Suzuki Grand Vitara JB416 / JB420. Manual — part 95

1D-48 Engine Mechanical: For M16A Engine with VVT

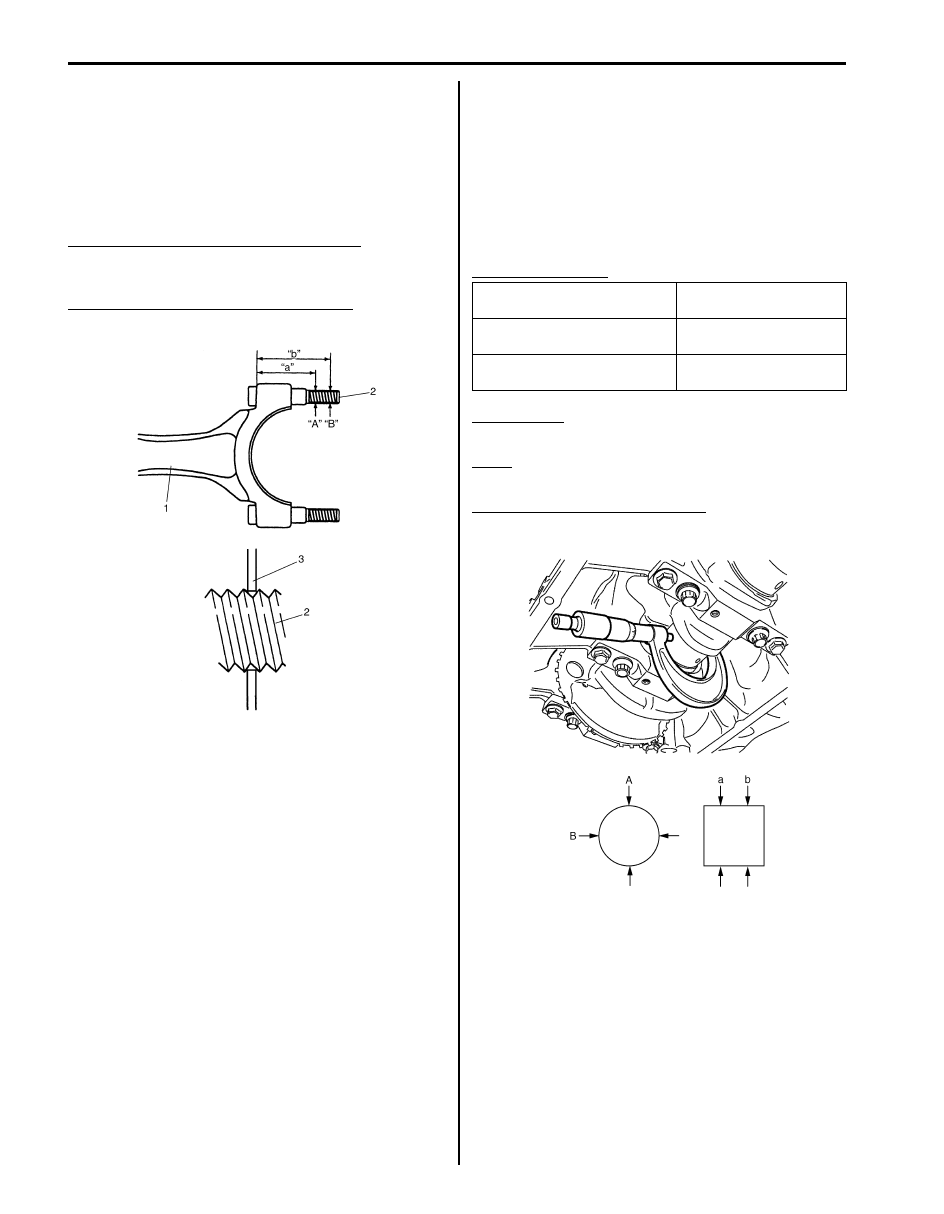

Connecting rod bolt deformation (Plastic

deformation tightening bolt)

Measure each thread diameter of connecting rod bolt (2)

at “A” on 32 mm (1.25 in.) from bolt mounting surface

and “B” on 40 mm (1.57 in.) from bolt mounting surface

by using a micrometer (3).

Calculate difference in diameters (“A” – “B”). If it is

exceeds limit, replace connected rod (1).

Connecting rod bolt measurement points

“a”: 32 mm (1.25 in.)

“b”: 40 mm (1.57 in.)

Connecting rod bolt diameter difference

Limit (“A” – “B”): 0.1 mm (0.004 in.)

Crank Pin and Connecting Rod Bearings

Inspection

S5JB0A1416034

Crank Pin Diameter

Inspect crank pin for uneven wear or damage. Measure

crank pin for out-of-round or taper with a micrometer. If

crank pin is damaged or out-of round or taper is out of

limit, replace crankshaft or regrind crank pin to undersize

and use undersize bearing.

Crank pin diameter

Out-of-round

A – B

Taper

a – b

Crank pin taper and out-of-round

Limit: 0.01 mm (0.0004 in.)

I2RH0B140119-01

Connecting rod bearing

size

Crank pin diameter

Standard

41.982 – 42.000 mm

(1.6528 – 1.6535 in.)

0.25 mm (0.0098 in.)

undersize

41.732 – 41.750 mm

(1.6430 – 1.6437 in.)

I2RH0B140120-01

Engine Mechanical: For M16A Engine with VVT 1D-49

Connecting Rod Bearing General Information

Service connecting rod bearings are available in

standard size and 0.25 mm (0.0098 in.) undersize

bearing, and standard size bearing has 5 kinds of

bearings differing in tolerance.

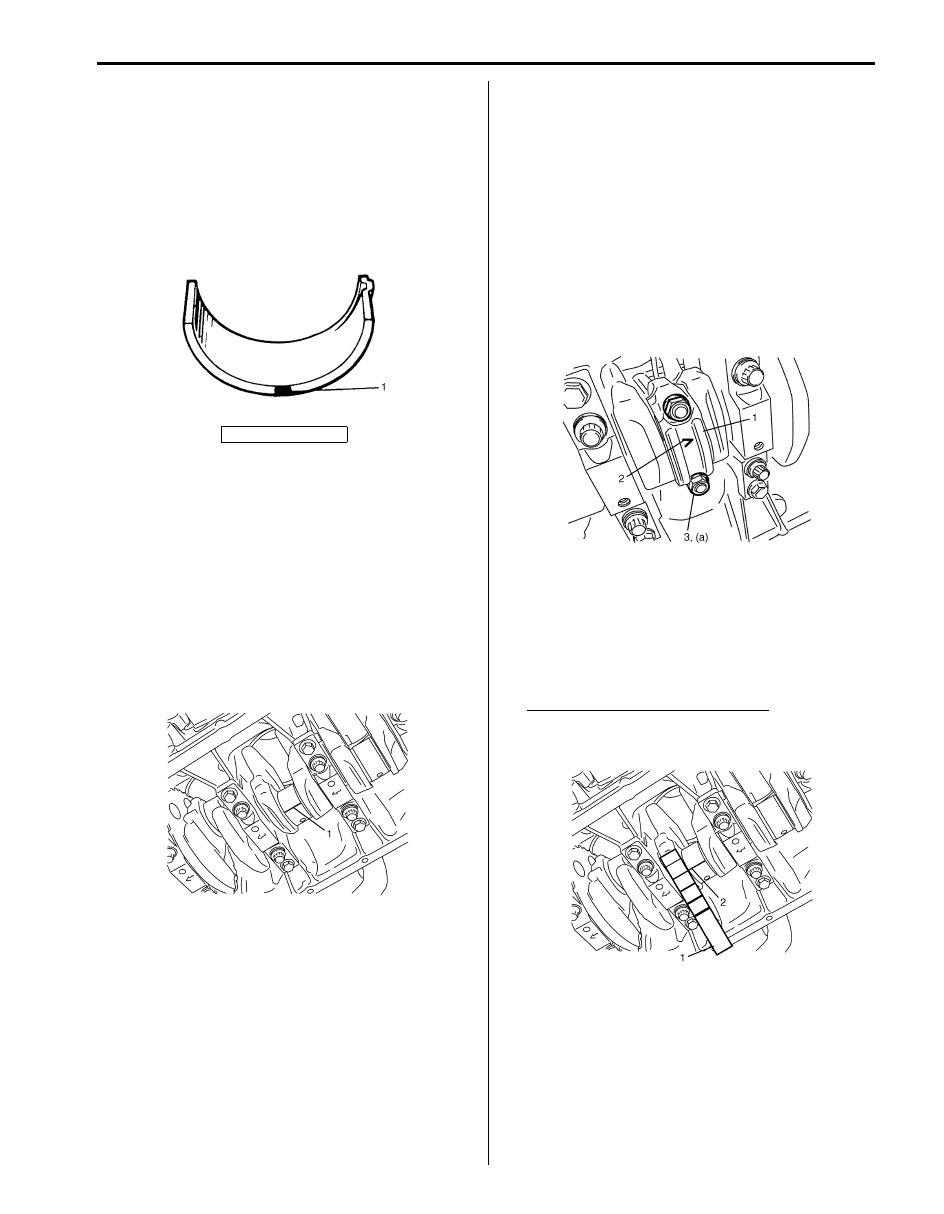

For identification of undersize bearing, it is painted red at

the position as indicated in the figure, undersize bearing

thickness is 1.605 – 1.615 mm (0.0632 – 0.0635 in.) at

the center of it.

Connecting Rod Bearing Visual Inspection

Inspect bearing shells for signs of fusion, pitting, burn or

flaking and observe contact pattern. Bearing shells

found in defective condition must be replaced.

Connecting Rod Bearing Clearance

1) Before checking bearing clearance, clean bearing

and crank pin.

2) Install bearing in connecting rod and bearing cap.

3) Place a piece of gauging plastic (1) to full width of

crank pin as contacted by bearing (parallel to

crankshaft), avoiding oil hole.

4) Install rod bearing cap (1) to connecting rod.

When installing cap, be sure to point arrow mark (2)

on cap to crankshaft pulley side, as shown in the

figure. After applying engine oil to rod bolts, tighten

cap nuts (3) gradually as follows.

a) Tighten all cap nuts to 15 N

⋅m (1.5 kgf-m, 11.0 lb-

ft)

b) Retighten them to 45

°

c) Repeat Step b) once again.

Tightening torque

Connecting rod bearing cap nut (a): 15 N

⋅m

(1.5 kgf-m, 11.0 lb-ft) and then retighten by

turning through 45

° twice

5) Remove cap and using a scale (1) on gauging

plastic envelope (2), measure gauging plastic (2)

width at the widest point (clearance).

If clearance exceed its limit, use a new standard size

bearing referring to “Selection of Connecting Rod

Bearings: For M16A Engine with VVT”.

After selecting new bearing, recheck clearance.

Connecting rod bearing clearance

Standard: 0.029 – 0.047 mm (0.0011 – 0.0018 in.)

Limit: 0.065 mm (0.0026 in.)

6) If clearance can not be brought to its limit even by

using a new standard size bearing, use next thicker

bearing and recheck clearance or regrind crank pin

to undersize and use 0.25 mm undersize bearing.

1. Red paint

I2RH01140164-01

I2RH0B140121-01

I2RH0B140122-01

I2RH0B140123-01

1D-50 Engine Mechanical: For M16A Engine with VVT

Selection of Connecting Rod Bearings

NOTE

• If bearing is in malcondition, or bearing

clearance is out of specification, select a

new standard bearing according to the

following procedure and install it.

• When replacing crankshaft or connecting

rod and its bearing due to any reason,

select new standard bearings to be

installed by referring to numbers stamped

on connecting rod and its cap and/or

alphabets stamped on crank web of No.3

cylinder.

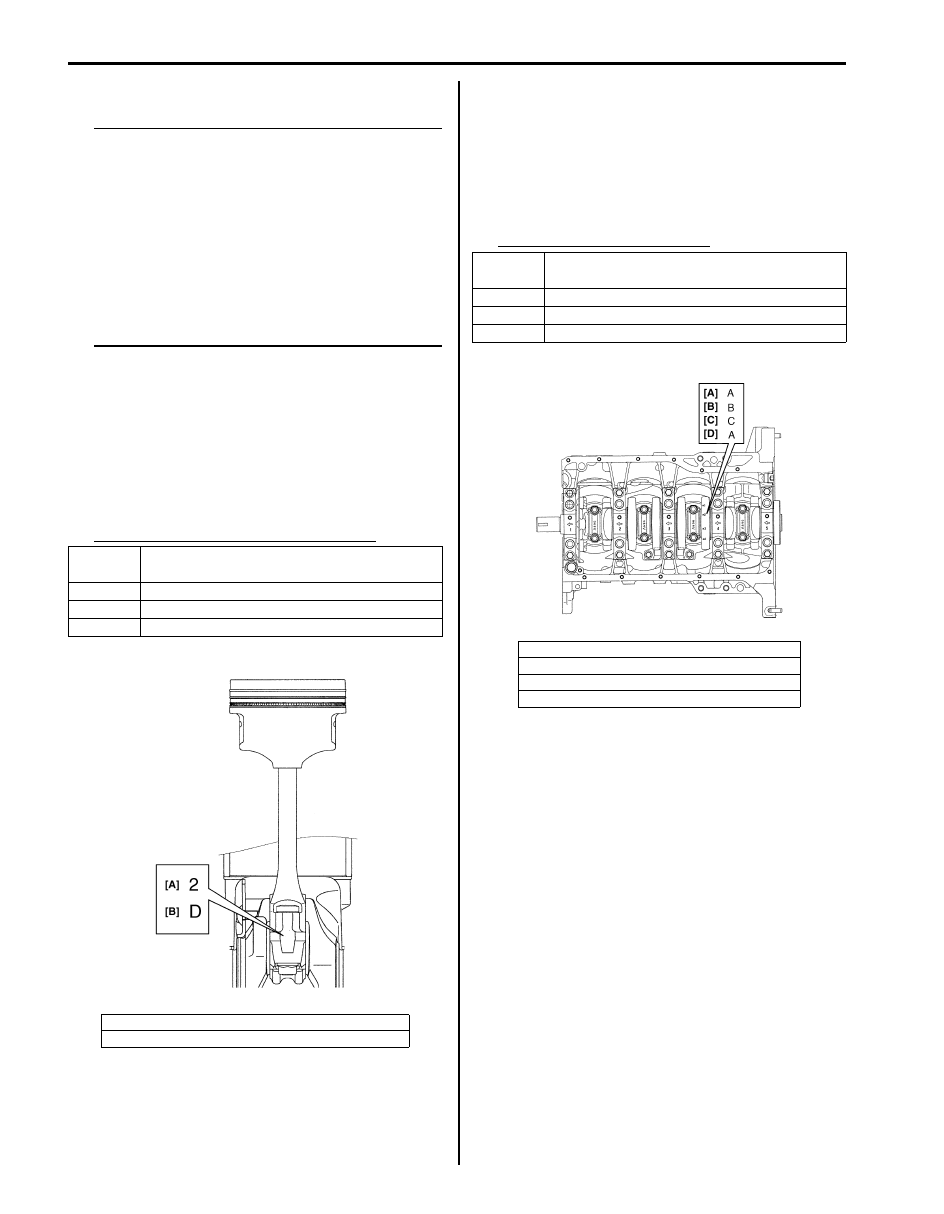

1) Check stamped numbers on connecting rod and its

cap as shown.

Three kinds of numbers (“1”, “2” and “3”) represent

the following connecting rod big end inside

diameters.

For example, stamped number “1” indicates that

corresponding connecting rod big end inside

diameter is 45.000 – 45.006 mm (1.7717 – 1.7718

in.).

Connecting rod big end inside diameter

2) Next, check crankshaft pin diameter. On crank web

No.3, four alphabets are stamped as shown in the

figure.

Three kinds of alphabet (“A”, “B” and “C”) represent

the following crankshaft pin diameter respectively.

For example, stamped “A” indicates that

corresponding crankshaft pin diameter is 41.994 –

42.000 mm (1.6533 – 1.6534 in.).

Crankshaft pin outer diameter

Stamped

numbers

Connecting rod big end inside diameter

1

45.0000 – 45.0060 mm (1.7717 – 1.7718 in.)

2

45.0061 – 45.0120 mm (1.7719 – 1.7721 in.)

3

45.0121 – 45.0180 mm (1.7722 – 1.7723 in.)

[A]: Connecting rod big end inside diameter number

[B]: Weight indication mark

I3RH0A140017-01

Stamped

alphabet

Crankshaft pin diameter

A

41.9940 – 42.0000 mm (1.6533 – 1.6534 in.)

B

41.9880 – 41.9939 mm (1.6531 – 1.6532 in.)

C

41.9820 – 41.9879 mm (1.6529 – 1.6530 in.)

[A]: Crankshaft pin diameter for No.1 cylinder

[B]: Crankshaft pin diameter for No.2 cylinder

[C]: Crankshaft pin diameter for No.3 cylinder

[D]: Crankshaft pin diameter for No.4 cylinder

I3RH0A140018-01

Engine Mechanical: For M16A Engine with VVT 1D-51

3) There are five kinds of standard bearings differing in

thickness. To distinguish them, they are painted in

the following colors at the position as indicated in the

figure.

Each color indicated the following thickness at the

center of bearing.

Standard size of connecting rod bearing

thickness

4) From number stamped on connecting rod and its cap

and alphabets stamped on crank web No.3,

determine new standard bearing to be installed to

connecting rod big end inside, by referring to the

table.

For example, if number stamped on connecting rod

and its cap is “1” and alphabet stamped on crank

web No.3 is “B”, install a new standard bearing

painted in “Black” to its connecting rod big end

inside.

Specification of new standard connecting rod

bearing size

Color

painted

Bearing thickness

Blue

1.4991 – 1.5020 mm (0.05902 – 0.05913 in.)

Yellow 1.4961 – 1.4990 mm (0.05890 – 0.05901 in.)

Nothing 1.4931 – 1.4960 mm (0.05878 – 0.05889 in.)

Black

1.4901 – 1.4930 mm (0.05867 – 0.05877 in.)

Green

1.4870 – 1.4900 mm (0.05855 – 0.05866 in.)

1. Paint

I3RH0A140019-01

Number stamped on

connecting rod and its cap

(connecting rod big end

inside diameter)

1

2

3

Alphabet stamped

on crank web No.3

(Crankshaft pin

diameter)

A

Green

Black

Nothing

B

Black

Nothing Yellow

C Nothing Yellow

Blue

New standard bearing to be

installed.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст