Suzuki Grand Vitara JB627. Manual — part 317

8B-94 Air Bag System:

Inspection of Intermittent and Poor

Connections

S6JB0B8204040

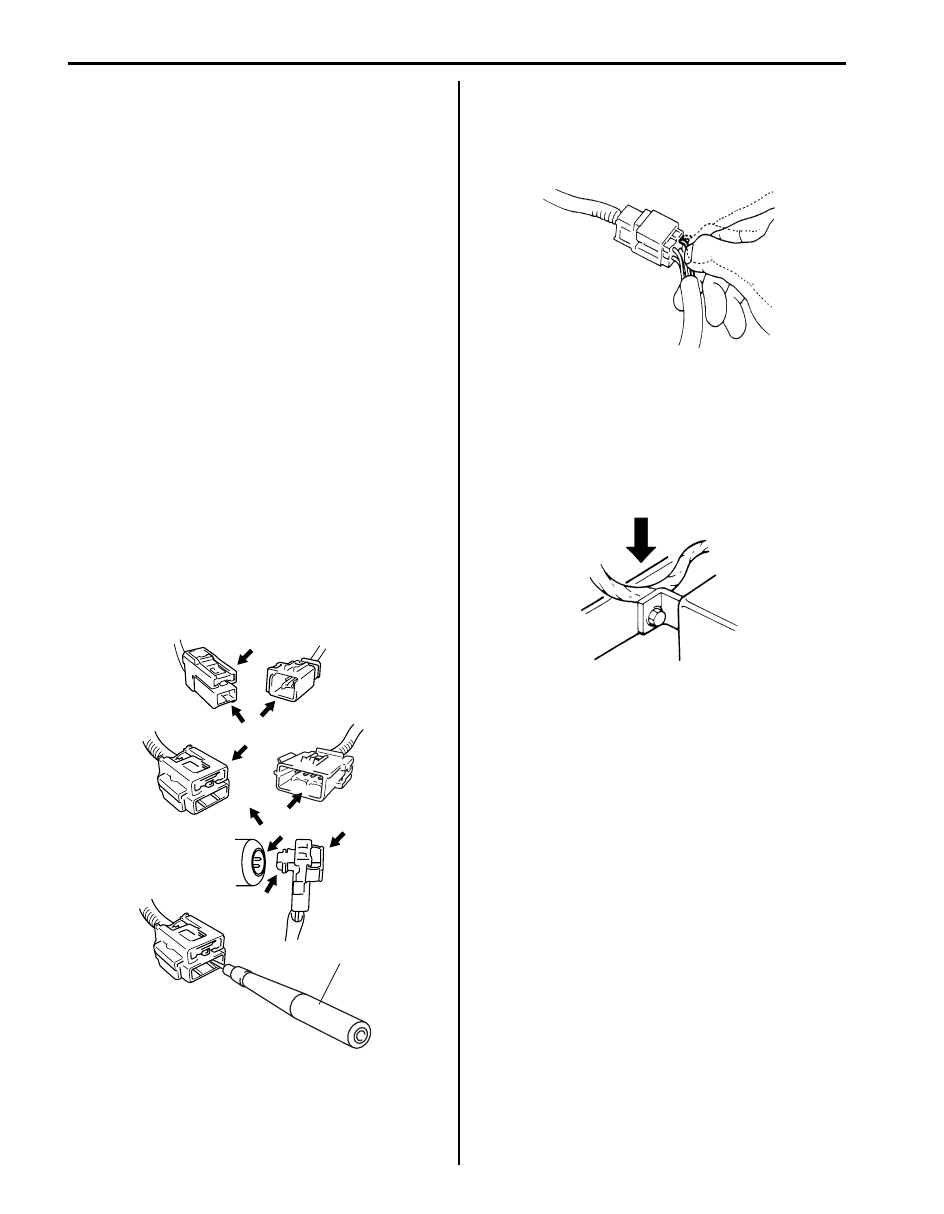

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully

seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must

be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to

moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

• Improperly formed or damaged terminals.

Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not enough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932-76010 Connector test adapter kit

• Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could

cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Air Bag System: 8B-95

Repair and Inspection Required after Accident

S6JB0B8204041

CAUTION

!

• All air bag system components, including

the electrical harness (component

mounting points), must be inspected after

an accident. If any components are

damaged or bent, they must be replaced

even if air bag system activation did not

occur.

• Never use air bag system parts from

another vehicle.

• Do not attempt to service the parts below.

Service of these parts is by replacement

only.

– Driver / Passenger air bag (inflator)

modules

– Driver / Passenger side-air bag (inflator)

modules

– Driver / Passenger side curtain-air bag

(inflator) modules

– Driver / Passenger seat belt

pretensioners

– Driver / Passenger forward-sensors

– Left / Right side-sensors

– SDM

– Contact coil

– Air bag wire harness in main harness,

instrument panel harness, floor harness,

passenger air bag harness and seat

harness.

• Proper operation of the sensors and air

bag system requires that any repairs to the

vehicle structure return it to its original

production configuration.

CAUTION

!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM

• Driver / Passenger forward-sensors

• Instrument panel

When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side-sensor

• SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faulty condition is found in the

following checks, replace faulty part.

Those components are:

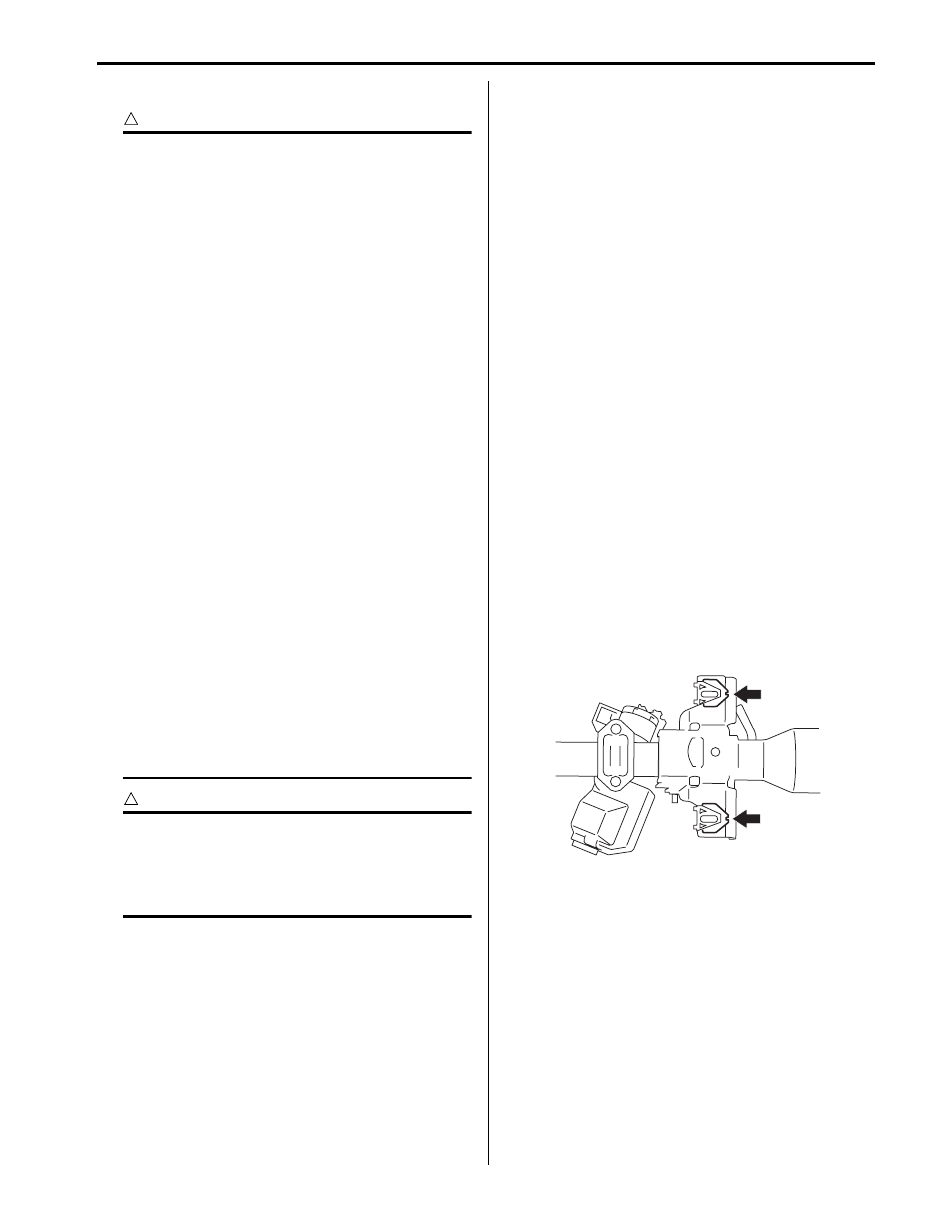

• Steering column (1) and shaft joints

– Check for length, damage and bend according to

“Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules

– Check for damage and bent.

I5JB0A820061-01

8B-96 Air Bag System:

• Steering wheel and driver air bag (inflator) module

– Check for damage or air bag (inflator) module

fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or

tightness.

• Contact coil

– Check wire harness and connectors for damage or

tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement

– Check for any distortion, bending, cracking or other

damage.

– Check instrument panel for cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or

tightness.

• SDM

– Check for external damage such as deformation,

scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its

proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching,

melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as

malfunctioning according to the diagnostic flow.

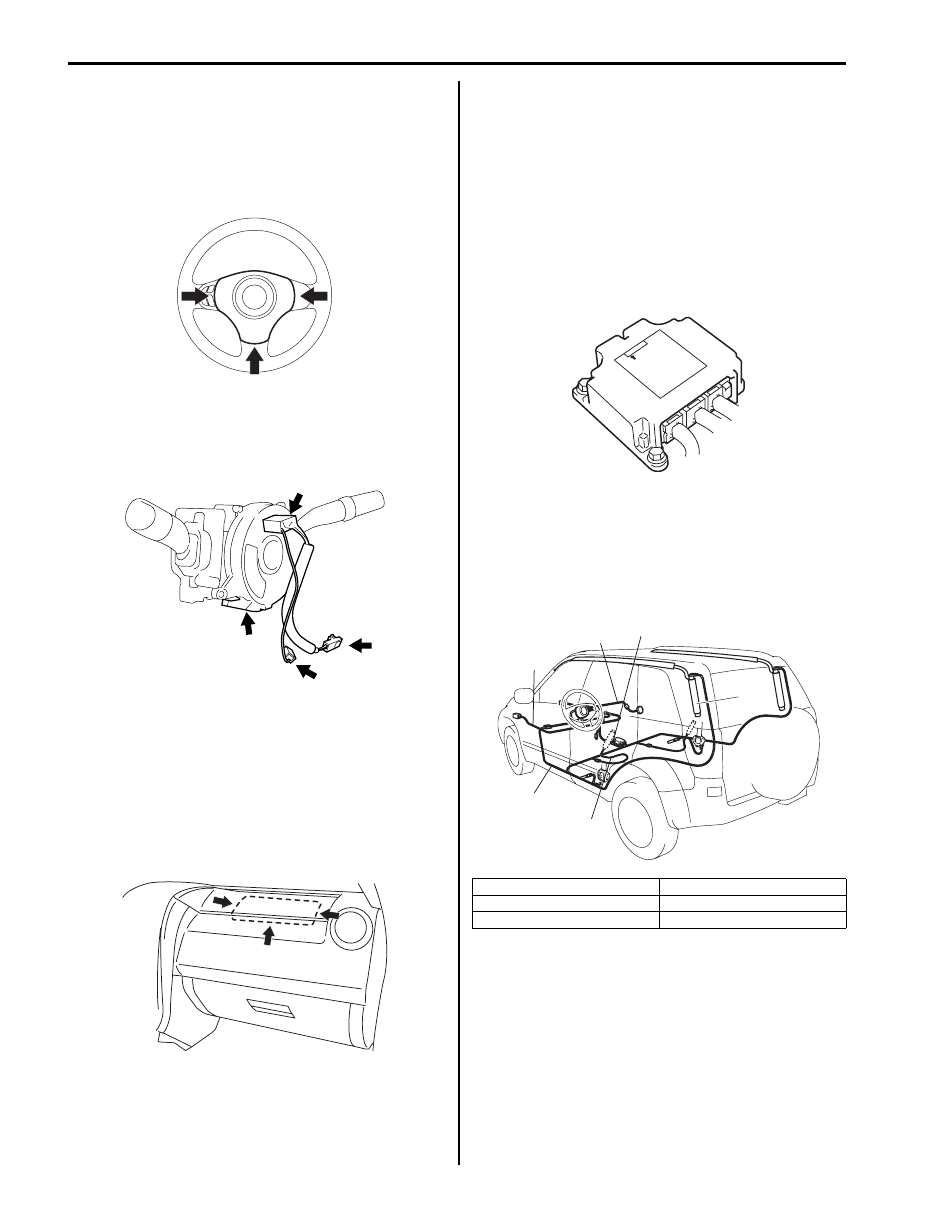

• Air bag wire harness and connections

– Check for damages, deformities or poor

connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

I5JB0A820062-01

I4RS0A820048-01

I5JB0A820063-01

1. Main harness

4. Seat harness

2. Instrument panel harness

5. Grounding point

3. Floor harness

I5JB0A820064-01

5

2

1

3

4

I5JB0A820006-01

Air Bag System: 8B-97

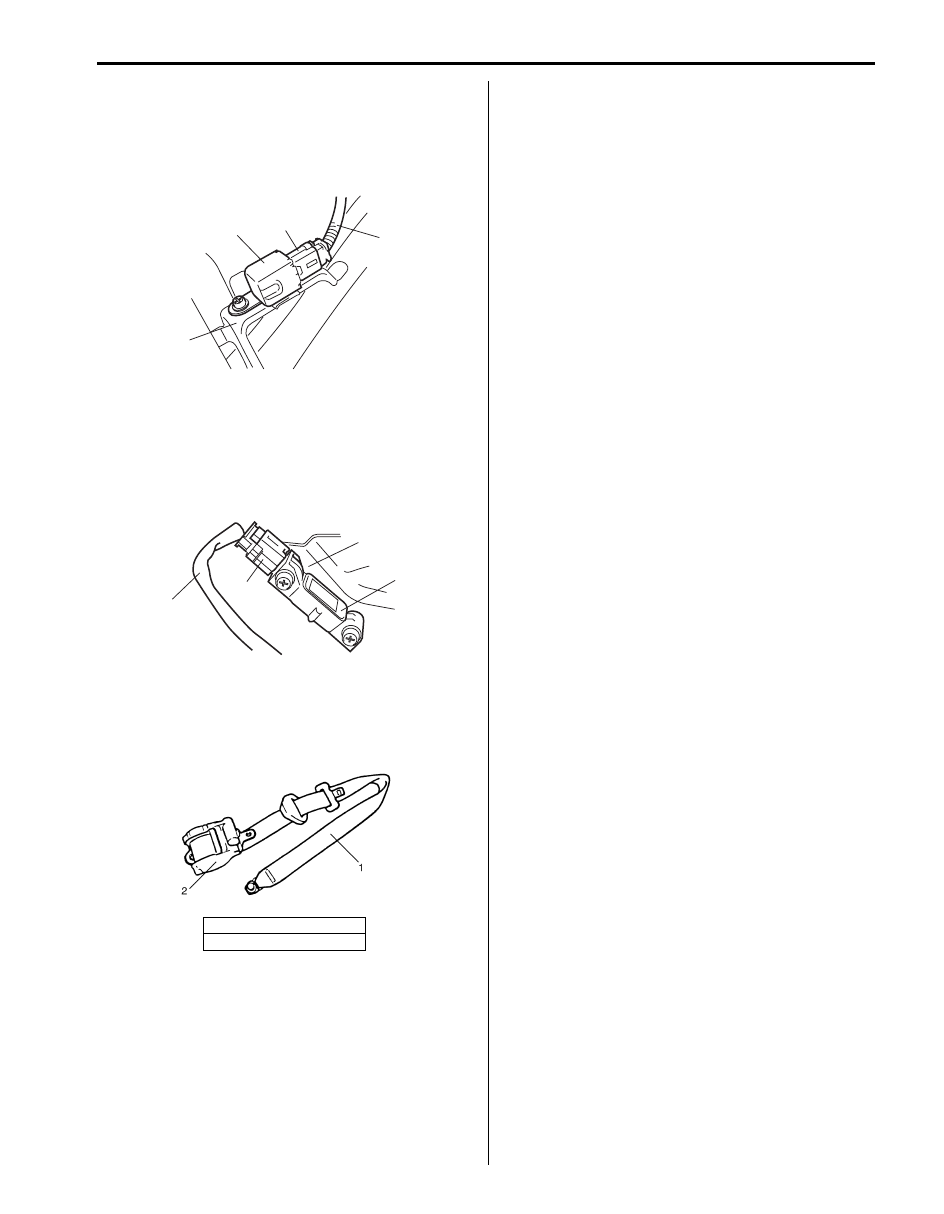

• Forward-sensor

– Check sensor (1) and bracket (2) for damage, bend

or rust.

– Check connector (3) or lead wire (4) of forward-

sensor for scorching, melting or damage.

• Side-sensor

– Check sensor (1) and under body (2) for dents,

cracks, deformation or rust.

– Check sensor connector (sensor side and harness

side) (3) or sensor lead wire (4) for damage, crack,

scorching or melting.

• Seat belt pretensioner

– Check for dents, cracks, damage or fitness

– Check harness and connector for damage or

tightness.

• Seat belts and mounting points

– Refer to “Front Seat Belt Components in Section

• “AIR BAG” warning light

– After vehicle is completely repaired, perform “Air

• Side-air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check trim cover for cracks or deformities.

– Check wire harness and connector for damage or

tightness.

• Side curtain-air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness wire harness and connector for

damage or tightness.

– Check headlining for cracks or deformation.

1. Seat belt

2. Retractor assembly

2

1

3

4

I5JB0A820065-01

4

3

2

1

I5JB0A820066-01

I3JA01820043-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст