

DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0603 A

Transmission Control Module (TCM) Random Access

Memory (RAM)

4.12

DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0604 A

Transmission Control Module (TCM) Long Term Memory

Performance

4.12

DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0711 C

Transmission Fluid Temperature (TFT) Sensor

Performance

4.13

DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

P0712 C

Transmission Fluid Temperature (TFT) Sensor Circuit Low

Voltage

4.13

DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

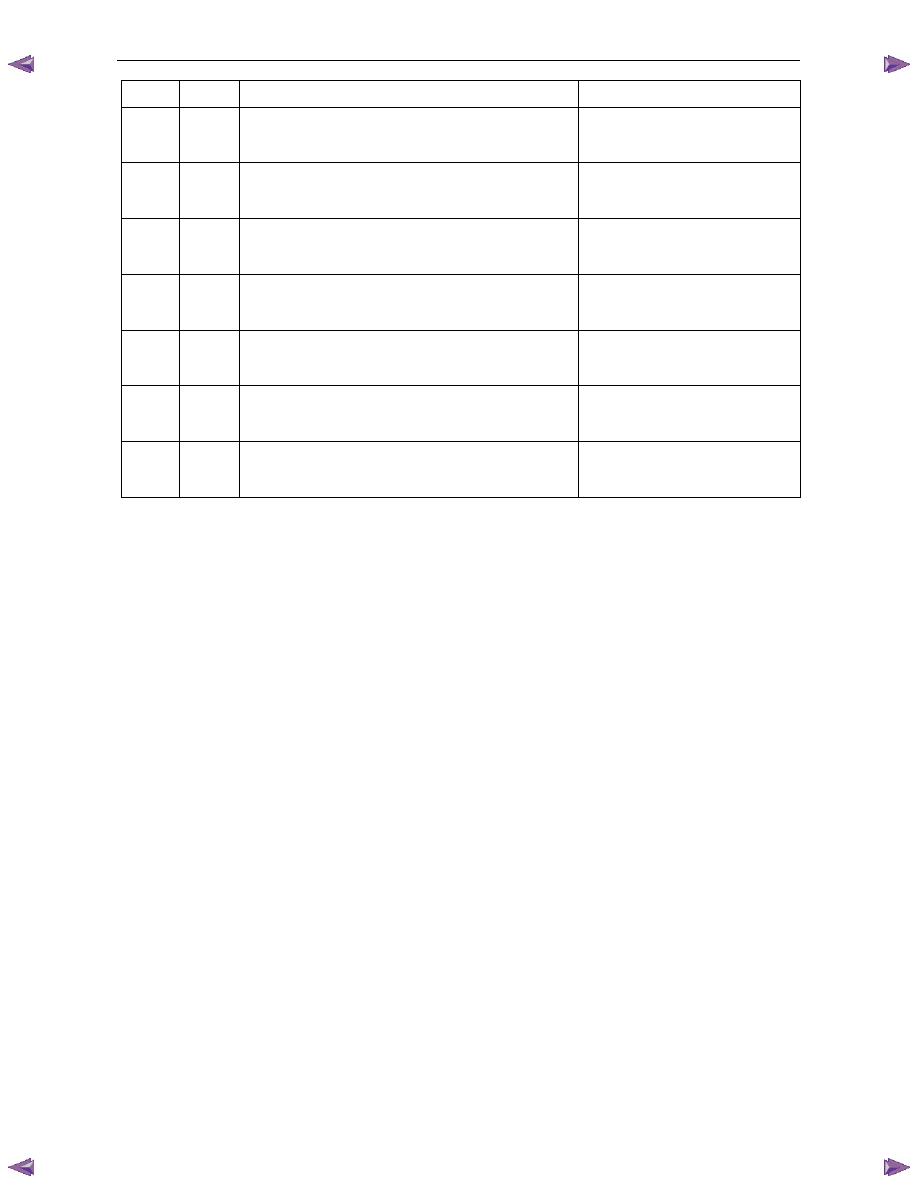

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–32

DTC Type

Description

Diagnostic

Table

P0713 C

Transmission Fluid Temperature (TFT) Sensor Circuit High

Voltage

4.13

DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

P0719 C

Brake Switch Circuit High Input (Stuck On)

4.14

DTC P0719 – Brake Switch

Circuit High Input (Stuck On)

P0722 B

Vehicle Speed Sensor Circuit Low Voltage

4.15

DTC P0722 – Vehicle Speed

Sensor Circuit Low Voltage

P0723 B

Vehicle Speed Sensor Circuit Intermittent

4.16

DTC P0723 – Vehicle Speed

Sensor Circuit Intermittent

P0724 C

Brake Switch Circuit Low Input (Stuck Off)

4.17

DTC P0724 – Brake Switch

Circuit Low Input (Stuck Off)

P0741 B

Torque Converter Clutch (TCC) System – Stuck Off

4.18

DTC P0741 – Torque

Converter Clutch System – Stuck Off

P0742 B

Torque Converter Clutch (TCC) System – Stuck On

4.17

DTC P0724 – Brake Switch

Circuit Low Input (Stuck Off)

P0751 B

1-2 Shift Solenoid (SS) Valve Performance – No First or

Fourth Gear

4.20

DTC P0751 – 1-2 Shift

Solenoid Valve Performance – No

First or Fourth Gear

P0752 B

1-2 Shift Solenoid (SS) Valve Performance – No Second or

Third Gear

4.21

DTC P0752 – 1-2 Shift

Solenoid Valve Performance – No

Second or Third Gear

P0756 A

2-3 Shift Solenoid (SS) Valve Performance – No First or

Second Gear

4.22

DTC P0756 – 2-3 Shift

Solenoid Valve Performance – No

First or Second Gear

P0757 A

2-3 Shift Solenoid (SS) Valve Performance - No Third or

Fourth Gear

4.23

DTC P0757 – 2-3 Shift

Solenoid Valve Performance – No

Third or Fourth Gear

P0787 A

3-2 Shift Solenoid (SS) Control Circuit Low Voltage

4.24

DTC P0787 – 3-2 Shift

Solenoid Control Circuit Low Voltage

P0788 A

3-2 Shift Solenoid (SS) Control Circuit High Voltage

4.25

DTC P0788 – 3-2 Shift

Solenoid Control Circuit High Voltage

P0894 B

Transmission Component Slipping

4.26

DTC P0894 – Transmission

Component Slipping

P0961 C

Line Pressure Control (PC) Solenoid System Performance

4.27

DTC P0961 – Line Pressure

Control Solenoid System Performance

P0973 B

1-2 Shift Solenoid (SS) Control Circuit Low Voltage

4.28

DTC P0973 – 1-2 Shift

Solenoid Control Circuit Low Voltage

P0974 B

1-2 Shift Solenoid (SS) Control Circuit High Voltage

4.29

DTC P0974 – 1-2 Shift

Solenoid Control Circuit High Voltage

P0976 A

2-3 Shift Solenoid (SS) Control Circuit Low Voltage

4.30

DTC P0976 – 2-3 Shift

Solenoid Control Circuit Low Voltage

P0977 A

2-3 Shift Solenoid (SS) Control Circuit High Voltage

4.31

DTC P0977 – 2-3 Shift

Solenoid Control Circuit High Voltage

P1621 A

Transmission Control Module (TCM) Long Term Memory

Performance

4.12

DTC P0601 to P0604 or

P1621 – TCM Malfunction

P1810 B

Transmission Fluid Pressure (TFP) Position Switch Circuit

4.32

DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

P1815 B

Transmission Fluid Pressure (TFP) Valve Position Switch -

Start in Wrong Range

4.32

DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–33

DTC Type

Description

Diagnostic

Table

P1816 B

Transmission Fluid Pressure (TFP) Valve Position Switch

Indicates Park/Neutral (P/N) with Drive Ratio

4.32

DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

P2763 B

Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit High Voltage

4.33

DTC P2763 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit High Voltage

P2764 B

Torque Converter Clutch (TCC) Pressure Control (PC)

Solenoid Control Circuit Low Voltage

4.34

DTC P2764 – Torque

Converter Clutch Pressure Control

Solenoid Control Circuit Low Voltage

P2769 B

Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit Low Voltage

4.35

DTC P2769 – Torque

Converter Clutch Enable Solenoid

Control Circuit Low Voltage

P2770 B

Torque Converter Clutch (TCC) Enable Solenoid Control

Circuit High Voltage

4.36

DTC P2770 – Torque

Converter Clutch Enable Solenoid

Control Circuit High Voltage

U0073 B

ECM CAN Bus Error

4.37

DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

U0100 B

ECM CAN Bus Error

4.37

DTC U0073 and U0100 –

CAN-Bus No Communication With

ECM (Engine Control Module)

4.9

DTC P0218 – Transmission Fluid

Overtemperature

DTC Description

This diagnostic procedure supports DTC P0218 Transmission Fluid Overtemperature.

Circuit Description

The flow of transmission fluid starts in the bottom pan and is drawn through the filter, control valve body assembly,

transmission case and into the oil pump assembly. The oil pump assembly pressurises the fluid and directs it to the

pressure regulator valve where it becomes the main supply of fluid to the various components and hydraulic circuits in

the transmission. Hot fluid exiting the torque converter flows through the converter clutch apply valve and into the

transmission cooler lines, to the oil cooler located in the vehicle radiator, and auxiliary cooler if equipped. From the cooler,

fluid returns to cool and lubricate the front of the transmission. In forward drive ranges, D4 fluid from the manual valve is

routed through an orificed cup plug in the rear of the transmission case to feed the rear lube fluid circuit.

When the transmission control module (TCM) detects a high transmission fluid temperature (TFT) for a long period of

time, DTC P0218 sets. DTC P0218 is a type C DTC.

Refer to 2

Wiring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

•

No DTCs P0711, P0712 or P0713.

•

The ignition switch is on for 5 seconds.

Conditions for Setting the DTC

The TFT is greater than 130°C for 600 seconds (10 minutes).

Action Taken When the DTC Sets

•

The TCM does not request the ECM to illuminate the MIL.

•

The TCM freezes transmission adapt functions.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст