Isuzu KB P190. Manual — part 967

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–82

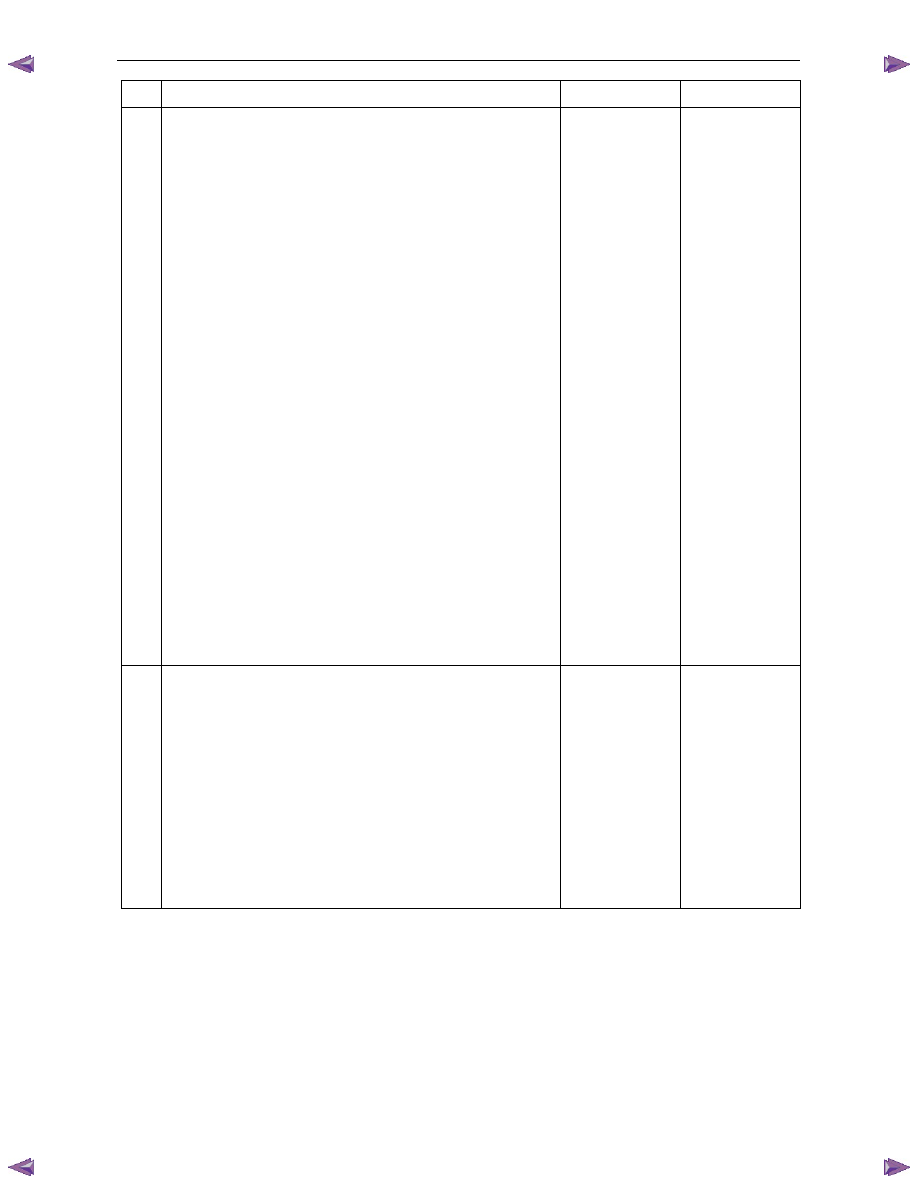

Step Action

Yes

No

3

1

Connect Tech 2 to the DLC.

2

Turn on the ignition, with the engine off.

N O T E

Before clearing the DTC, use the Tech

2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3

On Tech 2 select:

Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4

Select the relevant DTC and note the parameters at the time of

the DTC setting.

5

On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6

Follow the instructions on Tech 2 and clear the DTCs.

N O T E

It may be necessary to allow multiple TCC cycles to occur

to verify a slipping condition. It may also be necessary to

ensure the transmission is warm before performing this

step.

7

On Tech 2 select:

Automatic Transmission / Data Display / Transmission Data.

8

Drive the vehicle in 4th gear with the TCC commanded on.

On Tech 2, while TCC Solenoid status is On, is the TCC Slip Speed

within 130 – 800 RPM for 7 seconds?

Go to Step 4

Refer to Diagnostic

Aids within this

Section

4

1

Inspect the torque converter clutch (TCC) solenoid valve for the

following conditions:

•

internal malfunction, such as sediment or damage, and

•

damaged seals, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

2

Inspect the torque converter clutch pulse width modulation

(TCC PWM) solenoid valve for the following conditions:

•

internal malfunction, such as sediment or damage, and

•

damaged seals, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

Did you find and correct the condition?

Go to Step 14

Go to Step 5

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–83

Step Action

Yes

No

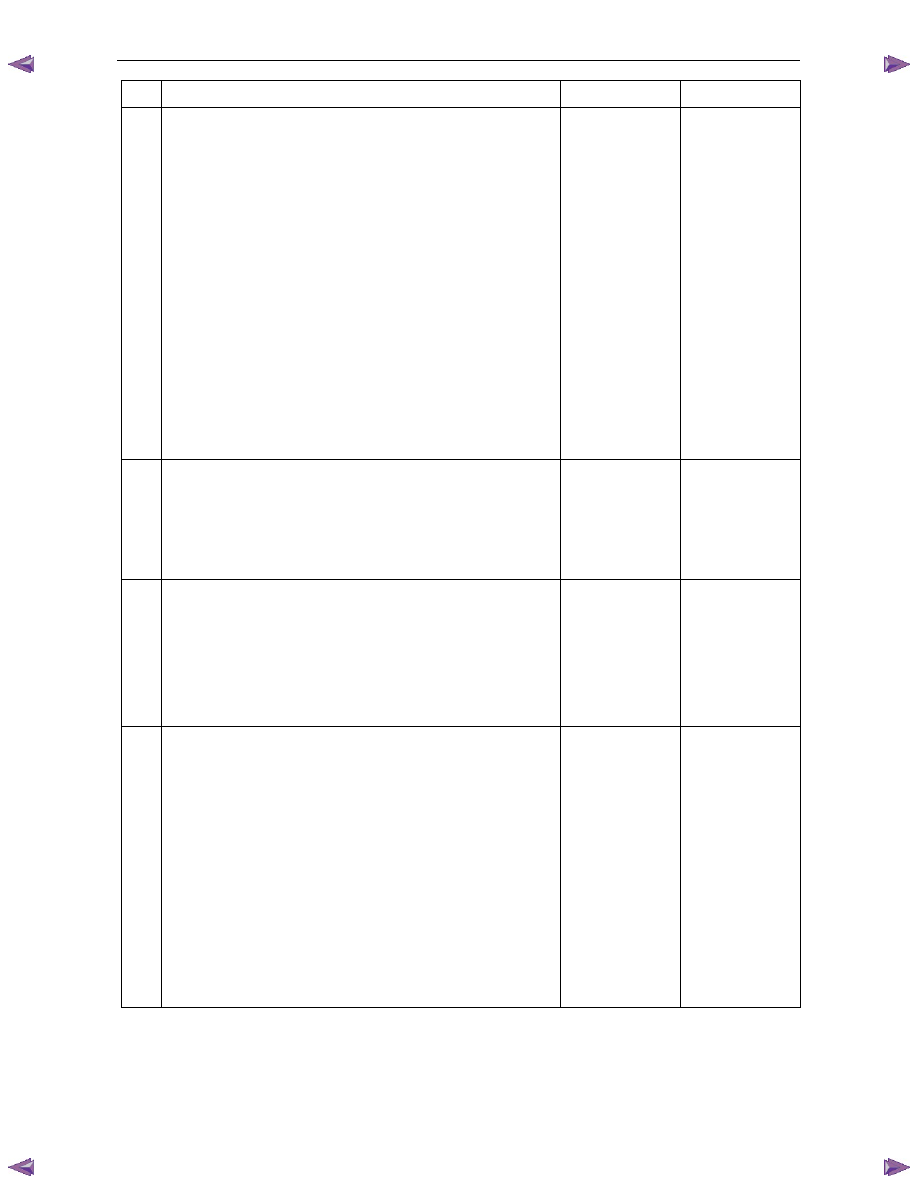

5

1

Inspect the 1-2 shift solenoid (SS) valve for the following

conditions:

•

internal malfunction, such as sediment or damage, and

•

damaged seals, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

2

Inspect the 2-3 shift solenoid (SS) valve for the following

conditions:

•

internal malfunction, such as sediment or damage, and

•

damaged seals, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

3

Inspect the 3-2 shift solenoid valve assembly for the following

conditions:

•

internal malfunction, such as sediment or damage, and

•

damaged seals, 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing.

Did you find and correct the condition?

Go to Step 14

Go to Step 6

6

Inspect the valve body assembly for the following conditions:

•

stuck regulator apply valve, and

•

scored regulator apply valve body, refer to 7C5 Automatic

Transmission – 4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 7

7

Inspect the torque converter assembly for the following conditions:

•

front stator shaft bushing for wear,

•

stator roller clutch not holding, and

•

external damage/leaks, refer to 7C5 Automatic Transmission –

4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 8

8

Inspect the oil pump assembly for the following conditions:

•

a stuck converter clutch valve,

•

the converter clutch valve is assembled backwards,

•

a incorrectly position converter clutch valve retaining ring,

•

a cocked converter clutch outer valve spring,

•

a incorrectly positioned pump to case gasket,

•

restricted orifice cup plugs,

•

damaged orifice cup plugs, and

•

over-tightened, or unevenly tightened pump body to cover bolts,

refer to 7C5 Automatic Transmission – 4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 9

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–84

Step Action

Yes

No

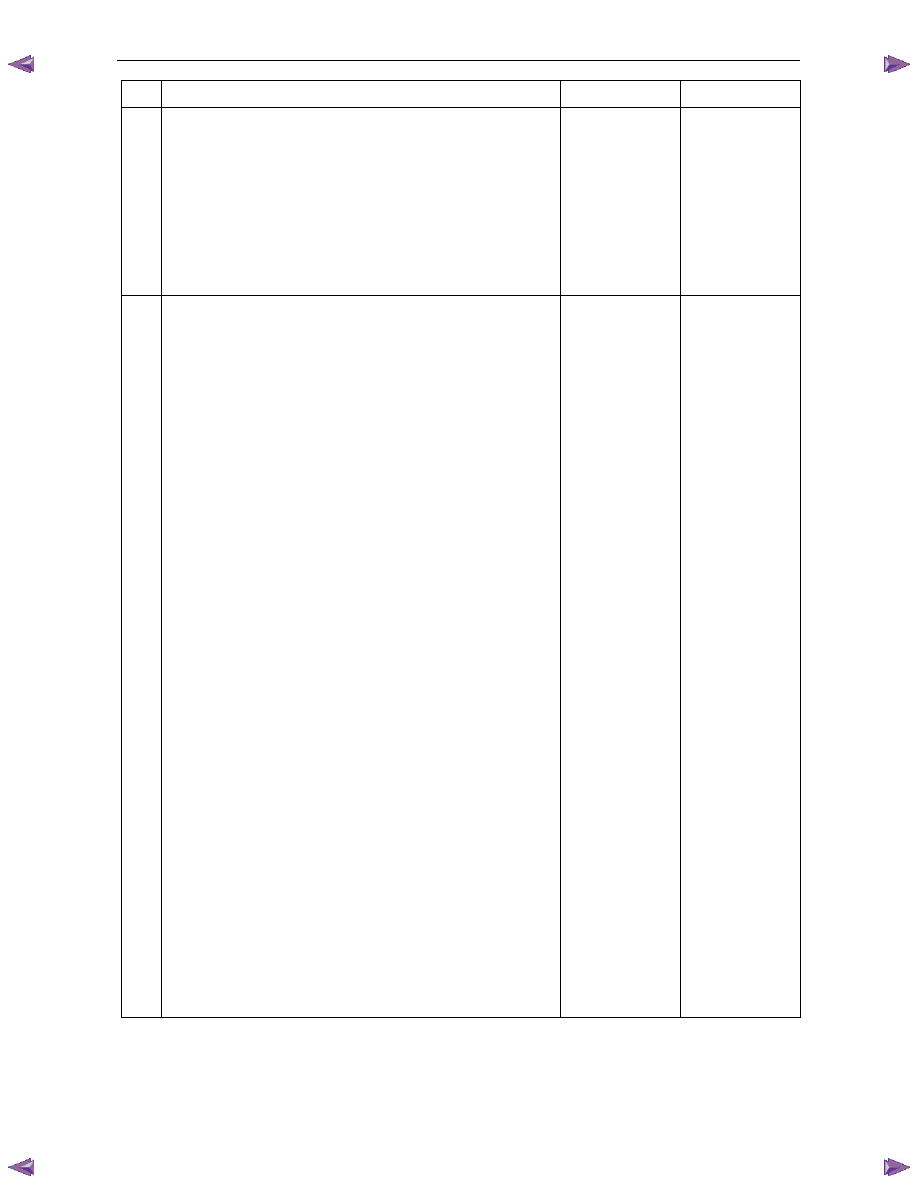

9

Inspect the input housing and shaft assembly for the following

conditions:

•

cut turbine shaft O-ring seal,

•

damaged turbine shaft O-ring seal,

•

restricted turbine shaft retainer and ball assembly, and

•

damaged turbine shaft retainer and ball assembly, refer to 7C5

Automatic Transmission – 4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 10

10 1

Inspect the 2-4 band assembly for the following conditions:

•

worn 2-4 band,

•

damaged 2-4 band,

•

incorrectly positioned 2-4 band,

•

incorrectly assembled 2-4 band, and

•

the band anchor pin is not engaged, refer to 7C5

Automatic Transmission – 4L60E – Unit Repair.

2

Inspect the 2-4 servo assembly for the following conditions:

•

restricted apply passages in the 2-4 servo assembly,

•

blocked apply passages in the 2-4 servo assembly,

•

nicks or burrs on the 2nd apply piston pin,

•

damaged 2nd apply piston pin,

•

incorrect 2nd apply piston pin,

•

nicks or burrs on the pin bore in the case,

•

damaged fourth servo piston,

•

incorrectly assembled fourth servo piston,

•

damaged servo bore in the case,

•

missing piston seals,

•

cut piston seals,

•

damaged piston seals,

•

porosity in the pistons,

•

porosity in the cover,

•

porosity in the case,

•

damaged piston seal grooves,

•

plugged orifice cup plug, and

•

missing orifice cup plug, refer to 7C5 Automatic

Transmission – 4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 11

Automatic Transmission – 4L60E – Electrical Diagnosis

Page 7C2–85

Step Action

Yes

No

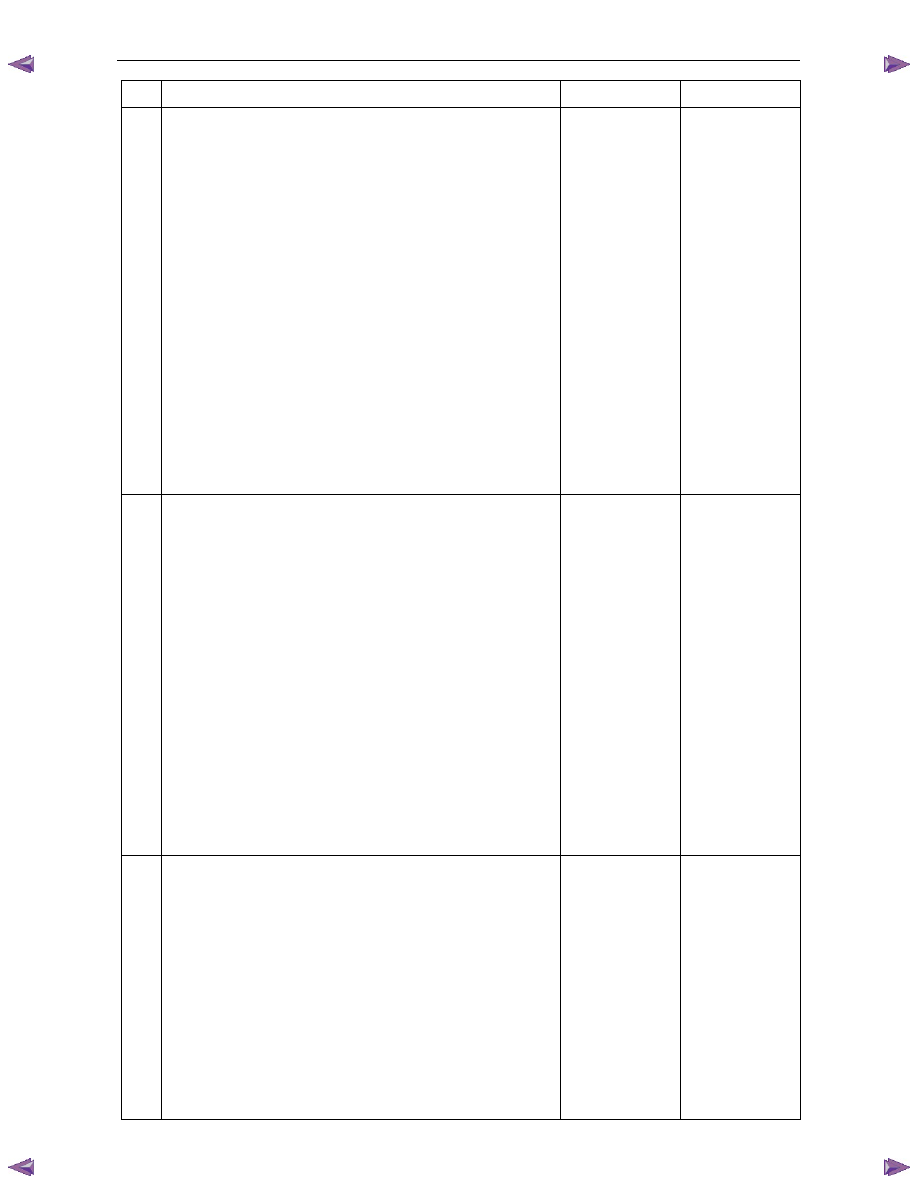

11 Inspect the forward clutch assembly for the following conditions:

•

worn clutch plates,

•

porosity in the forward clutch piston,

•

damaged forward clutch piston,

•

missing forward clutch piston inner and outer seals,

•

cut forward clutch piston inner and outer seals,

•

damaged forward clutch piston inner and outer seals,

•

missing input housing to forward clutch housing O-ring seal,

•

cut input housing to forward clutch housing O-ring seal,

•

damaged input housing to forward clutch housing O-ring seal,

•

damaged forward clutch housing,

•

damaged forward clutch housing retainer and ball assembly, and

•

forward clutch housing retainer and ball assembly is not sealing,

refer to 7C5 Automatic Transmission – 4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Go to Step 12

12 Inspect the 3-4 clutch assembly for the following conditions:

•

worn clutch plates,

•

porosity in the 3-4 clutch piston,

•

damaged 3-4 clutch piston,

•

missing 3-4 clutch inner and outer seals,

•

cut 3-4 clutch inner and outer seals,

•

damaged 3-4 clutch inner and outer seals,

•

damaged 3-4 clutch spring assembly,

•

damaged 3-4 clutch apply ring,

•

damaged piston seal grooves,

•

blocked orifice cup plug, and

•

missing orifice cup plug, refer to 7C5 Automatic Transmission –

4L60E – Unit Repair.

Did you find and correct the condition?

Go to Step 13

Check for an

intermittent fault in

the circuit, refer to

8A Electrical-Body

and Chassis

13 1

Change the transmission fluid and filter.

2

Inspect for correct transmission fluid level, refer to

7C4 Automatic Transmission – 4L60E – On-vehicle Servicing.

3

Add new fluid as necessary.

N O T E

The Clear TAPS function will clear all adapt cells. This may

affect transmission performance. The TCM will update the

transmission adapt cell values as the vehicle is driven.

4

On Tech 2 select:

Transmission / Programming / Reset TAP Cells

and follow Tech 2 instructions.

Did you complete the above procedure?

Go to Step 14

—

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст