Suzuki Grand Vitara JB416 / JB420. Manual — part 124

1F-12 Engine Cooling System:

Radiator Removal and Installation

S5JB0A1606014

Removal

1) Disconnect negative cable at battery.

2) For A/T, drain A/T fluid referring to “A/T Fluid Change

3) Drain coolant.

4) Remove cooling fan assembly referring to “Radiator

Cooling Fan Assembly Removal and Installation”.

5) For A/T, remove A/T fluid cooler inlet and outlet

hoses.

6) Remove radiator outlet hose from radiator.

7) Remove condenser bolts from condenser brackets.

8) Remove radiator from vehicle.

Installation

Reverse removal procedures, noting the following.

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

• After installation, verify there is no coolant leakage

each connection.

• Refill A/T fluid referring to “A/T Fluid Change in

Water Pump Removal and Installation (For M16

Engine Model)

S5JB0A1606017

Removal

1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump and generator drive belt

referring to “Water Pump and Generator Drive Belt

Removal and Installation (For M16 Engine) in

Section 1J”.

4) Remove water pump assembly (1).

Installation

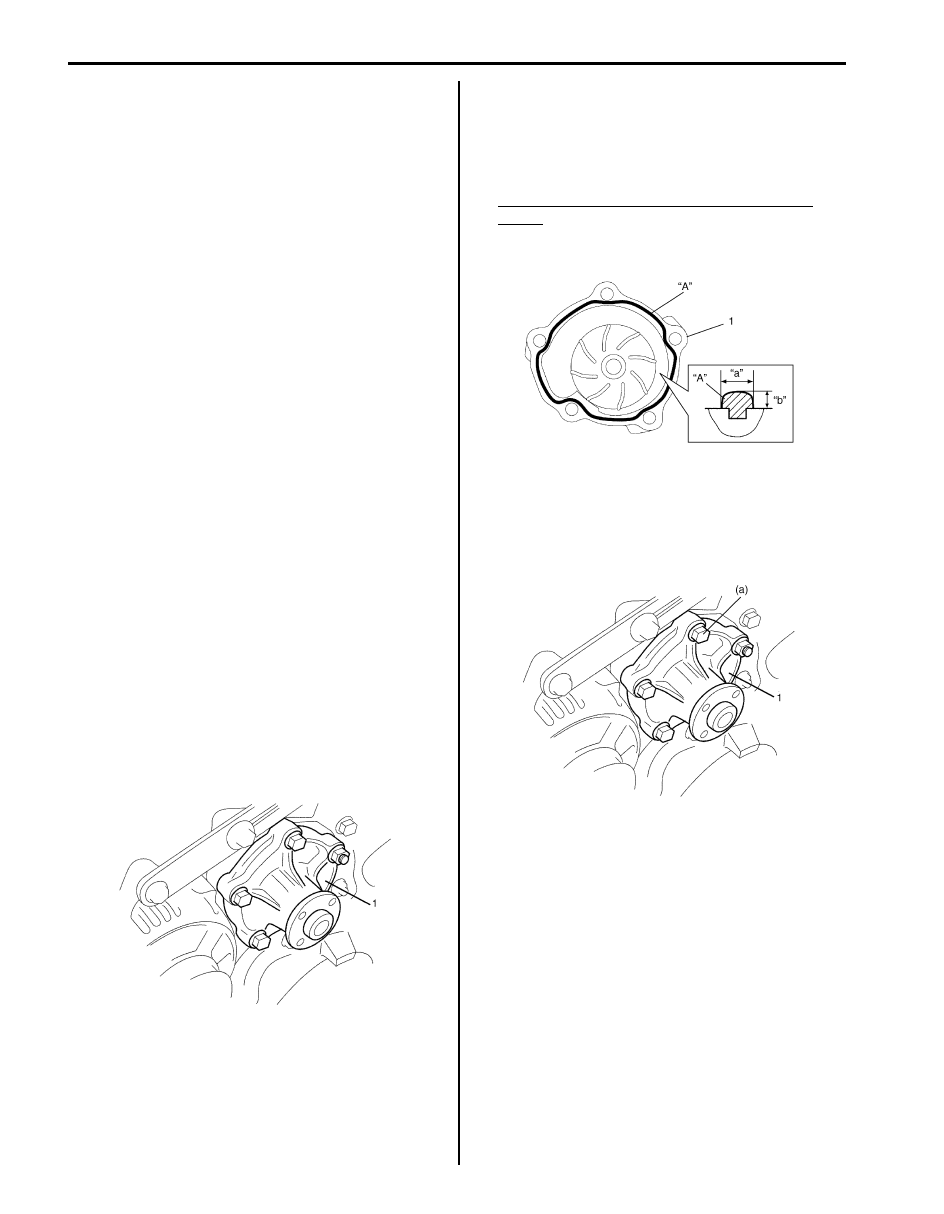

1) Apply sealant to mating surface of water pump (1) as

shown in the figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

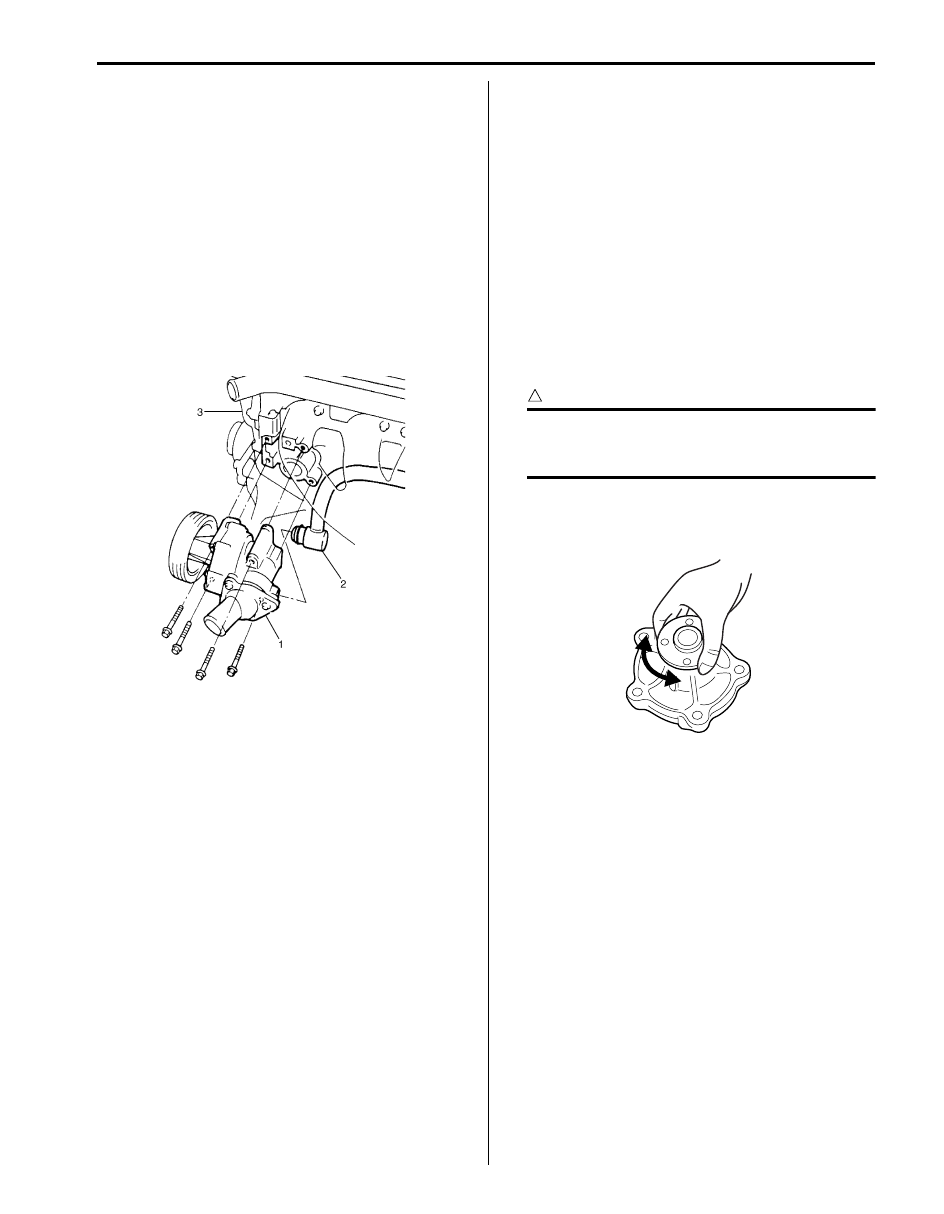

2) Install water pump assembly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump and generator drive belt referring

to “Water Pump and Generator Drive Belt Removal

and Installation (For M16 Engine) in Section 1J”.

5) Install P/S pump and A/C compressor drive belt (if

equipped) referring to “P/S Pump and A/C

Compressor (If Equipped) Drive Belt Removal and

Installation for M16 Engine Model in Section 6C”.

6) Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

I2RH0B160016-01

I3RM0A160016-01

I2RH0B160018-01

Engine Cooling System: 1F-13

Water Pump Removal and Installation (For J20

Engine Model)

S5JB0A1606023

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining”.

3) Remove water pump and generator drive belt

referring to “Water Pump and Generator Drive Belt

Removal and Installation (For J20 Engine) in Section

1J”.

4) Remove thermostat referring to “Thermostat

Removal and Installation (For J20 Engine Model)”.

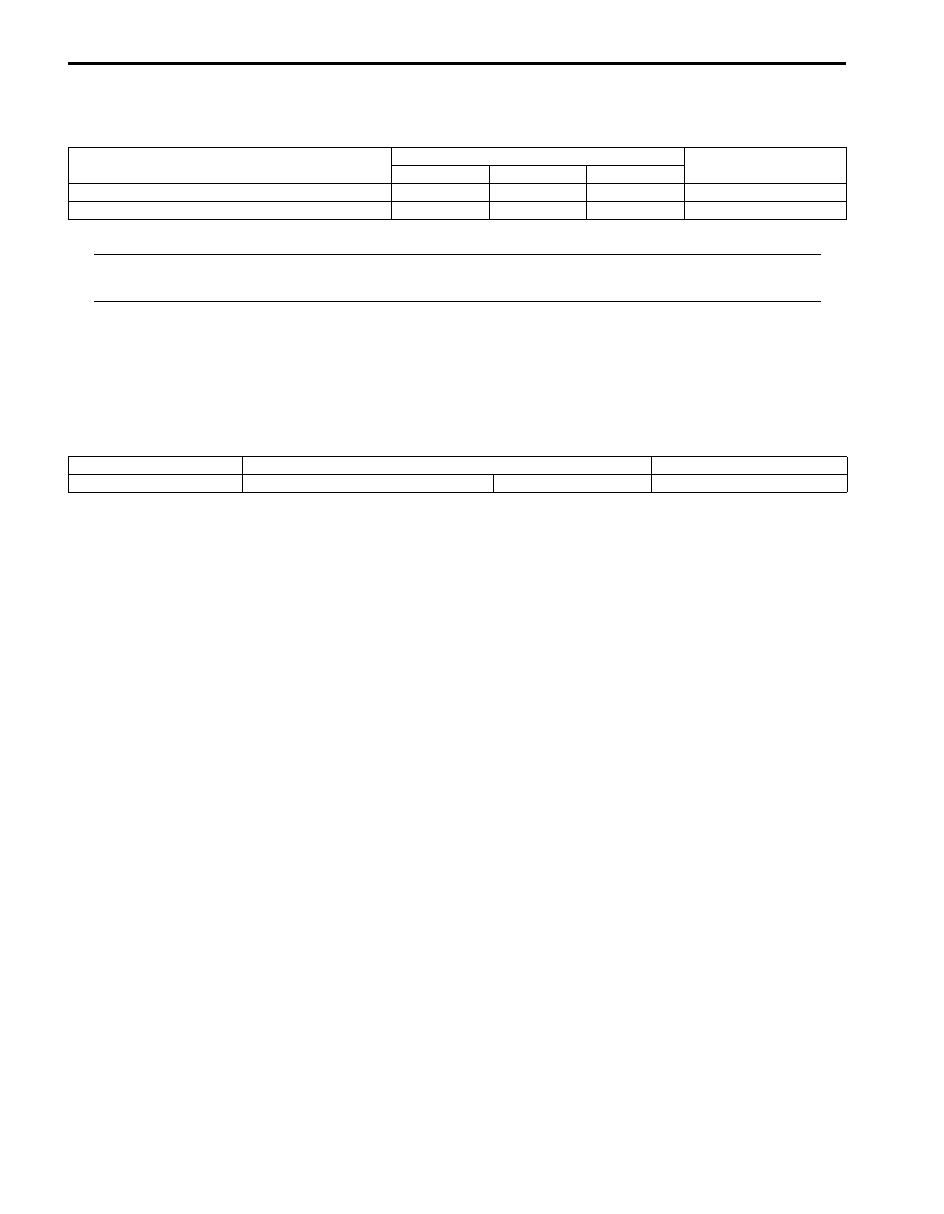

5) Disconnect heater pipe (2) from water pump (1).

6) Remove water pump (1) from cylinder block (3).

Installation

Reverse removal procedure for installation noting the

following points.

• Use new O-ring when installing.

• Install water pump assembly to cylinder block and

tighten bolts to specified torque.

Tightening torque

Water pump bolt: 25 N·m (2.5 kgf-m, 18.0 lb-ft)

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

• Verify that there is no coolant leakage at each

connection.

Water Pump Inspection

S5JB0A1606018

CAUTION

!

Do not disassemble water pump.

If any repair is required on pump, replace it

as assembly.

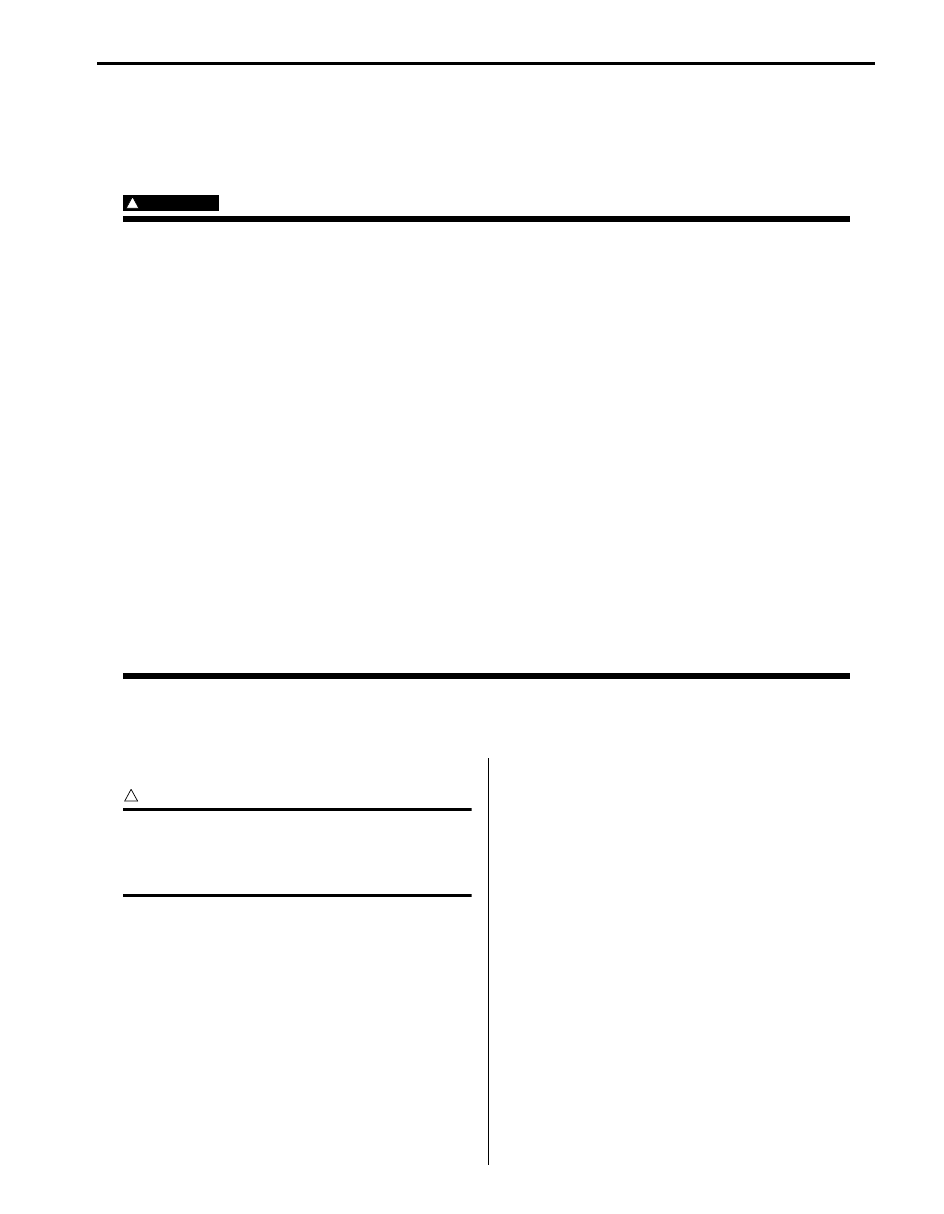

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

I5JB0A161016-01

I2RH0B160019-01

1F-14 Engine Cooling System:

Specifications

Tightening Torque Specifications

S5JB0A1607001

NOTE

The specified tightening torque is also described in the following.

“Cooling System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Recommended Service Material

S5JB0A1608001

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Water pump bolt and nut

25

2.5

18.0

Water pump bolt

25

2.5

18.0

Material

SUZUKI recommended product or Specification

Note

Water tight sealant

SUZUKI Bond No.1207F

P/No.: 99000–31250

Fuel System: 1G-1

Engine

Fuel System

Precautions

Precautions on Fuel System Service

S5JB0A1700001

WARNING

!

Before attempting service of any type on fuel system, the following should be always observed in

order to reduce the risk or fire and personal injury.

• Disconnect negative cable at battery.

• Do not smoke, and place no smoking signs near work area.

• Be sure to have CO

2

fire extinguisher handy.

• Be sure to perform work in a well-ventilated area and away from any open flames (such as gas hot

heater).

• Wear safety glasses.

• To relieve fuel vapor pressure in fuel tank, remove fuel filler cap from fuel filler neck and then

reinstall it.

• As fuel feed line is still under high fuel pressure even after stopping engine, loosening or

disconnecting fuel feed line directly may cause dangerous spout of fuel. Before loosening or

disconnecting fuel feed line, make sure to relieve fuel pressure referring to “Fuel Pressure Relief

Procedure”.

• A small amount of fuel may be released when the fuel line is disconnected. In order to reduce the

risk of personal injury, cover a shop cloth to the fitting to be disconnected. Be sure to put that cloth

in an approved container after disconnecting.

• Never run engine with fuel pump relay disconnected when engine and exhaust system are hot.

• Note that fuel hose connection varies with each type of pipe. Be sure to connect and clamp each

hose correctly referring to “Fuel Hose Disconnecting and Reconnecting”.

After connecting, make sure that it has no twist or kink.

• When installing injector or fuel feed pipe, lubricate its O-ring with gasoline.

General Description

Fuel System Description

S5JB0A1701001

CAUTION

!

This engine requires the unleaded fuel only.

The leaded and/or low lead fuel can result in

engine damage and reduce the effectiveness

of the emission control system.

The main components of the fuel system are fuel tank,

fuel pump assembly (with fuel filter and fuel level gauge),

fuel pressure regulator, fuel feed line and fuel vapor line.

For the details of fuel flow, refer to “Fuel Delivery System

Diagram”.

Fuel Delivery System Description

S5JB0A1701002

The fuel delivery system consists of the fuel tank, fuel

pump assembly (with built-in fuel filter), fuel pressure

regulator, delivery pipe, injectors, fuel return line, fuel

vapor line and fuel feed line.

The fuel in the fuel tank is pumped up by the fuel pump,

sent into delivery pipe and injected by the injectors.

As the fuel pump assembly is equipped with built-in fuel

filter, the fuel is filtered and its pressure is regulated after

being sent to the feed pipe.

The excess fuel at fuel pressure regulation process is

returned back into the fuel tank.

Also, fuel vapor generated in fuel tank is led through the

fuel vapor line into the EVAP canister.

For system diagram, refer to “Fuel Delivery System

Diagram”.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст