Isuzu KB P190. Manual — part 527

6B-4 ENGINE COOLING

Antifreeze Solution

• Calculating mixing ratio

Mixing ratio

=

Antifreeze solution (Lit/gal.)

Antifreeze solution (Lit/gal.) + Water (Lit/gal.)

NOTE: Antifreeze solution + Water = Total cooling system

capacity.

• Total Cooling System Capacity

8Lit

• Mixing ratio

Check the specific gravity of engine coolant in the cooling

system temperature ranges from 0

°C to 50°C using a

suction type hydrometer, then determine the density of the

engine coolant by referring to the table.

NOTE: The LLC is 50% at all environment in order to prevent

the corrosion of cooling system parts.

ENGINE COOLING 6B-5

Diagnosis

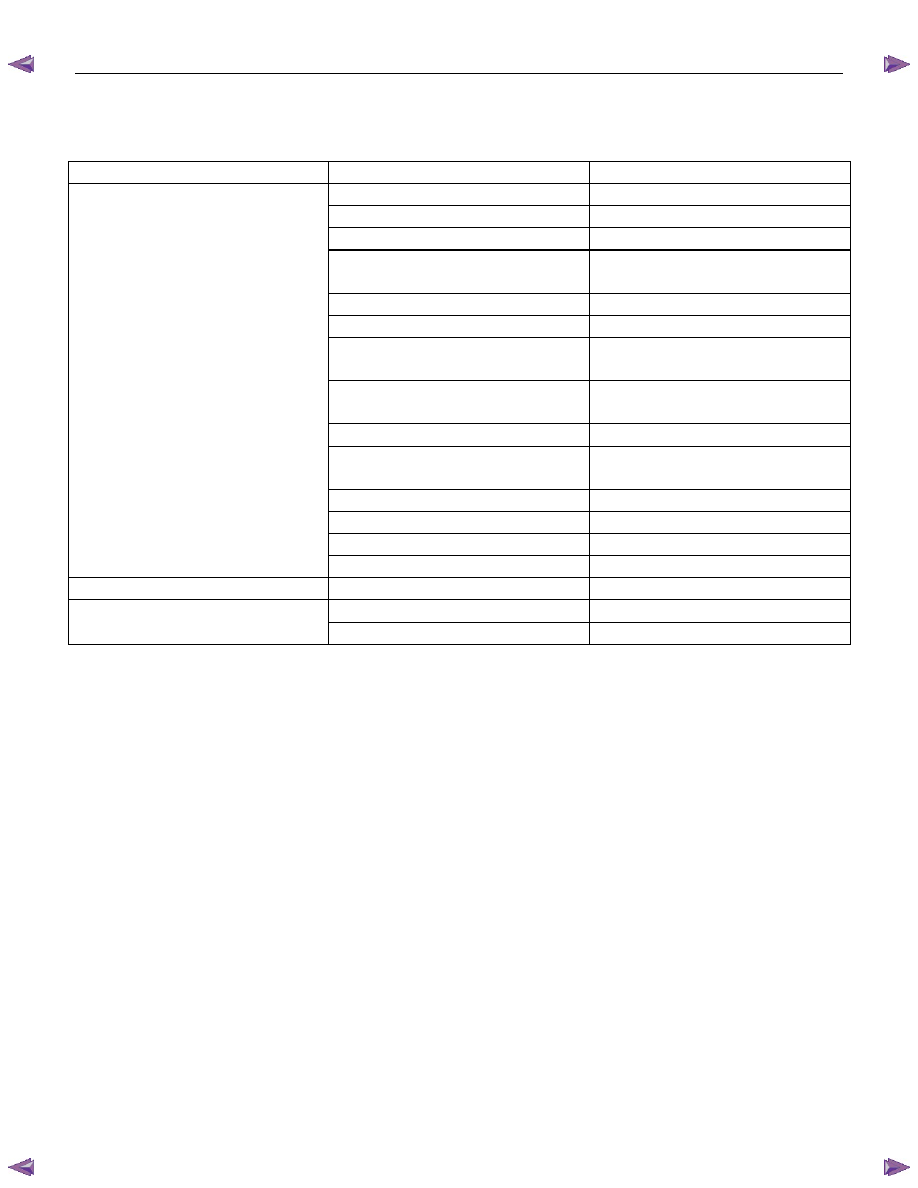

Engine Cooling Trouble

Condition Possible

cause Correction

Engine overheating

Low Engine Coolant level

Replenish

Thermo mater unit faulty

Replace

Faulty

thermostat

Replace

Faulty Engine Coolant temperature

sensor

Repair or replace

Clogged radiator

Clean or replace

Faulty radiator cap

Replace

Low engine oil level or use of

improper engine oil

Replenish or change oil

Clogged exhaust system

Clean exhaust system or replace

faulty parts

Faulty Throttle Position sensor

Replace throttle valve assembly

Open or shorted Throttle Position

sensor circuit

Repair or replace

Damaged cylinder head gasket

Replace

Loosen V-belt tension

Adjust belt tension or replace.

Collapsed

hoses

Replace

Faulty Fan clutch

Replace

Engine overcooling

Faulty thermostat

Replace

Engine slow to warm-up

Faulty thermostat

Replace

Thermo unit faulty

Replace

6B-6 ENGINE COOLING

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system and

perform any necessary service to ensure that it is clean, does

not leak and is in proper working order. The engine coolant

level should be between the "MIN" and "MAX" lines of reserve

tank when the engine is cold. If low, check for leakage and add

engine coolant up to the "MAX" line. There should not be any

excessive deposit of rust or scales around the radiator cap or

radiator filler hole, and the engine coolant should also be free

from oil.

Replace the engine coolant if excessively dirty.

1. Completely drain the cooling system by opening the drain

plug at the bottom of the radiator.

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING BURNED,

DO NOT REMOVE THE CAP WHILE THE ENGINE AND

RADIATOR ARE STILL HOT. SCALDING FLUID AND

STEAM CAN BE BLOWN OUT UNDER PRESSURE.

3. Disconnect all hoses from the engine coolant reserve tank.

Scrub and clean the inside of the reserve tank with soap

and water. Flush it well with clean water, then drain it. Install

the reserve tank and hoses.

4. Refill the cooling system with the engine coolant using a

solution that is at least 50 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the engine coolant reserve tank to "MAX" line when the

engine is cold.

6. Block the drive wheels and firmly apply the parking brake

and place the shift lever in the "NEUTRAL" position.

7. Remove the radiator cap. Start the engine and warm it up at

2,500 - 3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck and the

engine coolant level has gone down, replenish with the

engine coolant. Repeat this procedure until the engine

coolant level does not go down. Then stop the engine and

install the radiator cap. Let the engine cool down.

9. After the engine has cooled, replenish with engine coolant

up to the "MAX" line of the reserve tank.

10.

Start the engine. With the engine running at 3,000 rpm,

make sure there is no running water sound from the heater

core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to 10.

ENGINE COOLING 6B-7

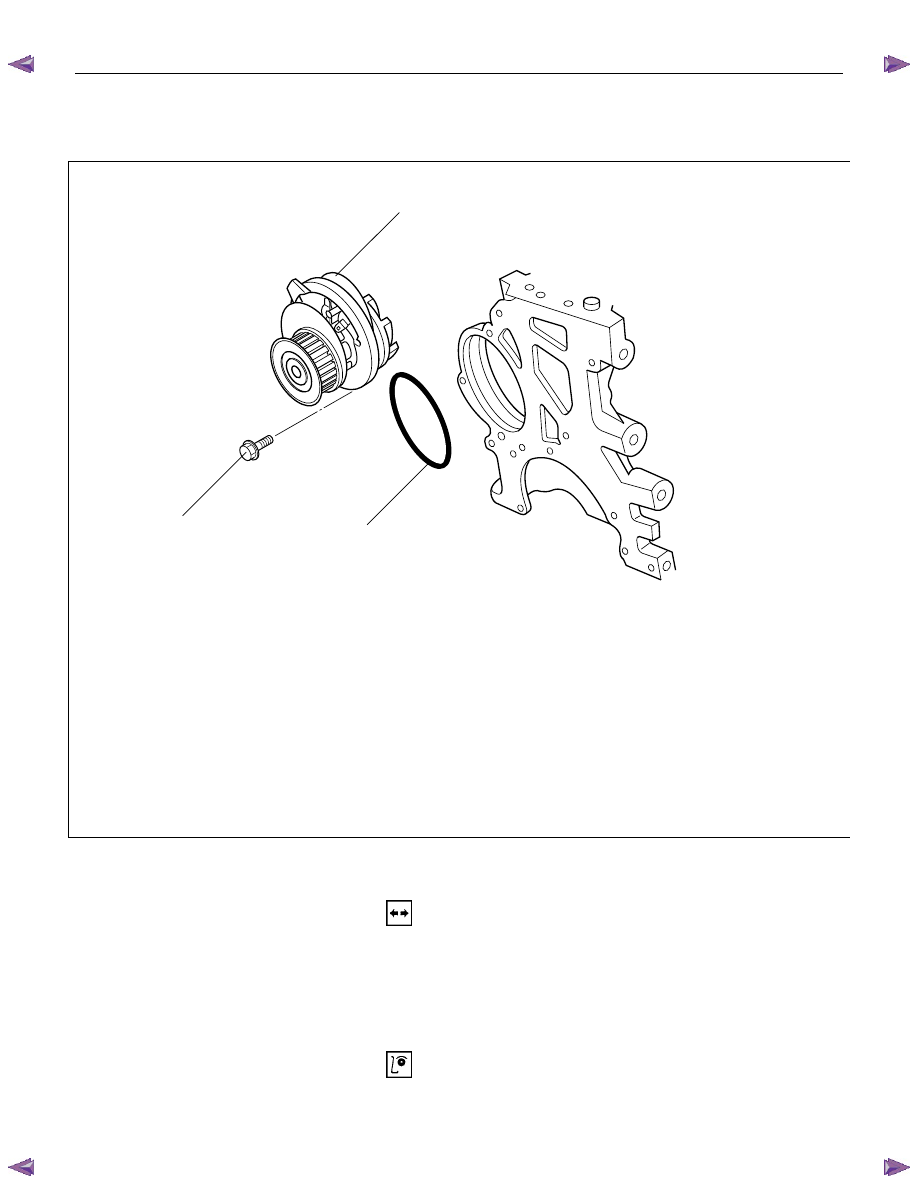

Water Pump

Water Pump and Associated Parts

Legend

1 Water Pump Assembly

2 O-Ring

3 Bolt

2

3

1

Removal

1. Disconnect battery ground cable.

2. Drain coolant.

3. Disconnect radiator hose (on inlet pipe side).

4. Remove timing belt, refer to "Timing Belt" in this manual.

5. Remove water pump assembly.

Inspection

Make necessary repair and parts replacement if extreme wear

or damage is found during inspection. Should any of the

following problems occur, the entire water pump assembly

must be replaced:

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст