Isuzu KB P190. Manual — part 864

Engine Management – V6 – Diagnostics

Page 6C1-2–178

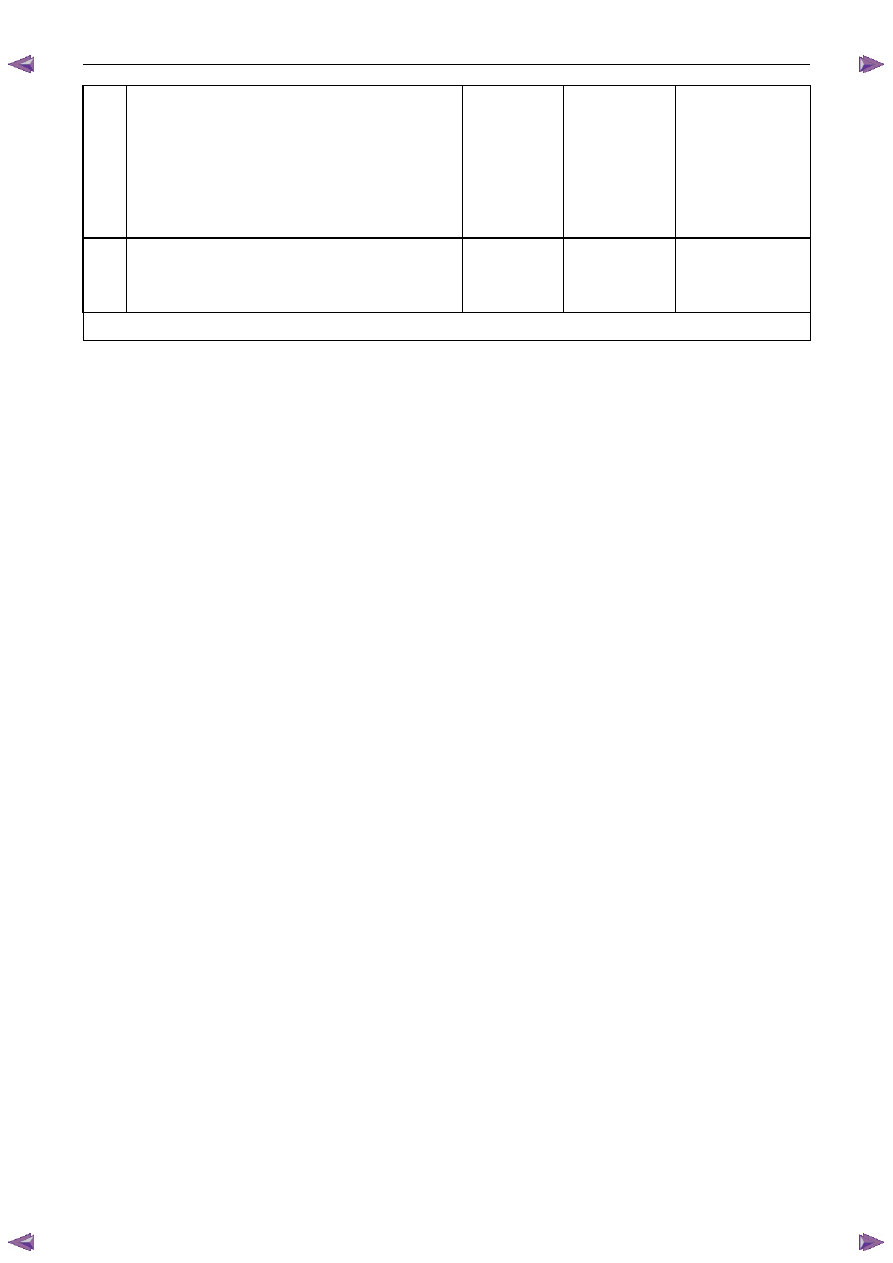

19

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for

running the DTC.

Does DTC P2097 or P2099 fail this ignition cycle?

—

Go to Step 2

Go to Step 20

20

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

—

Go to the

appropriate DTC

Table in this

Section System

OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.48 DTC

P2105

DTC Descriptor

This diagnostic procedure supports DTC P2105 – Throttle Control Forced Engine Shutdown.

Circuit Description

The ECM monitors and evaluates the accelerator pedal position (APP) sensors signal voltage along with other sensor

inputs to determine the desired throttle opening. To control the throttle plate movement, the ECM applies a pulse width

modulated (PWM) signal voltage to the throttle actuator motor through the throttle actuator motor control circuits.

•

At engine idle speed or when no current is flowing into the throttle actuator control (TAC) motor, a constant force

return spring holds the throttle plate at a constant seven percent throttle opening position.

•

To control the throttle opening, the ECM applies PWM voltage to the TAC motor. The ECM increases this PWM

voltage duty cycle to increase the throttle opening.

To decrease the throttle opening from the seven percent rest position, the ECM reverses the polarity of the TAC motor

control circuit then applies a PWM voltage to the TAC motor.

The ECM monitors the ignition supply voltage to ensure the correct operation of the engine management components

and sensors. DTC P2105 sets if the ECM detects an incorrect ignition voltage.

Conditions for Running the DTC

DTC P2105 runs continuously when the ECM completed the power-down process in the last ignition cycle.

Conditions for Setting the DTC

The ECM detects an incorrect voltage level at the ignition supply circuits.

Conditions for Clearing the DTC

DTC P2105 – Throttle Actuator Control (TAC) Module Internal Circuit is a Type A DTC. Refer to 1.4 Diagnostic Trouble

Codes in this Section, for action taken when a Type A DTC sets and conditions for clearing Type A DTC.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the TP actuator operation.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Engine Management – V6 – Diagnostics

Page 6C1-2–179

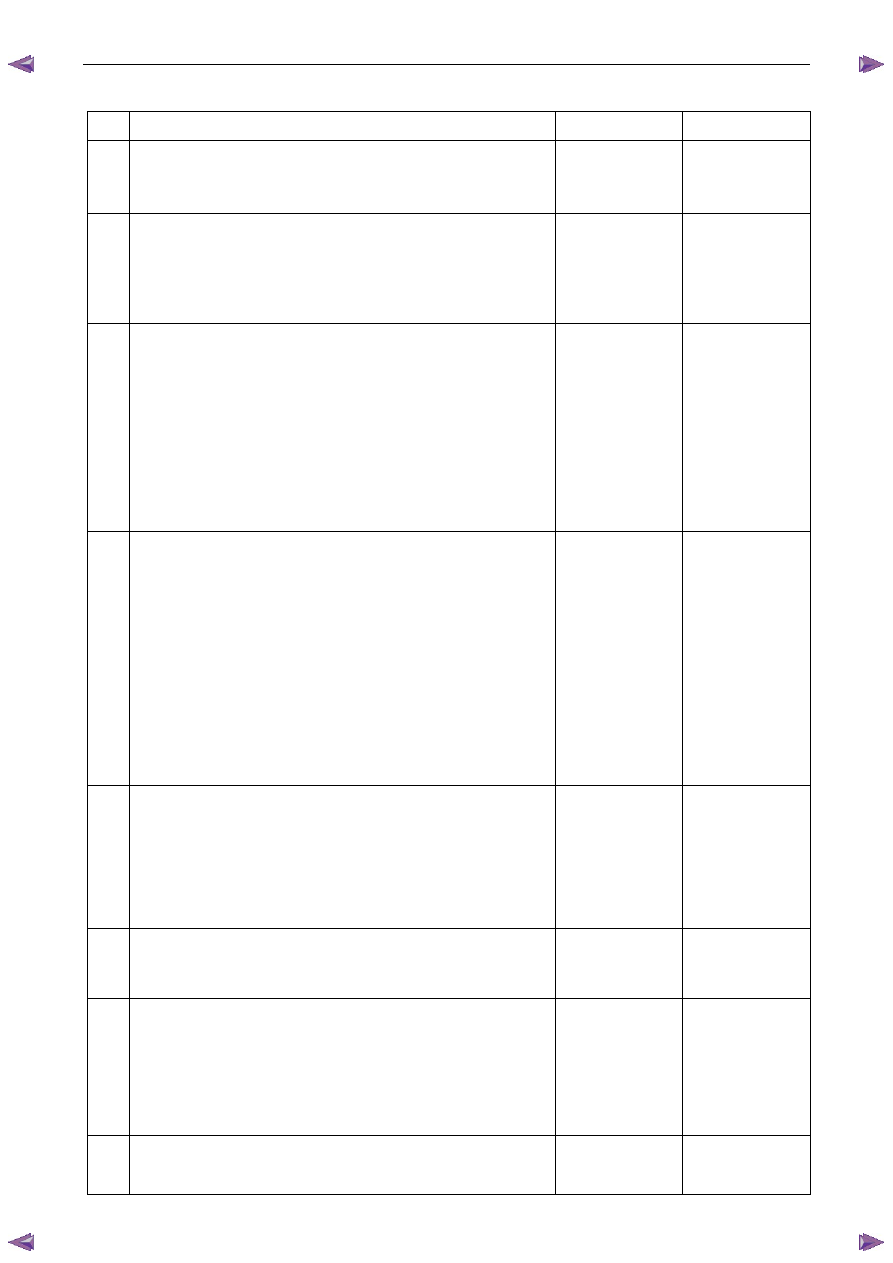

DTC P2105 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P2105 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Remove the ECM / TCM Fuse 32 from the engine compartment

relay panel assembly.

N O T E

Voltage may be available at both terminals of Fuse 32

because of normal voltage feed back condition. Therefore,

the fuse must be removed prior to testing.

2

Inspect the ECM / TCM Fuse 32 for an open circuit fault

condition.

Was any fault found and rectified?

Go to Step 7

Go to Step 4

4

1

Remove the engine control relay from the engine compartment

relay panel assembly.

2

Test the ignition circuit of the ECM, from the fuse terminal to the

Engine control relay for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

N O T E

The engine control relay supplies ignition voltage to other

components and sensors through the ECM ignition circuit.

A fault condition in this ignition circuit may trigger DTCs on

components or sensors connected to this circuit.

Was any fault found and rectified?

Go to Step 7

Go to Step 5

5

Disconnect the vehicle side wiring connector of the ECM. Refer to

6C1-3 Engine Management – V6 – Service Operations.

Test both ignition circuits of the ECM, from the fuse terminal to the

ECM wiring connector for a high resistance, open circuit, short to

ground or short to voltage fault condition. Refer to 8A Electrical - Body

and Chassis for information on electrical fault diagnosis.

Was any fault found and rectified?

Go to Step 7

Go to Step 6

6

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 7

—

7

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does DTC P2105 fail this ignition cycle?

Go to Step 2

Go to Step 8

8

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

Engine Management – V6 – Diagnostics

Page 6C1-2–180

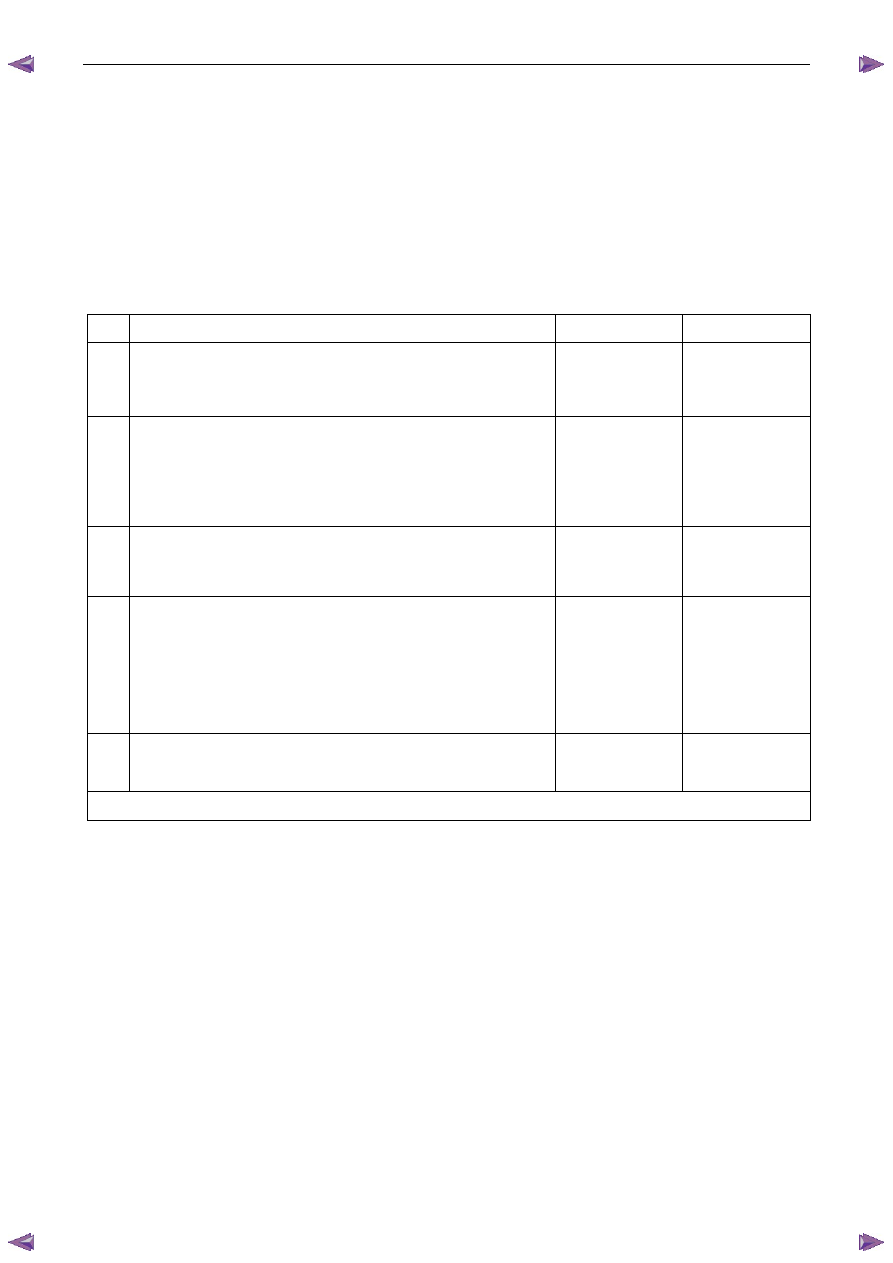

Step Action

Yes

No

When all diagnosis and repairs are completed, check the system for correct operation.

7.49 DTC

P2107

DTC Descriptor

This diagnostic procedure supports DTC P2107 – Throttle Control Malfunction.

Circuit Description

The ECM applies 5 V to the throttle position (TP) sensor 1 through the 5 V reference circuit 2701 and the ground

through the low reference circuit 2752. TP sensor 1 and TP sensor 2 share a common 5 V reference circuit and a

common low reference circuit.

The TP sensor 1 and TP sensor 2 have individual signal circuits with opposite functionality. These signal circuits provide

the ECM with a signal voltage that is proportional to the throttle plate movement.

•

The TP sensor 1 signal voltage is less than 1 V when the throttle plate is in closed position, which increases to

greater than 4 V when the throttle plate is moved to wide-open throttle.

•

The TP sensor 2 signal voltage is greater than 4 V when the throttle plate is in closed position, which decreases to

less than 1 V when the throttle plate is moved to wide-open throttle.

The ECM monitors and evaluates the accelerator pedal position (APP) sensors signal voltage along with other sensor

inputs to determine the desired throttle opening. To control the throttle plate movement, the ECM applies a pulse width

modulated (PWM) signal voltage to the throttle actuator motor through the throttle actuator motor control circuits.

•

At engine idle speed or when no current is flowing into the throttle actuator control (TAC) motor, a constant force

return spring holds the throttle plate at a constant seven percent throttle opening position.

•

To control the throttle opening, the ECM applies PWM voltage to the TAC motor. The ECM increases this PWM

voltage duty cycle to increase the throttle opening.

To decrease the throttle opening from the seven percent rest position, the ECM reverses the polarity of the TAC motor

control circuit then applies a PWM voltage to the TAC motor.

If the ECM detects the TP sensor 1 amplification output does not correlate with the TP sensor 1 signal voltage during a

predetermined sets of conditions, DTC P2107 sets.

Conditions for Running the DTC

DTC P2107 runs continuously once the following conditions are met:

•

The vehicle speed is 0 km/h.

•

The engine speed is less than 40 rpm

•

The engine coolant temperature is 5 – 60

° C.

•

The intake air temperature is 5 – 60

° C.

•

The ignition voltage is greater than 10 V.

•

The APP is less than 15 percent.

•

The ECM is performing the closed throttle test with the ignition switched on and the engine not running.

Conditions for Setting the DTC

The ECM detects that its internal TP sensor 1 amplification output does not correlate with the TP sensor 1 signal voltage.

Conditions for Clearing the DTC

DTC P2107 – Throttle Actuator Control Module Internal Circuit is a Type ‘C’ DTC. Refer to 1.4

Diagnostic Trouble

Codes in this Section, for action taken when a Type ‘C’ DTC sets and conditions for clearing Type ‘C’ DTC.

Engine Management – V6 – Diagnostics

Page 6C1-2–181

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the TP sensor operation.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

DTC P2107 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P2107 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

Replace the ECM. Refer to 6C1-3 Engine Management – V6 –

Service Operations.

Was the repair completed?

Go to Step 4

—

4

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does DTC P2107 fail this ignition cycle?

Go to Step 2

Go to Step 5

5

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.50 DTC P2122, P2123, P2127, P2128 or

P2138

DTC Descriptors

This diagnostic procedure supports the following DTCs:

•

DTC P2122 – Accelerator Pedal Position Sensor 1 Voltage Low

•

DTC P2123 – Accelerator Pedal Position Sensor 1 Voltage High

•

DTC P2127 – Accelerator Pedal Position Sensor 2 Voltage Low

•

DTC P2128 – Accelerator Pedal Position Sensor 2 Voltage High

•

DTC P2138 – Accelerator Pedal Position Sensor 1 – 2 Correlation

Circuit Description

The ECM applies a separate 5 V reference circuit and low reference circuit to the accelerator pedal position (APP)

sensor 1 and sensor 2. The APP sensors produce a signal voltage that represents the accelerator pedal position.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст