Suzuki Grand Vitara JB627. Manual — part 110

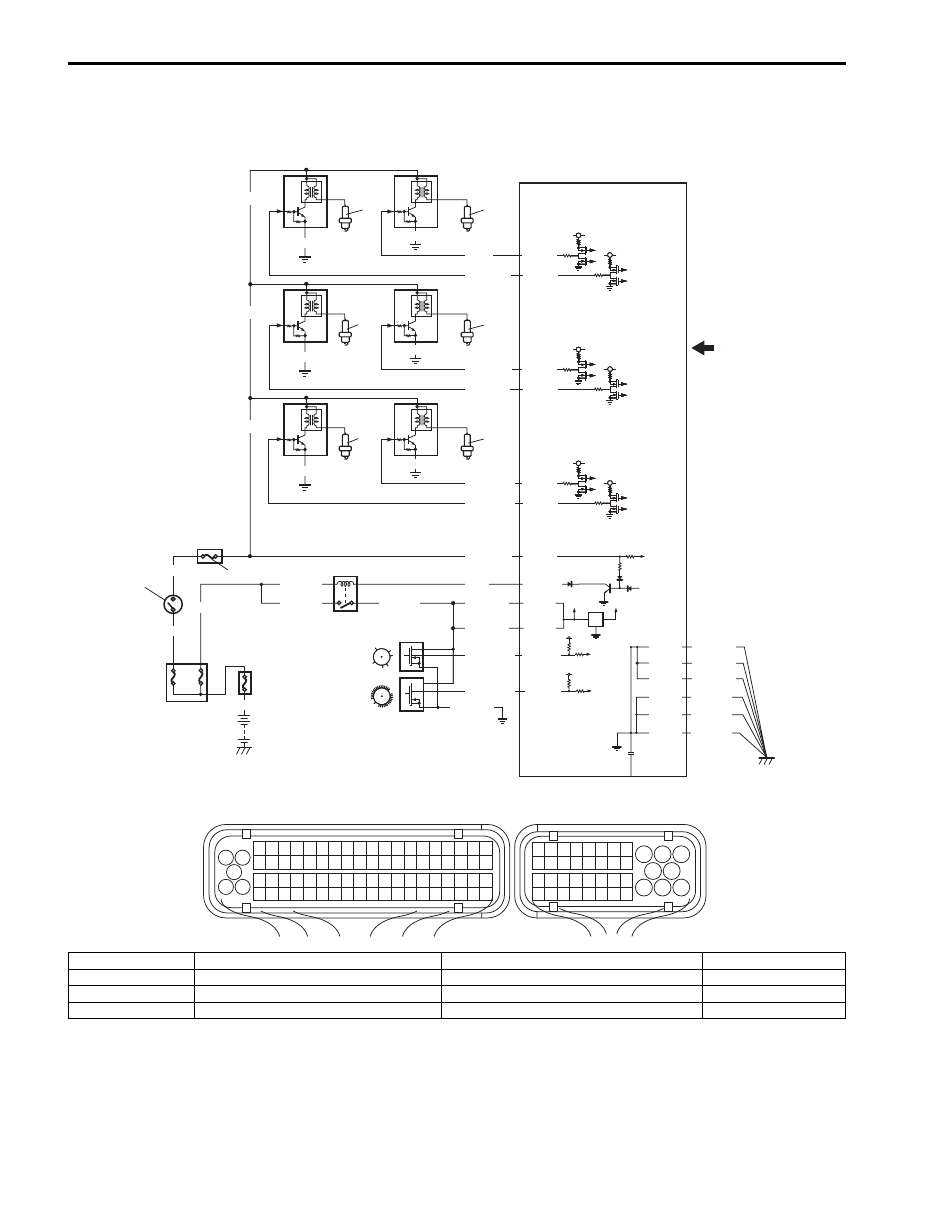

1H-2 Ignition System:

Schematic and Routing Diagram

Ignition System Wiring Circuit Diagram

S6JB0B1802001

E23-16

E23-8

12V

5V

E23-2

E23-3

BLK/WHT

BLU/BLK

BLU/BLK

BLU/BLK

BLK/RED

BLK/RED

BLK/RED

BLK/YEL

WHT/GRN

BLU

1

13

14

15

2

5V

WHT/RED

BLK/WHT

BRN/BLK

BRN

C37-76

C37-57

BLK/WHT

BRN/YEL

BRN/WHT

C37-75

C37-56

BLK/ORN

BLK/ORN

BLK/ORN

BLK/ORN

BLK/YEL

BLK/YEL

BLK/YEL

C37-47

10

10

10

10

6

8

7

9

3

BLK

BLK/ORN

C37-59

C37-58

C37-39

C37-80

C37-81

C37-73

BLK/ORN

BLK/ORN

WHT/BLU

C37-66

BLK/YEL

4

5

BLK/YEL

BLK/WHT

C37-55

BLK/ORN

BLK/ORN

10

10

12

PPL/RED

BRN/RED

C37-74

11

1

3 2

4

5

6

7

8

9

1110

12

13

14

15

16

17

18

19

20

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

33

34

35

36

37

38

39

40

32

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

I6JB01180001-01

1. Ignition switch

5. CKP sensor

9. Ignition coil assembly (For No.4 cylinder)

13. Main relay

2. “IG COIL” fuse

6. Ignition coil assembly (For No.1 cylinder)

10. Spark plug

14. Sensed information

3. ECM

7. Ignition coil assembly (For No.2 cylinder)

11. Ignition coil assembly (For No.5 cylinder)

15. Junction block

4. CMP sensor

8. Ignition coil assembly (For No.3 cylinder)

12. Ignition coil assembly (For No.6 cylinder)

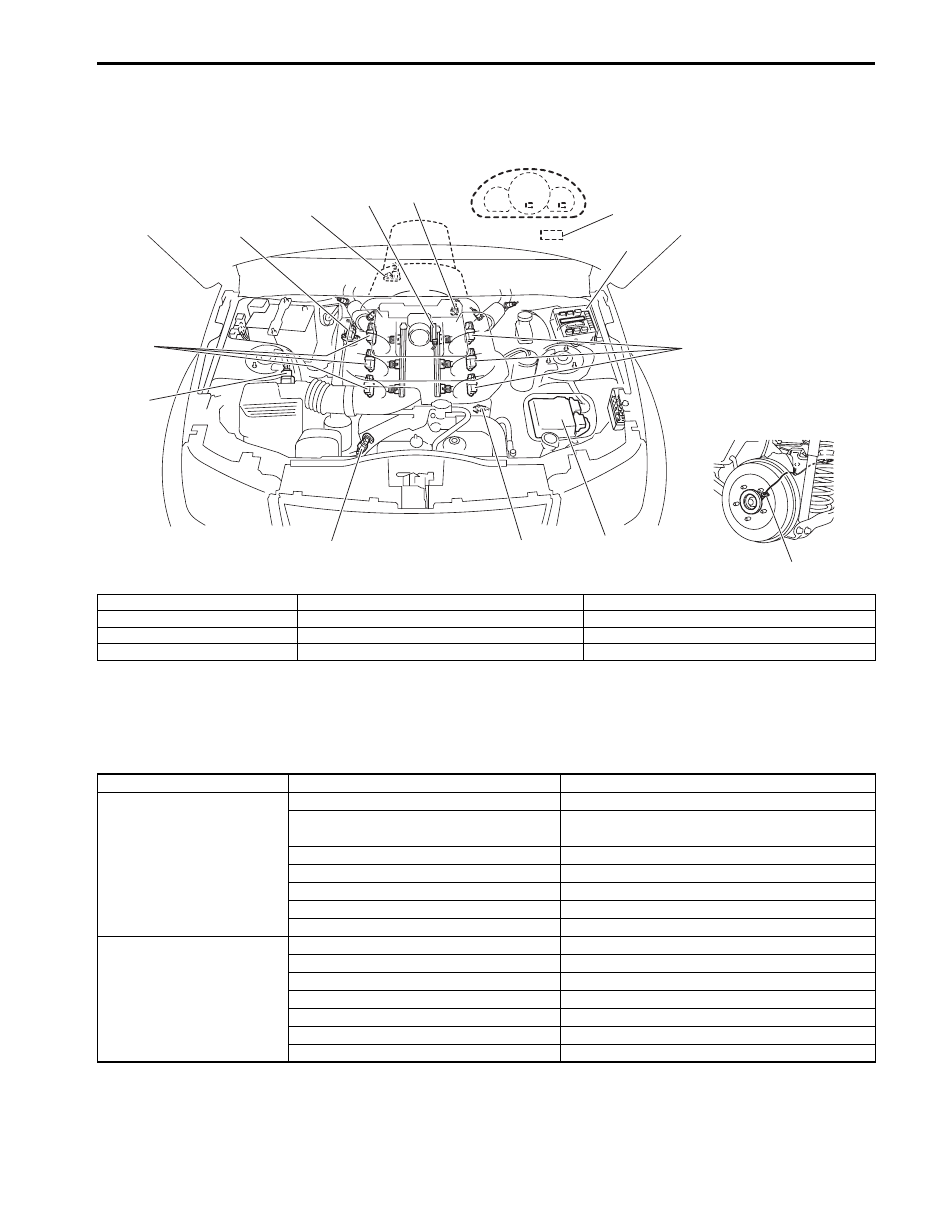

Ignition System: 1H-3

Component Location

Ignition System Components Location

S6JB0B1803001

Diagnostic Information and Procedures

Ignition System Symptom Diagnosis

S6JB0B1804001

12

12

6

2

1

3

4

5

7

8

9

11

10

I6JB01180002-01

1. ECM

5. ECT sensor

9. Data link connector

2. CMP sensor

6. MAF and IAT sensor

10. Rear wheel sensor (RH, LH) (VSS)

3. CKP sensor

7. Electric throttle body assembly

11. Fuse box No.2

4. MAP sensor (if equipped)

8. Knock sensor

12. Ignition coil assembly

Condition

Possible cause

Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark)

Blown fuse for ignition coil assembly

Replace.

Loose connection or disconnection of

lead wire

Connect securely.

Faulty spark plug(s)

Replace.

Faulty ignition coil assembly(s)

Replace.

Faulty CMP sensor or sensor rotor

Clean, tighten or replace.

Faulty CKP sensor or sensor plate

Clean, tighten or replace.

Faulty ECM

Replace.

Poor fuel economy or

engine performance

Incorrect ignition timing

Check related sensors and CKP sensor plate.

Faulty spark plug(s)

Replace.

Faulty ignition coil assembly(s)

Replace.

Faulty CMP sensor or sensor rotor

Clean, tighten or replace.

Faulty CKP sensor or sensor plate

Clean, tighten or replace.

Faulty ECM

Replace.

Faulty knock sensor

Replace.

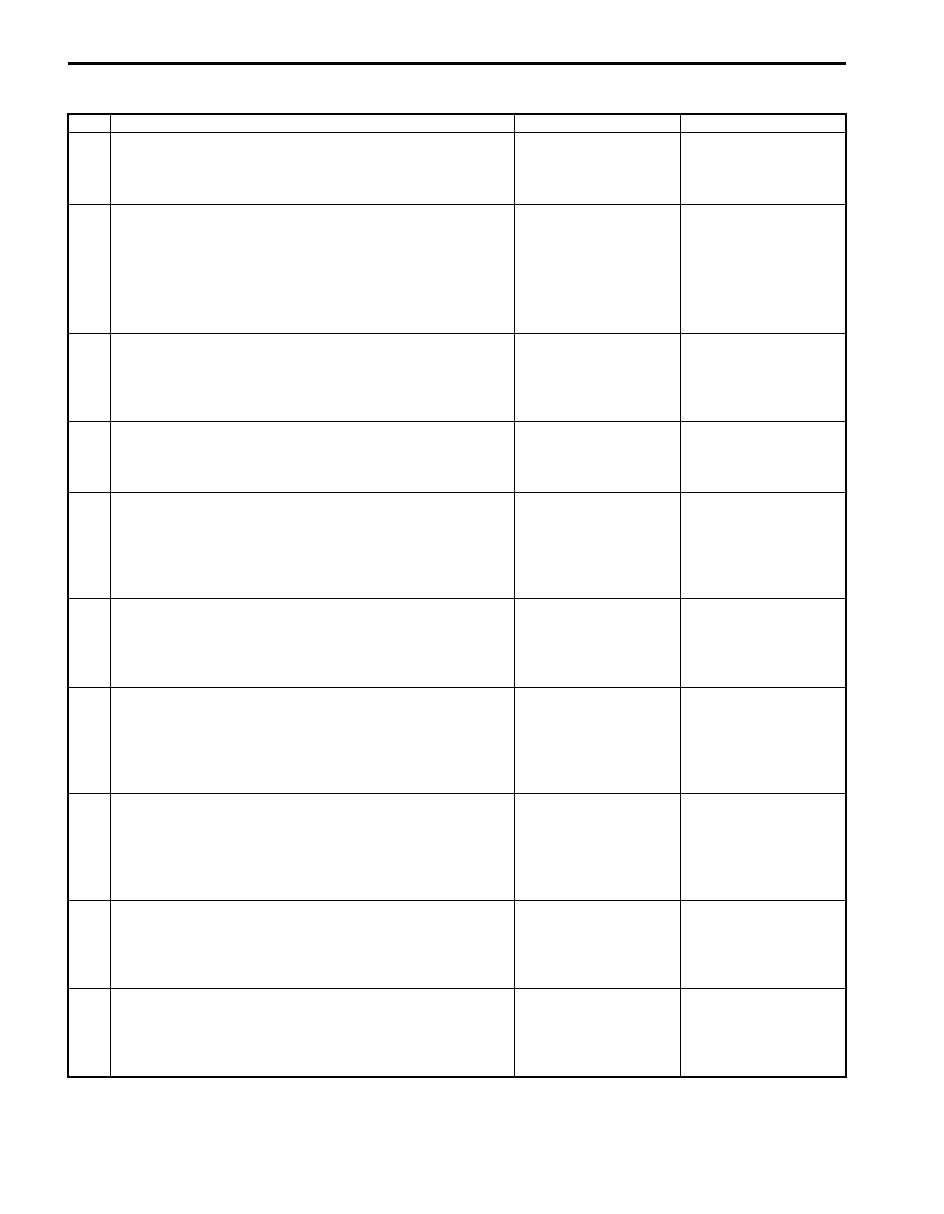

1H-4 Ignition System:

Ignition System Check

S6JB0B1804002

Step

Action

Yes

No

1

Was “Engine and Emission Control System Check”

performed?

Go to Step 2.

Go to “Engine and

Emission Control

System Check in

Section 1A”.

2

Ignition spark test

1) Check all spark plugs for condition and type referring to

2) If OK, perform ignition spark test referring to “Ignition

Is spark emitted from all spark plugs?

Go to Step 11.

Go to Step 3.

3

DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM?

Go to applicable DTC

diag. flow.

Go to Step 4.

4

Electrical connection check

1) Check ignition coil assemblies for electrical connection.

Are they connected securely?

Go to Step 5.

Connect securely.

5

Ignition coil assembly power supply and ground circuit

check

1) Check ignition coil assembly power supply and ground

circuits for open and short.

Are circuits in good condition?

Go to Step 6.

Repair or replace.

6

Ignition coil assembly check

1) Check ignition coil for resistance referring to “Ignition

Coil Assembly (Igniter and Ignition Coil) Inspection”.

Is check result satisfactory?

Go to Step 7.

Replace ignition coil

assembly.

7

CKP sensor check

1) Check CKP sensor referring to “Camshaft Position

(CMP) Sensor and Crankshaft Position (CKP) Sensor

Inspection in Section 1C”.

Is check result satisfactory?

Go to Step 8.

Tighten CKP sensor

bolt, replace CKP

sensor or CKP sensor

plate.

8

CMP sensor check

1) Check CMP sensor referring to “Camshaft Position

(CMP) Sensor and Crankshaft Position (CKP) Sensor

Inspection in Section 1C”.

Is check result satisfactory?

Go to Step 9.

Tighten CMP sensor

bolt, replace CMP

sensor or intake

camshaft.

9

Ignition trigger signal circuit check

1) Check ignition trigger signal wire for open, short and

poor connection.

Is circuit in good condition?

Go to Step 10.

Repair or replace.

10 A known-good ignition coil assembly substitution

1) Substitute a known-good ignition coil assembly and then

repeat Step 2.

Is check result of Step 2 satisfactory?

Go to Step 11.

Substitute a known-

good ECM and then

repeat Step 2.

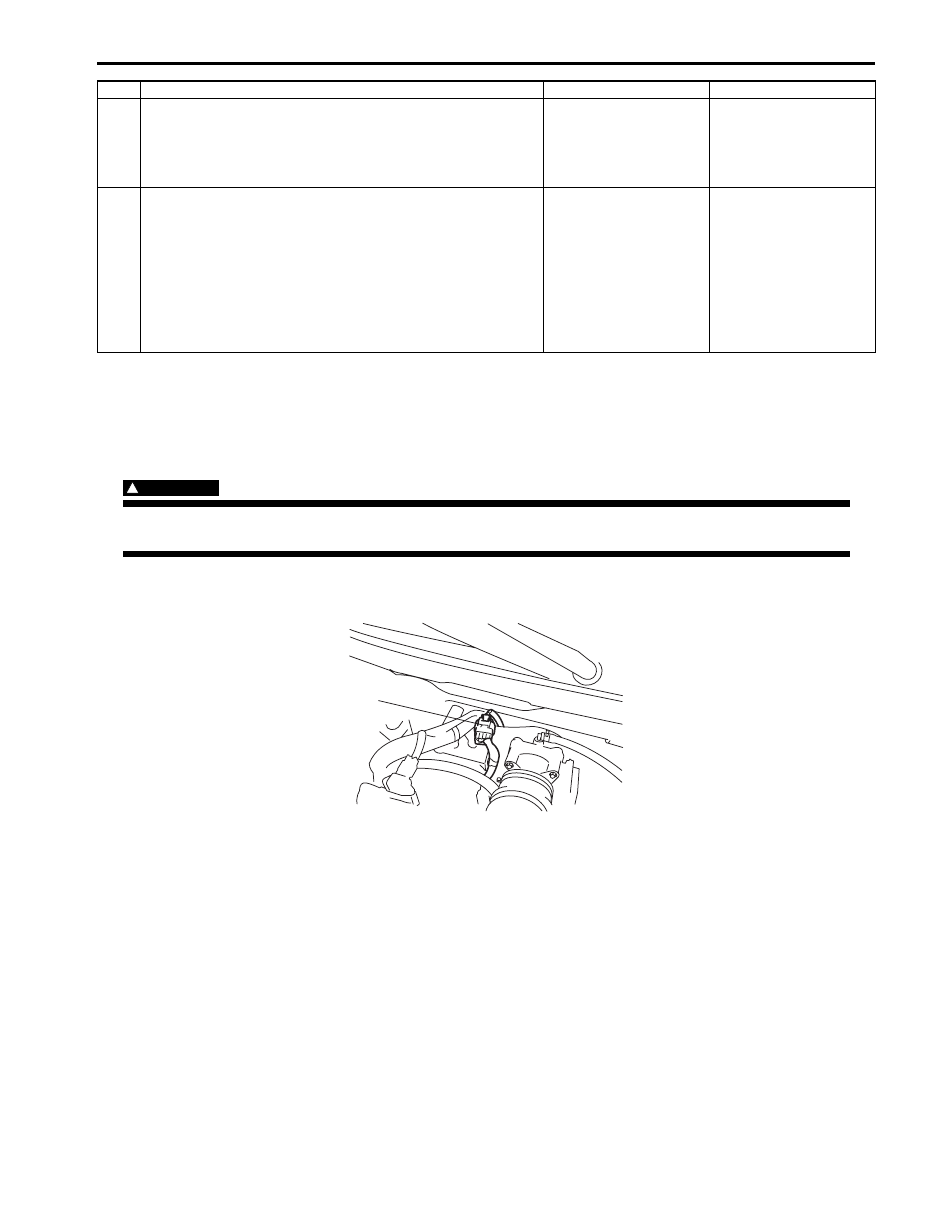

Ignition System: 1H-5

Reference

Refer to “Reference waveform No.17 to 20” and “Reference waveform No.24 to 26” under “Inspection of ECM and Its

Circuits in Section 1A” for waveform of ignition trigger signal.

Ignition Spark Check

S6JB0B1804003

WARNING

!

Without disconnection of injector coupler, combustible gas may come out from spark plug holes

during this test and may get ignited in engine room.

1) Remove surge tank cover.

2) Disconnect injector coupler (1).

3) Remove spark plug and check it for condition and type, referring to “Spark Plug Inspection”.

4) If OK, connect ignition coil coupler to ignition coil assembly and connect spark plug to ignition coil assembly.

Ground spark plug.

5) Crank engine and check if each spark plug sparks.

If no spark is emitted, inspect the related parts as described under “Ignition System Symptom Diagnosis”.

6) After checking, install spark plug referring to “Spark Plug Removal and Installation”.

7) Connect injector coupler.

8) Install surge tank cover.

11 Ignition timing check

1) Check initial ignition timing and ignition timing advance

referring to “Ignition Timing Inspection”.

Is check result satisfactory?

System is in good

condition.

Go to Step 12.

12 Knock sensor check

1) Confirm that knock sensor circuit is in good condition

referring to “DTC P0327 / P0328: Knock Sensor Circuit

Low / High in Section 1A”.

2) Check oscilloscope waveform of knock sensor signal

referring to “Reference waveform No.12” under

“Inspection of ECM and Its Circuits in Section 1A”.

Is check result satisfactory?

Check CMP sensor,

CMP sensor rotor tooth

of camshaft, CKP

sensor, CKP sensor

plate and/or input

signals related to this

system.

Substitute a known-

good knock sensor and

recheck.

Step

Action

Yes

No

1

I6JB01180003-02

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст