Isuzu KB P190. Manual — part 387

FUEL SYSTEM (4JK1/4JJ1) 6C-7

g. Check that the warning lamp in the meter is off.

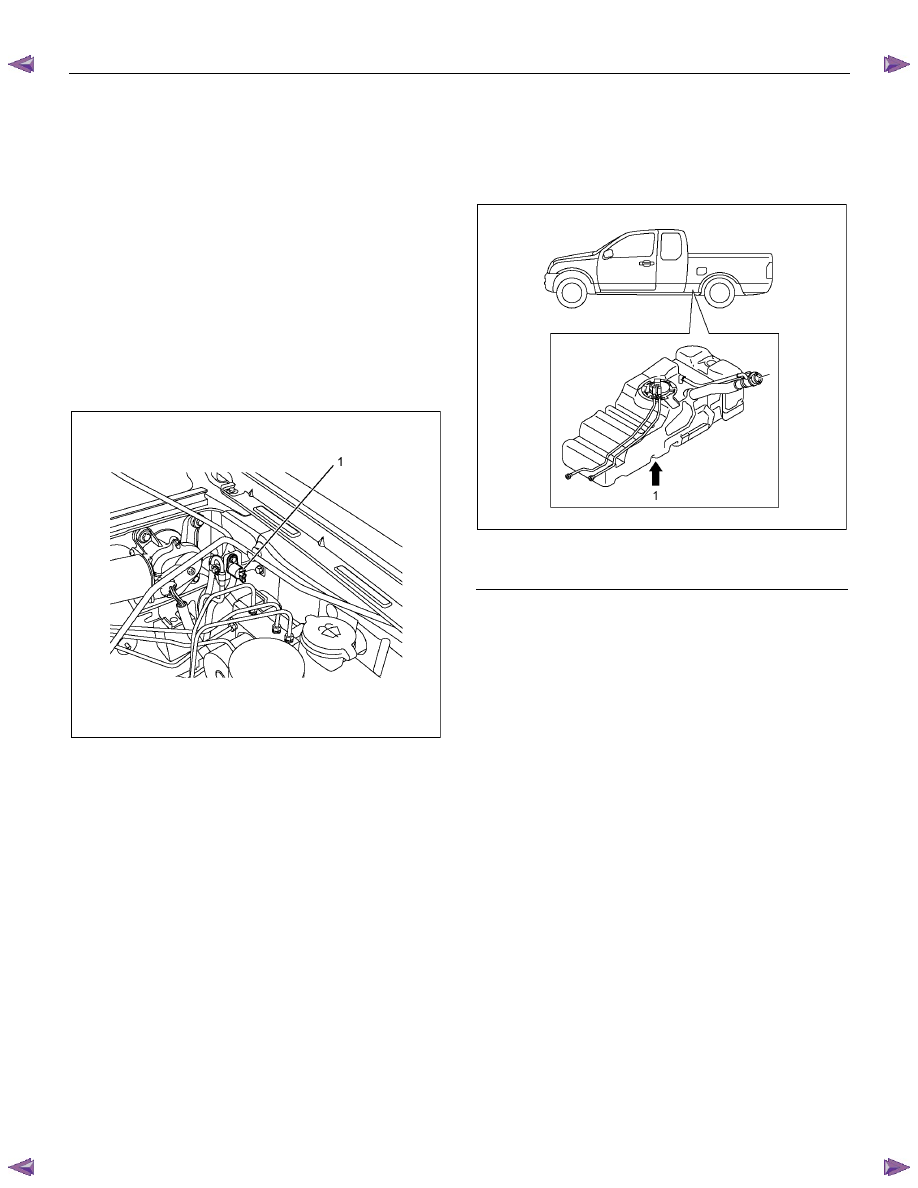

2. Draining with drain plug in engine room.

a. With the engine off, open the engine hood and

loosen the drain plug (1) located on the left

hand side of the engine room. (3-4 turns)

b. Turn the starter switch to the “ON” position for

10 seconds, and then turn the starter switch to

the “OFF” position for 10 seconds. Then, once

again turn the starter switch to the “ON”

position for 10 seconds.

c. Tighten the drain plug firmly.

d. After starting the engine, check that there is no

fuel leakage from the drain plug. Also check

that the water separator indicator has turned

off.

RTW76CSH001301

NOTE:

• If the water separator requires frequent draining,

have the fuel tank drained at your ISUZU/GM

Dealer.

• Be sure to stop the engine when draining the fuel

tank.

• Confirm that there are no combustible materials

under the drain hose, and use a receptacle to

catch the drained water.

Engine starting cautions

• Before starting the engine, turn the ignition switch

to the “ON” position. Wait 15 seconds. Return the

switch to the “LOCK” position. Repeat this

procedure 5 times.

• After starting the engine, allow it to idle for 10

minutes.

Fuel Pump Functional Check

1. Turn the starter switch to “ON” position.

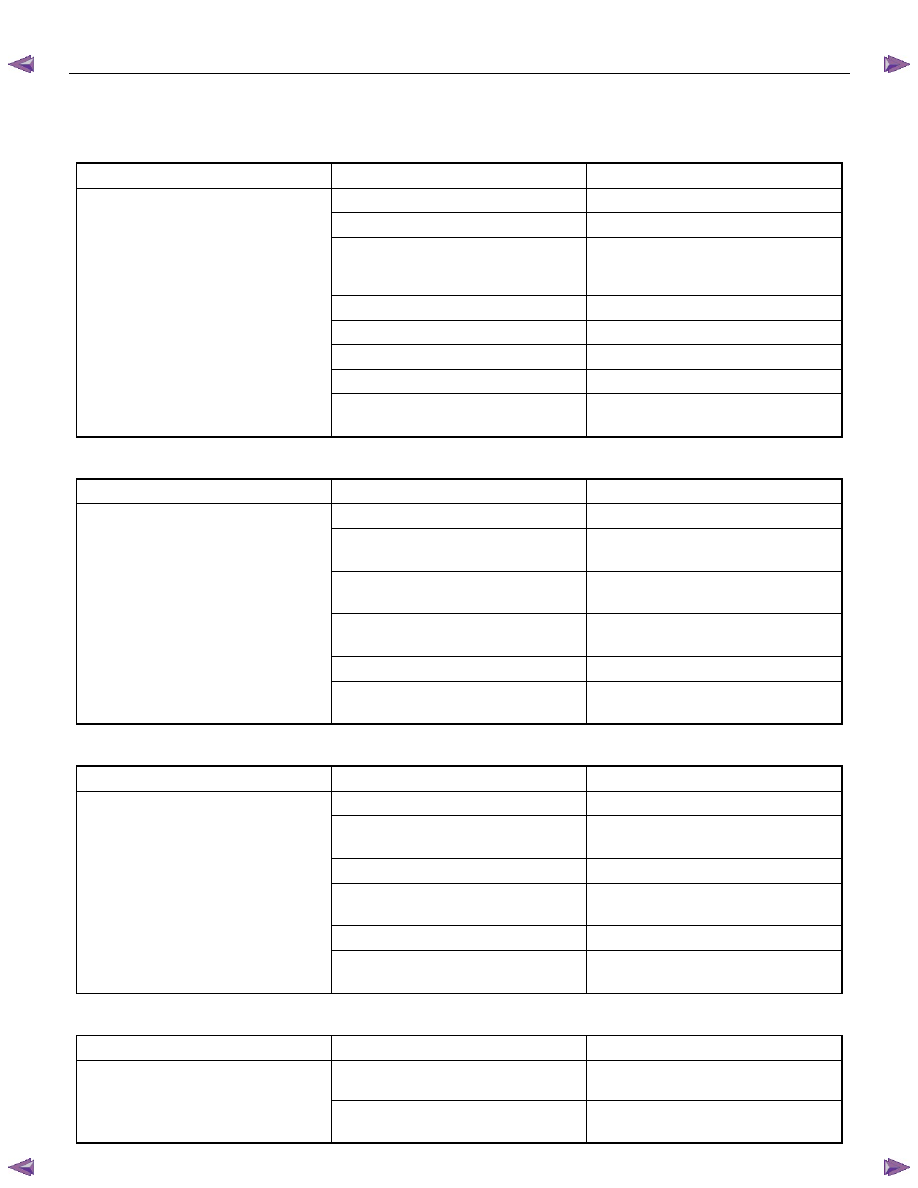

2. Touch the under portion of the Fuel Tank by the

hand as shown in the following figure within 12

seconds.

RTW56CSH003501

Legend

1. Touch this area by the hand

3. Make sure a vibration by the Fuel Pump is

detected.

Fuel Pump stops within 12 seconds of turning the

starter switch to the “ON” position.

When the check is repeated, return the starter

switch to the “LOCK” position for 10 – 15 seconds

and perform procedures 1 – 3.

WARNING:

FUEL PUMP FUNCTIONAL CHECK

MUST BE CONDUCTED UNDER THE FOLLOWING

CONDITIONS TO AVOID INJURY.

•••• APPLY THE PARKING BRAKE.

•••• STOP THE ENGINE.

6C-8 FUEL SYSTEM (4JK1/4JJ1)

Trouble Shooting

Problems with starting

Condition Possible

Cause Correction

Problems with starting

Fuel tank is empty

Fill the tank.

Air has entered the fuel system.

Bleed the air.

Fuel line or fuel cooler is clogged or

damaged. Connection to the fuel line

is loose.

Repair or replace the fuel line and

fuel cooler. Re-tighten the

connection.

Fuel filter element is clogged.

Replace the cartridge.

Fault in the feed pump

Replace the fuel supply pump.

Regulating valve is open.

Replace

Sticking of the fuel injector

Replace the fuel injector.

Defective engine control system

Diagnose the engine control system.

Hunting during idling

Condition Possible

Cause Correction

Hunting during idling

Air has entered the fuel system.

Bleed air from the fuel system.

Leakage or clogging of the fuel

system

Repair or replace the fuel system.

Drops of water have entered the fuel

system.

Replace the fuel.

Fuel filter element is clogged.

Replace the fuel filter element

(cartridge).

Sticking of the fuel injector

Replace the fuel injector.

Defective engine control system

Diagnose the engine control system.

Insufficient horsepower

Condition Possible

Cause Correction

Insufficient horsepower

Air has entered the fuel system.

Bleed air from the fuel system.

Leakage or clogging of the fuel

system

Repair or replace the fuel system.

Water mixes in the fuel system

Replace the fuel.

Fuel filter element is clogged.

Replace

the

element

or

the

cartridge.

Sticking of the fuel injector

Replace the fuel injector.

Defective engine control system

Diagnose the engine control system.

Maximum engine speed is too low

Condition Possible

Cause Correction

Maximum engine speed is too low

Fuel line, fuel cooler is clogged or

damaged.

Repair or replace the fuel line, fuel

cooler.

Defective engine control system

Diagnose the engine control system.

FUEL SYSTEM (4JK1/4JJ1) 6C-9

Engine does not stop

Condition Possible

Cause Correction

Engine does not stop

Defective engine control system

Diagnose the engine control system.

Exhaust gas is blue or black

Condition Possible

Cause Correction

Exhaust gas is blue or black.

Reduction in injection-valve opening

pressure or defective atomizing

status

Replace the fuel injector.

Engine control system malfunction

System diagnosis.

6C-10 FUEL SYSTEM (4JK1/4JJ1)

Fuel System Check

Description

Conforms to a fuel leak. Engine acceleration raises fuel

pressure and which increases the leak.

Leak could be in the following pipes and locations.

• Between injectors and fuel rail.

• Between fuel rail and fuel supply pump.

• Between fuel supply pump and fuel filter.

• Between fuel filter and fuel tank.

• Between pressure limiter and fuel cooler.

• Between fuel cooler and fuel tank.

• Between injector over flow and leak off pipe.

Diagnostic Aids

Check the following items.

• Air in the fuel line

• Clogged fuel filter

• Fuel pipe malfunction (Crushing, breakage,

clogging, disconnection, etc.)

• Fuel cooler malfunction (Crushing, breakage,

clogging, disconnection, etc.)

• Fuel tank malfunction

• Injector

malfunction

• Fuel supply pump malfunction

• Pressure limiter malfunction

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside

the insulation. Check for poor connections or a

damaged harness.

Inspect the ECM harness and connector for improper

mating, broken locks, improperly formed or damaged

terminals, poor terminal-to-wire connection, and

damaged harness.

ECU may set a DTC, if there is adequate air in fuel line.

Schematic Reference: Engine Controls Schematics

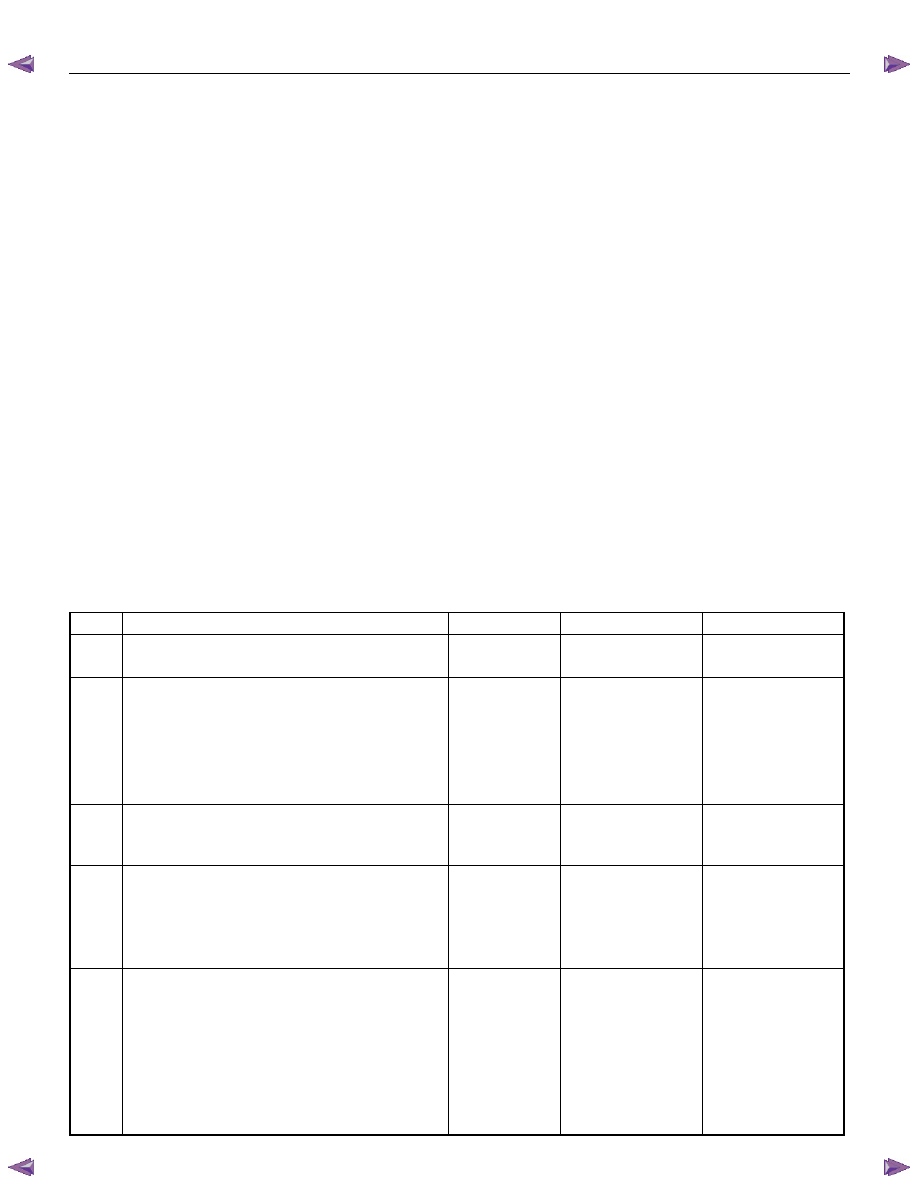

Step Action

Value(s)

Yes

No

1

Check the fuel quantity.

Was a problem found?

Go to Step 2

Add fuel and

Go to Step 2

2

Check the fuel quality.

1. Discharge the fuel from fuel tank

2. Replenish the tank with specified fuel

3. Bleed the air from the fuel system

4. Start the engine

Could the engine be started?

Go to Step 7 Go

to

Step 3

3

Bleed the air from fuel system. Refer to Fuel

System Air Bleeding in this section.

Is the action complete?

Go to Step 4

4

Check the main fuel filter for clogging.

Clean, repair, or replace as required.

Notice: Replacement of a fuel filter is checking

to a dealer.

Is the action complete?

Go to Step 5

5

Check the fuel line and fuel cooler for damage

and leakage.

Clean, repair, or replace as required.

• Crushed

areas

• Breakage

• Cracks

• Loose

connections

Is the action complete?

Go to Step 6

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст