Isuzu KB P190. Manual — part 870

Engine Management – V6 – Diagnostics

Page 6C1-2–202

Conditions for Setting the DTC

Condition 1

•

The ECM detects that the front HO2S is operating too rich while the rear HO2S is operating too lean and the ECM

detects that the fuel trim is at minimum control,

OR

•

The rear fuel trim, long and short term, is less than a threshold.

•

This DTC sets after the air flow coming into the engine accumulates to more than 200 grams and the above

conditions are met for more than 4 seconds.

Condition 2

•

The ECM detects that the rear HO2S is operating too lean while the ECM is commanding a rich air / fuel mixture.

•

This DTC sets after the air flow coming into the engine accumulates to more than 800 grams and the above

condition is met for more than 4 seconds.

Action Taken When the DTC Sets

•

The ECM activates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the

diagnostic runs and fails.

•

The ECM records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the

control module stores this information in the Failure Records. If the diagnostic reports a failure on the second

consecutive ignition cycle, the control module records the operating conditions at the time of the failure. The

control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

Conditions for Clearing the MIL/DTC

•

The control module turns OFF the malfunction indicator lamp (MIL) after four consecutive ignition cycles that the

diagnostic runs and does not fail.

•

A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

•

A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission

related diagnostic.

•

Use Tech 2 to clear the MIL and the DTC.

Additional Information

•

A HO2S fault condition may cause this DTC to set. Thoroughly inspect all items that could cause a rich condition.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since a fault condition in a wiring connector may trigger DTCs, always test the connectors related to this

diagnostic procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A

Electrical - Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

2

This step determines if a condition exists.

5

This step is testing for a rear HO2S sensor circuit condition. A circuit condition sets this DTC.

8

This step is testing for an intermittent circuit condition. Thoroughly inspect the HO2S circuits for an intermittent

circuit condition.

9

This step is testing for an intermittent circuit condition. Thoroughly inspect the HO2S circuits for an intermittent

circuit condition.

Engine Management – V6 – Diagnostics

Page 6C1-2–203

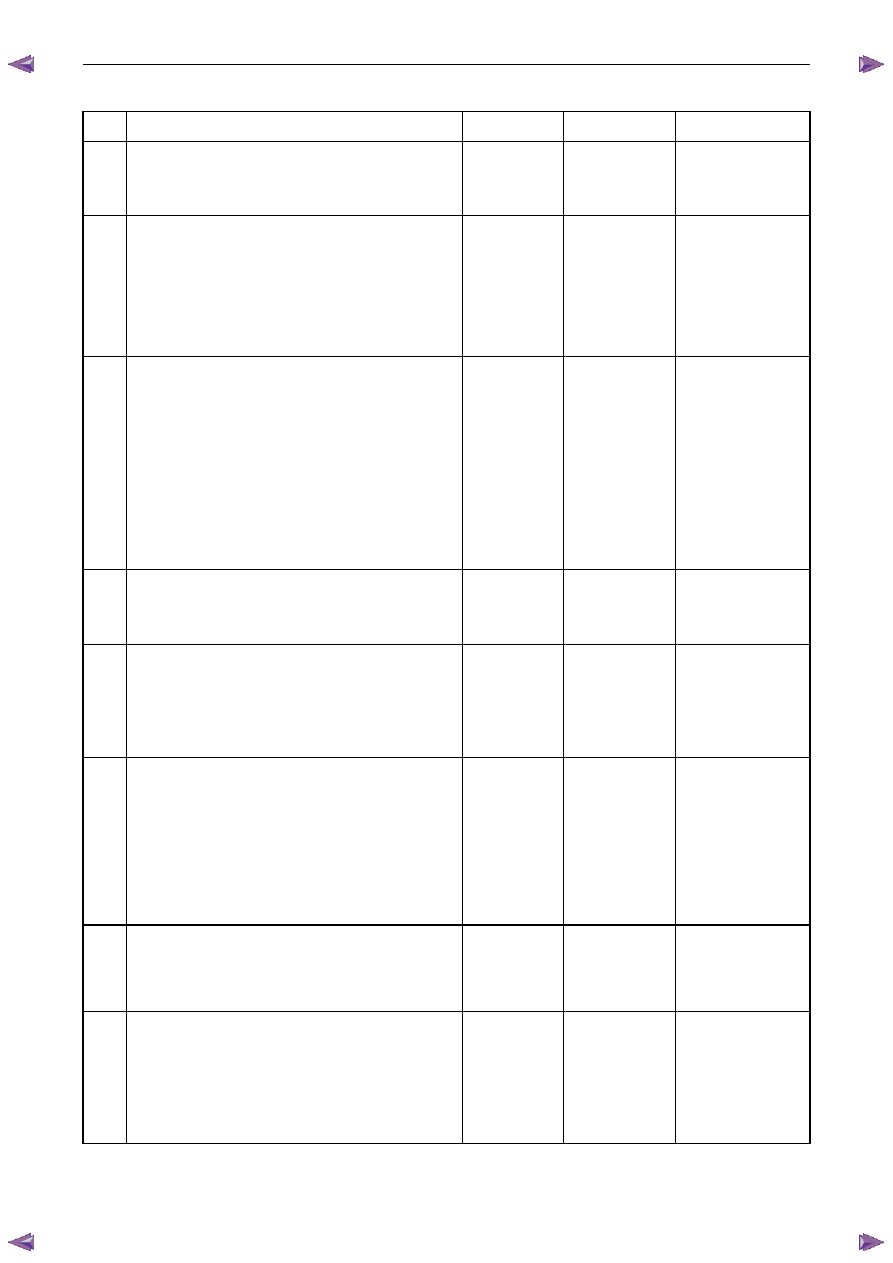

DTC P2196 or P2198 Diagnostic Table

Step Action

Value(s)

Yes

No

1

Has the Diagnostic System Check been completed?

—

Go to Step 2

Refer to

4.4 Diagnostic

System Check in this

Section

2

1

Allow the engine to reach operating temperature.

2

Operate the vehicle within the parameters

specified in Conditions for Running the DTC.

3

Observe the diagnostic trouble code (DTC)

information, using Tech 2.

Did DTC P2196 or DTC P2198 fail this ignition?

—

Go to Step 4

Go to Step 3

3

1

Observe the Freeze Frame and / or the Failure

records data for this DTC.

2

Turn the ignition OFF for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the Conditions for

Running the DTC. You may also operate the

vehicle within the conditions that you observed

from the Freeze Frame and / or the Failure

records data.

Does the DTC fail this ignition cycle?

—

Go to Step 4

Refer to Additional

Information in this

DTC.

4

Is DTC P0041, P0137, P0138, P0140, P0157, P0158,

or P0160 also set?

—

Go to the

appropriate DTC

Table in this

Section

Go to Step 5

5

1

Operate the engine above 1,200 RPM for

30 seconds.

2

Observe the appropriate rear HO2S voltage,

using Tech 2.

Is the voltage less than the specified value?

1,050 mV

Go to Step 8

Go to Step 6

6

1 Ignition

OFF.

2

Disconnect the appropriate rear heated oxygen

sensor (HO2S).

3

Ignition ON, engine OFF.

4

Observe the appropriate rear HO2S voltage

parameter with Tech 2.

Is the voltage within the specified range?

350 – 550 mV

Go to Step 12

Go to Step 7

7

1

Test the appropriate rear HO2S signal circuit for

a short to voltage. Refer to 8A Electrical - Body

and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 14

8

1

Shake the related HO2S harnesses for the front

sensor between the HO2S harness connector

and the engine control module (ECM) while

monitoring the appropriate HO2S lambda

parameter.

Does the HO2S parameter change abruptly while

moving the related harnesses?

—

Go to Step 15

Go to Step 9

Engine Management – V6 – Diagnostics

Page 6C1-2–204

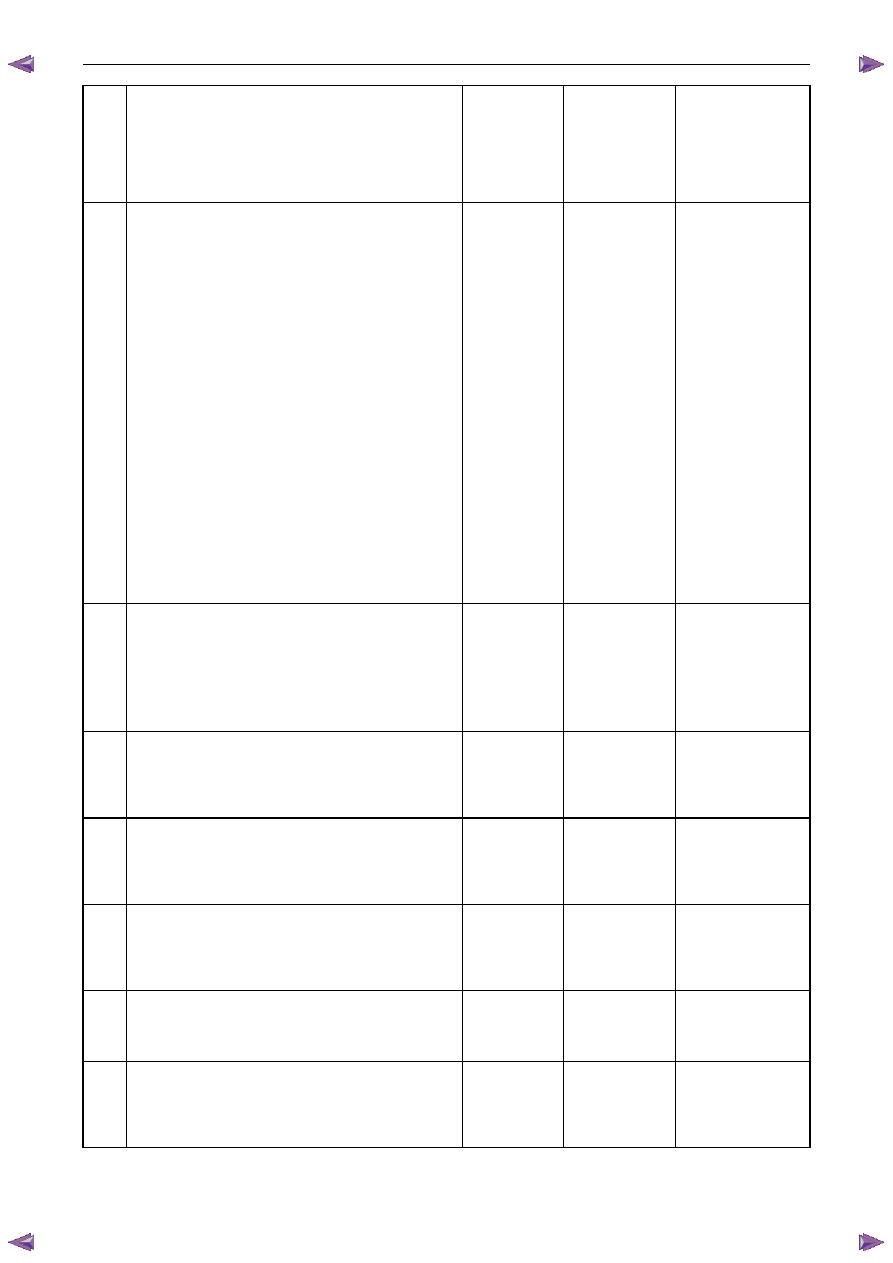

9

1

Shake the related HO2S harnesses for the rear

sensor between the HO2S harness connector

and the ECM while monitoring the appropriate

HO2S voltage parameter.

Does the HO2S parameter change abruptly while

moving the related harnesses?

—

Go to Step 15

Go to Step 10

10

1 Ignition

OFF.

2

Disconnect the front and rear heated oxygen

sensors.

3

Inspect the front and rear heated oxygen sensors

for the following conditions:

−

For damaged wiring between the HO2S

and the ECM – An intermittent circuit

condition may cause this DTC to set.

−

For terminal corrosion or water intrusion in

the HO2S harness connectors.

−

For the correct terminal tension.

−

The HO2S is securely installed and not

damaged.

−

For any exhaust leaks – Refer to 6F

Exhaust System – V6.

8

Repair as necessary. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 11

11

1

Disconnect the ECM.

2

Test the appropriate front heated oxygen sensor

circuits for being shorted together between the

HO2S connector and the ECM. Refer to 8A

Electrical - Body and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 13

12

1

Test for shorted terminals and for poor

connections at the HO2S. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 17

13

1

Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 16

14

1

Test for shorted terminals and for poor

connections at the ECM. Refer to 8A Electrical -

Body and Chassis.

Did you find and correct the condition?

—

Go to Step 19

Go to Step 18

15

1

Repair the circuit as necessary. Refer to 8A

Electrical - Body and Chassis.

Did you complete the repair?

—

Go to Step 19

—

16

1

Replace the HO2S 1. Refer to the Oxygen

Sensor 1 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement?

—

Go to Step 19

—

Engine Management – V6 – Diagnostics

Page 6C1-2–205

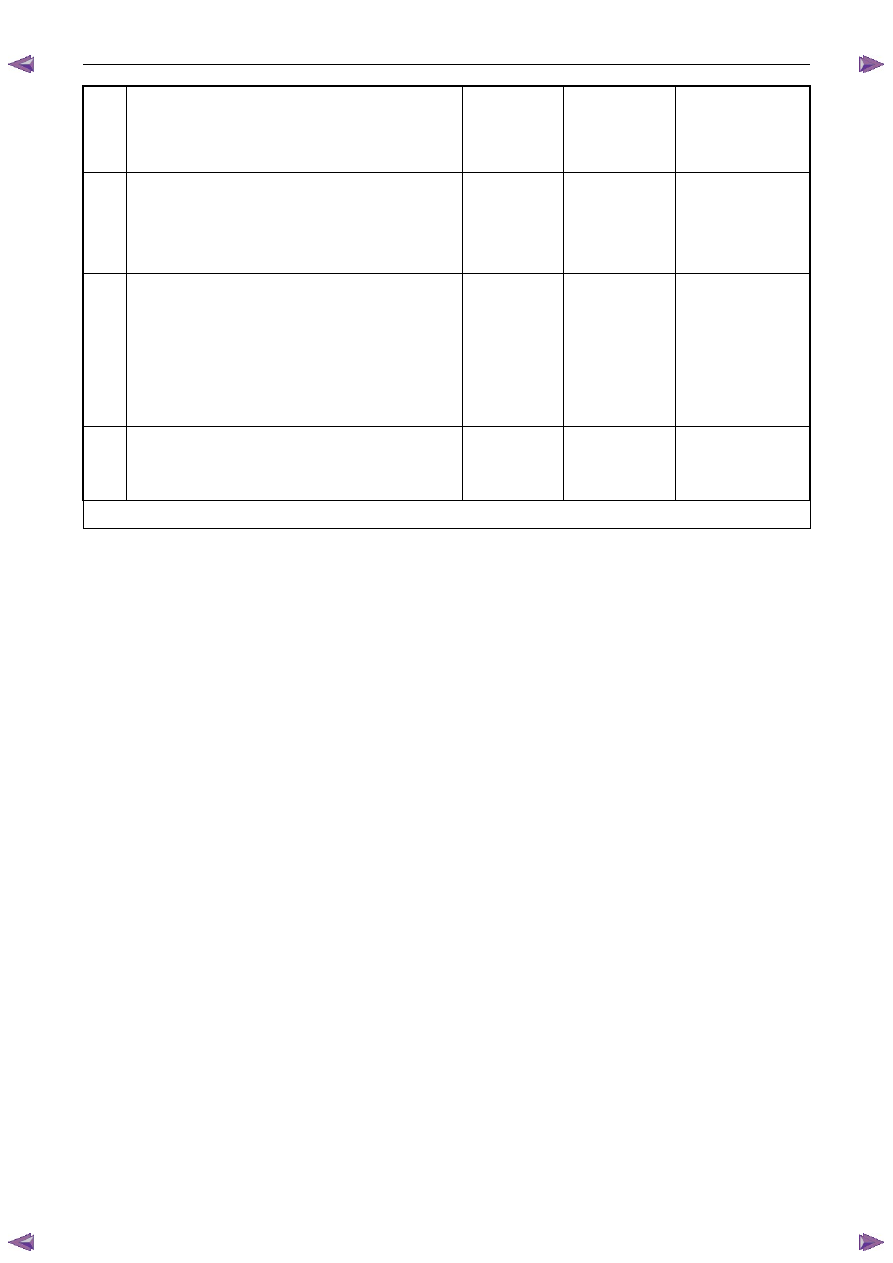

17

1

Replace the HO2S 2. Refer to the Oxygen

Sensor 2 procedure, in 6C1- Engine

Management – V6 Service Operations.

Did you complete the replacement?

—

Go to Step 19

—

18

1

Replace the ECM. Refer to Engine Control

Module (ECM) Remove, Reinstall and ECM

Reset in 6C1- Engine Management – V6 Service

Operations.

Did you complete the replacement?

—

Go to Step 19

—

19

1

Clear the DTCs, using Tech 2.

2

Turn OFF the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for

running the DTC.

Does DTC P2196 or P2198 fail this ignition cycle?

—

Go to Step 2

Go to Step 20

20

1

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTC?

—

Go to the

appropriate DTC

Table in this

Section System

OK

When all diagnosis and repairs are completed, clear all DTCs and verify correct operation

7.57 DTC P2227, P2228 or P2229

DTC Descriptor

This diagnostic procedure supports the following DTCs:

•

DTC P2227 – Barometric Pressure Sensor Circuit Range / Performance

•

DTC P2228 – Barometric Pressure Sensor Voltage Low

•

DTC P2229 – Barometric Pressure Sensor Voltage High

Circuit Description

The ECM applies a positive 5 V reference voltage to the barometric pressure (BARO) sensor through the 5 V reference

circuit and the ground through the low reference circuit.

The BARO sensor provides signal voltage to the ECM that is proportional to the atmospheric pressure changes through

the signal circuit. The ECM uses the BARO signal voltage to maintain the correct fuel delivery at different altitudes.

The ECM monitors and compares the BARO sensor signal voltage against a specified range. A BARO pressure sensor

circuit DTC sets if the ECM detects the BARO sensor signal voltage is outside the specified range.

Conditions for Running the DTC

DTC P2227

Runs continuously once the following conditions are met for 3 seconds:

•

DTCs P0121, P0122, P0123, P0221, P0222 or P0223 are not set.

•

The engine is running.

DTC P2228 and P2229

Runs continuously once the following conditions are met for 3 seconds:

•

DTCs P0101, P0102 or P0103 are not set.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст