Isuzu KB P190. Manual — part 1414

SUPPLEMENTAL RESTRAINT SYSTEM 9A-21

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNECESSARY SRS

REPAIRS.

The SRS control unit in Driver–Passenger SRS can

maintain sufficient voltage to cause a deployment for

up to 15 seconds after the ignition switch is turned

“OFF,” the battery is disconnected, or the fuse

powering the SRS control unit is removed.

Many of the service procedures require removal of the

“SRS” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected

from the deployment loop as noted in the “Disabling

the SRS” procedure that follows, service can begin

immediately without waiting for the 15 second time

period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove the

key.

1. Remove the SRS fuse “SRS”, from the side of the

driver’s side of the instrument panel fuse block or

disconnect the battery.

2. Disconnect the yellow connector at the base of the

steering column.

3.

Remove the glove box assembly, refer to

“Passenger Air Bag Assembly Replacement” in

this manual.

4. Disconnect the yellow connector behind the glove

box assembly.

CAUTION: With the “SRS” fuse removed and

ignition switched “ON”, the “SRS” warning lamp

will be “ON”. This is normal operation and does

not indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle or different model year air bag

assembly.

Use only a new air bag assembly matched to the

TFR/S which is being repaired.

Turn the ignition switch to “LOCK” and remove the

key.

1. Connect the yellow connector passenger air bag

assembly.

2.

Install the glove box assembly. Refer to

“Passenger air bag assembly replacement” in this

manual.

3. Connect the yellow connector at the base of the

steering column.

4. Install the “AIR BAG” fuse “SRS” to the side of the

driver’s side of the instrument panel fuse block or

connect the battery.

Turn the ignition switch to “ON” and verify that the

“SRS” warning lamp flashes seven times and then

turns to “LOCK”. If it does not operate as described,

perform the “SRS Diagnostic System Check” in this

manual.

Handling / Installation / Diagnosis

1. The air bag assembly should not be subjected to

temperatures above 65

°

C (150

°

F).

2. The air bag assembly, and SRS control unit,

should not be used if they have been dropped from

a height of 100 centimeters (3.28 feet) or more.

3. When the SRS control unit is replaced, it must be

oriented with the arrow on the sensor pointing

toward the front of the vehicle. It is very important

for the SRS control unit to be located flat on the

mounting surface, parallel to the vehicle datum

line. It is important that the SRS control unit

mounting surface is free of any dirt or other foreign

material.

4.

Do not apply power to the SRS unless all

components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble

code.

5. The “SRS Diagnostic System Check” must be the

starting point of any SRS diagnostics. The “SRS

Diagnostic System Check” will verify proper “SRS”

warning lamp operation and will lead you to the

correct chart to diagnose any SRS malfunctions.

Bypassing these procedures may result in

extended diagnostic time, incorrect diagnosis, and

incorrect parts replacement.

9A-22 SUPPLEMENTAL RESTRAINT SYSTEM

Air Bag Assembly Handling /

Shipping / Scrapping

Live (Undeployed) Air Bag Assembly

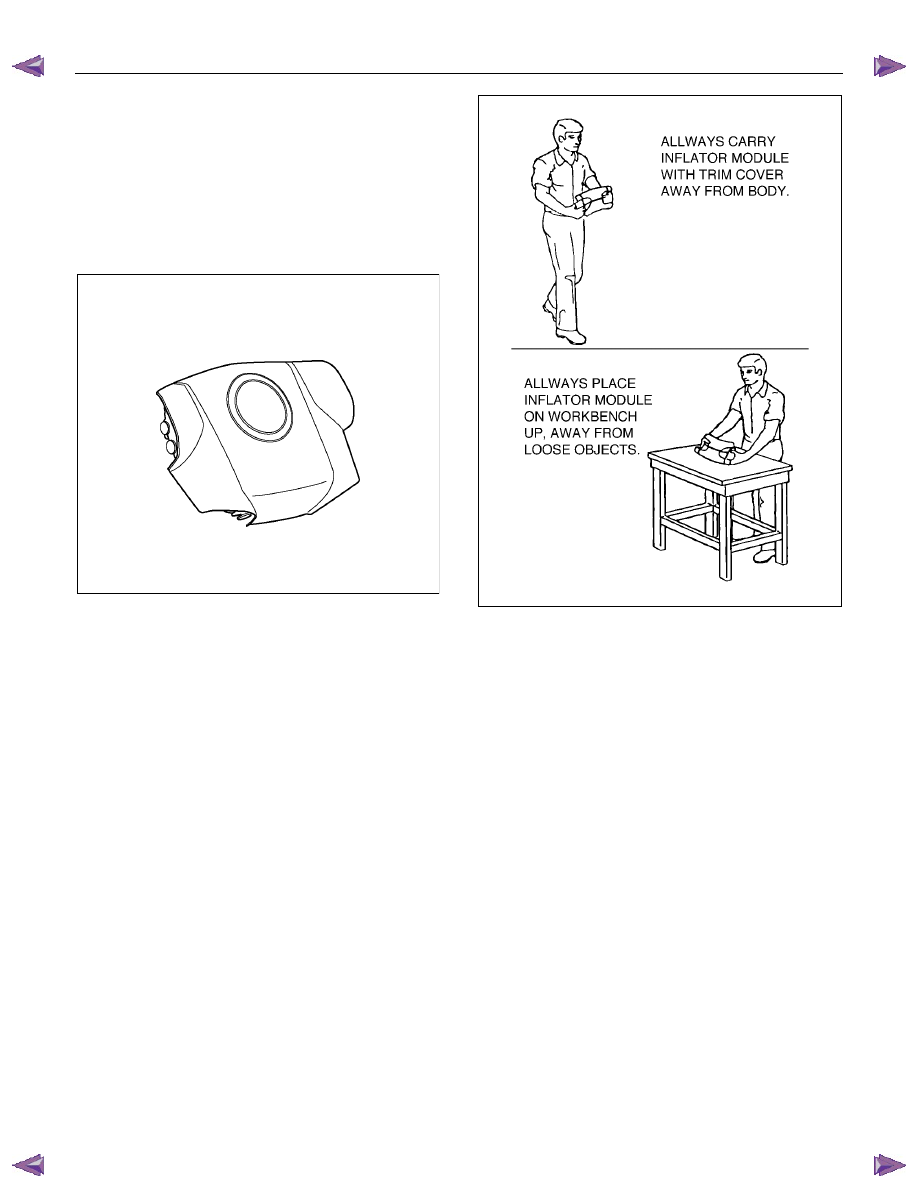

Special care is necessary when handling and storing a

live (undeployed) air bag assembly. The rapid gas

generation produced during deployment of the air bag

could cause the air bag assembly, or an object in front

of the air bag assembly, to be thrown through the air in

the unlikely event of an accidental deployment.

RTW79ASH000301

WARNING: WHEN CARRYING A LIVE AIR BAG

ASSEMBLY, MAKE SURE THE BAG OPENING IS

POINTED AWAY FROM YOU. IN CASE OF AN

ACCIDENTAL DEPLOYMENT, THE BAG WILL

THEN DEPLOY WITH MINIMAL CHANCE OF

INJURY. NEVER CARRY THE AIR BAG ASSEMBLY

BY THE WIRES OR CONNECTOR ON THE

UNDERSIDE OF THE MODULE.

827RS044

Air Bag Assembly Shipping Procedure

For Live (Undeployed) Air Bag

Assemblies

Service personnel should refer to the latest Service

Bulletins for proper SRS air bag assembly shipping

procedures.

Deployed Air Bag Assembly (Driver Side)

You should wear gloves and safety glasses. After the

air bag assembly has been deployed, the surface of

the air bag may contain a powdery residue. This

powder consists primarily of cornstarch (used to

lubricate the bag as it inflates) and by-products of the

chemical reaction. Sodium hydroxide dust (similar to

lye soap) is produced as a by-product of the

deployment reaction. The sodium hydroxide then

quickly reacts with atmospheric moisture and is

converted to sodium carbonate and sodium

bicarbonate (baking soda). Therefore, it is unlikely that

sodium hydroxide will be present.

SUPPLEMENTAL RESTRAINT SYSTEM 9A-23

Air Bag Assembly Scrapping Procedure

During the course of a vehicle's useful life, certain

situations may arise which will necessitate the disposal

of a live (undeployed) air bag assembly. This

information covers proper procedures for disposing of

a live air bag assembly.

Before a live air bag assembly can be disposed of, it

must be deployed. A live air bag assembly must not

be disposed of through normal refuse channels.

WARNING: FAILURE TO FOLLOW PROPER

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) AIR

BAG ASSEMBLY DISPOSAL PROCEDURES CAN

RESULT IN AIR BAG DEPLOYMENT WHICH MAY

CAUSE PERSONAL INJURY. AN UNDEPLOYED

AIR BAG ASSEMBLY MUST NOT BE DISPOSED

OF THROUGH NORMAL REFUSE CHANNELS.

THE UNDEPLOYED AIR BAG ASSEMBLY

CONTAINS SUBSTANCES THAT CAN CAUSE

SEVERE ILLNESS OR PERSONAL INJURY IF THE

SEALED CONTAINER IS DAMAGED DURING

DISPOSAL. DISPOSAL IN ANY MANNER

INCONSISTENT WITH PROPER PROCEDURES

MAY BE A VIOLATION OF FEDERAL, STATE, AND /

OR LOCAL LAW.

In situations which require deployment of a live air bag

assembly, deployment may be accomplished inside or

outside the vehicle. The method employed depends

upon the final disposition of the particular vehicle, as

noted in “Deployment Outside Vehicle” and

“Deployment Inside Vehicle” in this section.

Deployment Outside Vehicle (Driver Air

Bag Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be

returned to useful service after a functionally or

cosmetically deficient air bag assembly is replaced.

Deployment and disposal of a malfunctioning air bag

assembly is, of course, subject to any required

retention period.

For deployment of a live (undeployed) air bag

assembly outside the vehicle, the deployment

procedure must be followed exactly. Always wear

safety glasses during this deployment procedure until

a deployed air bag assembly is scrapped or until an

undeployed air bag assembly is shipped. Before

performing the procedures you should be familiar with

servicing the SRS and with proper handling of the air

bag assembly. Procedures should be read fully before

they are performed.

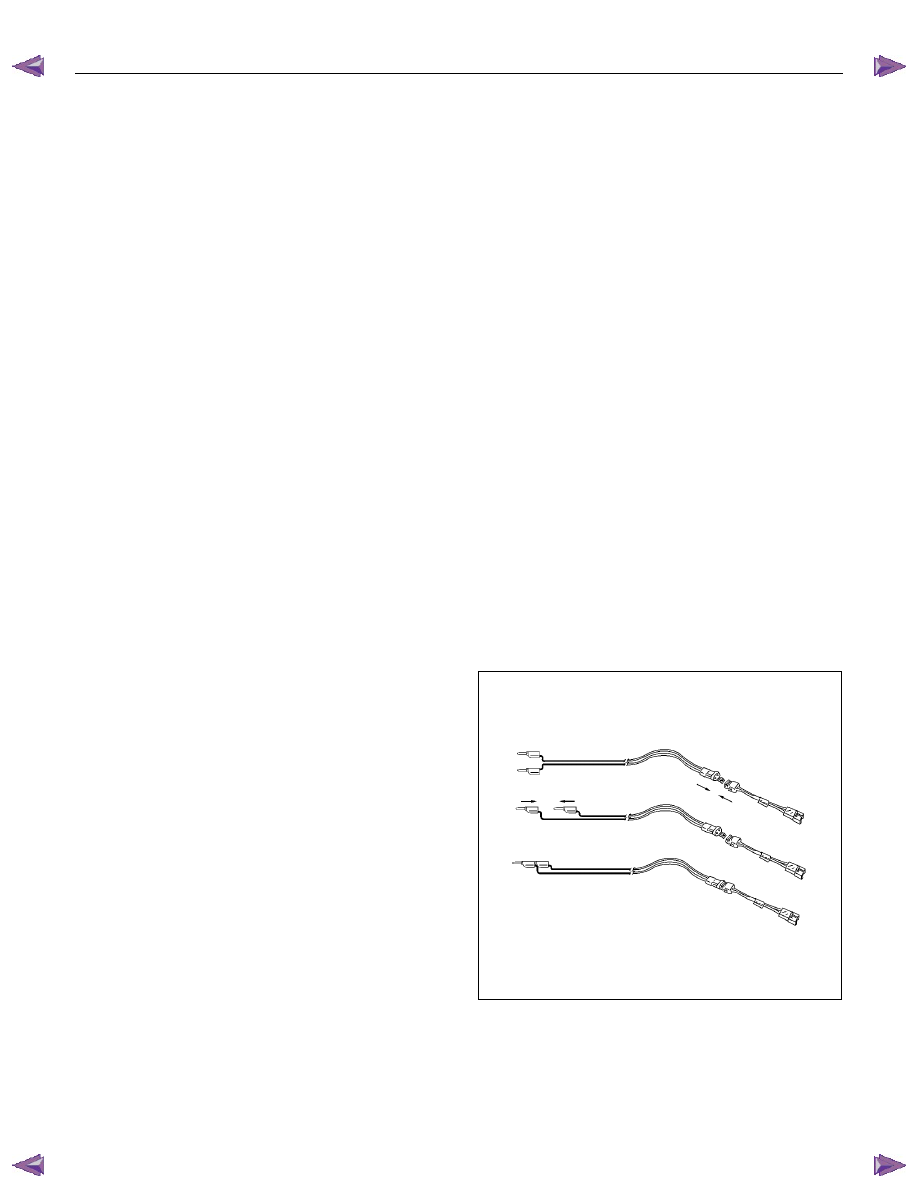

The following procedure requires use of a 5-8840-

2468-06 SRS deployment harness with appropriate

pigtail adapter. Do not attempt the procedure without

a 5-8840-2468-0 adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES

IN THE ORDER LISTED MAY RESULT IN

PERSONAL INJURY. NEVER CONNECT THE

DEPLOYMENT HARNESS TO ANY POWER

SOURCE BEFORE CONNECTING THE

DEPLOYMENT HARNESS TO THE DRIVER AIR

BAG ASSEMBLY. DEPLOYMENT HARNESS

SHALL REMAIN SHORTED AND NOT BE

CONNECTED TO A POWER SOURCE UNTIL THE

AIR BAG IS TO BE DEPLOYED. THE AIR BAG

ASSEMBLY WILL IMMEDIATELY DEPLOY THE AIR

BAG WHEN A POWER SOURCE IS CONNECTED

TO IT. WEAR SAFETY GLASSES THROUGHOUT

THIS ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

NOTE: This information applies only to driver air bag

assembly. Refer to “Deployment Outside Vehicle

(Passenger Air Bag assembly)” in this section for

information on passenger air bag assembly scrapping.

1. Turn the ignition switch to “LOCK”, remove the key

and put on safety glasses.

2.

Inspect the 5-8840-2468-0 SRS Deployment

Harness and appropriate pigtail adapter for

damage. If the harness or pigtail adapter is

damaged, discard and obtain a replacement.

3. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. The SRS deployment harness shall remain

shorted and not be connected to a power source

until the air bag is to be deployed.

827RS004

4. Connect the appropriate pigtail adapter to the SRS

deployment harness.

5. Remove the driver air bag assembly from the

vehicle. Refer to “Inflator Module Removal” in this

manual.

9A-24 SUPPLEMENTAL RESTRAINT SYSTEM

WARNING: WHEN STORING A LIVE AIR BAG

ASSEMBLY OR WHEN LEAVING A LIVE AIR BAG

ASSEMBLY UNATTENDED ON A BENCH OR

OTHER SURFACE, ALWAYS FACE THE AIR BAG

AND TRIM COVER UP AND AWAY FROM THE

SURFACE. THIS IS NECESSARY SO THAT A FREE

SPACE IS PROVIDED TO ALLOW THE AIR BAG TO

EXPAND IN THE UNLIKELY EVENT OF

ACCIDENTAL DEPLOYMENT. FAILURE TO

FOLLOW PROCEDURES MAY RESULT IN

PERSONAL INJURY.

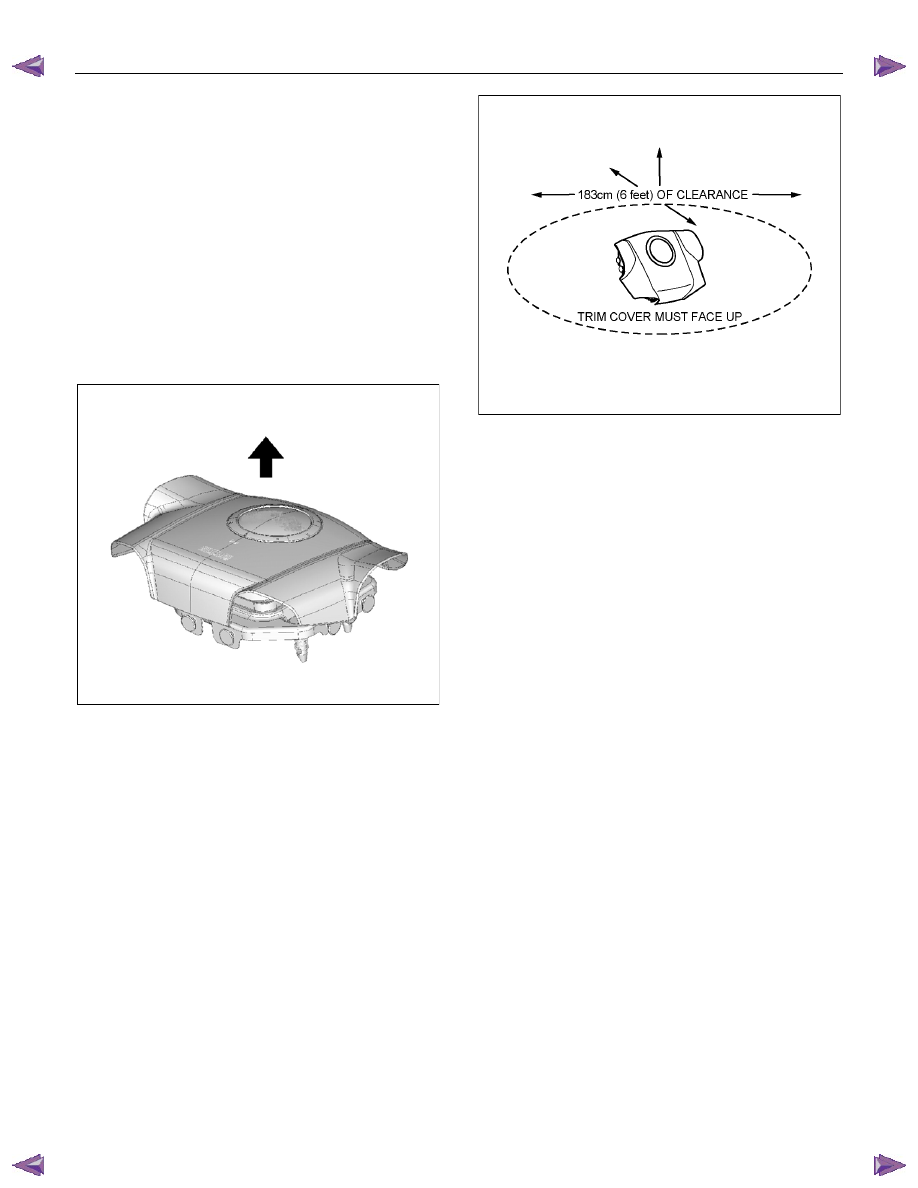

6. Place the driver air bag assembly on a work bench

or other surface away from all loose or flammable

objects with its trim cover facing up, away from the

surface.

RTW79ASH001101

7. Clear a space on the ground about 183 cm (six

feet) in diameter where the driver air bag assembly

is to be deployed. A paved, outdoor location

where there is no activity is preferred. If an

outdoor location is not available, a space on the

shop floor where there is no activity and there is

sufficient ventilation is recommended. Ensure no

loose or flammable objects are within the

deployment area.

RTW79ASH001201

8. Place the driver air bag assembly, with its trim

cover facing up, on the ground in the space just

cleared.

9. Stretch the SRS deployment harness and pigtail

adapter from the driver air bag assembly to its full

length.

10. Place a power source near the shorted end of the

SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps minimum.

A vehicle battery is suggested.

11. Connect the driver air bag assembly to the pigtail

adapter on the SRS deployment harness. The

deployment harness shall remain shorted and not

be connected to a power source until the air bag is

to be deployed. The driver air bag assembly will

immediately deploy the air bag when a power

source is connected to it.

NOTE: Ensure that the pigtail adapter is firmly seated

into the driver air bag assembly connector. Failure to

fully seat the connectors may leave the shorting bar

located in the driver air bag assembly connector

functioning (shorted) and may result in no deployment

of the driver air bag assembly.

12. Verify that the area around the driver air bag

assembly is clear of all people and loose or

flammable objects.

13. Verify that the driver air bag assembly is resting

with its trim cover facing up.

14. Notify all people in the immediate area that you

intend to deploy the driver air bag. The

deployment will be accompanied by a substantial

noise which may startle the uninformed.

15.

Separate the two banana plugs on the SRS

deployment harness.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст