Suzuki Grand Vitara JB416 / JB420. Manual — part 215

4E-37 ABS:

Front Wheel Speed Sensor Inspection

S5JB0A4506007

Check sensor for damage.

If any malcondition is found, replace.

Rear Wheel Speed Sensor On-Vehicle

Inspection

S5JB0A4506008

Refer to “Front Wheel Speed Sensor On-Vehicle

Inspection” since rear wheel speed sensor is the same

as front wheel speed sensor.

Rear Wheel Speed Sensor Removal and

Installation

S5JB0A4506009

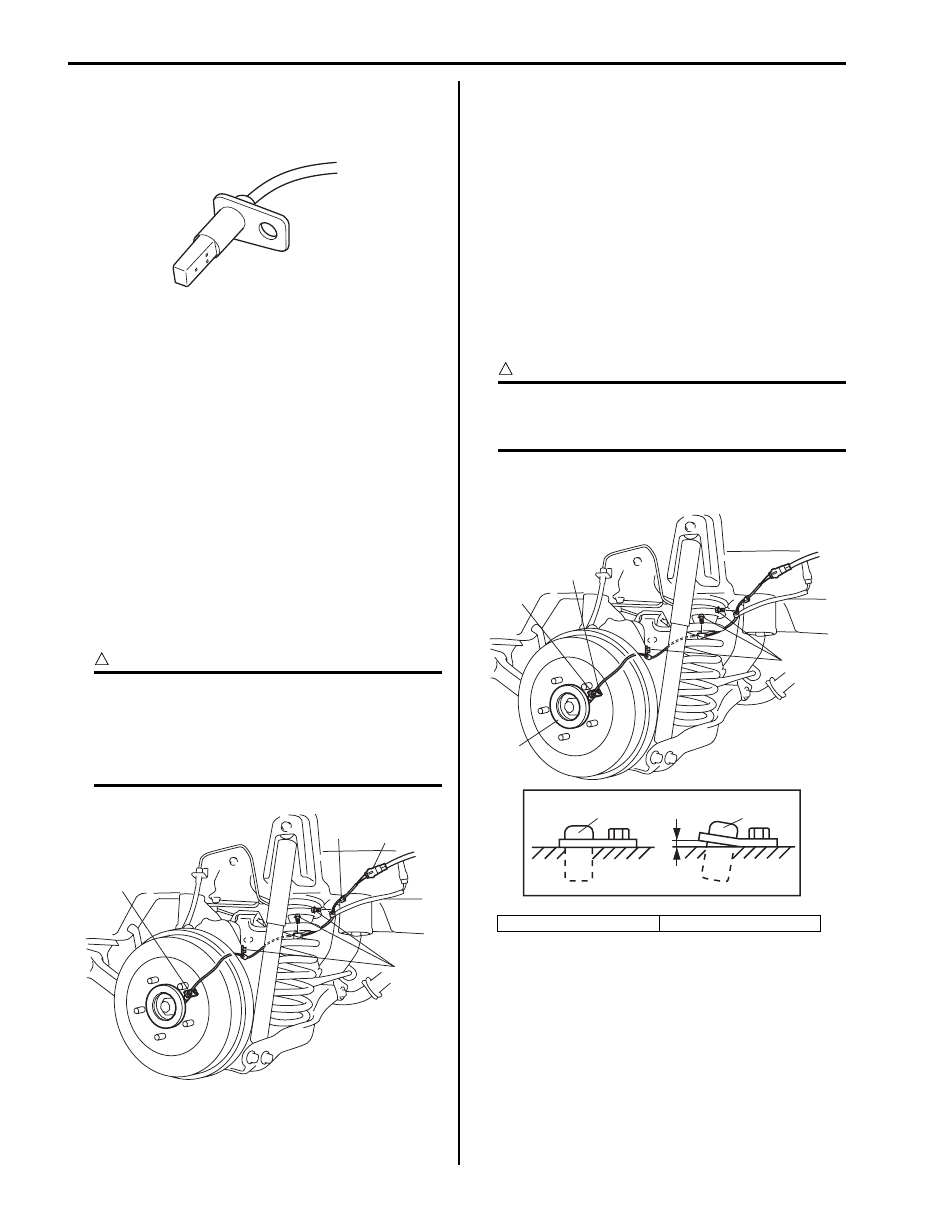

Removal

1) Disconnect negative cable from battery.

2) Disconnect rear wheel speed sensor coupler (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp (4) and clamp bolts (2).

5) Remove rear wheel speed sensor (3) from knuckle.

CAUTION

!

• Do not pull wire harness when removing

rear wheel speed sensor.

• Do not cause damage to surface of rear

wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Installation

Reverse removal procedure for installation noting the

following.

• Check that no foreign material is attached to sensor

(1) and mating encoder (2).

• Be sure to install wheel speed sensor (1) and its bolt

at the correct (upper) position as shown in figure.

Tighten sensor bolt and harness clamp bolts to

specified torque.

Tightening torque

Rear wheel speed sensor bolt (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Rear wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

CAUTION

!

Do not pull or twist wire harness more than

necessary when installing rear wheel speed

sensor.

• Check that there is no clearance between sensor and

brake back plate.

I5JB0A450031-01

3

1

2

4

I5JB0A450032-02

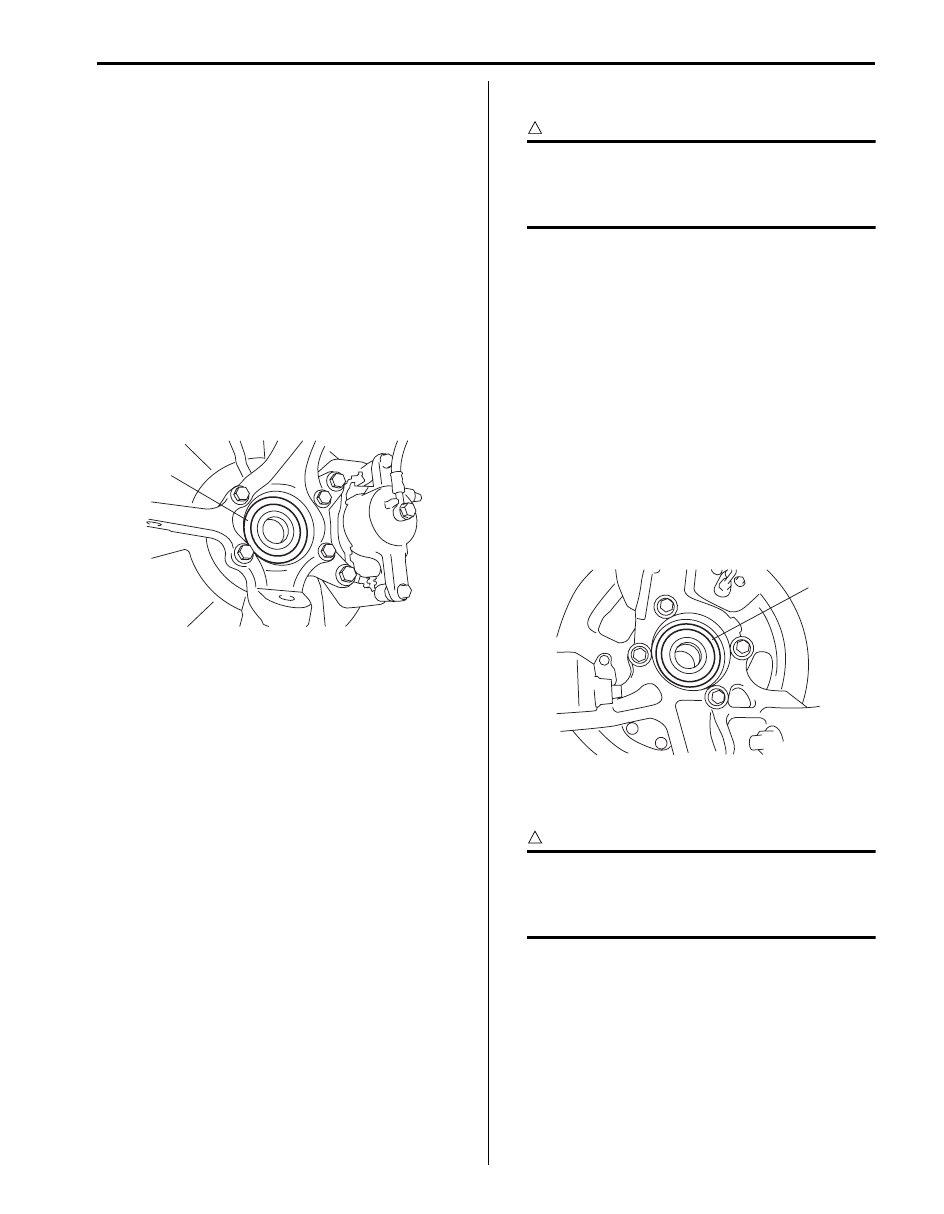

[A]: OK

[B]: NG

[A]

[B]

2

1

(a)

(b)

1

1

I5JB0A450033-01

ABS: 4E-38

Rear Wheel Speed Sensor Inspection

S5JB0A4506010

Refer to “Front Wheel Speed Sensor Inspection” since

rear wheel speed sensor is the same as front wheel

speed sensor.

Front Wheel Encoder On-Vehicle Inspection

S5JB0A4506011

Before inspect front wheel encoder, remove front drive

shaft referring to “Front Drive Shaft Assembly Removal

and Installation: Front in Section 3A”.

• Check encoder (1) for being crack, damaged or

deformed.

• Turn wheel and check if encoder rotation is free from

eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, repair or replace. Refer to “Front

Wheel Hub Assembly Removal and Installation in

Section 2B”.

Front Wheel Encoder Removal and Installation

S5JB0A4506012

CAUTION

!

Front wheel encoder is included in front

wheel hub assembly. If front wheel encoder

needs to replaced, replace it as a front wheel

hub assembly.

For removal and installation of front wheel hub

assembly, referring to “Front Wheel Hub Assembly

Removal and Installation in Section 2B”.

Rear Wheel Encoder On-Vehicle Inspection

S5JB0A4506013

Before inspect rear wheel encoder, remove rear drive

shaft referring to “Rear Drive Shaft Assembly Removal

and Installation: Rear in Section 3A”.

• Check encoder (1) for being crack, damaged or

deformed.

• Turn wheel and check if encoder rotation is free from

eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, repair or replace. Refer to “Rear

Wheel Hub Assembly Removal and Installation in

Section 2C”.

Rear Wheel Encoder Removal and Installation

S5JB0A4506014

CAUTION

!

Rear wheel encoder is included in rear wheel

hub assembly. If rear wheel encoder needs to

replaced, replace it as a rear wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Assembly

Removal and Installation in Section 2C”.

1

I5JB0A450034-01

1

I5JB0A450035-01

4E-39 ABS:

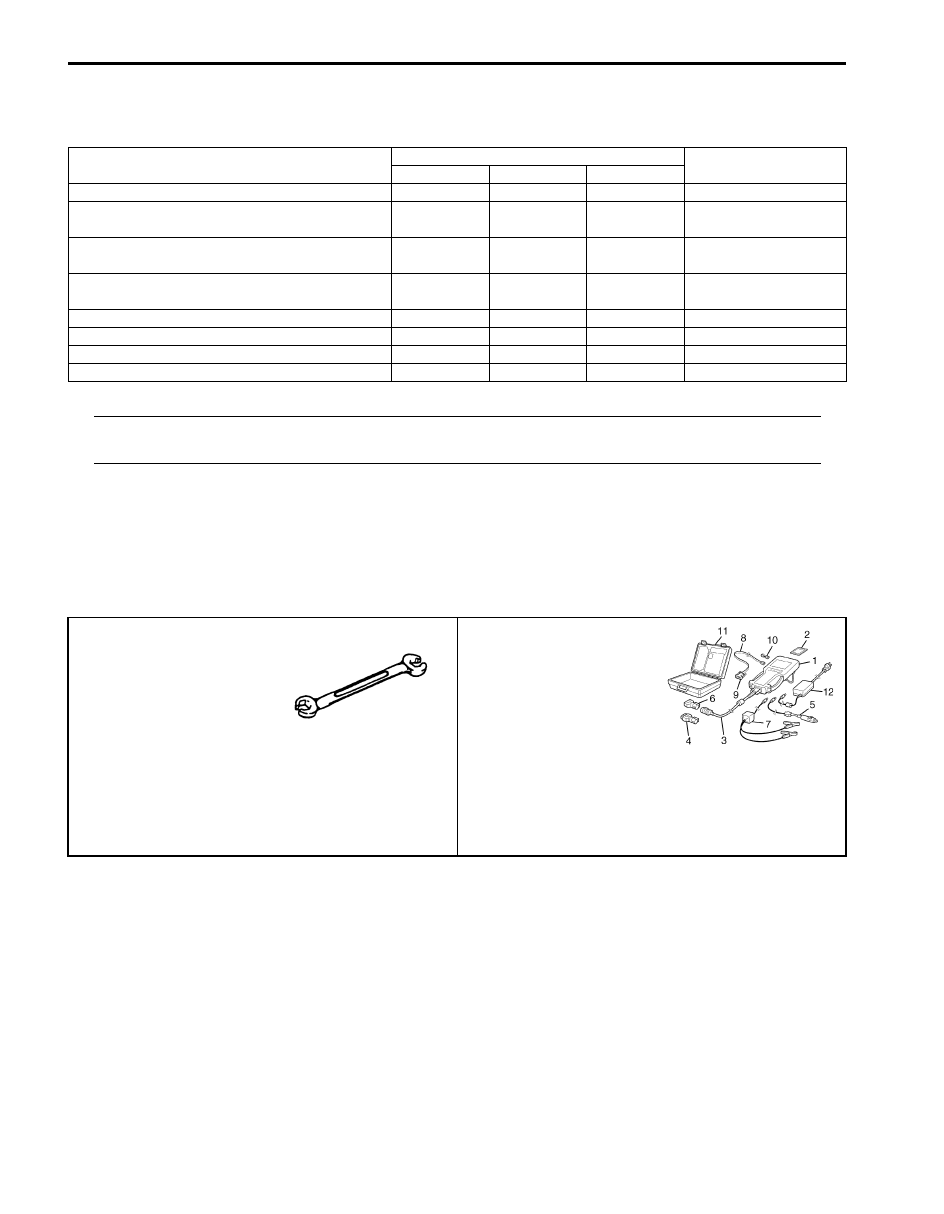

Specifications

Tightening Torque Specifications

S5JB0A4507001

NOTE

The specified tightening torque is also described in the following.

“ABS Hydraulic Unit / Control Module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fastener Information in Section 0A”.

Special Tools and Equipment

Special Tool

S5JB0A4508001

Fastening part

Tightening torque

Note

N

⋅m

kgf-m

lb-ft

Brake pipe flare nut

16

1.6

11.5

ABS hydraulic unit / control module assembly

bolt

9

0.9

6.5

ABS hydraulic unit / control module assembly

bracket bolt

25

2.5 18.0

ABS hydraulic unit / control module assembly

bracket nut

25

2.5 18.0

Front wheel speed sensor bolt

11

1.1

8.0

Front wheel speed sensor harness clamp bolt

11

1.1

8.0

Rear wheel speed sensor bolt

11

1.1

8.0

Rear wheel speed sensor harness clamp bolt

11

1.1

8.0

09950–78220

SUZUKI scan tool

Flare nut wrench (10 mm)

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. Power

supply ) / )

Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions . . . . . . . . . . . . .5-1

Precautions. . . . . . . . . . . . . . . . 5-1

Precautions for Transmission / Transaxle. . . . 5-1

Automatic Transmission/Transaxle. ... 5A-1

Precautions. . . . . . . . . . . . . . ...5A-1

Reassembly . . . . . . . . . . . . . .. 5A-1

General Description . . . . . . . . . . . .5A-3

Automatic Transmission Description. . . . ... 5A-3

Clutch / Brake Functions of Automatic

Transmission. . . . . . . . . . . . . . 5A-5

Table of A/T System Component Operation . ... 5A-6

Automatic Gear Shift Table. . . . . . . . . 5A-7

CAN Communication System Description. . ... 5A-9

Electronic Shift Control Input / Output Table. .5A-11

Brake Interlock System Description . . . . ..5A-12

A/T Diagnosis General Description . . . . ...5A-12

On-Board Diagnostic System Description. . .5A-12

Schematic and Routing Diagram. . . . . ..5A-14

Electronic Shift Control Input / Output

Diagram . . . . . . . . . . . . . . ..5A-14

Electronic Shift Control System Wiring

Diagram . . . . . . . . . . . . . . ..5A-15

Component Location . . . . . . . . . . .5A-17

Electronic Shift Control System Components

Location . . . . . . . . . . . . . . ..5A-17

Diagnostic Information and Procedures. . ..5A-18

A/T System Check . . . . . . . . . . . 5A-18

Malfunction Indicator Lamp (MIL) Check . . .. 5A-20

Transmission Warning Light Operation Check

(Vehicle is Equipped with Engine Diagnosis

Connector) . . . . . . . . . . . . . ..5A-20

“POWER” Lamp Operation Check . . . . . 5A-20

DTC Table. . . . . . . . . . . . . . .5A-21

DTC Check . . . . . . . . . . . . . ...5A-22

DTC Clearance . . . . . . . . . . . . . 5A-23

Fail Safe Table. . . . . . . . . . . . .. 5A-24

Scan Tool Data . . . . . . . . . . . . . 5A-26

Visual Inspection. . . . . . . . . . . ...5A-29

A/T Basic Check . . . . . . . . . . . ...5A-29

Road Test . . . . . . . . . . . . . . .5A-30

Manual Road Test. . . . . . . . . . . .5A-31

Stall Test . . . . . . . . . . . . . . ...5A-32

Time Lag Test . . . . . . . . . . . . ...5A-33

Line Pressure Test . . . . . . . . . . . 5A-34

Engine Brake Test. . . . . . . . . . . .5A-35

“P” Range Test. . . . . . . . . . . . ..5A-35

A/T Symptom Diagnosis. . . . . . . . . 5A-36

No Gear Shift to 4th Gear . . . . . . . . .5A-43

No Lock-Up Occurs. . . . . . . . . . ...5A-44

Transmission Warning Light Circuit Check –

Transmission Warning Light Circuit Check –

“POWER” Light Circuit Check – Light Does

Not Come “ON” at Ignition Switch ON. . . .5A-46

DTC P0705: Transmission Range Sensor

Circuit Malfunction. . . . . . . . . . ...5A-46

DTC P0707: Transmission Range Sensor

Circuit Low . . . . . . . . . . . . . ..5A-48

DTC P0712: Transmission Fluid Temperature

Sensor “A” Circuit Low . . . . . . . . . 5A-50

DTC P0713: Transmission Fluid Temperature

Sensor “A” Circuit High . . . . . . . . ...5A-51

DTC P0717: Input / Turbine Speed Sensor

Circuit No Signal . . . . . . . . . . . .5A-52

DTC P0722: Output Speed Sensor Circuit No

Signal . . . . . . . . . . . . . . . ..5A-53

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON. . . . . . . . . . . . . . .5A-54

DTC P0751 / P0752: Shift Solenoid-A

Performance or Stuck OFF / Shift Solenoid-

A Stuck ON . . . . . . . . . . . . . .5A-55

DTC P0756 / P0757: Shift Solenoid-B

Performance or Stuck OFF / Shift Solenoid-

B Stuck ON . . . . . . . . . . . . . .5A-56

DTC P0962: Pressure Control Solenoid “A”

Control Circuit Low. . . . . . . . . . ..5A-57

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст