Suzuki Grand Vitara JB627. Manual — part 13

1A-1 Engine General Information and Diagnosis:

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine Service

S6JB0B1100001

The following information on engine service should be

noted carefully, as it is important in preventing damage,

and in contributing to reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer

resulting in damaged oil pick-up unit.

• It should be kept in mind, while working on engine,

that 12-volt electrical system is capable of violent and

damaging short circuits. When performing any work

where electrical terminals could possibly be

grounded, ground cable of the battery should be

disconnected at battery.

• Any time the air cleaner, air intake pipe, throttle body

or intake manifold is removed, the intake opening

should be covered. This will protect against accidental

entrance of foreign material which could follow intake

passage into cylinder and cause extensive damage

when engine is started.

• When disconnecting couplers, don’t pull wire harness

but make sure to hold coupler itself. With lock type

coupler, be sure to unlock before disconnection.

Attempt to disconnect coupler without unlocking may

result in damage to coupler. When connecting lock

type coupler, insert it till clicking sound is heard and

connect it securely.

Precautions in Diagnosing Trouble

S6JB0B1100002

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be

cleared as well as checked by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

• It is indistinguishable which module turns on MIL

because not only ECM but also TCM (A/T model)

turns on MIL (For details of on-board diagnostic

system for A/T model, refer to “On-Board Diagnostic

System Description in Section 5A”). Therefore, check

both ECM and TCM (A/T model) for DTC when MIL

lights on. When checking ECM for DTC, keep in mind

that DTC is displayed on the scan tool as follows

depending on the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by

each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles

If two or more diagnostic trouble codes (DTCs) are

stored, proceed to the flow of the DTC which has

detected earliest in the order and follow the instruction

in that table.

If no instructions are given, troubleshoot diagnostic

trouble codes according to the following priorities.

a. Diagnostic trouble codes (DTCs) other than DTC

P0171 / P0172 / P0174 / P0175 (Fuel system too

lean/too rich), DTC P0300 / P0301 / P0302 /

P0303 / P0304 / P0305 / P0306 (Misfire detected)

and DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 / P0174 / P0175 (Fuel

system too lean/too rich) and DTC P0401 / P0402

(EGR flow malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 /

P0305 / P0306 (Misfire detected)

IYSQ01110001-01

Engine General Information and Diagnosis: 1A-2

• Be sure to read “Precaution for CAN Communication

System in Section 00” before inspection and observe

what is written there.

• ECM Replacement

When substituting a known good ECM, check for the

following conditions. Neglecting this check may cause

damage to known good ECM.

– Resistance value of all relays, actuators is as

specified respectively.

– MAF sensor MAP sensor, TP sensor and A/C

refrigerant pressure sensor are in good condition

and none of power circuits of these sensors is

shorted to ground.

• Communication of ECM, BCM, combination meter,

keyless start control module (if equipped), ABS or

ESP

® control module, 4WD control module (if

equipped), steering angle sensor (ESP

® model) and

TCM (A/T model), is established by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM.

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.

Precautions for DTC Troubleshooting

S6JB0B1100003

• Before performed trouble shooting, be sure to read

the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or

pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referring to

“Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work,

perform “DTC Confirmation Procedure” and confirm

that the trouble has been corrected.

Precautions of ECM Circuit Inspection

S6JB0B1100004

• ECM connectors are waterproofed. Each terminal of

the ECM connectors is sealed up with the grommet.

Therefore, when measuring circuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into the sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are

different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S6JB0B1100005

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of

battery replacement or “DOME” fuse removal.

• To erase DTCs P0122, P0123, P0222, P0223, P2101,

P2102, P2103, P2108, P2119 and/or P2135.

• To replace ECM.

• To replace throttle body and/or accelerator pedal

position (APP) sensor assembly.

1A-3 Engine General Information and Diagnosis:

General Description

Statement of Cleanliness and Care

S6JB0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thousands of inch). Accordingly, when

any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to

friction areas during assembly to protect and lubricate

the surface on initial operation.

• Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings and crankshaft

journal bearings are removed for service, they should

be retained in order. At the time of installation, they

should be installed in the same locations and with the

same mating surfaces as when removed.

• Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

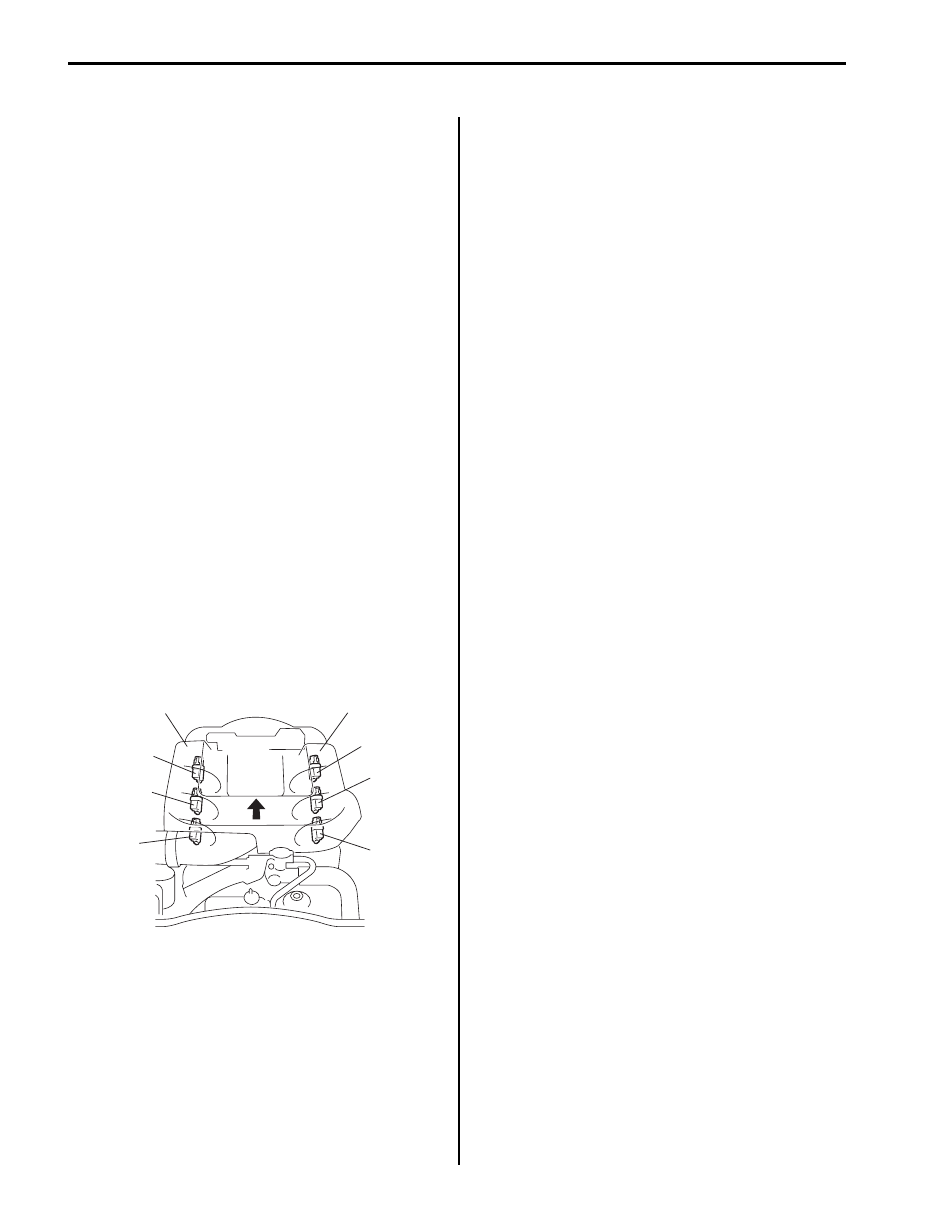

• Throughout this manual, the 6 cylinders of the engine

are identified by numbers;

No.1 (1), No.3 (3) and No.5 (5) of LH bank (7) and

No.2 (2), No.4 (4) and No.6 (6) of RH bank (8) as

counted from crankshaft pulley side (9) to flywheel

side (10).

Engine Diagnosis General Description

S6JB0B1101002

This vehicle is equipped with an engine and emission

control system which are under control of ECM.

The engine and emission control system in this vehicle

are controlled by ECM. ECM has an On-Board

Diagnostic system which detects a malfunction in this

system and abnormality of those parts that influence the

engine exhaust emission. When diagnosing engine

troubles, be sure to have full understanding of the outline

of “On-Board Diagnostic System Description” and each

item in “Precautions in Diagnosing Trouble” and execute

diagnosis according to “Engine and Emission Control

System Check”.

There is a close relationship between the engine

mechanical, engine cooling system, ignition system,

exhaust system, etc. and the engine and emission

control system in their structure and operation. In case of

an engine trouble, even when the malfunction indicator

lamp (MIL) doesn’t turn ON, it should be diagnosed

according to “Engine and Emission Control System

Check”.

On-Board Diagnostic System Description

S6JB0B1101003

ECM in this vehicle has the following functions.

• When the ignition switch is turned ON with the engine

at a stop, MIL (1) turns ON to check the malfunction

indicator lamp (MIL) (1) and its circuit.

• When ECM detects a malfunction which gives an

adverse effect to vehicle emission while the engine is

running, it makes the malfunction indicator lamp in the

meter cluster of the instrument panel turn ON or flash

(flashing only when detecting a misfire which can

cause damage to the catalyst) and stores the

malfunction area (DTC according to SAE J2012) in its

memory.

(If it detects that continuously 3 driving cycles are

normal after detecting a malfunction, however, it

makes MIL turn OFF although DTC stored in its

memory will remain.)

• As a condition for detecting a malfunction in some

areas in the system being monitored by ECM and

turning ON the malfunction indicator lamp due to that

malfunction, 2 driving cycle detection logic is adopted

to prevent erroneous detection.

• When a malfunction is detected, engine and driving

conditions then are stored in ECM memory as freeze

frame data. (For the details, refer to description on

Freeze frame data.)

7

5

3

1

9

10

2

4

6

8

I6JB01110007-02

Engine General Information and Diagnosis: 1A-4

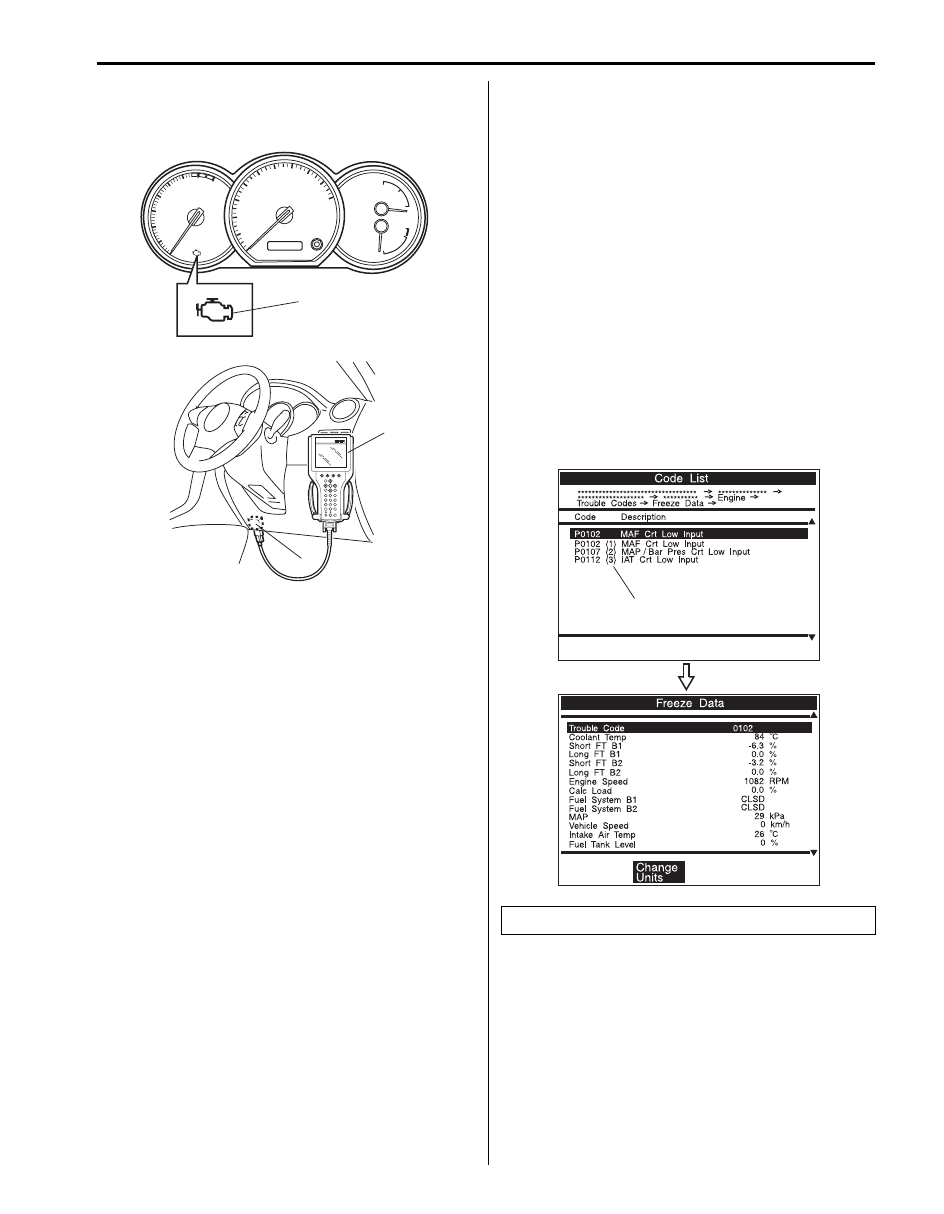

• It is possible to communicate via DLC (data link

connector) (2) by using not only SUZUKI scan tool (3)

but also OBD generic scan tool.

Warm-Up Cycle

A warm-up cycle means sufficient vehicle operation such

that the coolant temperature has risen by at least 22

°C

(40

°F) from engine starting and reaches a minimum

temperature of 70

°C (160 °F).

Driving Cycle

A “Driving Cycle” consists of engine startup driving mode

where a malfunction would be detected if present and

next engine startup.

2 Driving Cycle Detection Logic

The malfunction detected in the first driving cycle is

stored in ECM memory (in the form of pending DTC and

freeze frame data) but the malfunction indicator lamp

does not light at this time. It lights up at the second

detection of same malfunction also in the next driving

cycle.

Pending DTC

Pending DTC means a DTC detected and stored

temporarily at 1 driving cycle of the DTC which is

detected in the 2 driving cycle detection logic.

Freeze Frame Data

ECM stores the engine and driving conditions (in the

form of data as shown) at the moment of the detection of

a malfunction in its memory. This data is called “Freeze

frame data”.

Therefore, it is possible to know engine and driving

conditions (e.g., whether the engine was warm or not,

where the vehicle was running or stopped, where air/fuel

mixture was lean or rich) when a malfunction was

detected by checking the freeze frame data. Also, ECM

has a function to store each freeze frame data for three

different malfunctions in the order as the malfunction is

detected. Utilizing this function, it is possible to know the

order of malfunctions that have been detected. Its use is

helpful when rechecking or diagnosing a trouble.

An example of freeze frame data

1

(A)

1

I5JB0C110019-02

[A]: 1st, 2nd or 3rd in parentheses here represents which position in the

order the malfunction is detected.

[A]

I5JA01112021-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст