Isuzu KB P190. Manual — part 372

6A-128 ENGINE MECHANICAL (4JK1/4JJ1)

Reassembly

1. Install the crank angle sensor rotor.

• Attach by making a rotor tooth’s running out

side into a front side.

• Apply Loctite #262 or the equivalent to the bolt

threads (if a new bolt is used, Loctite

application is not required).

Tightening torque: 12 N

⋅⋅⋅⋅m (1.2 kg⋅⋅⋅⋅m / 104 lb in)

RTW76ASH001601

Legend

1. Crank Angle Sensor Rotor

2. Pin

Inspection

1. Thrust clearance

• Measure the crankshaft end play at the center

journal of the crankshaft.

• Do this before removing the crankshaft bearing

caps. If the measured value exceeds the

specified limit, the crankshaft thrust bearing

must be replaced.

Axial play of the crankshaft

mm (in)

Standard 0.10

(0.004)

Limit 0.30

(0.012)

Note:

Measure the thrust clearance before dismounting.

015RY00002

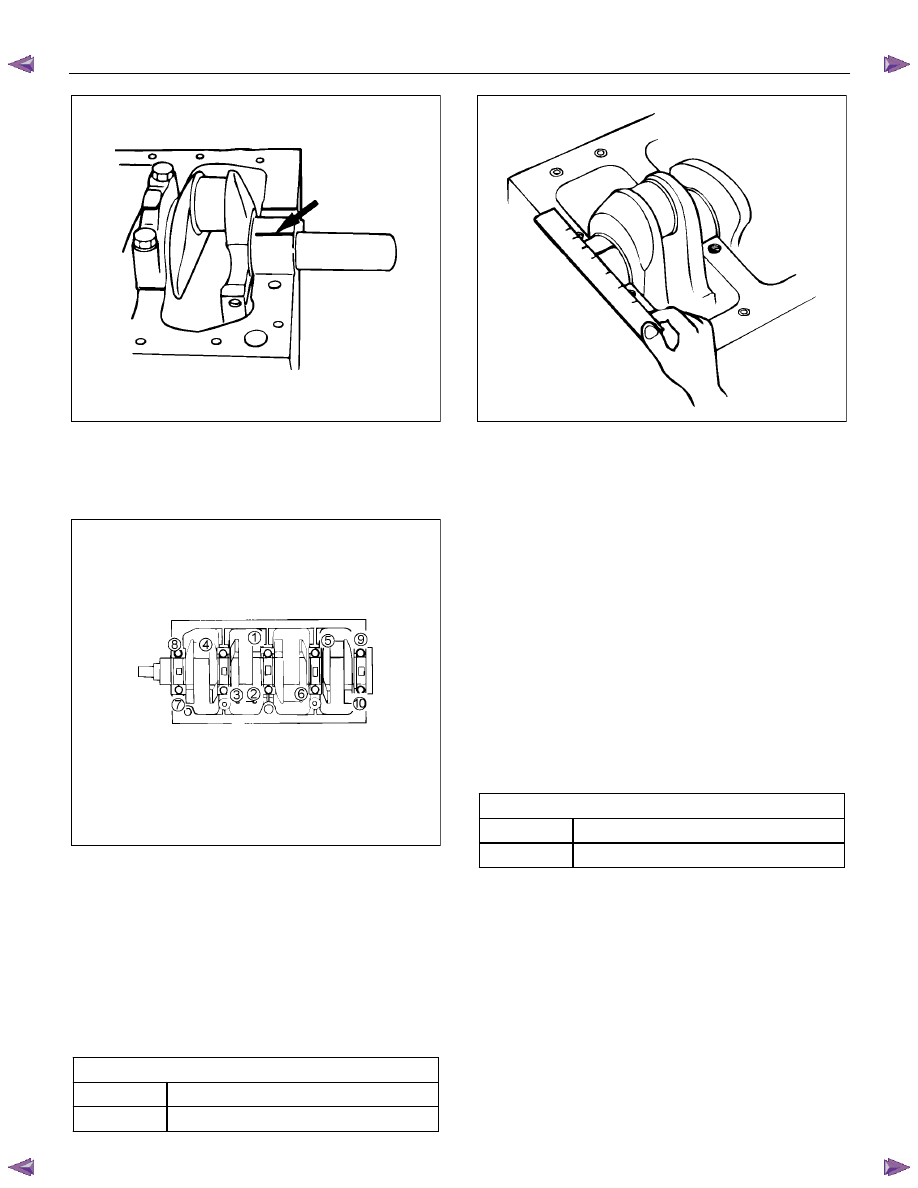

2. Main bearing clearance

• Remove the crank case.

Set out disassembled main bearings in the

order of the numbers.

• Remove the crankshaft. Remove the main

bearings.

• Clean the crankshaft journal and upper and

lower bearings.

• Check the bearings for damage or excessive

wear.

If you find damage or excessive wear, replace

the bearings in pairs.

• Place the upper bearings and the crankshaft on

the cylinder block. Install the crankshaft so that

it is horizontal.

Note:

Turn the crankshaft about 30 degrees to allow the

bearings to settle in.

• Place plastigage on the crankshaft journal as

shown.

• Place the lower bearings at original positions on

the bearing cap.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-129

015RY00012

• Install the bearing cap and tighten bolts to the

specified tightening torque.

• Tighten the bearing cap in the sequence shown

using a torque wrench and an angle gauge.

015LX129

Tightening torque: 166 N

⋅⋅⋅⋅m (16.9 kg⋅⋅⋅⋅m / 122 lb ft)

Note:

Do not turn the crankshaft after you have tightened the

bearing cap.

• Loosen the bolts and gently remove the bearing

cap.

• Measure the widest part of the Plastigage

flattened by tightening the bearing cap to

determine the clearance.

Journal oil clearance

mm (in)

Standard

0.032 - 0.077 (0.0013 - 0.0030)

Limit 0.11

(0.0043)

LNW21BSH024401

• If the journal oil clearance exceeds the limit,

replace the main bearings altogether or the

crankshaft.

• Remove the Plastigage from the bearings and

the crankshaft.

Inspection of the crankshaft

• Check the crankshaft journal and crank pin

surfaces for wear and damage. Check the oil

seal contact surface for excessive wear and

damage.

• Check the oil port for clogging.

3. Crankshaft run-out

Carefully set the crankshaft on the V block. Slowly

turn the crankshaft to measure the run-out. If the

crankshaft run-out exceeds the limit, replace the

crankshaft.

Crankshaft run-out

mm (in)

Standard

0.05 or less (0.0020 or less)

Limit 0.08

(0.003)

6A-130 ENGINE MECHANICAL (4JK1/4JJ1)

015LX061

4. Measure the journal and the crankpin diameters

and uneven wear.

• Measure outer diameters of the journal and the

pin and calculate differences between the

maximum and the minimum values. Take

measurements at four positions for both the

journal and the pin.

LNW21BSH024601

Crankshaft outside diameter

mm (in)

Standard

Limit

Journal

69.917 – 69.932

(2.7526 – 2.7532)

69.91

(2.7524)

Pin

52.915 – 52.930

(2.0833 – 2.0839)

52.9

(2.083)

Note:

Tufftriding (soft nitriding treatment) is applied to

enhance strength of the crankshaft. Therefore, you

should not polish the surface of the crankshaft.

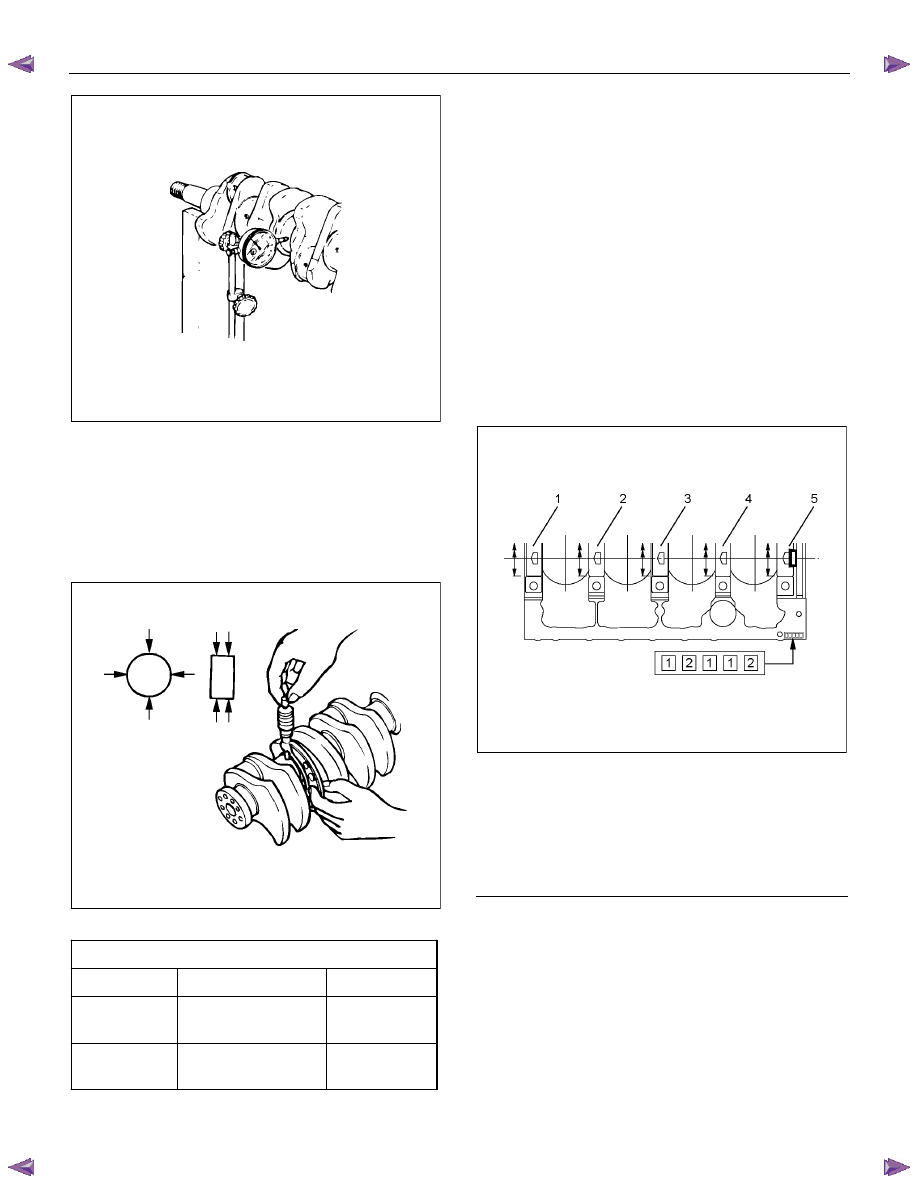

Crankshaft bearing selection

• Crankshaft bearing selection is based on the

measured diameters of the crankshaft journals

and the bearing inserts.

• Match the crankshaft bearing housing grade

marks and the crankshaft journal grade marks

in the table below to determine the correct

crankshaft bearing size.

• Crankshaft bearing housing grade marks 1, 2

or 3 are stamped on the rear right hand side of

the cylinder block.

RTW56ASH017101

Legend

1. No.1

2. No.2

3. No.3

4. No.4

5. No.5

• The crankshaft journal grade marks (1 or -, 2 or

--, 3 or ---) are stamped on each crankshaft

journal web.

The crankshaft journal and bearing clearance

must be the same for each position after

installation of the crankshaft and the crankshaft

bearings.

ENGINE MECHANICAL (4JK1/4JJ1) 6A-131

4JK1

RTW56ASH023901

Legend

1. No.1

2. No.2

3. No.3

4. No.4

5. No.5

NOTE:

The crankshaft journal mark No. 4 is stamped on

crankshaft No. 4 journal web front side or rear side.

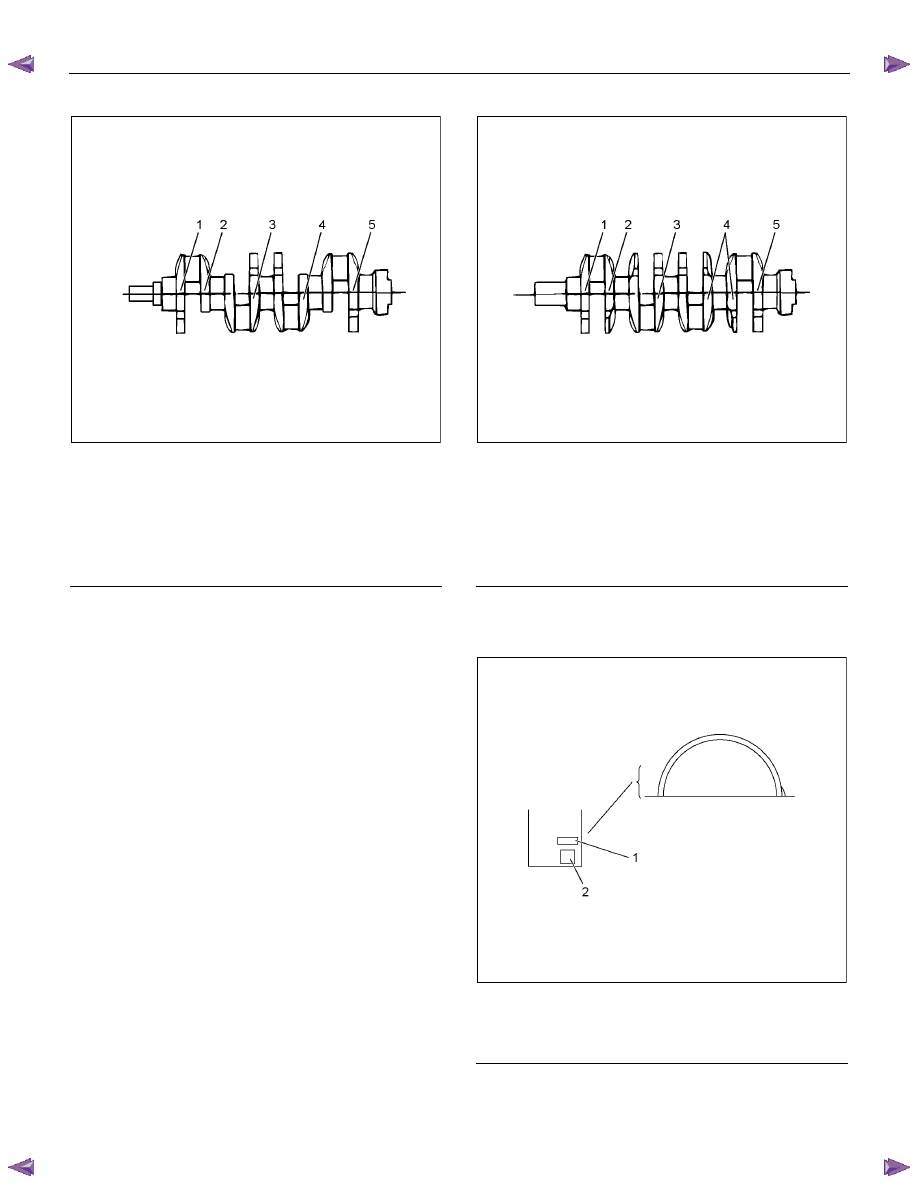

4JJ1

RTW56ASH017201

Legend

1. No.1

2. No.2

3. No.3

4. No.4

5. No.5

Note:

Be careful about difference in the shape of the bearings

when installing them.

RTW56ASH017301

Legend

1. Lot

No.

2. Size

Code

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст