Isuzu KB P190. Manual — part 180

BRAKES 5C-21

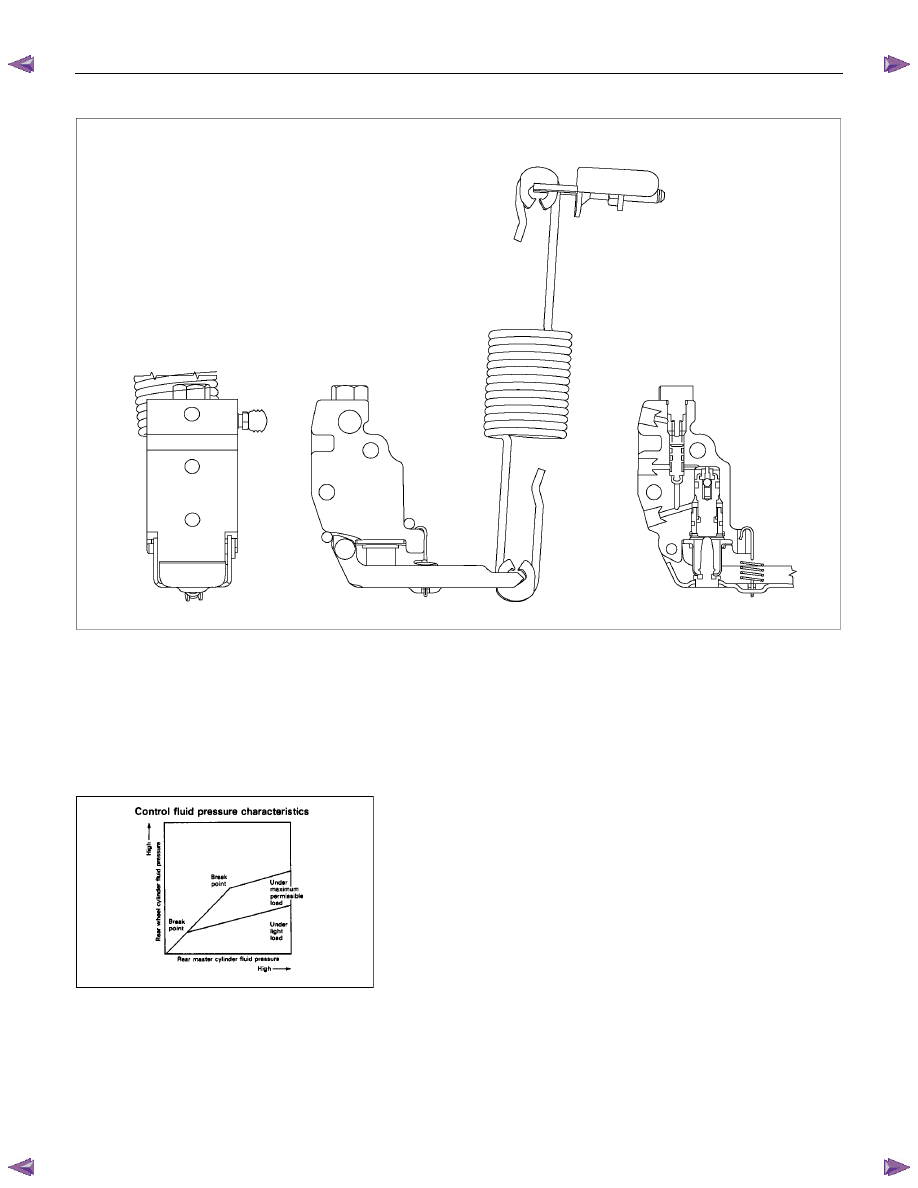

LOAD SENSING PROPORTIONING VALVE (LSPV)

RTW35CMF000101

Structure and Operation

The following is an explanation of the structure and operation

of the spring type load sensing device.

This device controls the fluid pressure to the rear brakes in

accordance with changes in rear axle load (vertical

displacements of the rear axle springs).

•••• Structure

This device consists of a load sensing spring and a valve.

The valve is mounted through a bracket to the frame.

One end of the load sensing spring is fixed to the valve at

the frame and the other end to the rear axle housing

through a bracket.

5C-22 BRAKES

RTW35CSH001001

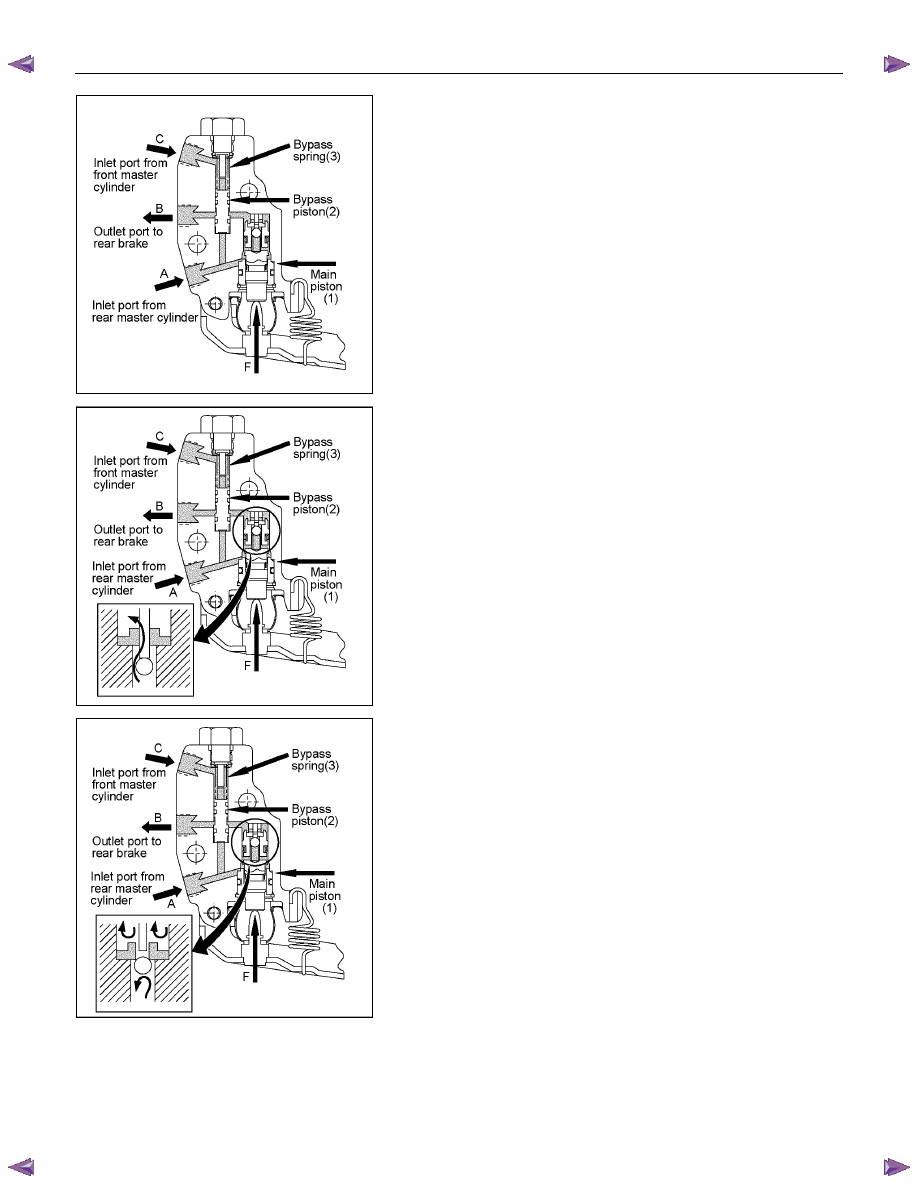

•••• Operation

1) Outline

When the LSPV (Load Sensing Proportioning Valve)

detects a change in load weight, the load sensing spring

stretches.

Its reaction force is transmitted to the bottom of the load

sensing valve to secure an optimum rear wheel cylinder

fluid pressure break point in proportion to the actual load

weight.

Besides, if the front brake system should fail, the device is

designed to prevent the master cylinder fluid pressure from

decreasing and to apply it directly to the rear wheel cylinder

to obtain a sufficient braking performance.

RTW35CSH001101

2) Bellow cutting point.

The Force (F) keeps the main piston (1) the rest position.

The inlet pressure (A) and outlet pressure (B) are the same

as well as the inlet pressure (C) from front master cylinder.

The bypass piston (2) is kept on rest position by equilibrium

of the pressures (A) and (C) and the bypass spring load (3).

RTW35CSH001201

3) Cutting point.

The cutting point is given by relation between force (F), that

is the load applied by suspension of the vehicle and the

main piston area (1). The cutting point is achieved when the

force generated by hydraulic pressure is upper than the

force (F) given by the load suspension. The main piston (1)

moves from the rest position closing the valve. In this

moment the inlet pressure (A) is upper than the outlet

pressure (B). The bypass piston (2) continues on the rest

position by equilibrium of (A) and (C) pressure.

BRAKES 5C-23

RTW35CSH001301

4) Failure on front master cylinder.

In case of failure on front master cylinder the pressure on

the inlet port (C) drop to zero. The pressure from inlet port

(A) acts on the bypass piston (2) and move it by comprising

of bypass spring (3). It makes possible the communication

between the inlet port (A) to outlet port (B) through the

bypass system. The outlet pressure (B) reaches the inlet

pressure (A) and the LSPV is bypassed.

Valve Maintenance

In the case to fluid lead or other a abnormalities, faulty valve

should be replaced.

Note:

The load sensing proportioning valve is not repairable and

must be replaced as a completed assembly.

LOAD SENSING PROPORTIONING

VALVE (LSPV) ADJUSTMENT

RTW35CSH000301

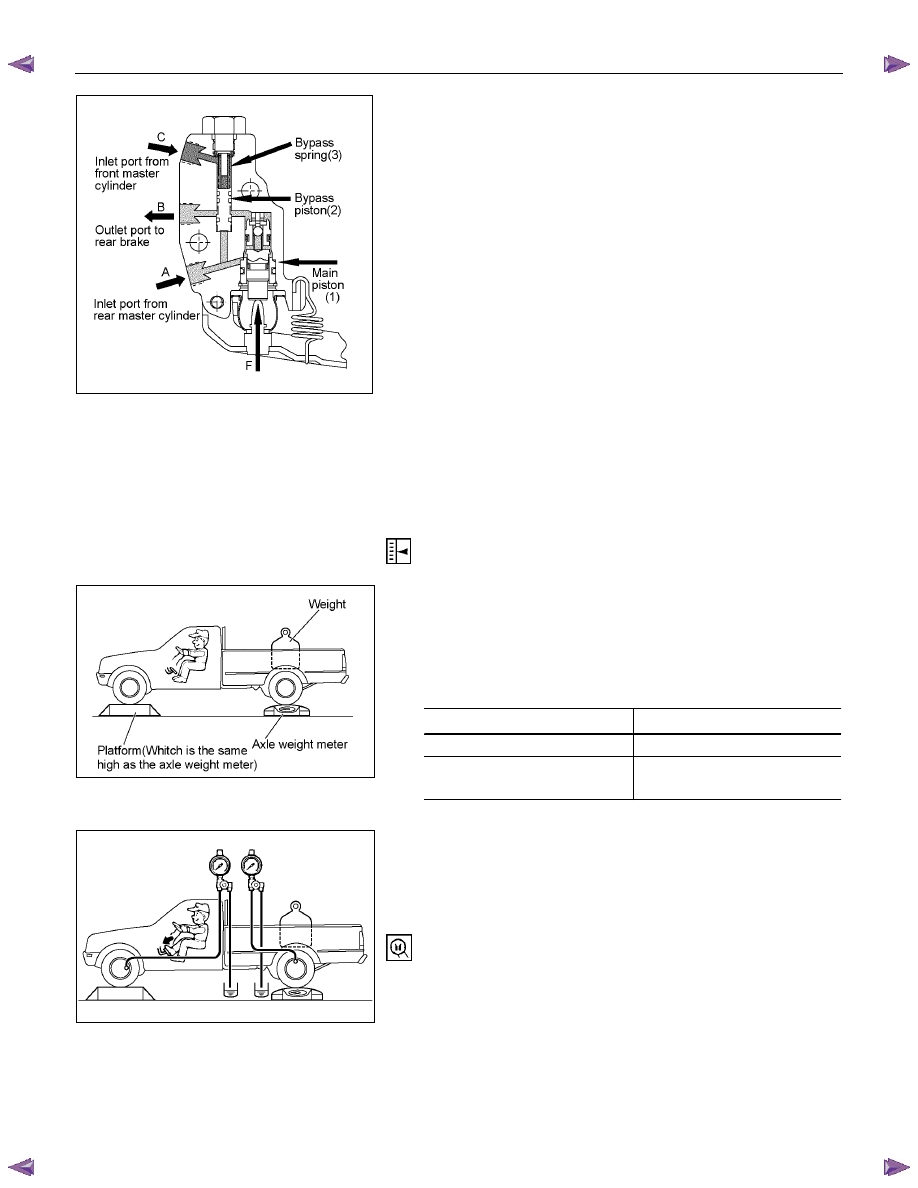

1. Fluid Pressure Measurement

1) Rear axle weight adjustment

With an axle weight meter, adjust the rear axle weight

with a person sitting in the driver’s seat and a weight

loaded in the rear body.

N (kg/lb)

MODEL Adjustment

value

4

× 2

7845 (800/1764)

4

× 2 HIGH RIDE

4

× 4

9316 (950/2095)

RTW35CSH000101

2) Installation of a fluid pressure gauge

Remove the air bleeder of the left hand wheel front and

rear brakes. Bleed air out of the fluid pressure gauge

with the measurement hose of the fluid pressure gauge

installed.

Pressure Tester: Brake oil (Fluid pressure gauge)

5-8840-2190-0

5C-24 BRAKES

RTW35CSH000201

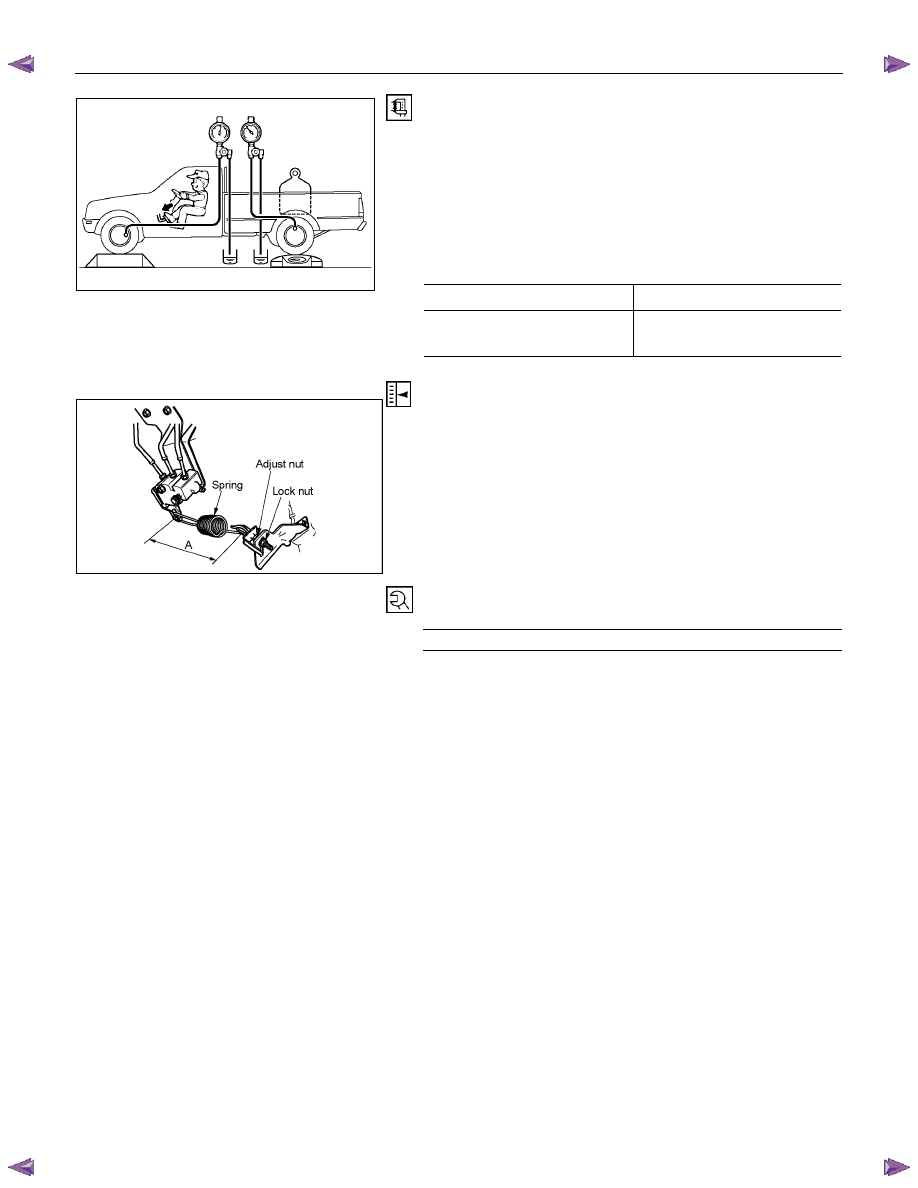

3) Rear wheel cylinder fluid pressure measurement

Step on the brake pedal until the fluid pressure of the

front wheel cylinder gets to 9.8Mpa (100kg/cm

2

), and

check the rear wheel cylinder fluid pressure. (Read the

value of the front wheel cylinder fluid pressure 2

seconds after the measurement. When measuring the

LSPV fluid pressure, keep the brake pedal pressed

down without stepping it down twice or releasing it.)

Rear Wheel Cylinder Fluid Pressure

MPa (kg/cm

2

)

2WD 6.77

±0.83 (69.0±8.5)

2WD (With High Ride

Suspension), 4WD

6.77

±0.83 (69.0±8.5)

RTW35CSH000401

2. Oil Pressure Adjustment

1) LSPV spring length adjustment

Loosen the adjust nut of the LSPV spring joint, and

adjust the length of the LSPV spring.

When the oil pressure is insufficient, turn the adjust nut

clockwise to extend the span “A”. When the oil pressure

is too high, turn the adjust nut counterclockwise to

reduce the span “A”.

2) After adjustment, tighten the lock nut securely.

Lock Nut Torque

N

⋅m (kgf⋅m/lb⋅ft)

11-20 (1.1-2.0/8-14)

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст