Isuzu KB P190. Manual — part 627

Engine Mechanical – V6

Page 6A1–29

2.3

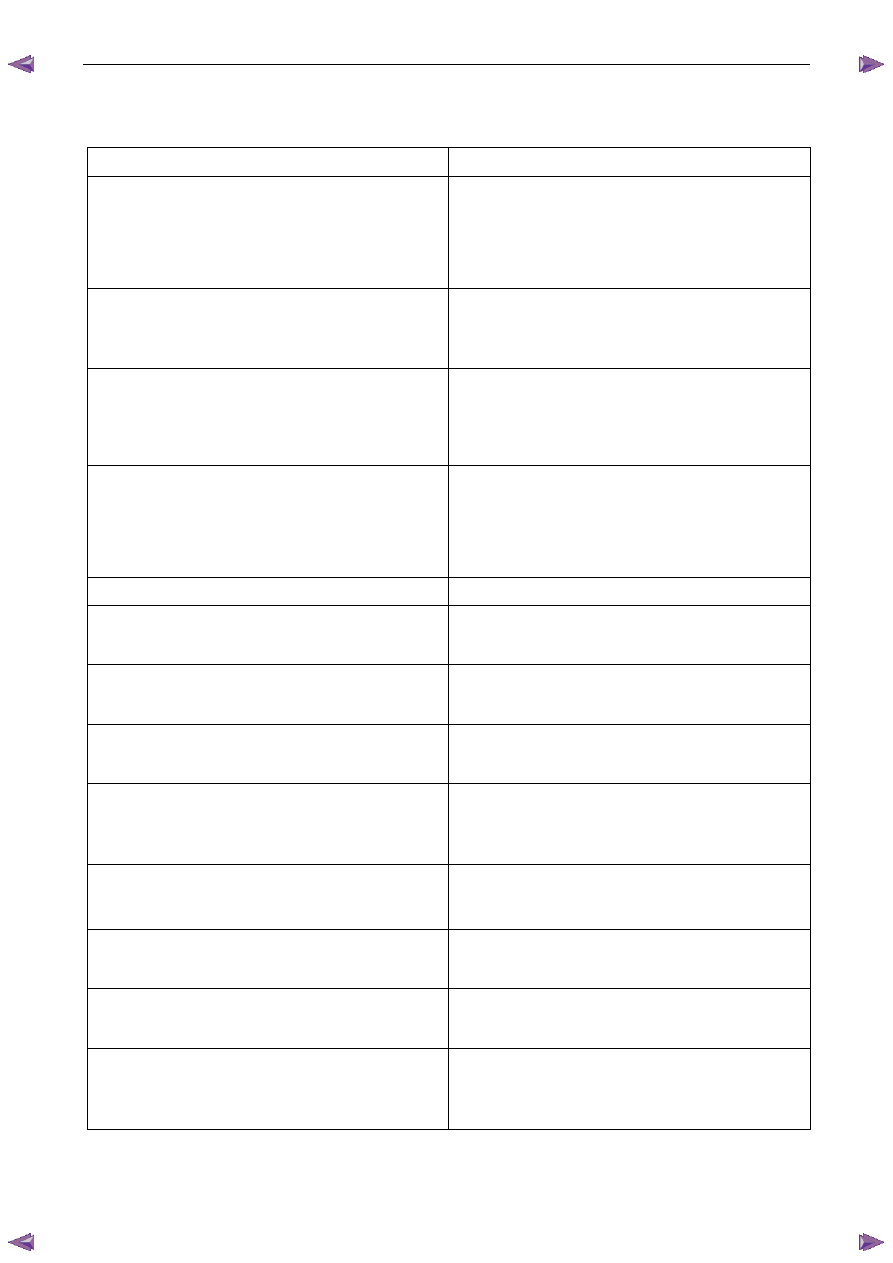

Engine Misfire without Internal Engine

Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an actual misfire condition.

Replace the accessory drive belt, refer to 3.5 Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs.

Worn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition.

Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs.

Loose or incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire DTC may be present without an actual misfire

condition.

Repair or replace the flexplate or crankshaft balancer as

required, refer to 3.13

Crankshaft Balancer Assembly

or 4.3

Flexplate Assembly.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Restricted exhaust system.

A severe restriction in the exhaust flow can cause

significant loss of engine performance and may set a DTC.

Possible causes of restrictions in the exhaust system

include collapsed/dented pipes and blocked mufflers and/or

catalytic converters.

Repair or replace exhaust system components as required,

refer to 8B Exhaust System.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Incorrectly installed or damaged vacuum hoses.

Repair or replace vacuum hoses as required.

Incorrect sealing between the intake manifold and cylinder

heads, upper intake manifold and lower intake manifold,

throttle body and intake manifold.

Repair or replace the intake manifold, throttle body gaskets,

cylinder heads, throttle body as required.

Incorrectly installed or damaged barometric

pressure(BARO) sensor and/or seal. The seal should not

be torn or damaged.

Repair or replace the BARO sensor and/or seal as

required, refer to 6C1-3 Engine Management – V6 –

Service Operations.

Incorrectly installed or damaged EVAP purge solenoid

and/or O-ring seal.

Repair or replace the EVAP purge solenoid and/or seal as

required, refer to 6C1-3 Engine Management – V6 –

Service Operations

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or rocker arms.

The SHLAs, rocker arms and roller bearings should be

intact and in the correct position.

Replace the SHLAs and/or rocker arms as required, refer to

3.21

Stationary Hydraulic Lash Adjuster or 3.20

Rocker

Arm.

Stuck valves.

Carbon build up on the valve stems can result in the valves

not closing correctly.

Repair or replace as required, refer to 3.22 Cylinder Head

Assembly.

Excessively worn or misaligned timing chain/s.

Replace the timing chain/s and components as required,

refer to 3.16

Timing Chains, Tensioners, Shoes and

Guides.

Worn camshaft lobes.

Replace the camshaft/s and SHLAs as required, refer to

3.19

Camshaft or 3.21 Stationary Hydraulic Lash

Adjuster.

Excessive oil pressure.

A lubrication system with excessive oil pressure may lead

to excessive lash adjuster pump-up and loss of

compression.

1

Perform an oil pressure test, refer to 3.1

Engine

Oil.

2

Repair or replace the engine oil pump as required,

refer to 3.17 Oil Pump Assembly.

Engine Mechanical – V6

Page 6A1–30

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder head and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat.

1

Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2

Inspect the cylinder heads, cylinder block and/or head

gaskets, refer to 3.22 Cylinder Head Assembly and/or

4.7 Cylinder Block.

3

Repair or replace components as required.

Worn piston rings.

Oil consumption may or may not cause the engine to

misfire.

1

Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2

Check the cylinders for a loss of compression, refer to

2.15

Engine Compression Test.

3

Perform compression testing to identify the cause of

low compression.

4

Repair or replace components as required.

A damaged crankshaft reluctor wheel.

A damaged crankshaft reluctor wheel can result in different

symptoms depending on the severity and location of the

damage.

Systems with severe reluctor ring damage may exhibit

periodic loss of crankshaft position, stop delivering a signal,

and then re-sync the crankshaft position.

Systems with slight reluctor ring damage may exhibit no

loss of crankshaft position and no misfire may occur,

however, a DTC may set.

Replace the crankshaft as required, refer to 4.6

Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

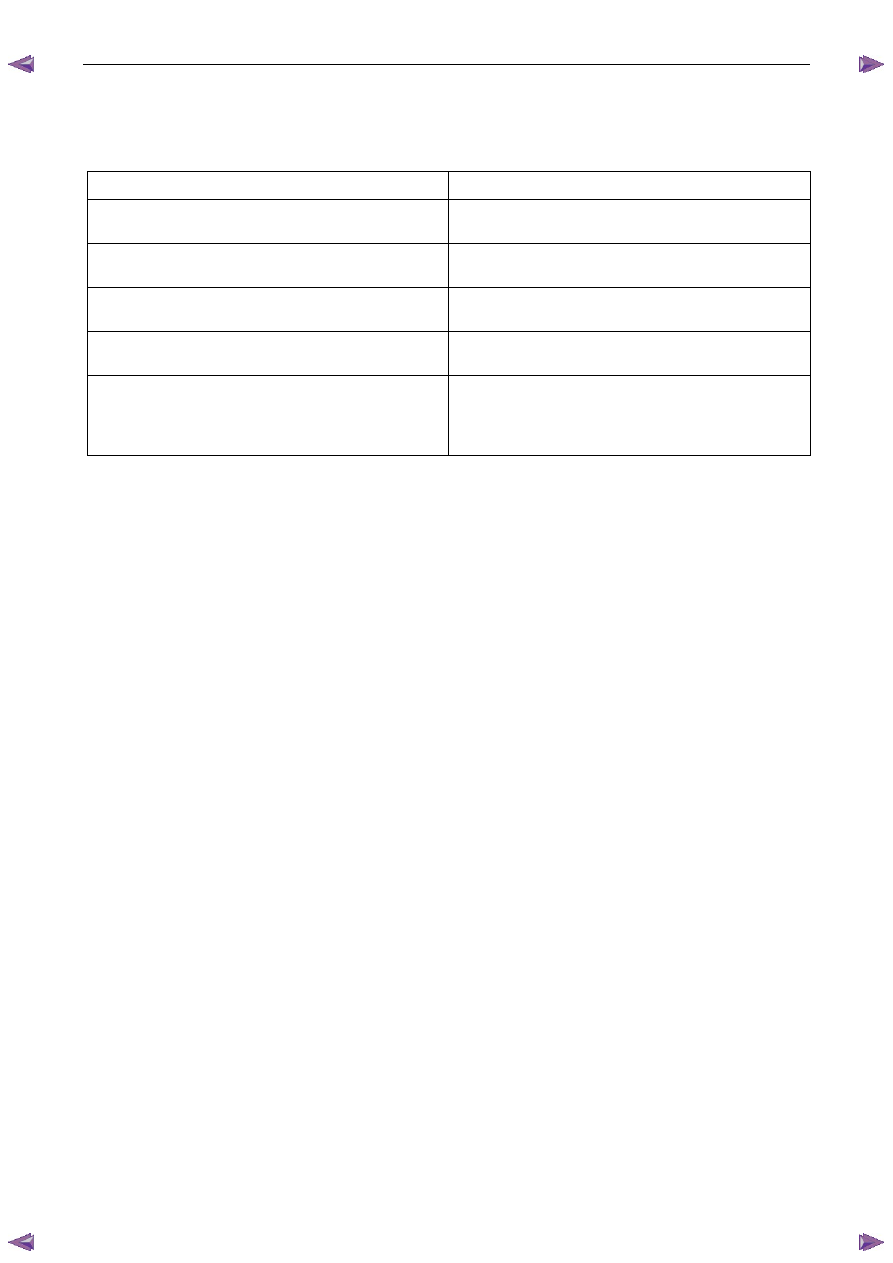

2.4

Engine Misfire with Abnormal Internal

Lower Engine Noises

Cause Correction

Abnormalities, severe cracking, bumps or missing areas in

the accessory drive belt.

Abnormalities in the accessory drive system and/or

components may cause engine speed variations that result

in a misfire diagnostic trouble code (DTC). A misfire code

may be present without an actual misfire condition.

Replace the accessory drive belt, refer to 3.5 Accessory

Drive Belt.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Worn, damaged or misaligned accessory drive components

and excessive pulley run-out may lead to a misfire DTC.

A misfire code may be present without an actual misfire

condition.

Inspect the components and repair or replace as required.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Loose or Incorrectly fitted flexplate or crankshaft balancer

assembly.

A misfire code may be present without an actual misfire

condition.

Repair or replace the flexplate or crankshaft balancer as

required, refer to 3.13

Crankshaft Balancer Assembly

or 4.3

Flexplate Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire.

1

Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2

Check the cylinders for a loss of compression, refer to

2.15

Engine Compression Test.

3

Perform compression testing to identify the cause of

low compression.

4

Repair or replace components as required.

Worn crankshaft thrust bearing.

Severely worn thrust surfaces on the crankshaft and/or

thrust bearing may permit fore and aft movement of the

crankshaft and create a DTC without an actual misfire

condition being present.

Replace the crankshaft and/or bearings as required, refer to

4.6

Crankshaft and Main Bearings.

Refer to 6C1-2 Engine Management – V6 – Diagnostics to

check for DTCs

Engine Mechanical – V6

Page 6A1–31

2.5

Engine Misfire with Abnormal Valve

Train Noise

Cause Correction

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or valve rocker arms.

The SHLAs, rocker arm and roller bearings should be intact

and in the correct position.

Replace the SHLAs and/or rocker arms as required, refer to

3.21

Stationary Hydraulic Lash Adjuster or 3.20

Rocker

Arm.

Stuck valves.

Carbon build up on the valve stems can result in the valves

not closing correctly.

Repair or replace as required, refer to 3.22 Cylinder Head

Assembly.

Excessively worn or misaligned timing chain/s.

Replace the timing chain/s and components as required,

refer to 3.16

Timing Chains, Tensioners, Shoes and

Guides.

Worn camshaft lobes.

Replace the camshaft/s and SHLAs as required, refer to

3.19

Camshaft or 3.21 Stationary Hydraulic Lash

Adjuster.

Sticking camshaft lash adjusters.

Replace the lash adjusters as required, refer to 3.21

Stationary Hydraulic Lash Adjuster.

2.6

Engine Misfire with Coolant

Consumption

Cause Correction

Faulty cylinder head gasket and/or cracking or other

damage to the cylinder heads and cylinder block coolant

passages.

Coolant consumption may or may not cause the engine to

overheat.

1

Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2

Inspect the cylinder heads, cylinder block and/or head

gaskets, refer to 3.22 Cylinder Head Assembly and/or

4.7 Cylinder Block.

3

Repair or replace components as required.

2.7

Engine Misfire with Excessive Oil

Consumption

Cause Correction

Worn valves, valve guides and/or valve stem oil seals.

1

Inspect the spark plugs for coolant saturation, refer to

6C1-3 Engine Management – V6 – Service

Operations.

2

Repair or replace components as required, refer to

3.22

Cylinder Head Assembly.

Worn or broken piston rings.

Oil consumption may or may not cause an actual misfire.

1

Inspect the spark plugs for oil deposits, refer to 6C1-3

Engine Management – V6 – Service Operations.

2

Check the cylinders for a loss of compression, refer to

2.15

Engine Compression Test.

3

Perform compression testing to identify the cause of

low compression.

4

Repair or replace components as required.

2.8

Engine Noise on Start-up, but only

Lasting a Few Seconds

N O T E

A cold piston knock, which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when the specific cylinder’s

Engine Mechanical – V6

Page 6A1–32

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Oil filter anti-drain back valve faulty.

Replace the oil filter adaptor, refer to 3.3

Oil Filter

Adaptor.

Incorrect oil viscosity.

Drain the engine oil and replace with the correct viscosity

oil, refer to 3.1

Engine Oil.

High camshaft stationary hydraulic lash adjuster (SHLA)

leak down rate.

Replace the SHLA as required, refer to 3.21 Stationary

Hydraulic Lash Adjuster.

Worn crankshaft thrust bearing.

Inspect and replace the crankshaft and/or bearings as

required, refer to 4.6

Crankshaft and Main Bearings.

Damaged or faulty oil filter by-pass valve.

1

Inspect the oil filter by-pass valve for correct

operation.

2

Repair or replace the oil filter adaptor/by-pass valve

as required.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст