Isuzu KB P190. Manual — part 154

BRAKE CONTROL SYSTEM 5A-23

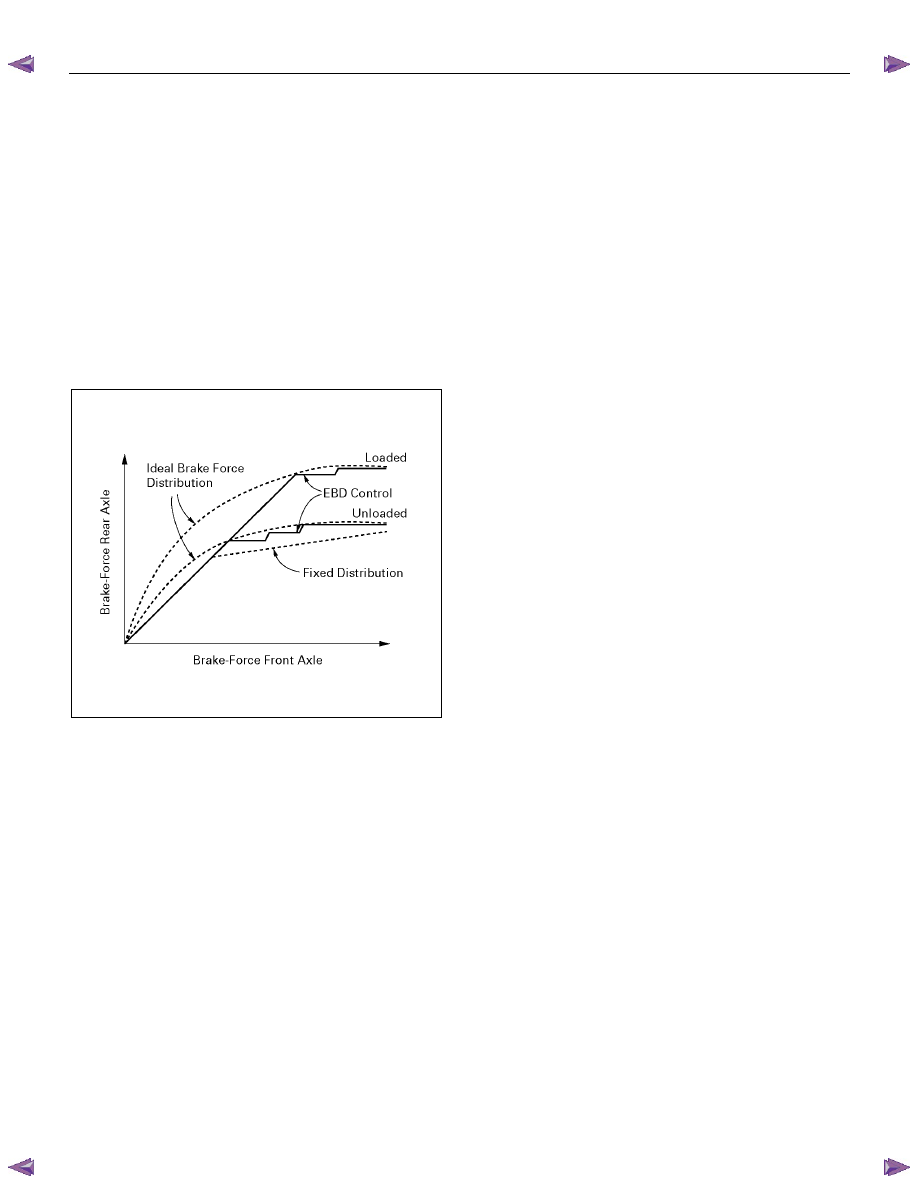

Electronic Brake-force Distribution (EBD) System

ABS has the EBD function. EBD is a function which

controls braking force distribution of a front wheel and a

rear wheel, and makes brake fluid pressure of a rear

wheel the optimal. If the rate of slip of a rear wheel

becomes greater compared to a front wheel, the brake

fluid pressure of a rear wheel will be controlled in order

to perform braking force distribution between the front

and rear wheels. EBD enables the braking power of a

rear wheel to always be utilized for the maximum

according to the load change concerning the back axis

according to the vehicle’s loading state (No luggage,

loading, etc.), deceleration, etc. Brake fluid pressure

control to a rear wheel is performed by the EBD function

which uses the ABS function without the mechanical

proportioning valve.

C05L300016

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying

more force the pedal will continue to travel toward the

floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly

used throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EBD

Electronic Brake-force Distribution

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

FR

Front Right

GEN

Generator

H/U

Hydraulic Unit

MV

Millivolts

RR

Rear

RPS

Revolutions per Second

VDC

DC Volts

VAC

AC Volts

W/L

Warning Lamp

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS problems can be classified into two types, those

which can be detected by the ABS warning lamp and

those which can be detected as a vehicle abnormality

by the driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

• Box Wrench

• Brake

Fluid

• Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

5-8840-0366-0 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

5A-24 BRAKE CONTROL SYSTEM

Computer System Service Precautions

The Anti-lock Brake System and Electronic Brake-force

Distribution interfaces directly with the Electronic

Hydraulic Control Unit (EHCU) which is a control

computer that is similar in some regards to the Engine

Control Module. These modules are designed to

withstand normal current draws associated with vehicle

operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for

opens or shorts, do not ground or apply voltage to any

of the circuits unless instructed to do so by the

appropriate diagnostic procedure. These circuits should

only be tested with a high impedance multimeter

5-8840-0366-0 or special tools as described in this

section. Power should never be removed or applied to

any control module with the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure to

observe these precautions may result in Anti-lock Brake

System and Electronic Brake-force Distribution

damage.

•

If welding work is to be performed on the vehicle

using an electric arc welder, the EHCU and valve

block connectors should be disconnected before the

welding operation begins.

•

The EHCU and valve block connectors should

never be connected or disconnected with the

ignition “ON”.

Note:

•

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS and Brake” warning lamp

will illuminate. But actually no trouble exists. When

the DTC is not detected and the ABS and BRAKE

warning lamp is on, “How to erase code” is

performed and an ABS and BRAKE warning lamp

are off.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS) and

Electronic Brake-force Distribution (EBD) System

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS and EBD

to a non-operative state by removing the fuse for the

ABS. After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning Lamp does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may

be helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be

useful in isolating the failure. Most intermittent

problems are caused by faulty electrical connections or

wiring. When an intermittent failure is encountered,

check suspect circuits for:

•

Suspected harness damage.

•

Poor mating of connector halves or terminals not

fully seated in the connector body (backed out).

•

Improperly formed or damaged terminals.

Test Driving ABS Complaint Vehicles

If there has been an abnormality in the lighting pattern

of the “ABS” warning lamp, the fault can be located in

accordance with the “DIAGNOSIS BY “ABS” WARNING

LAMP ILLUMINATION PATTERN”. Although such

problems can be detected by the driver as a vehicle

symptom, it is still necessary to perform a test drive

following the test procedure mentioned below, in order

to reproduce the symptom for problem diagnosis on a

symptom basis:

1. Start the engine and make sure that the “ABS” W/L

goes OFF. If the W/L remains ON, it means that

the Diagnostic Trouble Code (DTC) is stored.

Therefore, read the code and locate the fault.

Note: The DTC cannot be cleared if the vehicle speed

does not exceed about 10km/h (6mph) at DTC, even

though the repair operation is completed.

2. Start the vehicle and accelerate to about 30 km/h

(19 mph) or more.

3. Slowly brake and stop the vehicle completely.

4. Then restart the vehicle and accelerate to about 40

km/h (25 mph) or more.

5. Brake at a time so as to actuate the ABS and stop

the vehicle.

6. Be cautious of abnormality during the test. If the

W/L is actuated while driving, read the DTC and

locate the fault.

7. If the abnormality is not reproduced by the test,

make best efforts to reproduce the situation

reported by the customer.

8. If the abnormality has been detected, repair in

accordance with the “SYMPTOM DIAGNOSIS”.

Note:

•

Be sure to perform a test drive on a wide, even road

with light traffic.

•

If an abnormality is detected, be sure to suspend

the test and start trouble diagnosis at once.

BRAKE CONTROL SYSTEM 5A-25

“ABS” Warning Lamp

When ABS and problems occur that actuate the “ABS”

warning lamp, the code corresponding to the problem is

stored in the EHCU. Only ordinary braking is available

when the ABS is deactivated. Even when the “ABS”

warning lamp is actuated, if the starter switch is set ON

after setting it OFF once, the EHCU checks up on the

entire system. If there is no abnormality, the EHCU

judges ABS to work correctly and the warning lamp is lit

normally, even though the problem code is stored.

NOTE: Illumination of the “ABS” warning lamp indicates

that anti-lock braking is no longer available. Power

assisted braking without anti-lock control is still

available.

Normal Operation

“ABS ” Warning Lamp

When the ignition is first moved from “OFF” to “RUN”,

the amber “ABS” warning lamp will turn “ON”. The

“ABS” warning lamp will turn “ON” during engine

starting and will usually stay “ON” for approximately

three seconds after the ignition switch is returned to the

“ON” position. The warning lamp should remain “OFF”

at all other times.

Brake (EBD) Warning Lamp

RTW75ASH000101

Vehicles equipped with the EBD (Electronic Brake-force

Distribution) System have a “Brake” warning lamp on

the instrument panel.

If the ABS warning lamp and Brake warning lamp are

turned "ON", then EBD has failed. ( Parking brake

switch is "OFF")

In the following conditions, the EBD warning lamp is

"ON".

•

Starter switch is "ON", engine "OFF".

( Parking brake switch is "OFF")

If engine is started, then EBD warning lamp is "OFF".

( Parking brake switch is "OFF")

5A-26 BRAKE CONTROL SYSTEM

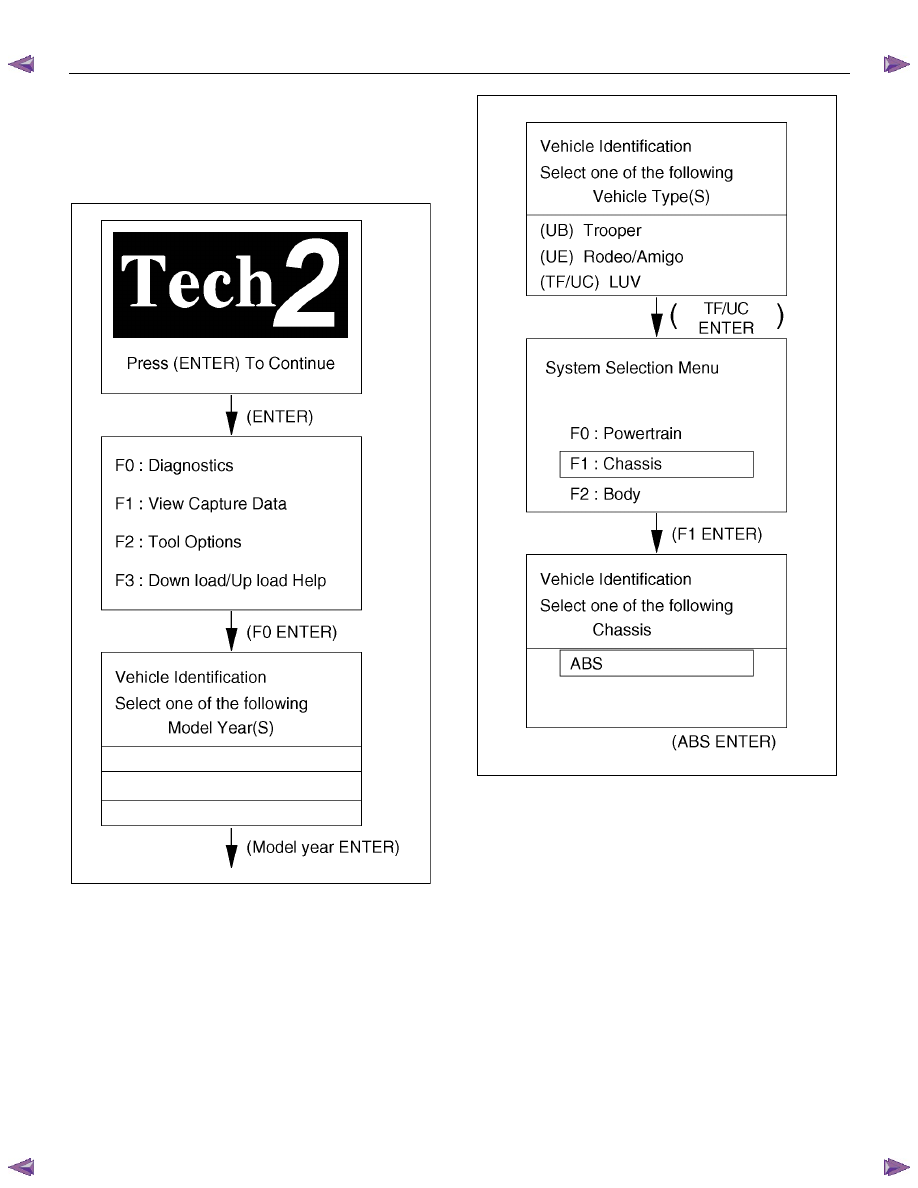

Tech 2 Scan Tool

Operating Procedure

The power up screen is displayed when you power

up the tester with the systems PCMCIA card. Follow

the operating procedure below.

060R100102

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст