Isuzu KB P190. Manual — part 561

6E–74

ENGINE DRIVEABILITY AND EMISSIONS

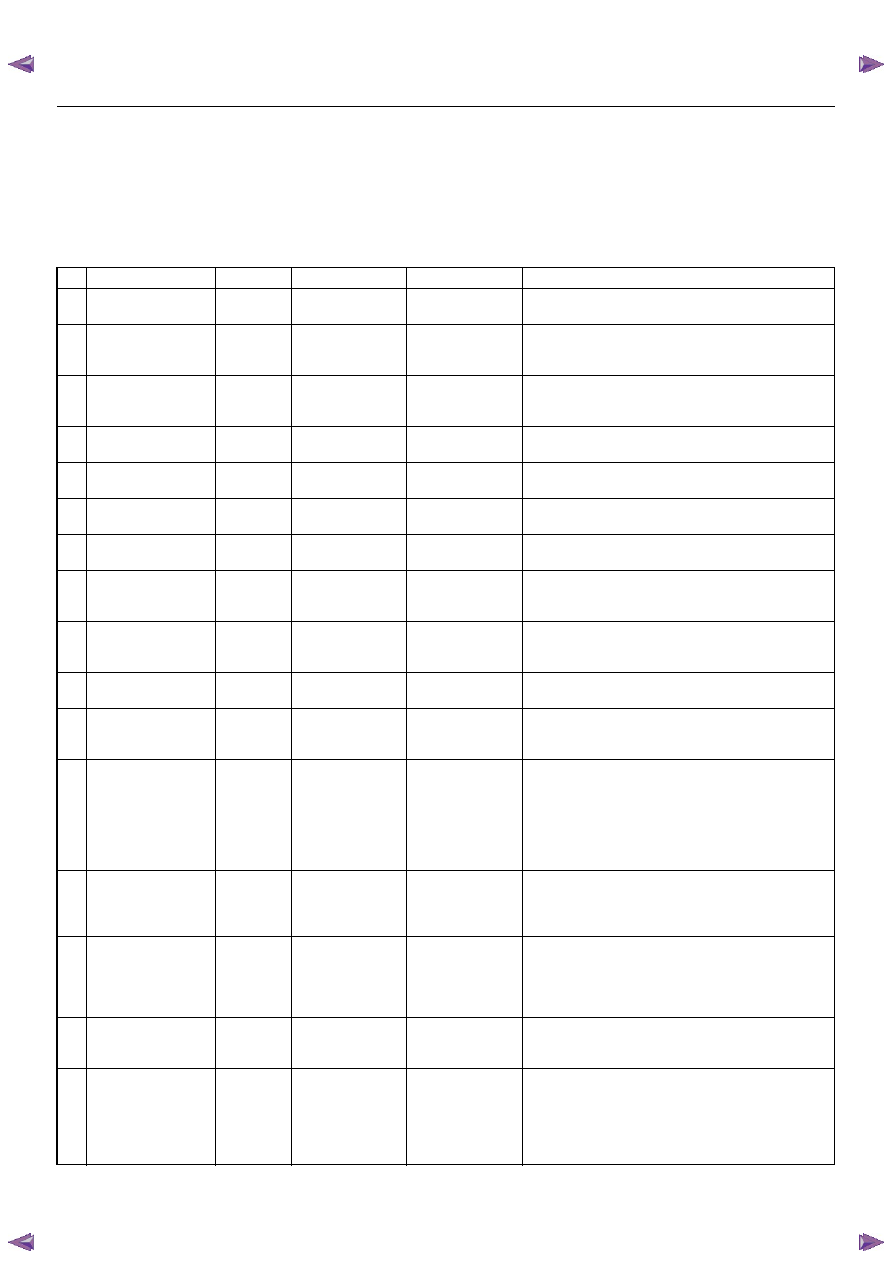

TYPICAL SCAN DATA & DEFINITIONS (O

2

SENSOR DATA)

Use the Typical Values Table only after the On-Board Diagnostic System Check has been completed, no DTC(s) were

noted, and you have determined that the on-board diagnostics are functioning properly. Tech 2 values from a

properly-running engine may be used for comparison with the engine you are diagnosing.

Condition : Vehicle stopping, engine running, air conditioning off & after warm-up (Coolant temperature approximately

80 deg.)

Tech 2 Parameter

Units

Idle

2000rpm

Description

1

Engine Speed

rpm

710 - 875

1950 - 2050

The actual engine speed is measured by ECM from the

CKP sensor 58X signal.

2

Desired Idle Speed

rpm

825

800

-

850

The desired engine idle speed that the ECM

commanding. The ECM compensates for various engine

loads.

3

Engine Coolant

Temperature

°C or °F

80 - 90

80 - 90

The ECT is measured by ECM from ECT sensor output

voltage. When the engine is normally warm upped, this

data displays approximately 80 °C or more.

4

Start Up ECT (Engine

Coolant Temperature)

°C or °F

Depends on ECT

at start-up

Depends on ECT

at start-up

Start-up ECT is measured by ECM from ECT sensor

output voltage when engine is started.

5

Intake Air

Temperature

°C or °F

Depends on

ambient temp

Depends on

ambient temp

The IAT is measured by ECM from IAT sensor output

voltage. This data is changing by intake air temperature.

6

Start Up IAT (Intake

Air Temperature)

°C or °F

Depends on IAT at

start-up

Depends on IAT at

start-up

Start-up IAT is measured by ECM from IAT sensor output

voltage when engine is started.

7

Manifold Absolute

Pressure

kPa

31 - 36

25 - 30

The MAP (kPa) is measured by ECM from MAP output

voltage. This data is changing by inlet manifold pressure.

8

Barometric Pressure

kPa

Depends on

altitude

Depends on

altitude

The barometric pressure is measured by ECM from the

MAP sensor output voltage monitored during key up and

wide open throttle. This data is changing by altitude.

9

Throttle Position

%

0

2 - 4

Throttle position operating angle is measured by the

ECM from throttle position output voltage. This should

display 0% at idle and 99 - 100% at full throttle.

10

Calculated Air Flow

g/s

3.5 -4.50

8.0 - 10.0

This displays intake air amount. The mass air flow is

measured by ECM from the MAF sensor output voltage.

11

Air Fuel Ratio

14.6:1

14.6:1

This displays the ECM commanded value. In closed

loop, this should normally be displayed around 14.2:1 -

14.7:1.

12

Fuel System Status

Open Loop/

Close Loop

Close Loop

Close Loop

When the engine is first started the system is in “Open

Loop” operation. In “Open Loop”, the ECM ignores the

signal from the oxygen sensors. When various

conditions (ECT, time from start, engine speed & oxygen

sensor output) are met, the system enters “Closed Loop”

operation. In “Closed Loop”, the ECM calculates the air

fuel ratio based on the signal from the oxygen sensors.

13

Engine Load

%

2 - 5

5 - 10

This displays is calculated by the ECM form engine

speed and MAF sensor reading. Engine load should

increase with an increase in engine speed or air flow

amount.

14

B1 O

2

Sensor Ready

(Bank 1)

Yes/No

Yes

Yes

This displays the status of the exhaust oxygen sensor.

This display will indicate “Yes” when the ECM detects a

fluctuating oxygen sensor output voltage sufficient to

allow closed loop operation. This will not occur unless

the oxygen sensor is warmed up.

15

B1S1 Status

(Bank 1 Sensor 1)

Rich / Lean

Rich / Lean

Rich / Lean

This displays dependent on the exhaust oxygen sensor

output voltage. Should fluctuate constantly “Rich” and

“Lean” in closed loop.

16

Fuel Trim Learned

Yes/No

Yes

Yes

When conditions are appropriate for enabling long term

fuel trim corrections, fuel trim learn will display “Yes”.

This indicates that the long term fuel trim is responding

to the short term fuel trim. If the fuel trim lean displays

“No”, then long term fuel trim will not respond to changes

in short term fuel trim.

ENGINE DRIVEABILITY AND EMISSIONS

6E–75

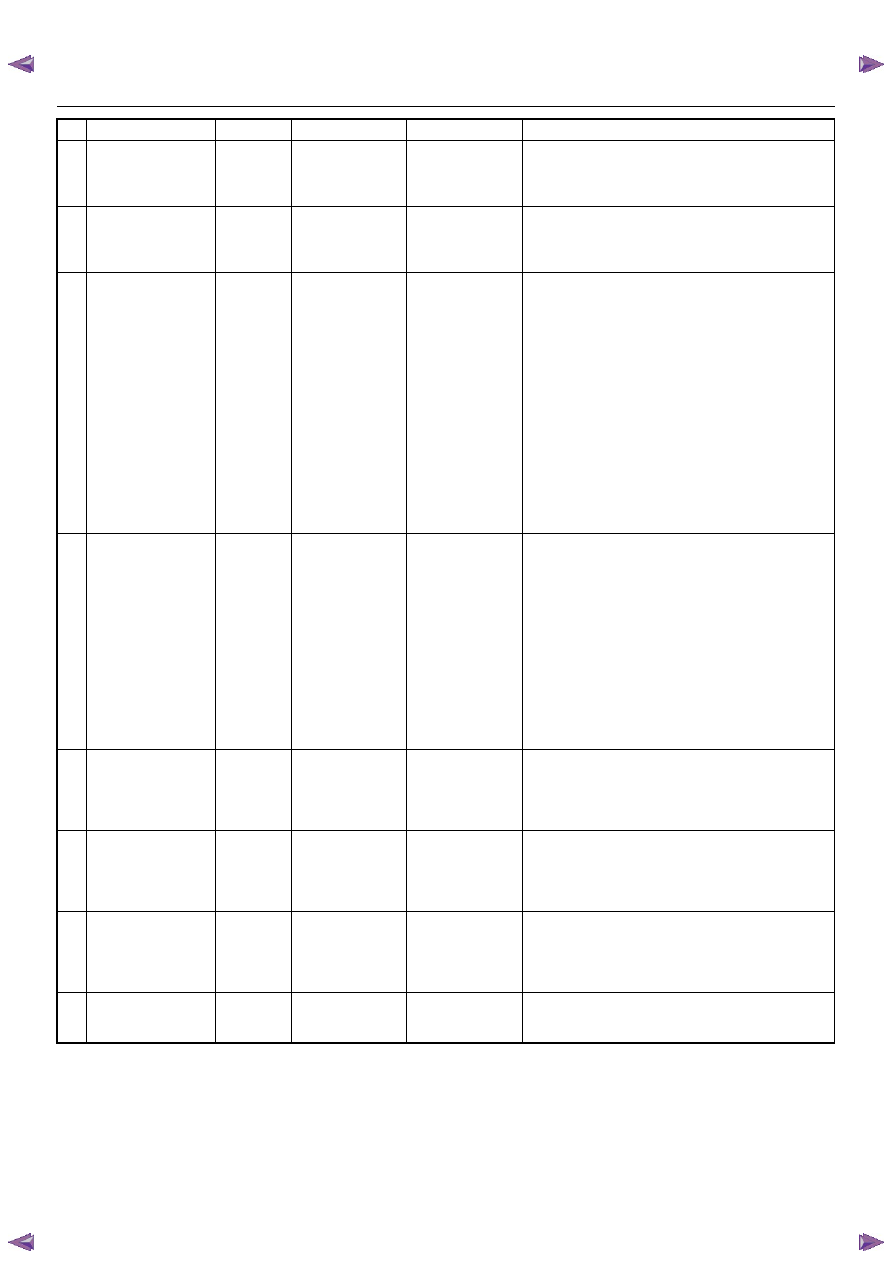

17

Fuel Trim Cell

15 - 20

1 - 2

This displays dependent on engine speed and calculated

intake air flow reading. A plot of engine speed versus

intake air flow amount is divided into the cells. Fuel trim

cell indicates which cell is currently active.

18

B1S1 O

2

Sensor

(Bank1 Sensor 1)

mV

50 - 950

50 -950

This displays the exhaust oxygen sensor output voltage.

Should fluctuate constantly within a range between

10mV (lean exhaust) and 1000mV (rich exhaust) while

operating in closed loop.

19

B1 Short Term Fuel

Trim (Bank 1)

%

-6 - 0

-6 - 0

The short term fuel trim to a bank represents a short term

correction to the bank fuel delivery by the ECM in

response to the amount of time the bank fuel control

oxygen sensor voltage spends above or below the

450mV threshold. If the oxygen sensor voltage has

mainly remained less than 450mV, indicating a lean air/

fuel, short term fuel trim will increase into the positive

range above 0% and the ECM will pass fuel. If the

oxygen sensor voltage stays mainly above the threshold,

short term fuel trim will decrease below 0% into the

negative range while the ECM reduces fuel delivery to

compensate for the indicated rich condition. Under

certain conditions such as extended idle and high

ambient temperatures, canister purge may cause short

term fuel trim to read in the negative range during normal

operation. Fuel trim values at maximum authority may

indicate an excessively rich or lean system.

20

B1 Long Term Fuel

Trim (Bank 1)

%

-10 - 0

-5 - 0

The long term fuel trim is delivered from the short term

fuel term values and represents a long term correction of

fuel delivery for bank in question. A value of 0% indicates

that fuel delivery requires no compensation to maintain

the ECM commanded air fuel ratio. A negative value

indicates that the fuel system is rich and fuel delivery is

being reduced (decreased injector pulse width). A

positive value indicates that a lean condition exists and

the ECM is compensating by add fuel (increased injector

pulse width). Because long term fuel trim tends to follow

short term fuel trim, a value in the negative range due to

canister purge at idle should not be considered unusual.

Fuel trim values at maximum authority may indicate an

excessively rich or lean system.

21

Injection Pulse Width

ms

3.0 - 1.0

3.0

-

4.0

This displays the amount of time the ECM is

commanding each injector On during each engine cycle.

A longer injector pulse width will cause more fuel to be

delivered. Injector pulse width should increase with

increased engine load.

22

Power Enrichment

Yes/No

No

No

The ECM provides the extra amount of fuel when it

detects a rapid increase in the throttle position and air

flow (Power Enrichment). Under this condition the ECM

should detect a “rich condition (high oxygen sensor

voltage).

23

Deceleration Fuel

Cutoff

Active/

Inactive

Inactive

Inactive

The ECM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air

flow. When deceleration is very fast, the ECM may cut off

fuel completely. Until enable conditions meet the engine

revolution less than 1000rpm or MAP less than 10kPa.

24

Time From Start

-

-

This displays the engine time elapsed since the engine

was started. If the engine is stopped, engine run time will

be reset to 00:00:00

Tech 2 Parameter

Units

Idle

2000rpm

Description

6E–76

ENGINE DRIVEABILITY AND EMISSIONS

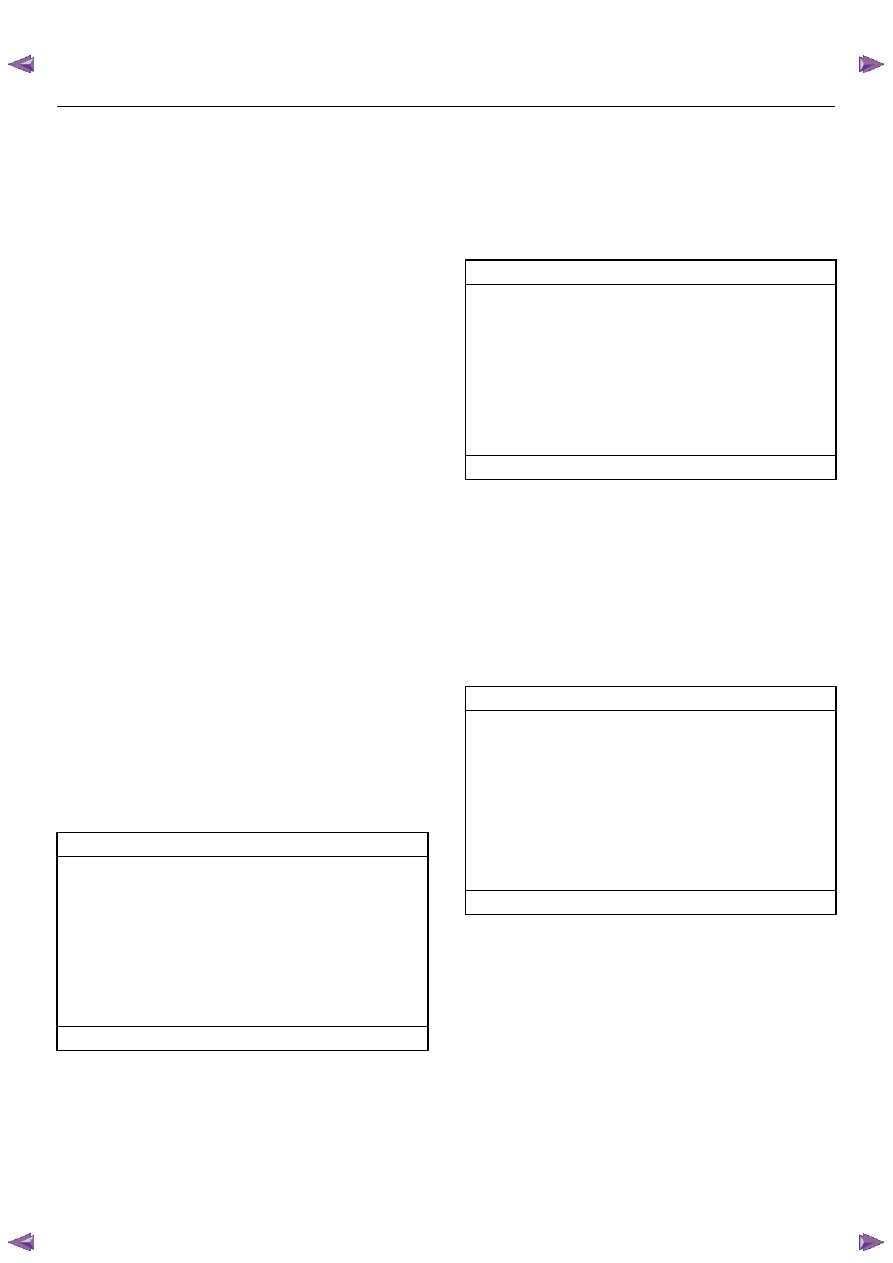

MISCELLANEOUS TEST

The state of each circuit can be tested by using

miscellaneous test menus. Especially when DTC

cannot be detected, a faulty circuit can be diagnosed by

testing each circuit by means of these menus.

Even DTC has been detected, the circuit tests using

these menus could help discriminate between a

mechanical trouble and an electrical trouble.

Connect Tech 2 and select “Powertrain”, “2.XL L4

HV240” & “Miscellaneous Test”.

F0: Lamps

F0: Malfunction Indicator Lamp

When the Tech 2 is operated, “Malfunction Indicator

Lamp (Check Engine Lamp)” is turned on or off.

The circuit is normal if the “Malfunction Indicator Lamp

(Check Engine Lamp)” in the instrument panel is turned

on or off in accordance with this operation.

F1: Relays

F0: Fuel Pump Relay

When the Tech 2 is operated, fuel pump relay signal

turns ON or OFF.

The circuit is normal if fuel pump sound is generated in

accordance with this operation when key switch is

turned ON.

F1: A/C Clutch Relay

When the Tech 2 is operated, A/C clutch relay signal

turns ON or OFF.

The circuit is normal if A/C compressor clutch is

energized in accordance with this operation when the

engine is running.

F2: EVAP

F0: Purge Solenoid

When the Tech 2 is operated, duty ratio of EVAP purge

solenoid is changed 10%-by-10%.

• Press “Increase” key.

Then, EVAP Purge Solenoid is increases 10%-by-

10%.

• Press “Quit” Key.

F3: IAC System

F0: IAC Control

When the Tech 2 is operated, “Idle Air Control”

increases or decreases 5steps-by-5steps up to

150steps.

The circuit is normal if idle engine speed is changed in

accordance with this operation.

• Press “Increase” key.

Then, Idle Air Control is increases 1osteps-by-

10steps up to 160steps. Engine speed is also

changed by this operation.

• Press “Quit” Key.

F1: IAC Reset

When the Tech 2 is operated, “Idle Air Control” resets.

The circuit is normal if idle engine speed is droped in

accordance with this operation.

• Press “Increase” key.

Then, Desired Idle speed is increases 50rpm-by-

50rpm up to 1550rpm. Engine speed is also changed

by this operation.

• Press “Quit” Key.

Purge Solenoid

Engine Speed

800 RPM

Desired Idle Speed

762 RPM

Engine Coolant Temperature

80 °C

Start Up ECT

50 °C

Intake Air Temperature

30 °C

Start Up IAT

25 °C

Manifold Absolute Pressure

35kPa

EVAP Purge Solenoid

30%

IAC Control

Engine Speed

800 RPM

Desired Idle Speed

762 RPM

Engine Coolant Temperature

80 °C

Start Up ECT

50 °C

Intake Air Temperature

30 °C

Start Up IAT

25 °C

Manifold Absolute Pressure

35kPa

Idle Air Control

30 Steps

IAC Reset

Engine Speed

800 RPM

Desired Idle Speed

762 RPM

Engine Coolant Temperature

80 °C

Start Up ECT

50 °C

Intake Air Temperature

30 °C

Start Up IAT

25 °C

Manifold Absolute Pressure

35kPa

Idle Air Control

30 Steps

ENGINE DRIVEABILITY AND EMISSIONS

6E–77

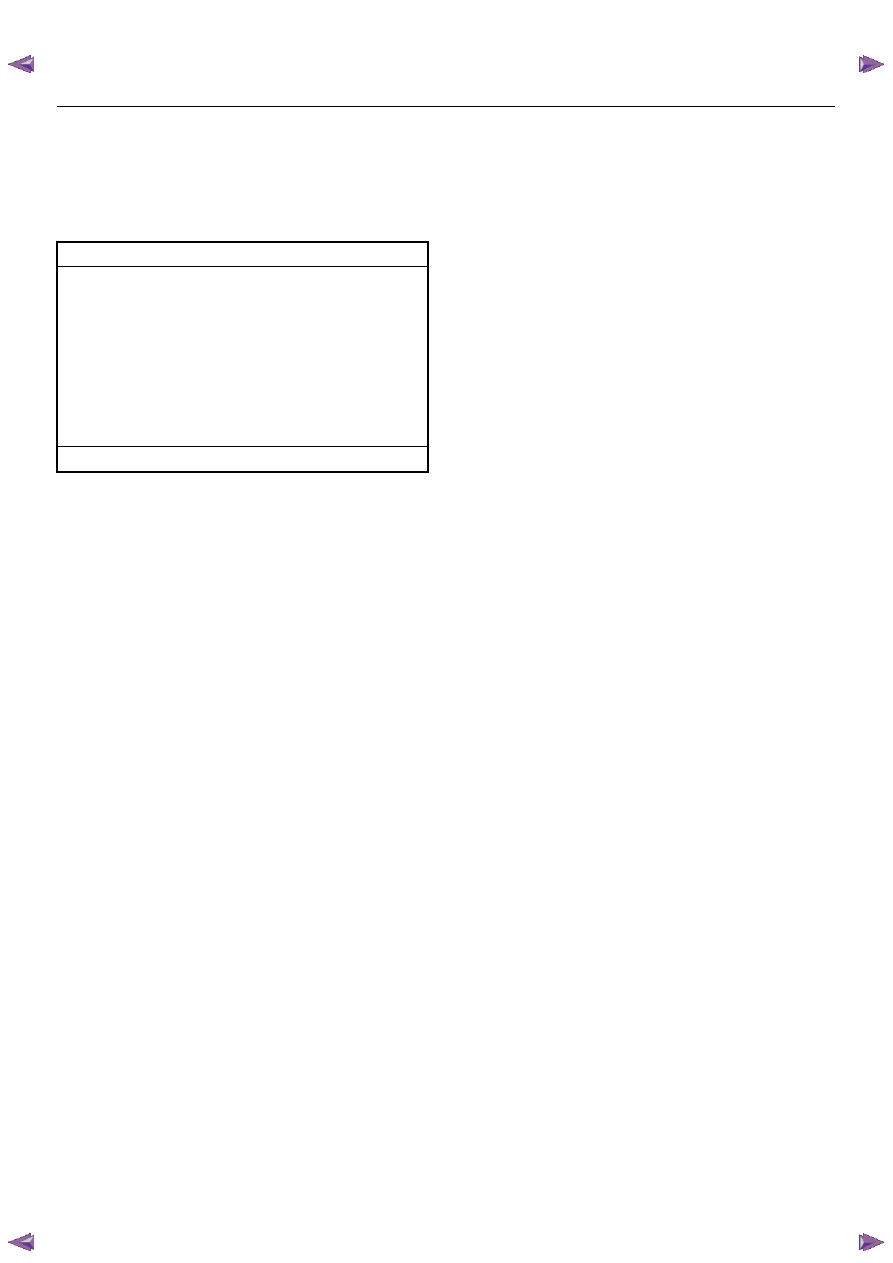

F4: Injector Balance Test

When the Tech 2 is operated, selected injector turns ON

or OFF.

The circuit is normal if engine vibration is changed at

selected cylinder in accordance with this operation

when engine is idling.

• Press “Injector Off” key.

Then, engine speed drops and vibration occurs when

a cylinder is selected.

• Press “Quit” Key.

Injector Balance Test

Engine Speed

800 RPM

Desired Idle Speed

762 RPM

Engine Coolant Temperature

80

Start Up ECT

50

Intake Air Temperature

30

Start Up IAT

25

Manifold Absolute Pressure

35kPa

Injector 1

On

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст