Isuzu KB P190. Manual — part 277

6E-74 Engine Control System (4JH1)

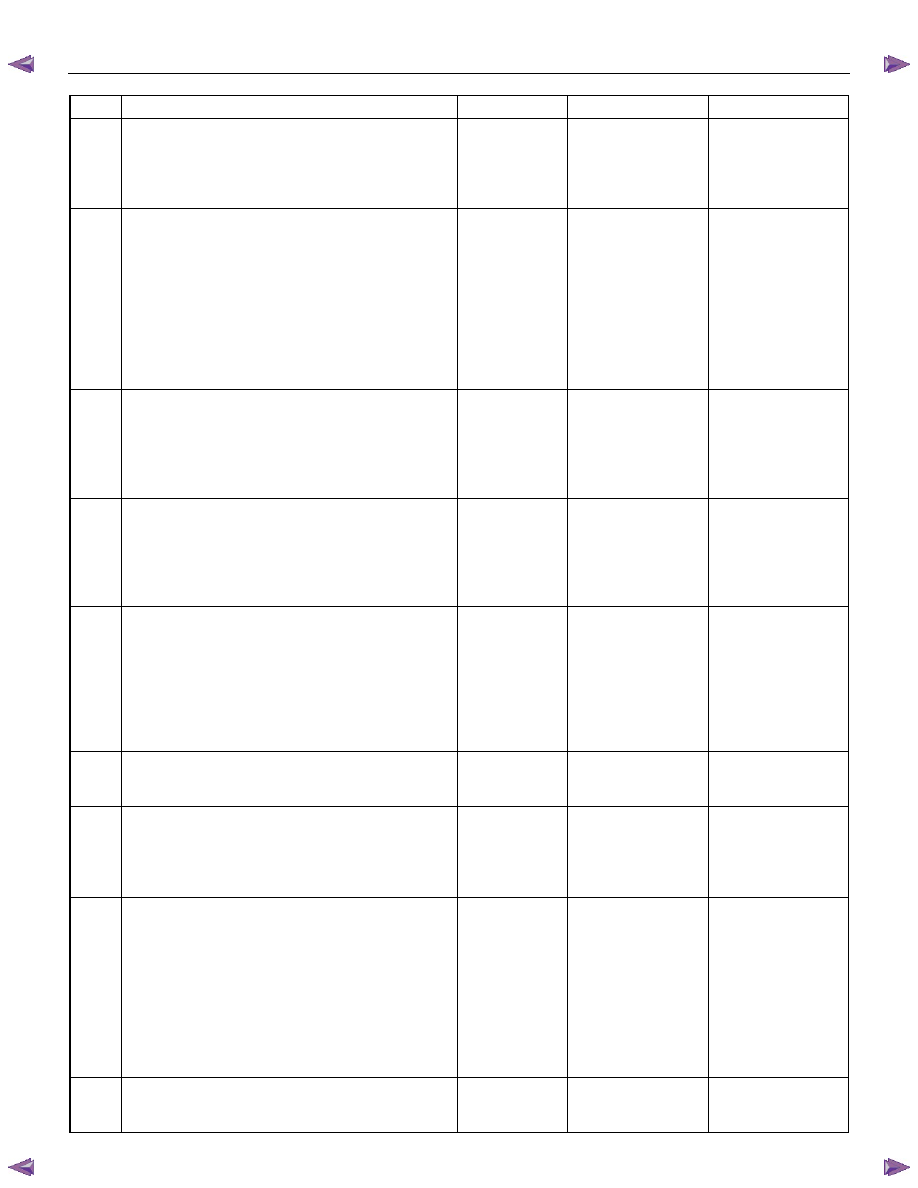

Step Action

Value(s)

Yes

No

4

1. Turn OFF the ignition.

2. Connect a test lamp between the low reference

circuit of the MAF sensor harness (pin 3 of C-116

connector) and a battery voltage.

Does the test lamp illuminate?

Go to Step 7

Go to Step 6

5

Important: The MAF sensor may be damaged if the

sensor signal circuit is shorted to a voltage source.

1. Test the signal circuit between the engine control

module (ECM) (pin 88 of C-57 connector) and

the MAF sensor (pin 5 of C-116 connector) for

the following conditions:

• A short to battery or ignition voltage

• A short to 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11

Go to Step 10

6

1. Test the low reference circuit between the ECM

(pin 92 of C-57 connector) and the MAF sensor

(pin 3 of C-116 connector) for an open circuit or

high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 11

Go to Step 8

7

1. Turn OFF the ignition.

2. Inspect for an intermittent and for a poor

connection at the harness connector of the MAF

sensor (pin 3 of C-116 connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11

Go to Step 9

8

1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor

connection on the MAF sensor circuit at the

harness connector of the ECM (pin 92 of C-57

connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 11

Go to Step 10

9

Replace the MAF sensor. Refer to Mass Air Flow

Sensor Replacement in this section.

Did you complete the replacement?

Go to Step 11

10

Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 11

11

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Accelerate the engine between idle and W.O.T.

(accelerator pedal full travel) many times while

observing the DTC Information with the scan

tool.

Did the DTC fail this ignition?

Go to Step 3

Go to Step 12

12

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Engine Control System (4JH1) 6E-75

DTC P0105 (Symptom Code 1) (Flash Code 34)

Circuit Description

The vacuum pressure sensor is installed to the

turbocharger wastegate control hose and it detects the

regulated vacuum pressure to the turbocharger

wastegate valve. The vacuum pressure sensor is a

transducer that varies voltage according to changes in

the vacuum pressure inside the vacuum hose. The

vacuum pressure sensor has the following circuits.

• 5 volts reference circuit

• Low reference circuit

• Vacuum pressure sensor signal circuit

The engine control module (ECM) supplies 5 volts to

the vacuum pressure sensor on the 5 volts reference

circuit. The ECM also provides a ground on the low

reference circuit. The vacuum pressure sensor provides

a signal to the ECM on the vacuum pressure signal

circuit which is relative to the vacuum pressure changes

in the turbocharger wastegate valve control hose. The

ECM should detect a low signal voltage at a high

vacuum pressure and high signal voltage at a low

vacuum pressure. The ECM monitors the vacuum

pressure sensor signal for voltage outside the normal

range of the vacuum pressure sensor. If the ECM

detects an excessively high vacuum pressure sensor

signal voltage, this DTC will set.

Condition for Running the DTC

• The ignition switch is ON.

Condition for Setting the DTC

• The ECM detects that the vacuum pressure

sensor signal voltage is more than 4.4 volts for 3

seconds.

Action Taken When the DTC Sets

• The ECM illuminates the malfunction indicator

lamp (MIL) when the diagnostic runs and fails.

• The ECM limits fuel injection quantity.

• The ECM uses a barometric pressure of 615 hPa

for turbocharger wastegate valve control.

Condition for Clearing the MIL/DTC

• The ECM turns OFF the MIL when the diagnostic

runs and does not fail.

• A history DTC clears after 40 consecutive driving

cycles without a fault. Or clear with the scan tool.

Diagnostic Aids

• If an intermittent condition is suspected, refer to

Intermittent Conditions in this section.

Test Description

The number below refers to the step number on the

diagnostic table.

3. If the vacuum pressure sensor signal circuit between

the ECM and the sensor is normal, the sensor signal

voltage low DTC P0105 (Symptom Code 2) will set.

DTC P0105 (Symptom Code 1) (Flash Code 34)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

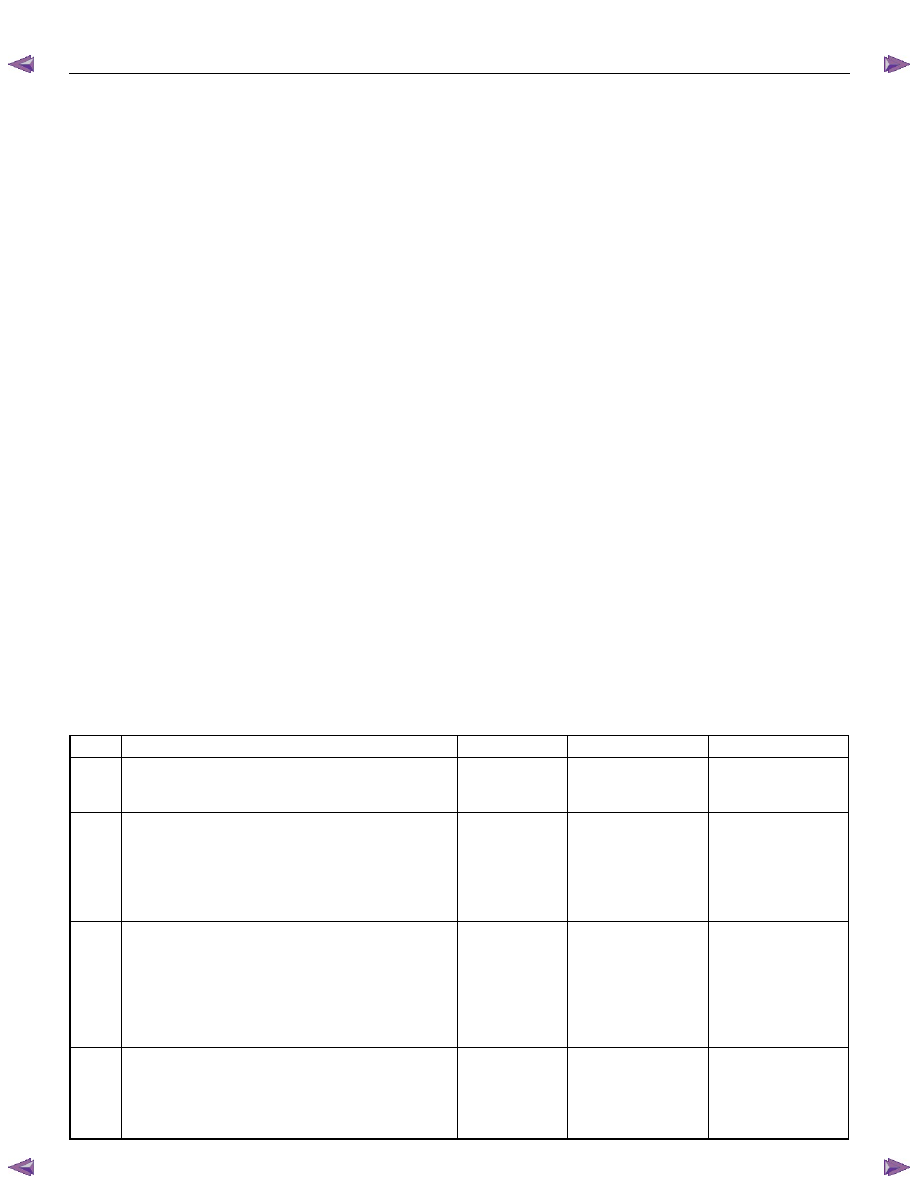

Step Action

Value(s)

Yes

No

1

Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2

Go to Diagnostic

System Check-

Engine Controls

2

1. Install the scan tool.

2. Turn OFF the ignition for 30 seconds.

3. Start the engine.

4. Monitor the Diagnostic Trouble Code (DTC)

Information with the scan tool.

Does the DTC fail this ignition?

Go to Step 3

Go to Diagnostic

Aids

3

1. Turn OFF the ignition.

2. Disconnect the vacuum pressure sensor harness

connector.

3. Turn ON the ignition, with the engine OFF.

4. Monitor the DTC Information with the scan tool.

Does DTC P0105 (Symptom Code 2) set, but not

DTC P0105 (Symptom Code 1)?

Go to Step 4

Go to Step 6

4

1. Turn OFF the ignition.

2. Connect a test lamp between the low reference

circuit of the vacuum pressure sensor harness

(pin 2 of C-124 connector) and battery voltage.

Does the test lamp illuminate?

Go to Step 5

Go to Step 7

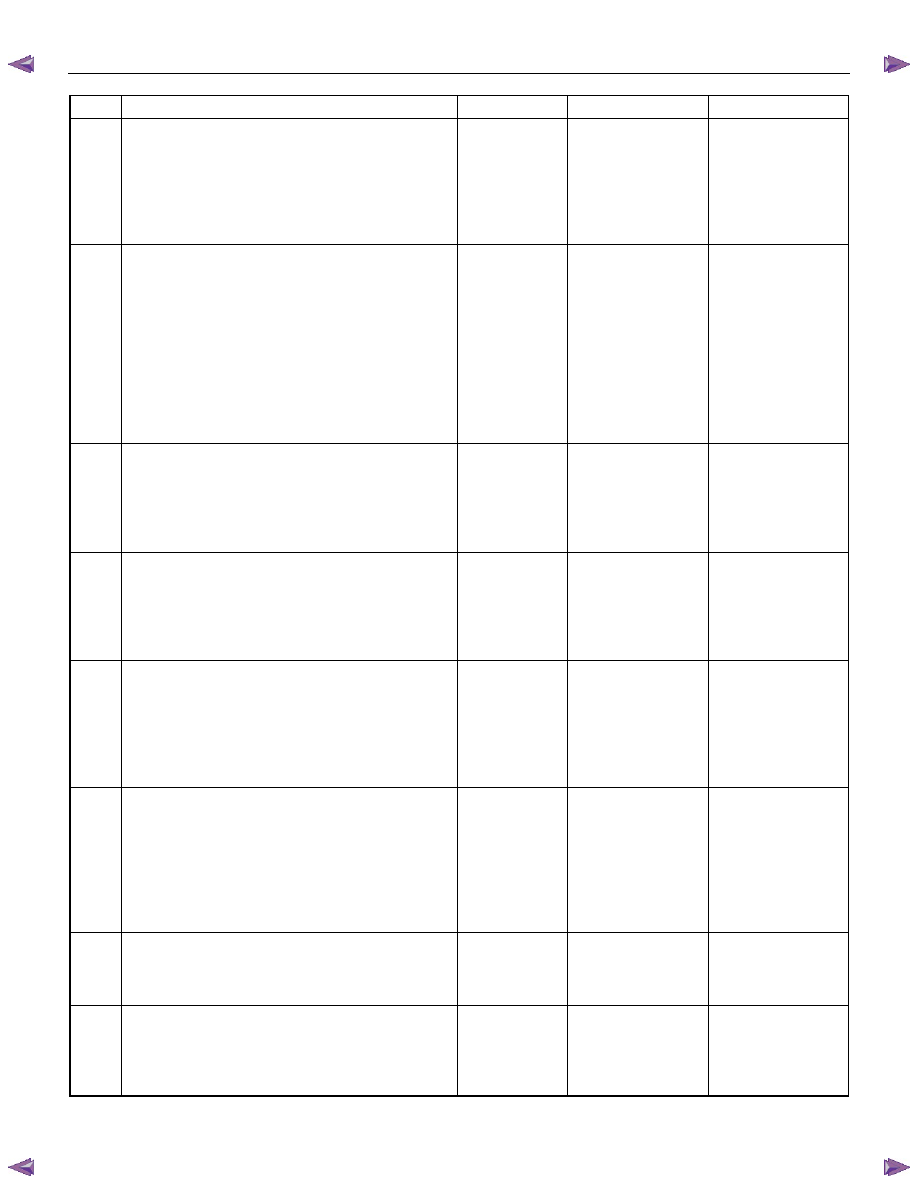

6E-76 Engine Control System (4JH1)

Step Action

Value(s)

Yes

No

5

1. Turn OFF the ignition.

2. Connect a DMM between the 5 volts reference

circuit of the vacuum pressure sensor harness

(pin 3 of C-124 connector) and a known good

ground.

3. Turn ON the ignition, with the engine OFF.

Is the DMM voltage more than the specified value?

5.5 volts

Go to Step 8

Go to Step 9

6

Important: The vacuum pressure sensor may be

damaged if the sensor signal circuit is shorted to a

voltage source.

1. Test the signal circuit between the engine control

module (ECM) (pin 85 of C-57 connector) and

the vacuum pressure sensor (pin 1 of C-124

connector) for the following conditions:

• A short to battery or ignition voltage

• A short to any 5 volts reference

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13

Go to Step 12

7

1. Test the low reference circuit between the ECM

(pin 93 of C-57 connector) and the vacuum

pressure sensor (pin 2 of C-124 connector) for

an open circuit or high resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13

Go to Step 10

8

1. Test the 5 volts reference circuit between the

ECM (pin 57 of C-56 connector) and the vacuum

pressure sensor (pin 1 of C-124 connector) for a

short to battery or ignition voltage.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 13

Go to Step 12

9

1. Turn OFF the ignition.

2. Inspect for an intermittent and for a poor

connection at the harness connector of the

vacuum pressure sensor (pin 2 of C-124

connector).

3. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 13

Go to Step 11

10

1. Turn OFF the ignition.

2. Disconnect the ECM harness connector.

3. Inspect for an intermittent and for a poor

connection on the vacuum pressure sensor

circuit at the harness connector of the ECM (pin

93 of C-57 connector).

4. Repair the connection(s) as necessary.

Did you find and correct the condition?

Go to Step 13

Go to Step 12

11

Replace the vacuum pressure sensor. Refer to

Vacuum Pressure Sensor Replacement in this

section.

Did you complete the replacement?

Go to Step 13

12

Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 13

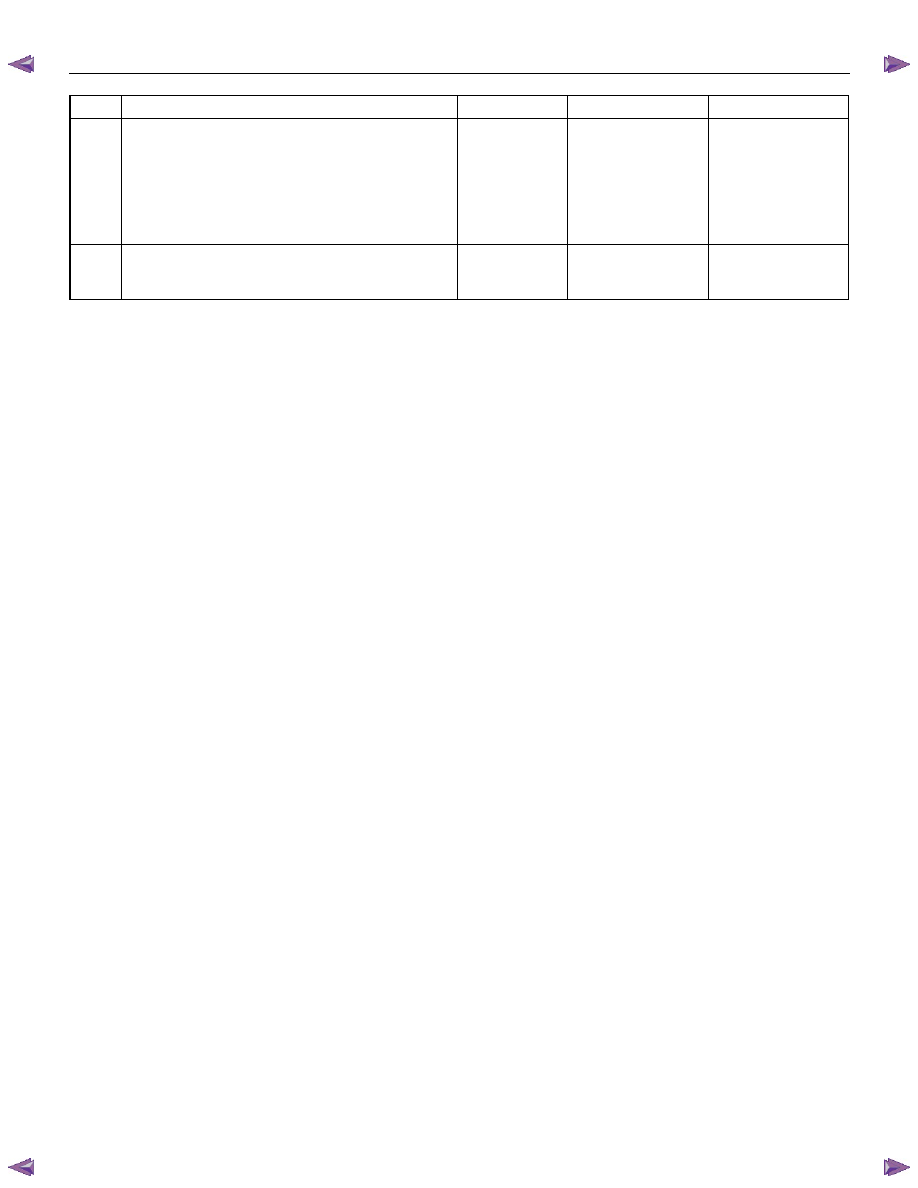

Engine Control System (4JH1) 6E-77

Step Action

Value(s)

Yes

No

13

1. Reconnect all previously disconnected harness

connector(s).

2. Clear the DTCs with the scan tool.

3. Turn OFF the ignition for 30 seconds.

4. Start the engine.

5. Monitor the DTC Information with the scan tool.

Did the DTC fail this ignition?

Go to Step 3

Go to Step 14

14

Observe the DTC Information with the scan tool.

Are there any DTCs that you have not diagnosed?

Go to Diagnostic

Trouble Code (DTC)

List System

OK

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст