Isuzu KB P190. Manual — part 297

6E-154 Engine Control System (4JH1)

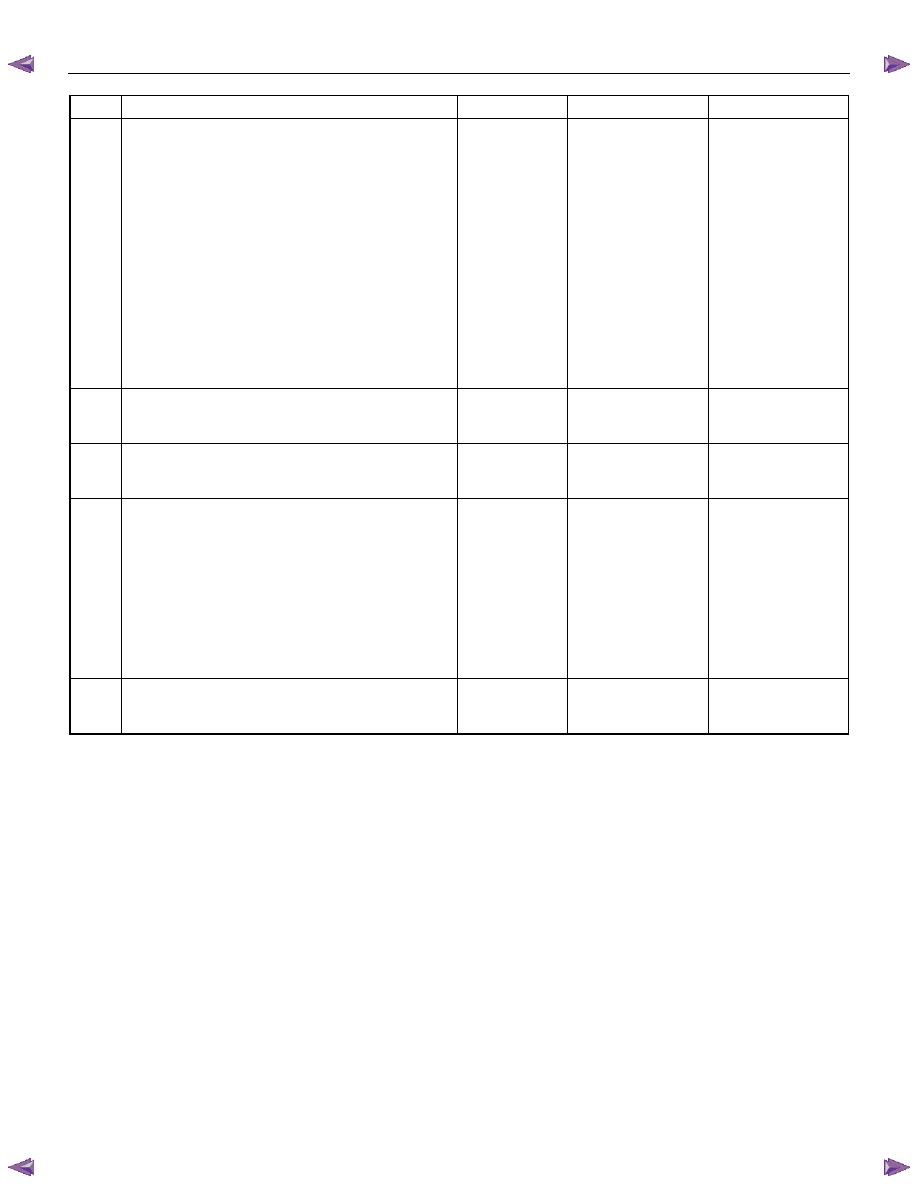

Step Action

Value(s)

Yes

No

7

1. Turn OFF the ignition.

2. Disconnect the MAF sensor harness connector.

3. Inspect for an intermittent, for a poor connection

and corrosion at the harness connector of the

MAF sensor (pin 3 of C-116 connector).

4. Disconnect the engine control module (ECM)

harness connector.

5. Inspect for an intermittent, for a poor connection

and corrosion on each MAF sensor circuit at the

harness connector of the ECM (pin 92 of C-57

connector).

6. Test for high resistance on each MAF sensor

circuit.

7. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 10

Go to Step 8

8

Replace the EGR valve. Refer to EGR Valve

Replacement in engine mechanical section.

Did you complete the replacement?

Go to Step 10

9

Replace the EGR solenoid valve. Refer to EGR

Solenoid Valve Replacement in this section.

Did you complete the replacement?

Go to Step 10

10

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and warm up (allow engine

coolant temperature to reach at least 60°C

[140°F]) while observing the MAF Sensor

parameter with the scan tool.

Does the MAF Sensor parameter follow the Desired

MAF parameter within 50 mg/strk?

Go to Step 11

Go to Step 2

11

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Engine Control System (4JH1) 6E-155

DTC P0400 (Symptom Code 8) (Flash Code 32)

Circuit Description

The engine control module (ECM) controls the exhaust

gas recirculation (EGR) flow amount based on the

engine speed, engine coolant temperature, intake air

temperature, barometric pressure and fuel injection

quantity. The ECM controls the EGR valve by

controlling the EGR solenoid valve. The mass air flow

(MAF) sensor monitors EGR gas flow amount. An

expected MAF amount should be detected while the

engine running. If the ECM detects that detects a short

to battery or ignition voltage on the EGR solenoid valve

control circuit, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the high voltage condition

on the EGR solenoid valve control circuit for longer

than 3 seconds when the solenoid valve is

commanded ON.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the control circuit of the EGR solenoid valve

between the ECM and the solenoid valve is normal, the

control circuit voltage low DTC P0400 (Symptom Code

4) will set.

DTC P0400 (Symptom Code 8) (Flash Code 32)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

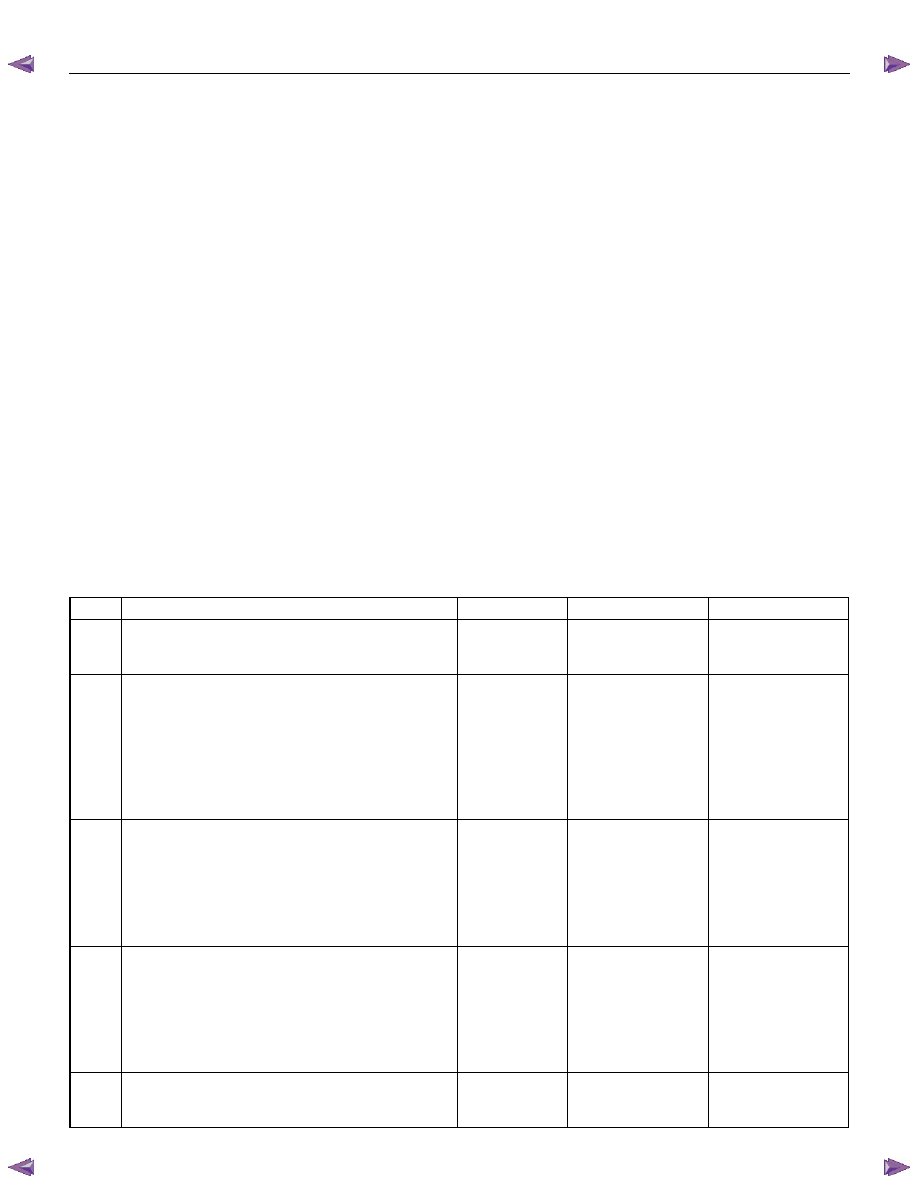

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine and warm up (allow engine

coolant temperature to reach at least 60°C

[140°F]).

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3

Go to Diagnostic

Aids

3

1. Turn OFF the ignition.

2. Disconnect the EGR control solenoid valve

harness connector.

3. Start the engine.

4. Monitor the DTC Information with the scan tool.

Does the DTC P0400 (Symptom Code 4) set, but not

DTC P0400 (Symptom Code 8)?

Go to Step 5

Go to Step 4

4

1. Test the control circuit between the engine

control module (ECM) (pin 97 of C-57 connector)

and the EGR solenoid valve (pin 2 of C-115

connector) for a short to battery or ignition

voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7

Go to Step 6

5

Replace the EGR solenoid valve. Refer to EGR

Solenoid Valve Replacement in this section.

Did you complete the replacement?

Go to Step 7

6E-156 Engine Control System (4JH1)

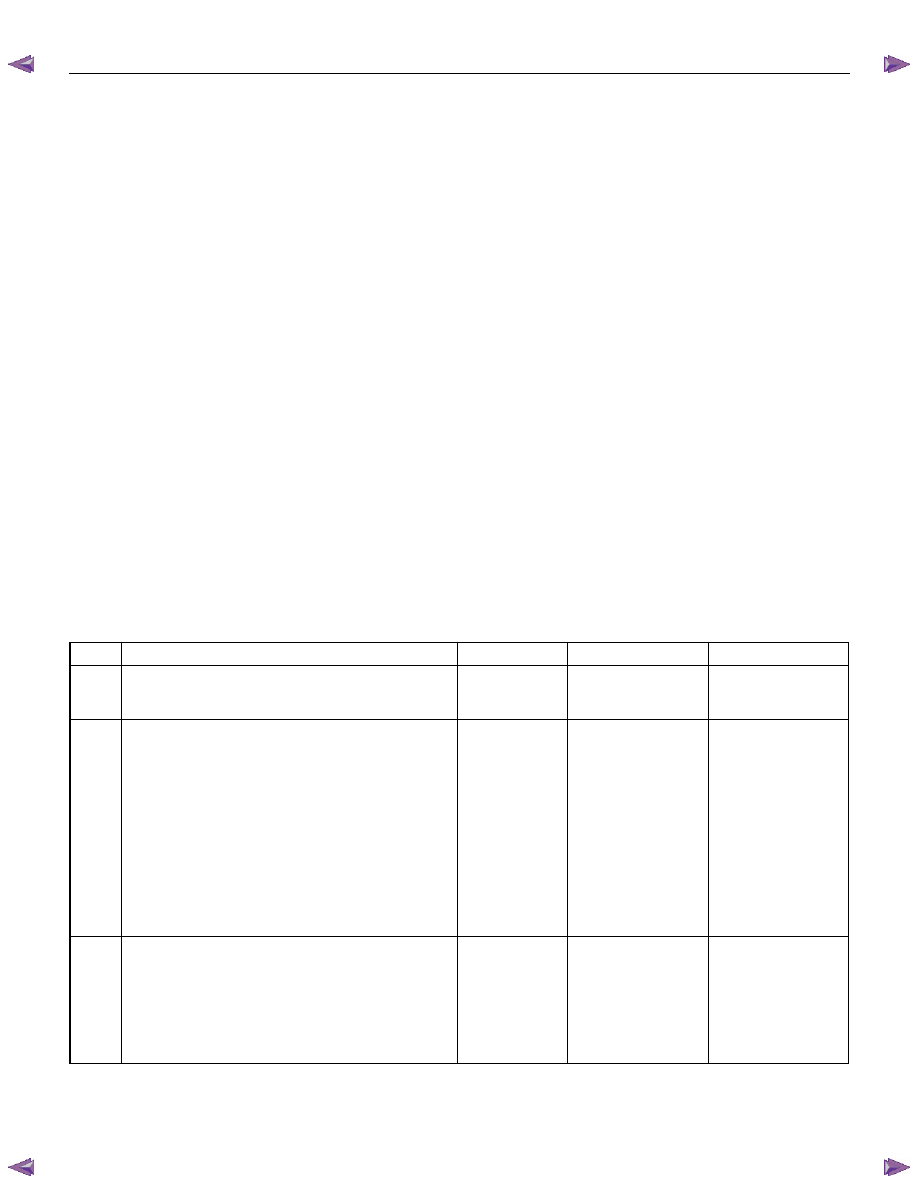

Step Action

Value(s)

Yes

No

6

Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 7

7

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine and warm up (allow engine

coolant temperature to reach at least 60°C

[140°F]).

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3

Go to Step 8

8

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Engine Control System (4JH1) 6E-157

DTC P0500 (Symptom Code 1, A) (Flash Code 24)

Circuit Description

The vehicle speed sensor (VSS) is used by the engine

control module (ECM) and speedometer, which

generates a speed signal from the transmission output

shaft. The VSS has the following circuits.

• Ignition voltage feed circuit

• VSS signal circuit

• VSS low reference circuit

The VSS uses a hall effect element. It interacts with the

magnetic field created by the rotating magnet and

outputs square wave pulse signal. The 12 volts

operating supply from the Meter fuse (except 2WD with

A/T) or Back Up fuse (2WD with A/T). The ECM

calculates the vehicle speed by the VSS. If the vehicle

is 2WD with automatic transmission, VSS signals are

sent from the transmission control module (TCM). If the

ECM detects VSS signals are generated with high

frequencies, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vehicle speed is higher

than 200 km/h (125 MPH) for 5 seconds.

(Symptom Code 1)

• The ECM detects that the vehicle speed sensor

signal frequency is too high for 0.6 seconds.

(Symptom Code A)

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM uses a vehicle speed substitution of 5

km/h (3 MPH) for engine control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• Electrical or magnetic interference may affect

intermittent condition.

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

DTC P0500 (Symptom Code 1, A) (Flash Code 24)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Chart for 2WD with A/T

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Inspect all of the circuits going to the automatic

transmission (A/T) vehicle speed sensor (VSS)

for the following:

• Routed too closely to fuel injection solenoid

wiring or components

• Routed too closely to after-market add-on

electrical equipment

• Routed too closely to solenoids, relays, and

motors

2. If you find incorrect routing, correct the harness

routing.

Did you find and correct the condition?

Go to Step 7

Go to Step 3

3

1. Turn OFF the ignition.

2. Disconnect the A/T VSS harness connector.

3. Inspect for an intermittent and for poor

connections at the harness connector of the A/T

VSS (pins 1, 2 and 3 of E-30 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 7

Go to Step 4

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст