Suzuki Grand Vitara JB627. Manual — part 293

8A-5 Seat Belts:

Front Seat Belt Inspection

S6JB0B8106003

WARNING

!

• Never attempt to disassemble or repair the

seat belt pretensioner (retractor

assembly). If any abnormality is found, be

sure to replace it with new one as an

assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Seat Belt”, before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

unactivation of the seat belt pretensioner

when necessary.

• Never measure resistance of pretensioner

or disassemble it. Otherwise, personal

injury may result.

CAUTION

!

If seat belt pretensioner (retractor assembly)

was dropped from a height of 30 cm (1 ft) or

more, it should be replaced.

Seat belts and attaching parts can affect the vital

components and systems of a vehicle.

Therefore, they should be inspected carefully and

replaced with genuine parts only.

Seat Belt

• The seat belt webbing or strap should be free from

damage.

Retractor Assembly (with Seat Belt Pretensioner)

1) Let the seat belt retract fully to confirm its easy

retraction.

• The retractor assembly should lock webbing when

pulled quickly.

• The front seat belt retractor assembly (1) should

pass the inspection and should lock webbing even

when tilted (approx. 15

°) toward the fore and aft or

right and left directions.

2) Check retractor assembly (1) with seat belt

pretensioner appearance visually for following

symptoms and if any one of them is applicable,

replace it with a new one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner

(retractor assembly).

• Seat belt pretensioner (retractor assembly) is

damaged or a strong impact (e.g., dropping) was

applied to it.

Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Switch

Check driver side seat belt switch for continuity by using

ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuity

I5JB0A810005-02

1. Buckle tongue

2. Buckle catch

I2RH01810005-01

I4RS0B810001-01

Seat Belts: 8A-6

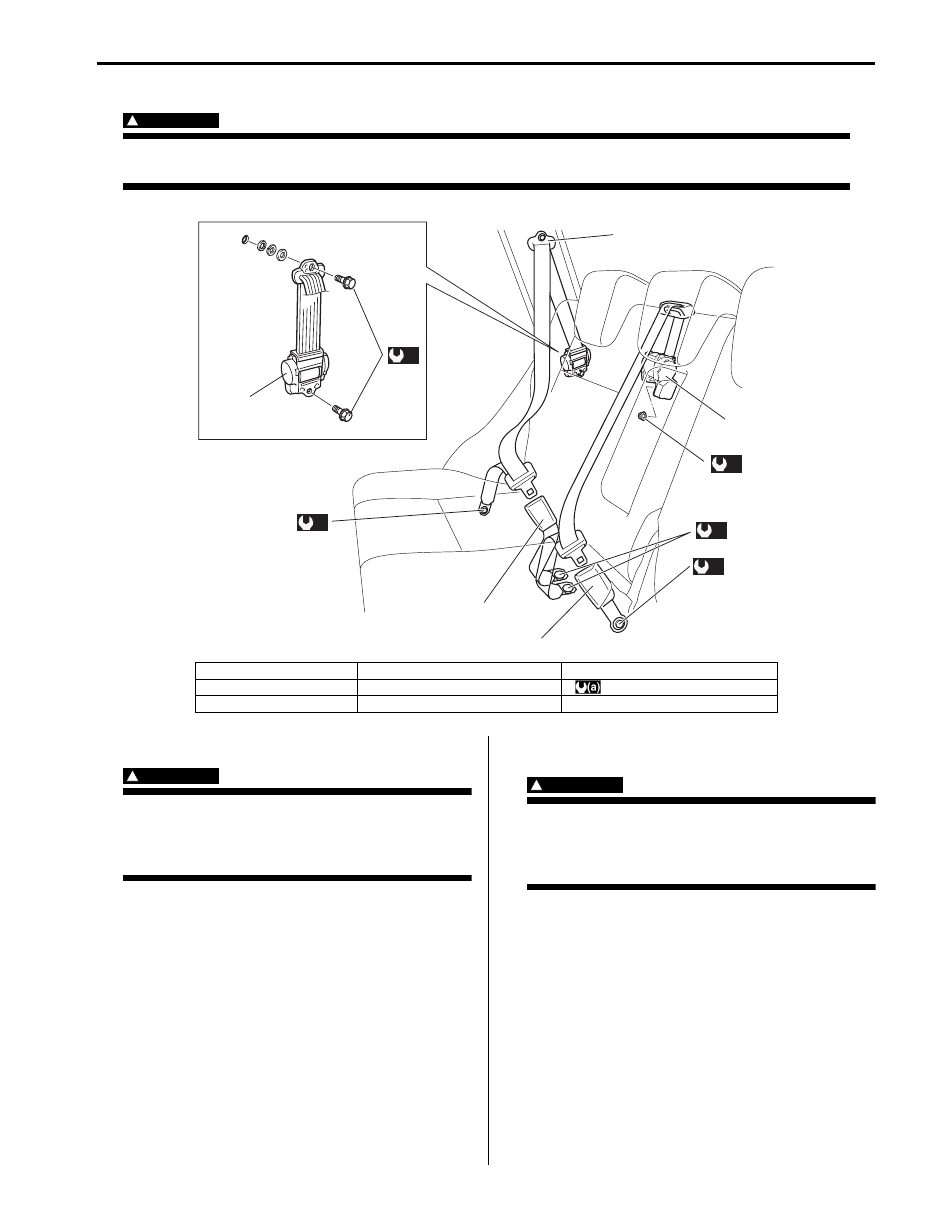

Rear Seat Belt Components

S6JB0B8106004

WARNING

!

Be sure to read “Precautions on Service and Diagnosis of Seat Belt” before starting to work and

observe every precaution during work.

Rear Seat Belt Removal and Installation

S6JB0B8106005

WARNING

!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

Removal

1) Remove rear side sill scuff, rear side lower trim and

rear pillar trim referring to “Head Lining Removal and

Installation in Section 9H”.

2) Remove rear seat belt referring to “Rear Seat Belt

Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.

Rear Seat Belt Inspection

S6JB0B8106006

WARNING

!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front

• As to seat belts with A-ELR, check them as follows.

– With vehicle at stop, pull seat belt all the way out,

let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retract a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

(a)

(a)

(a)

(a)

(a)

3

1

4

6

5

2

I5JB0A810006-01

1. Upper anchor

4. Rear center retractor assembly

7. Rear seat belt

2. Lower anchor

5. Buckle for rear seat belt

: 35 N

⋅m (3.5 kgf-m, 25.5 lb-ft)

3. Retractor assembly

6. Buckle for rear center seat belt

8A-7 Seat Belts:

Specifications

Tightening Torque Specifications

S6JB0B8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Air Bag System: 8B-1

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6JB0B8200001

WARNING

!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver,

passenger, side of both sides and curtain of both

sides) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.

• When handling the air bag (inflator) modules (driver,

passenger, side of both sides and curtain of both

sides), seat belt pretensioners (driver and passenger),

SDM, forward-sensor or side-sensor, be careful not to

drop it or apply an impact to it. If an excessive impact

was applied (e.g., SDM, forward-sensor and side-

sensor are dropped, air bag (inflator) module is

dropped from a height of 90 cm (3 ft) or more, seat

belt pretensioner (retractor assembly) is dropped from

a height of 30 cm (1 ft) or more), never attempt

disassembly or repair but replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver, passenger,

side of both sides and curtain of both sides) and seat

belt pretensioner connectors (driver and passenger)

respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING

!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст