Suzuki Grand Vitara JB627. Manual — part 262

6C-9 Power Assisted Steering System:

P/S Fluid Leakage Check

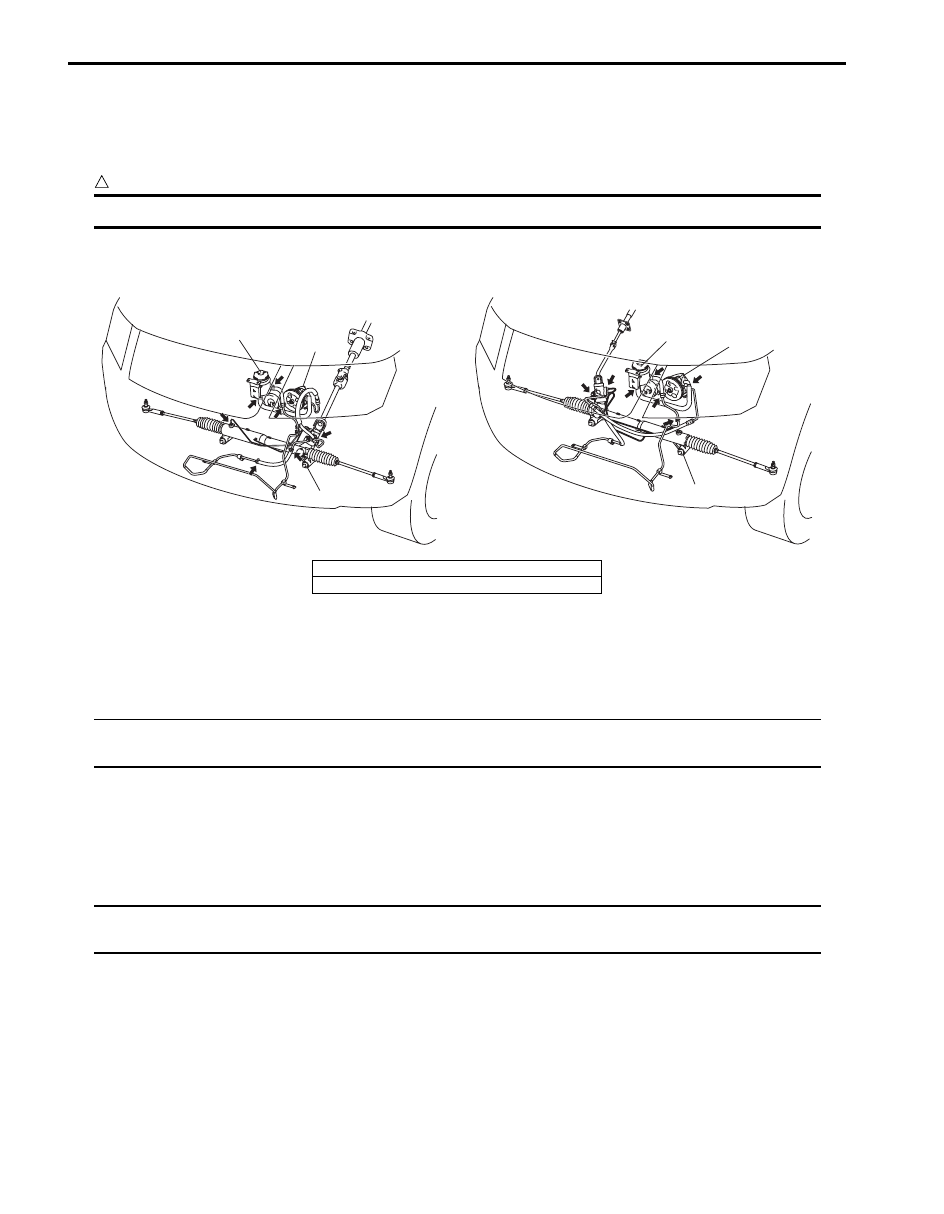

S6JB0B6306003

Start engine and turn steering wheel fully to the right and left so that maximum hydraulic pressure is provided.

Then visually check P/S gear case assembly (1), P/S pump (2) and P/S fluid reservoir (3) themselves and each joint of

their connecting pipes for leakage.

CAUTION

!

Never keep steering wheel turned fully for longer than 10 seconds.

P/S System Air Bleeding Procedure

S6JB0B6306004

1) Hoist the front end of vehicle and apply safety stands.

2) Fill P/S fluid reservoir with fluid up to specified level.

NOTE

Before starting engine, place transmission gear shift lever in “Neutral” (shift selector lever to “P”

range for A/T model), and set parking brake.

3) After running engine at idling speed for 3 to 5 seconds, stop it and add fluid to satisfy specification.

4) With engine stopped, turn steering wheel to the right and left as far as it stops, repeat it a few times and fill fluid to

specified level.

5) With engine running at idling speed, repeat stop-to-stop turn of steering wheel till all foams in P/S fluid reservoir

are gone.

NOTE

Make sure to bleed air completely. If air remains in fluid, P/S pump may make humming noise or

steering wheel may feel heavy.

6) Finally check to make sure that fluid is filled to specified level.

3

2

1

3

2

1

[B]

[A]

I6JB0B630004-01

[A]: LHD model

[B]: RHD model

Power Assisted Steering System: 6C-10

P/S Pump and A/C Compressor (If Equipped)

Drive Belt Inspection and Adjustment

S6JB0B6306005

Inspection

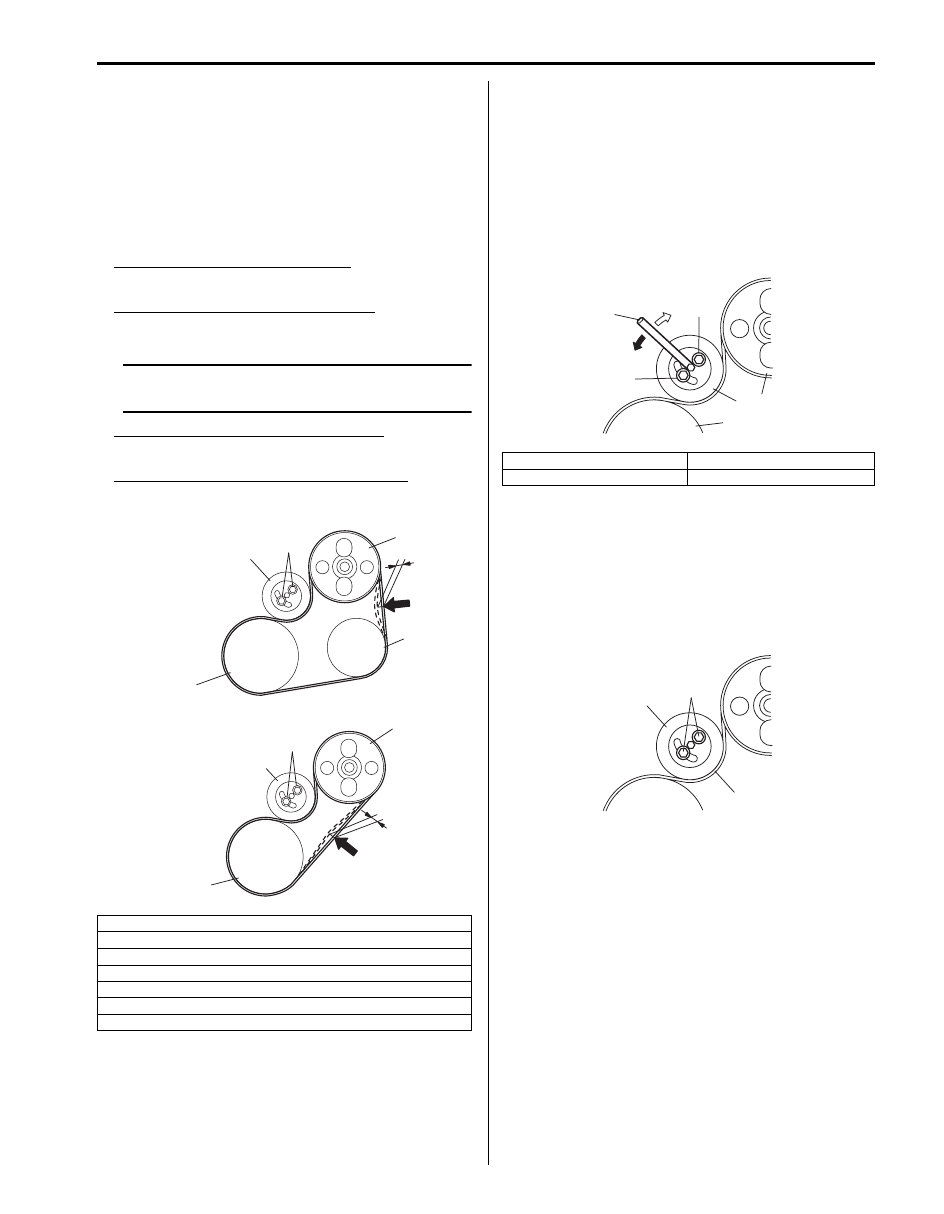

• Check that belt is free from any damage and properly

fitted in pulley groove.

• Check belt tension by measuring how much it deflects

when pushed at intermediate point between pulleys

with about 10 kg (22 lb) force.

Deflection of P/S belt with A/C (a)

: 5.5 – 6.5 mm (0.21 – 0.25 in.)

Deflection of P/S belt without A/C (b)

: 4 – 9 mm (0.16 – 0.35 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specifications.

Deflection of new P/S belt with A/C (a)

: 5 – 6 mm (0.19 – 0.23 in.)

Deflection of new P/S belt without A/C (b)

: 4 – 9 mm (0.16 – 0.35 in.)

Adjustment

1) To adjust P/S belt tension, loosen tension pulley

bolts (1) and turn tension pulley (2) using hexagon

wrench (3).

2) Adjust belt tension to specification, and then tighten

tension pulley bolts (1) to specified torque.

Tightening torque

P/S belt tension pulley bolt (a): 25 N·m (2.5 kgf-

m, 18.5 lb-ft)

P/S Pump and A/C Compressor (If Equipped)

Drive Belt Removal and Installation

S6JB0B6306006

Removal

1) Remove tension pulley bolts (1).

2) Remove tension pulley (3) and P/S pump drive belt

(2).

Installation

Reverse removal procedure noting the following

instruction.

Adjust belt tension referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Inspection and

Adjustment”.

1. P/S pump pulley

2. A/C compressor pulley (if equipped)

3. Crankshaft pulley

4. Tension pulley

5. Tension pulley bolt

[A]: with A/C

[B]: without A/C

4

5

4

3

3

2

1

1

[A]

[B]

“a”

“b”

5

I5JB0C630001-01

4. Crank shaft pulley

6. Tight

5. Loose

7. P/S pump pulley

3

4

2

7

6

1, (a)

1, (a)

5

I6JB0B630005-01

3

2

1

I6JB01630005-01

6C-11 Power Assisted Steering System:

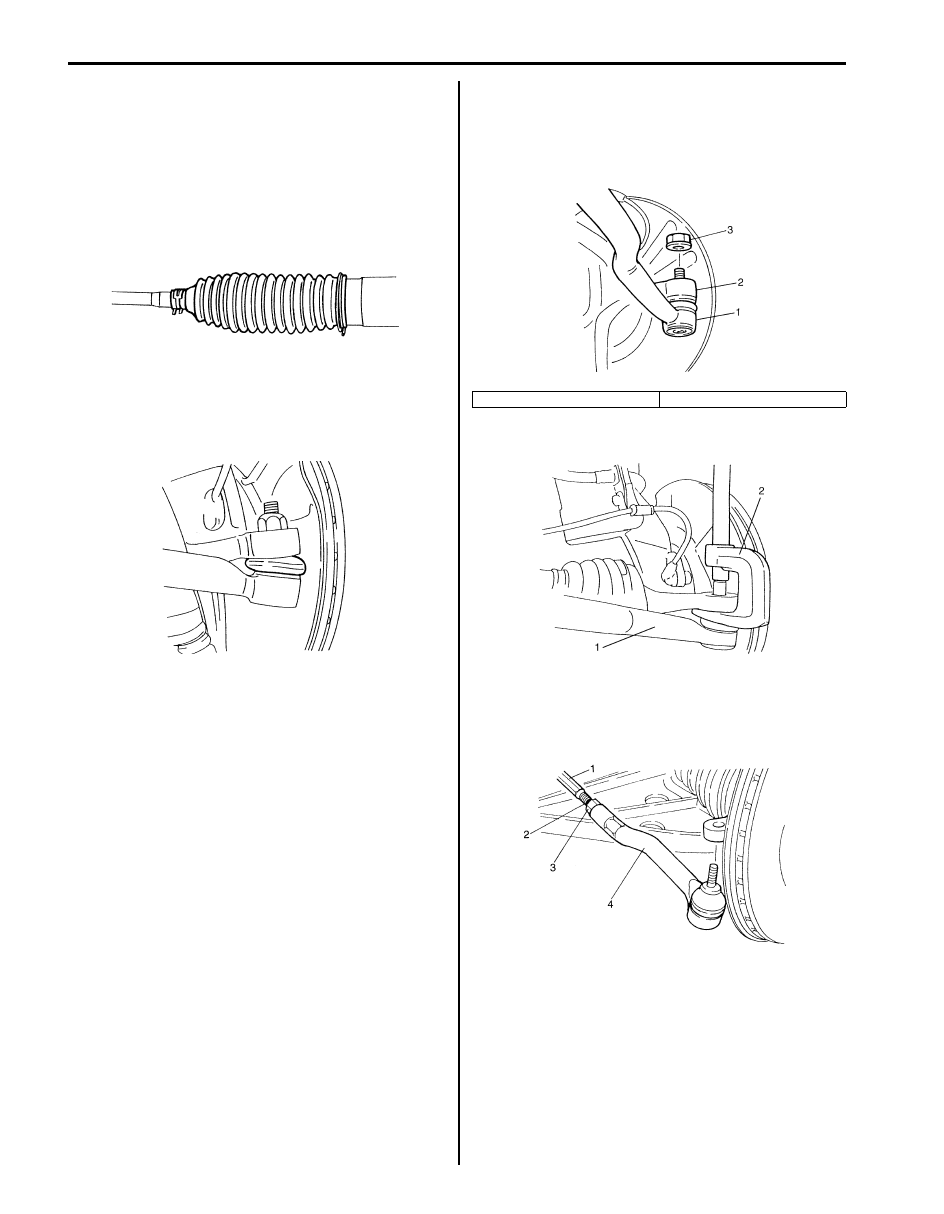

Steering Rack Boot Check

S6JB0B6306007

• Check boot for crack and damage which, if any,

means possibility of rusty gear, entry of dust or lack of

grease. Also, check if any of such faulty conditions

exists.

• Check steering rack boot for dent or breakage.

If there is a dent, keep boot in most compressed state

for some seconds to correct dent.

Tie-Rod End Boot Check

S6JB0B6306008

Check boot for crack and damage and if any, replace it

with a new one.

Tie-Rod End Removal and Installation

S6JB0B6306009

Removal

1) Hoist vehicle and remove wheel.

2) Remove tie-rod end nut (3).

3) Disconnect tie-rod end (1) by using puller (2).

4) To facilitate adjustment after installation, put a mark

(2) on tie-rod thread indicating position of tie-rod end

lock nut (3). Then loosen lock nut (3) and remove tie-

rod end (4) from tie-rod (1).

IYSQ01630013-01

IYSQ01630014-01

1. Tie-rod end

2. Knuckle

IYSQ01630015-01

IYSQ01630016-01

IYSQ01630017-01

Power Assisted Steering System: 6C-12

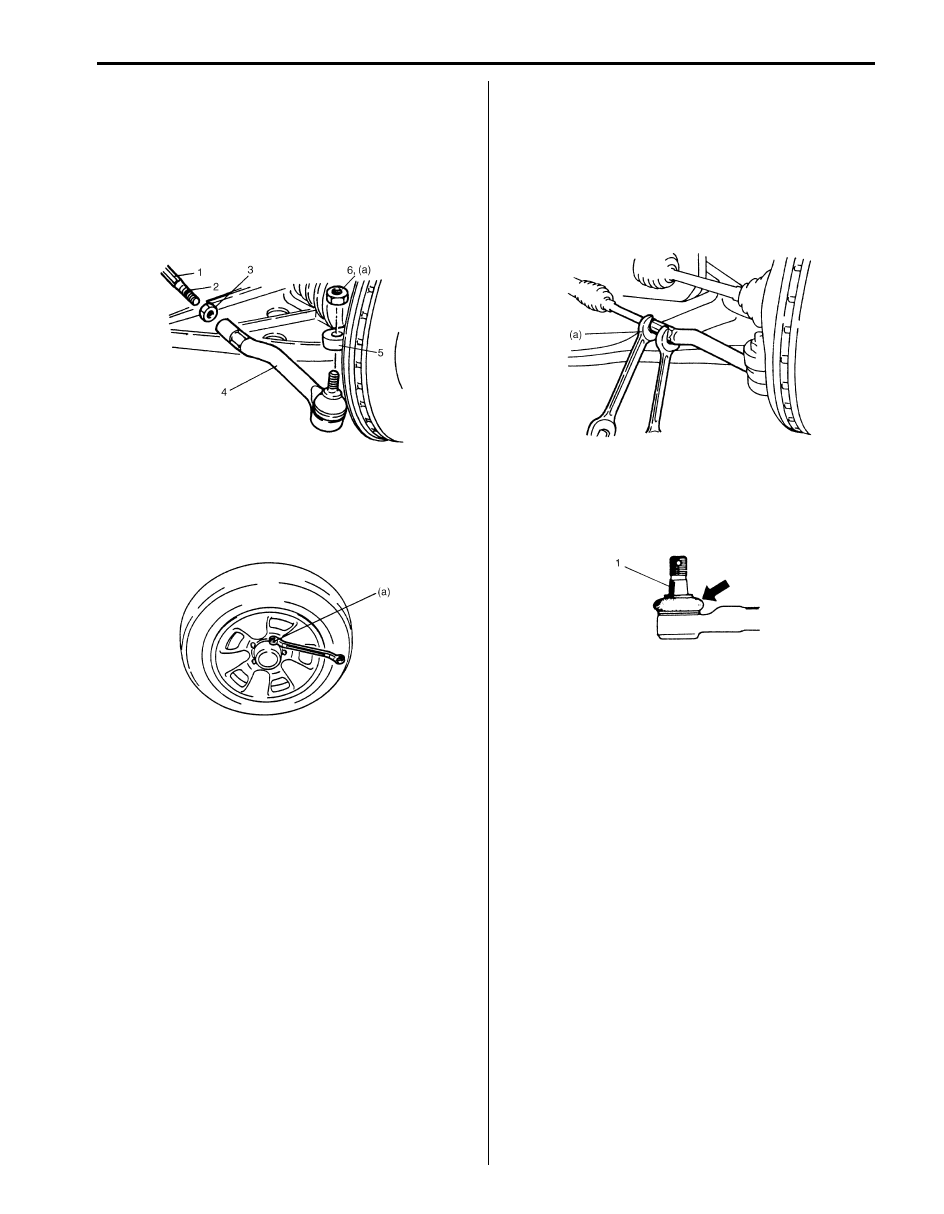

Installation

1) Install tie-rod end lock nut (3) and tie-rod end (4) to

tie-rod (1). Tighten lock nut (3) to mark (2) on tie-rod

thread.

2) Install tie-rod end (4) to knuckle (5). Tighten new tie-

rod end nut (6) to specified torque.

Tightening torque

Tie-rod end nut (a): 43 N·m (4.3 kgf-m, 31.0 lb-ft)

3) After installing wheels, lower vehicle and tighten

wheel nuts to specified torque.

Tightening torque

Wheel nut (a): 100 N·m (10.0 kgf-m, 72.5 lb-ft)

4) Check that proper amount of toe-in is obtained

referring to “Front Wheel Alignment Inspection and

Adjustment in Section 2B”.

5) After confirming proper amount of toe-in, tighten tie-

rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 65 N·m (6.5 kgf-m, 47.0

lb-ft)

Tie-Rod End Ball Joint Inspection

S6JB0B6306010

Inspect for play in tie-rod end ball joint (1). If found

defective, replace.

IYSQ01630018-01

IYSQ01630019-01

IYSQ01630020-01

IYSQ01630021-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст