Isuzu KB P190. Manual — part 837

Engine Management – V6 – Diagnostics

Page 6C1-2–70

Additional Information

•

The MAF sensor circuit DTCs is a Type B DTC. Refer to 1.4 Diagnostic Trouble Codes in this Section, for action

taken when a Type B DTC sets and conditions for clearing Type B DTC.

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the MAF sensor operation.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Inspect the MAF sensor for an incorrectly routed harness or if the harness is too close to the following:

−

ignition coil,

−

solenoids,

−

relays, and

−

motors.

•

A low minimum air rate may cause this DTC to set during deceleration. Inspect for the following conditions:

−

a plugged or a collapsed intake air duct, or a dirty air filter element,

−

objects that block the MAF sensor air inlet screen, and

−

sticking or dirty throttle plate or throttle bore.

•

Any un-metered air that enters the engine may cause this DTC to set. Inspect for vacuum leaks in the following:

−

intake manifold,

−

throttle body,

−

barometric pressure (BARO) sensor seal,

−

EVAP canister purge valve seal,

−

brake booster system,

−

air induction system, and

−

crankcase ventilation system.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3 Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

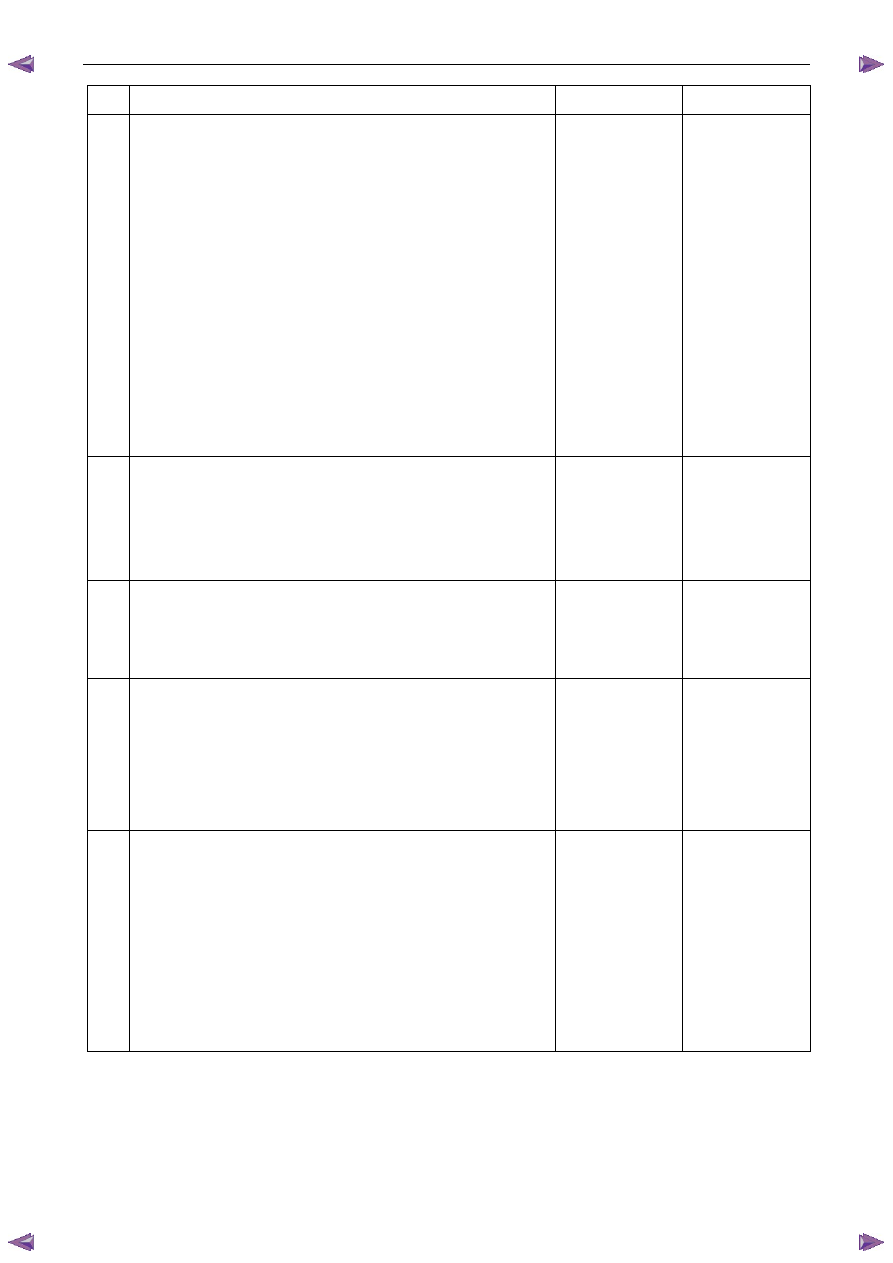

DTC P0101, P0102 or P0103 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P0101, P0102 or P0103 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

Engine Management – V6 – Diagnostics

Page 6C1-2–71

Step Action

Yes

No

3

Inspect for the following fault conditions:

•

engine vacuum leak,

•

air leak in the intake air duct between the MAF sensor and the

throttle body,

•

plugged or collapsed intake air duct,

•

objects that block the MAF sensor inlet screen,

•

restricted air filter element,

•

restricted throttle plate or carbon build-up around the throttle

plate,

•

unseated engine oil dipstick,

•

loose or missing engine oil cap, and

•

over filled crankcase.

Was any fault found and rectified?

Go to Step 14

Go to Step 4

4

1

Disconnect the MAF sensor wiring connector.

2

Connect a test lamp between the MAF sensor ignition voltage

circuit and the ECM housing.

3

Switch on the ignition with the engine not running.

Does the test lamp illuminate?

Go to Step 5

Go to Step 11

5

1

Switch on the ignition with the engine not running.

2

Using a digital multimeter, measure the voltage between the

MAF sensor 5 V reference circuit and the ECM housing.

Does the multimeter display 4.8 – 5.2 V?

Go to Step 6

Go to Step 8

6

1

Switch off the ignition.

2

Connect a 3 A fused jumper wire between the MAF sensor 5 V

reference circuit and signal circuit.

3

Switch on the ignition with the engine not running.

4

Using Tech 2, observe the MAF sensor voltage parameter.

Does Tech 2 display 4.8 – 5.2 V?

Go to Step 7

Go to Step 9

7

1

Switch off the ignition.

2

Remove ECM Fuse 29 from the engine compartment fuse and

relay panel assembly.

3

Using a digital multimeter, measure the resistance between the

MAF sensor low reference circuit and the ECM housing.

N O T E

Install ECM Fuse 29 to the engine compartment fuse and

relay panel assembly after completing the test.

Does the multimeter display 5

Ω?

Go to Step 12

Go to Step 10

Engine Management – V6 – Diagnostics

Page 6C1-2–72

Step Action

Yes

No

8

Test the MAF sensor 5 V reference circuit for a high resistance, open

circuit or short to voltage fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

N O T E

The MAF sensor shares the 5 V reference circuit with

other sensors. A fault condition in the 5 V reference circuit

will trigger DTCs on sensors that share this circuit.

Was any fault found and rectified?

Go to Step 14

Go to Step 13

9

Test the MAF sensor signal circuit for a high resistance, open circuit,

short to ground or short to voltage fault condition. Refer to 8A

Electrical - Body and Chassis for information on electrical fault

diagnosis.

Was any fault found and rectified?

Go to Step 14

Go to Step 13

10 Test the MAF sensor low reference circuit for a high resistance or an

open circuit fault condition. Refer to 8A Electrical - Body and Chassis

for information on electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 14

Go to Step 13

11 Repair the high resistance or open circuit fault condition in the MAF

sensor circuit ignition voltage. Refer to 8A Electrical - Body and

Chassis for information on electrical wiring repair procedures.

Was the repair completed?

Go to Step 14

—

12 Replace the MAF sensor. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 14

—

13 Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 14

—

14 1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the MAF Sensor Circuit DTCs fail this ignition cycle?

Go to Step 2

Go to Step 15

15 Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.7

DTC P0112 or P0113

DTC Descriptors

This diagnostic procedure supports the following DTCs:

•

DTC P0112 – Intake Air Temperature Sensor Circuit Low Voltage

•

DTC P0113 – Intake Air Temperature Sensor Circuit High Voltage

Circuit Description

The ECM applies a reference 5 V to the intake air temperature (IAT) sensor signal circuit and ground through the low

reference circuit. The IAT sensor is a variable resistor that measures the engine intake air temperature.

Engine Management – V6 – Diagnostics

Page 6C1-2–73

•

Increased temperature in the intake air decreases the resistance value of the IAT sensor. This increases the IAT

sensor pull-down rate to ground. Therefore, the higher the intake air temperature, the lower the signal voltage

output of the IAT sensor.

•

Decreased temperature in the intake air increases the resistance value of the IAT sensor. This reduces the IAT

sensor pull-down rate to ground. Therefore, the lower the intake air temperature, the higher the signal voltage

output of the IAT sensor.

An IAT sensor circuit DTC sets if the ECM detects the intake air temperature is outside the specified range.

Conditions for Running the DTC

Runs continuously once the following conditions are met:

•

The engine is running for longer than 3.0 minutes.

•

The engine is idling for longer than 10.0 seconds

Conditions for Setting the DTC

DTC P0112

The ECM detects the intake air temperature is greater than 132

°C for longer than 3.0 seconds.

DTC P0113

The ECM detects the intake air temperature is less than - 38

°C for longer than 3.0 seconds.

Conditions for Clearing the DTC

The IAT sensor DTCs are Type B DTCs. Refer to 1.4

Diagnostic Trouble Codes in this Section, for action taken when

a Type B DTC sets and conditions for clearing Type B DTC.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the IAT Sensor operation.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Test the IAT sensor using the IAT Temperature vs. Resistance in 6C1-3 Engine Management – V6 – Service

Operations. If the engine has sat overnight, the IAT sensor should display within 3

°C of the ECT sensor values.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3

Tests the signal circuit of the IAT sensor.

4

Measures the integrity of the IAT sensor low reference circuit. Removal of the ECM Fuse 29 enables the ECM to

power down completely prior to the test procedure.

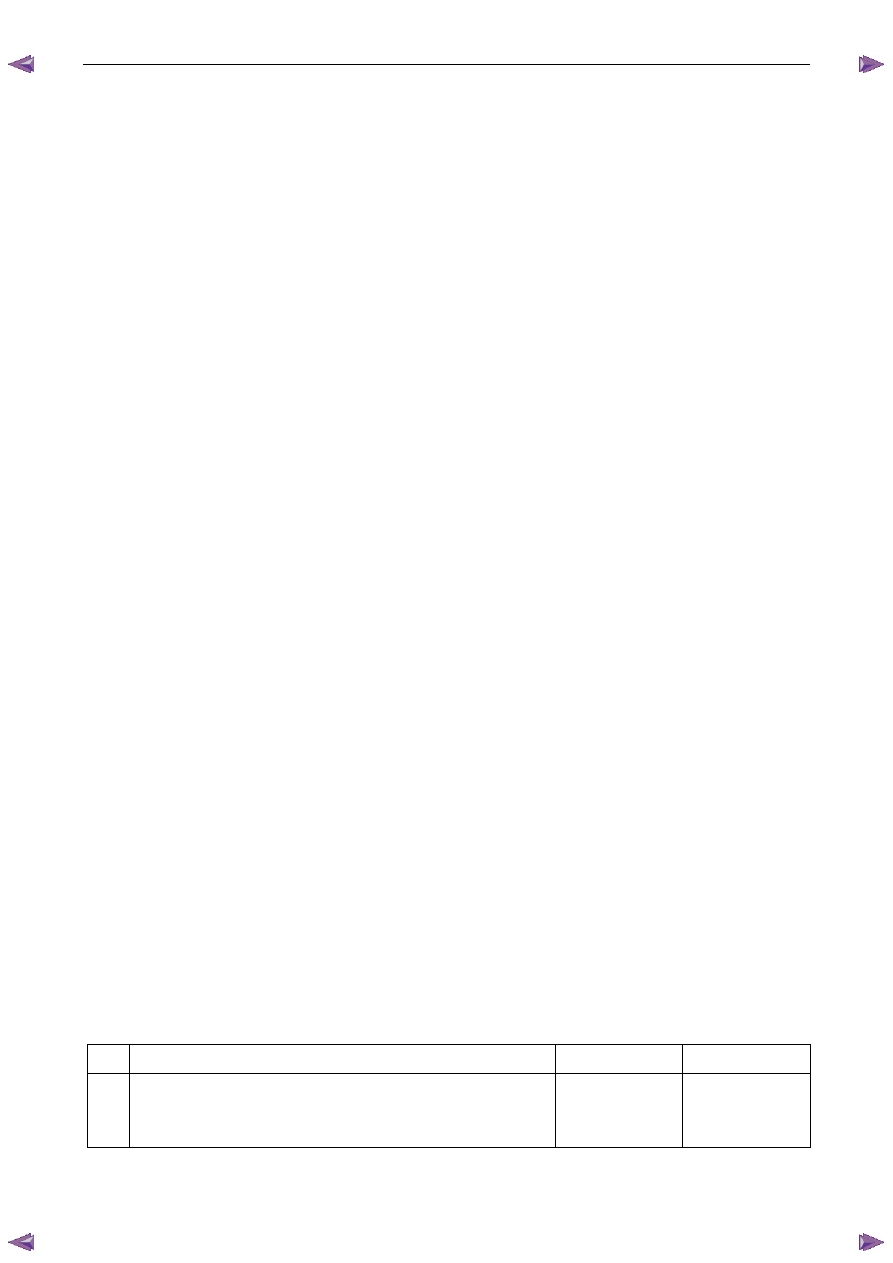

DTC P0112 or P0113 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст