Isuzu KB P190. Manual — part 241

6B – 20 ENGINE COOLING

FAN CLUTCH WITH COOLING FAN

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear, damage or any other abnormal condition are found through

inspection.

033R300001

Visually inspect for damage, leak (sillicon grease) or other

abnormal conditions.

1. Inspection

(on-vehicle)

1) Turn the fan clutch by hand when in a low temperature

condition before starting the engine, and confirm that it

can be turned readily.

2) Start the engine to warm it up until the temperature at

the fan clutch portion gets to around 80

°C. Then stop

the engine and confirm that the fan clutch can be

turned with considerable effort (clutch torque) when

turned by hand.

If the fan clutch rotates more readily, however, this

indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.

033RY00011

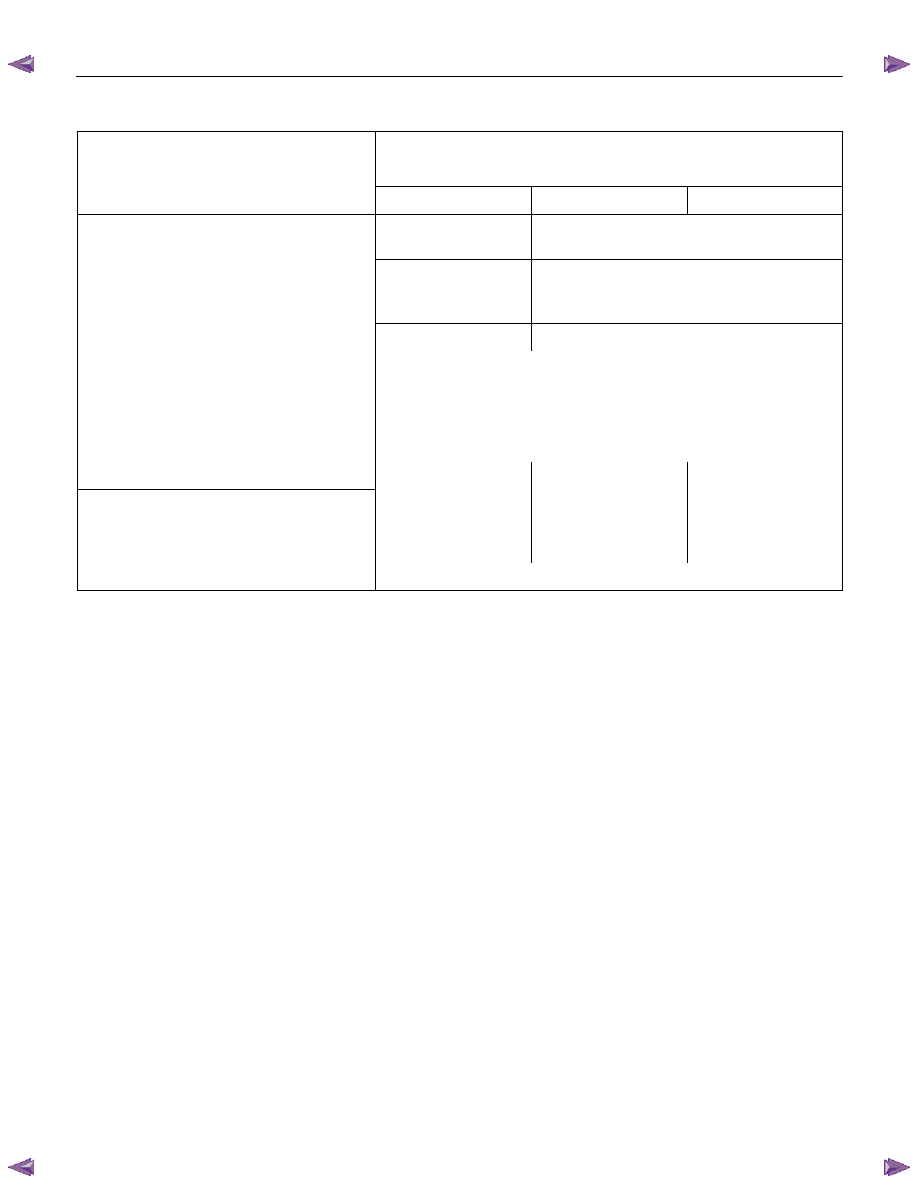

2. Inspection (in unit)

Warm up the bimetal of the fan clutch by using the heat

gun until the temperature gets to about 80

°C when

measured with the thermistor. Then confirm that the fan

clutch can be turned with considerable effort (clutch

torque).

If the fan clutch retates more readily at this time, this

indicates that the silicone grease is leaking internally.

Replace the fan clutch with a new one.

SPECIAL TOOLS

Illustration

Tool Number

Tool Name

5-8840-0277-0 Cap

tester

5-8840-2663-0 Adapter

SECTION 6C

FUEL SYSTEM

TABLE OF CONTENTS

PAGE

Main Data and Specifications. . . . . . . . . . . . . . . . . . . . . ... 6C - 2

General Description . . . . . . . . . . . . . . . . . . . . . . . . . .. 6C - 3

Fuel Flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 3

Fuel Filter and Water Separator . . . . . . . . . . . . . . . . . . . ... 6C - 4

Injection Pump. . . . . . . . . . . . . . . . . . . . . . . . . . ... 6C - 6

Injection Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 7

Fuel Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 11

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tube / Quick - Connector Fittings. . . . . . . . . . . . . . . . . . 6C - 14

Filler Neck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6C - 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 17

Injection Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . ... 6C - 18

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . .. 6C - 18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6C - 21

Injection Nozzle (4JA1L) . . . . . . . . . . . . . . . . . . . . . . . ... 6C - 25

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6C - 25

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 6C - 26

Special tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 6C - 37

FUEL SYSTEM 6C – 1

6C – 2 FUEL SYSTEM

MAIN DATA AND SPECIFICATIONS

Description

Item

4JA1T (L)

4JA1TC

4JH1TC

Injection pump type

Bosch distributor

VE type

Bosch distributor VP44 type

Governor type

Mechanical variable

(Half speed oil

pressure)

Electrical controled

Timer type

Oil pressure

Electrical controled

Fuel feed pump type

Vane with input shaft

Injection nozzle type

Hole type

Number of injection nozzle orifices

5

Injection nozzle orifices

Inside diameter

mm (in)

0.19 (0.0075)

0.17 (0.0067)

0.21 (0.0083)

19.1 (195)

19.0 (194)

19.5 (199)

Injection nozzle designed operating

pressure MPa (kg/cm

2

) 1st

2nd

25.0 (255)

33.5 (328)

33.8 (331)

Main fuel filter type

Disposable cartridge paper element

Precautions

When working on the fuel system, there are several things

to keep in mind:

• Any time the fuel system is being worked on,

disconnect the negative battery cable except for

those tests where battery voltage is required.

• Always keep a dry chemical (Class B) fire

extinguisher near the work area.

• Replace all pipes with the same pipe and fittings that

were removed.

• Clean and inspect “O” rings. Replace if required.

• Always relieve the line pressure before servicing any

fuel system components.

• Do not attempt repairs on the fuel system until you

have read the instructions and checked the pictures

relating to that repair.

• Adhere to all Notices and Cautions.

NOTE:

Injection nozzle adjustment is possible only on the 4JA1L

engine.

FUEL SYSTEM 6C – 3

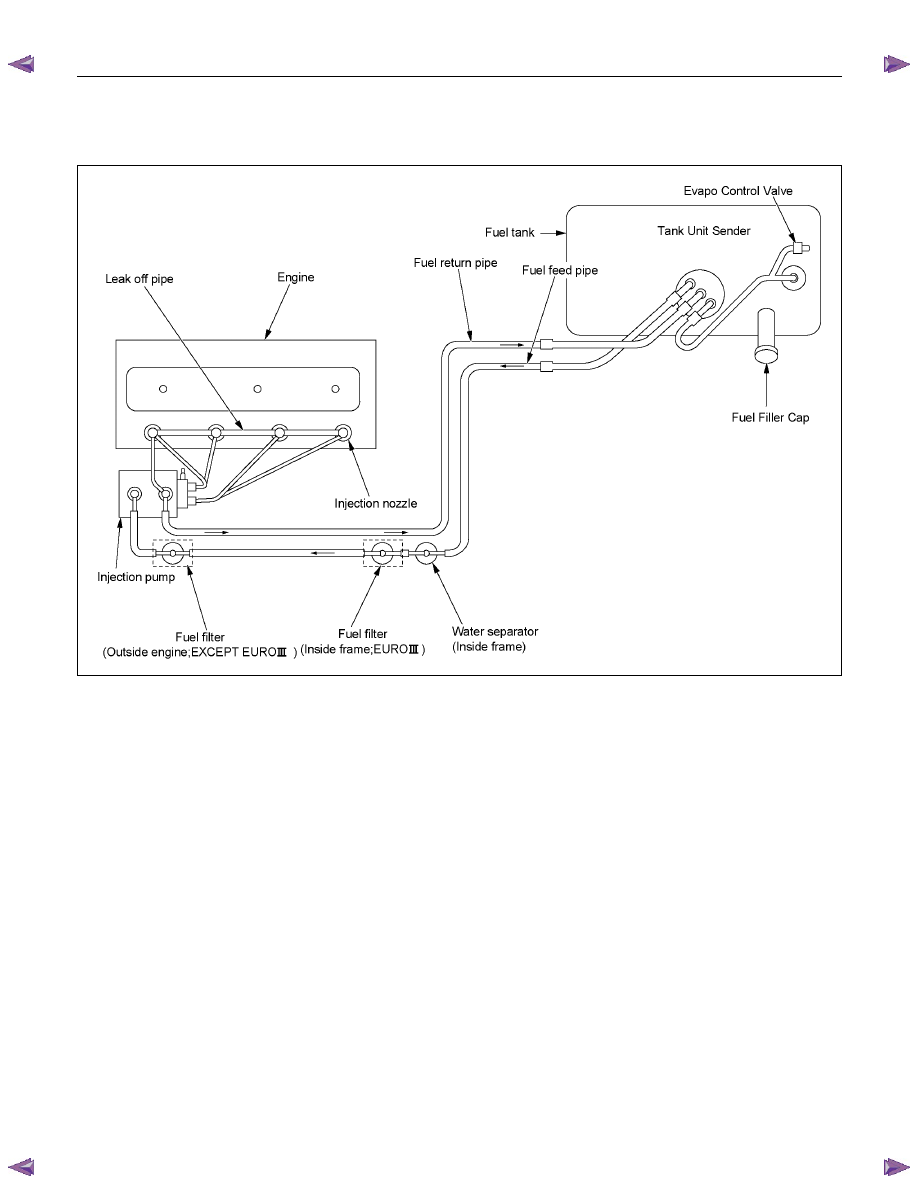

GENERAL DESCRIPTION

FUEL FLOW

RTW66CMF000101

The fuel system consists of the fuel tank, the fuel filter, the water separator, the injection pump, and the injection

nozzle.

The fuel from the fuel tank passes through the water separator and the fuel filter where water particles and other

foreign material are removed from the fuel.

Fuel, fed by the injection pump plunger, is delivered to the injection nozzle in the measured volume at the optimum

timing for efficient engine operation.

NOTE:

1 If it find abnormal condition on the fuel injector, refer to section 6E ENGINE DRIVEABILITY AND

EMISSIONS.

2

Do not contain "Additive for water drain" with fuel.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст