Suzuki Grand Vitara JB416 / JB420. Manual — part 146

2B-14 Front Suspension:

Installation

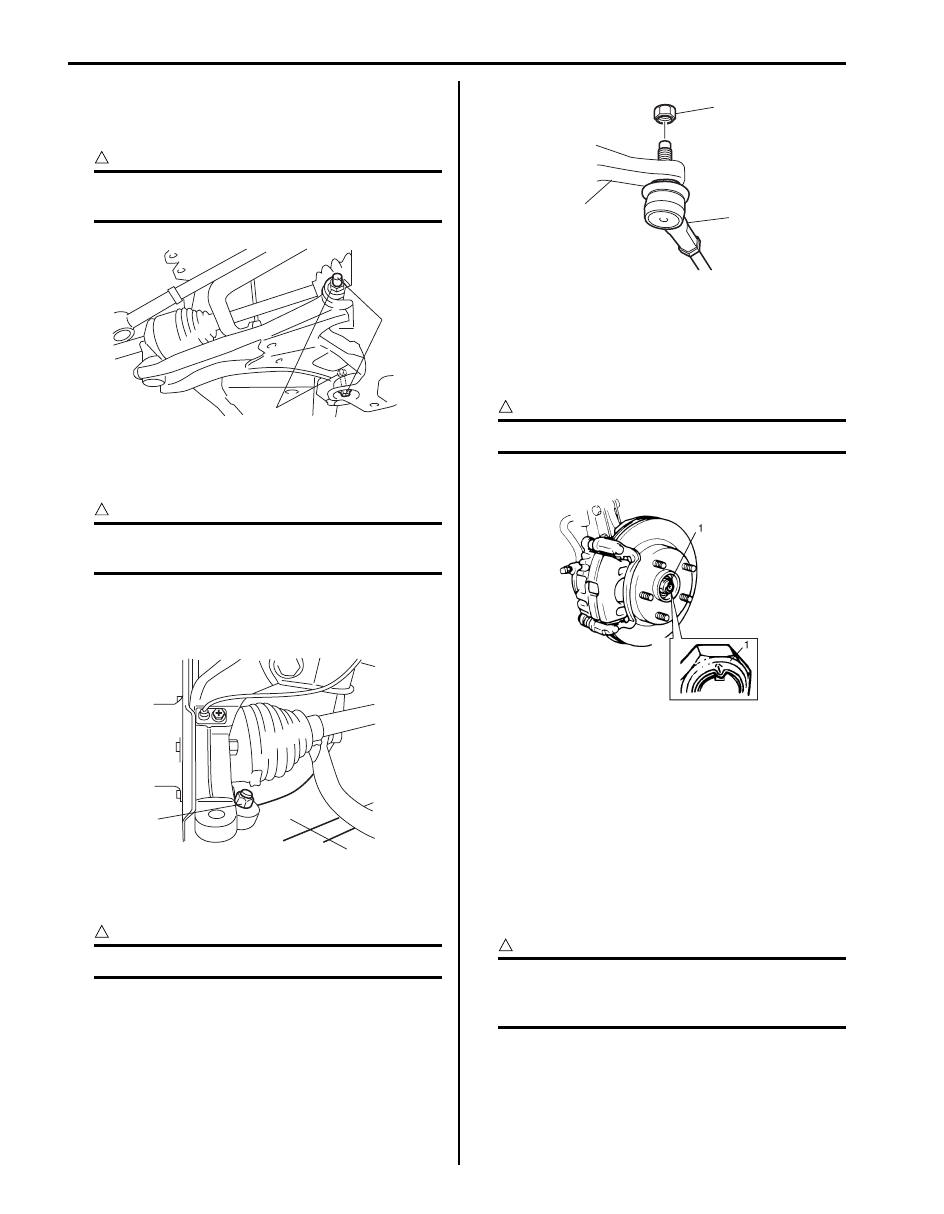

1) Install suspension control arm bolts (1) and tighten

suspension control arm nuts (2) temporarily by hand.

CAUTION

!

If reuse suspension control arm nut, apply

engine oil to thread and bearing.

2) Connect suspension control arm (1) to steering

knuckle and then tighten new suspension control

arm ball joint nut (2) to specified torque.

CAUTION

!

Never reuse the removed suspension control

arm ball joint nut.

Tightening torque

Suspension control arm ball joint nut (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

3) Connect tie-rod end (1) to steering knuckle (2) and

then tighten new nut (3) to specified torque.

CAUTION

!

Never reuse the removed tie-rod end nut.

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Depress foot brake pedal and hold it there. Tighten

new drive shaft nut (1) to specified torque.

Tightening torque

Drive shaft nut (a): 220 N·m (22.0 kgf-m, 159.5

lb-ft)

CAUTION

!

Never reuse drive shaft nut (1).

5) Caulk drive shaft nut (1) as shown.

6) Connect front height sensor (if equipped) to

suspension control arm for left side referring to

“Height Sensor Removal and Installation (If

Equipped) in Section 9B”.

7) Install wheel and lower vehicle.

8) Tighten wheel nuts to specified torque.

Tightening torque

Wheel nut: 100 N·m (10.0 kgf-m, 72.5 lb-ft)

9) Tighten suspension control arm nuts to specified

torque with vehicle weight on suspension.

CAUTION

!

It is the most desirable to have vehicle off

hoist and in non-loaded condition when

tightening them.

Tightening torque

Suspension control arm nut: 135 N·m (13.5 kgf-

m, 98.0 lb-ft)

1

2

I5JB0A220033-01

2,(a)

1

I5JB0A220034-02

2

3,(a)

1

I5JB0A220028-01

I5JB0A220021-01

Front Suspension: 2B-15

Suspension Control Arm / Bushing

Disassembly and Assembly

S5JB0A2206010

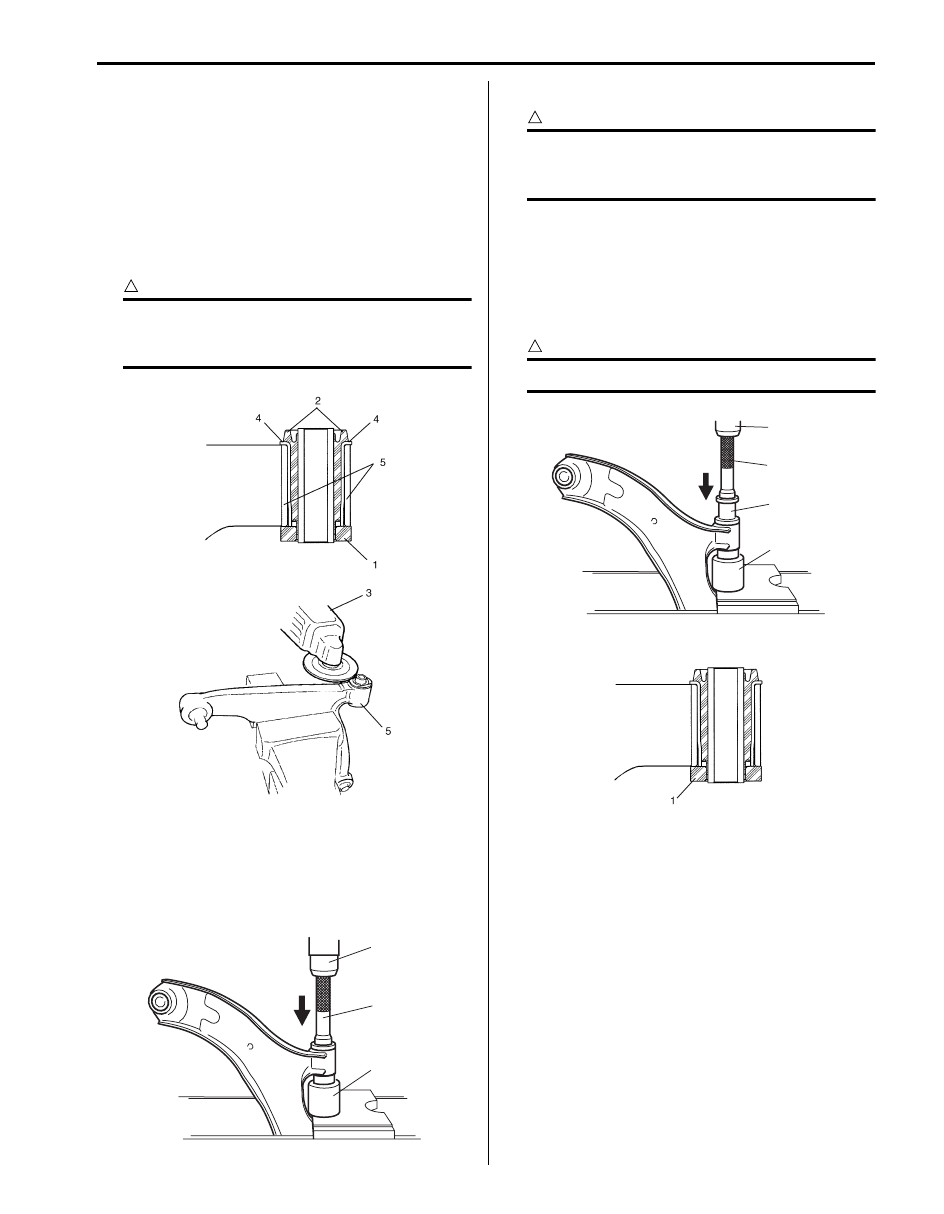

Disassembly

1) Remove rubber stopper (1).

2) Cut rubber (2) of flange of suspension control arm

front bushing.

3) Using grinder (3), grind off flange (4) of front

bushing.

CAUTION

!

Be careful not to damage suspension control

arm (5) when grinding flange (4) of front

bushing with grinder.

4) Push out bushing by using hydraulic press (2) and

special tools.

Special tool

(A): 09945–55410

(B): 09913–75821

Assembly

CAUTION

!

Apply grease (included in the repair kit) to

ball joint and inside of ball stud boot when

the ball stud boot is replaced.

1) Front bushing

Press-fit front bushing (1) by using special tools and

press (2).

Special tool

(A): 09945–55410

(B): 09913–75821

CAUTION

!

Be sure to use new bushing.

2) Install rubber stopper (1).

I5JB0A220027-02

1

(A)

(B)

I5JB0A220035-01

2

(B)

1

(A)

I5JB0A220036-01

I5JB0A220037-01

2B-16 Front Suspension:

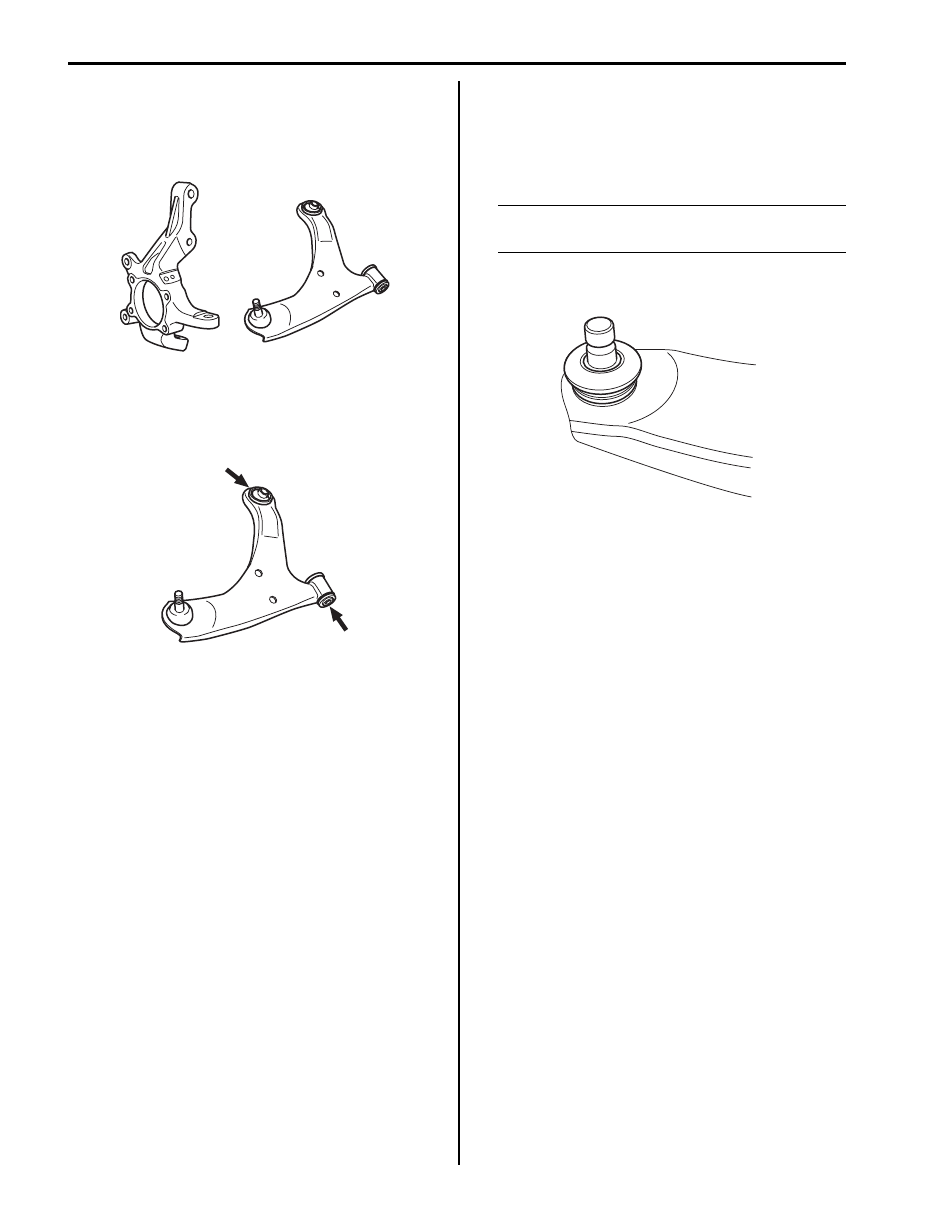

Suspension Control Arm / Steering Knuckle

Check

S5JB0A2206011

Inspect for cracks, deformation or damage.

If defective, replace.

Suspension Control Arm Bushing Check

S5JB0A2206012

Inspect for damage, wear or deterioration.

If defective, replace.

Suspension Control Arm Joint Check

S5JB0A2206013

• Check smooth rotation of ball stud.

• Check damages of ball stud.

• Check damages of dust cover.

NOTE

Suspension control arm and arm joint cannot

be separated.

If there is any damage to either parts, control arm

assembly must be replaced as a complete unit.

I5JB0A220038-01

I5JB0A220039-01

I4RS0B220023-01

Front Suspension: 2B-17

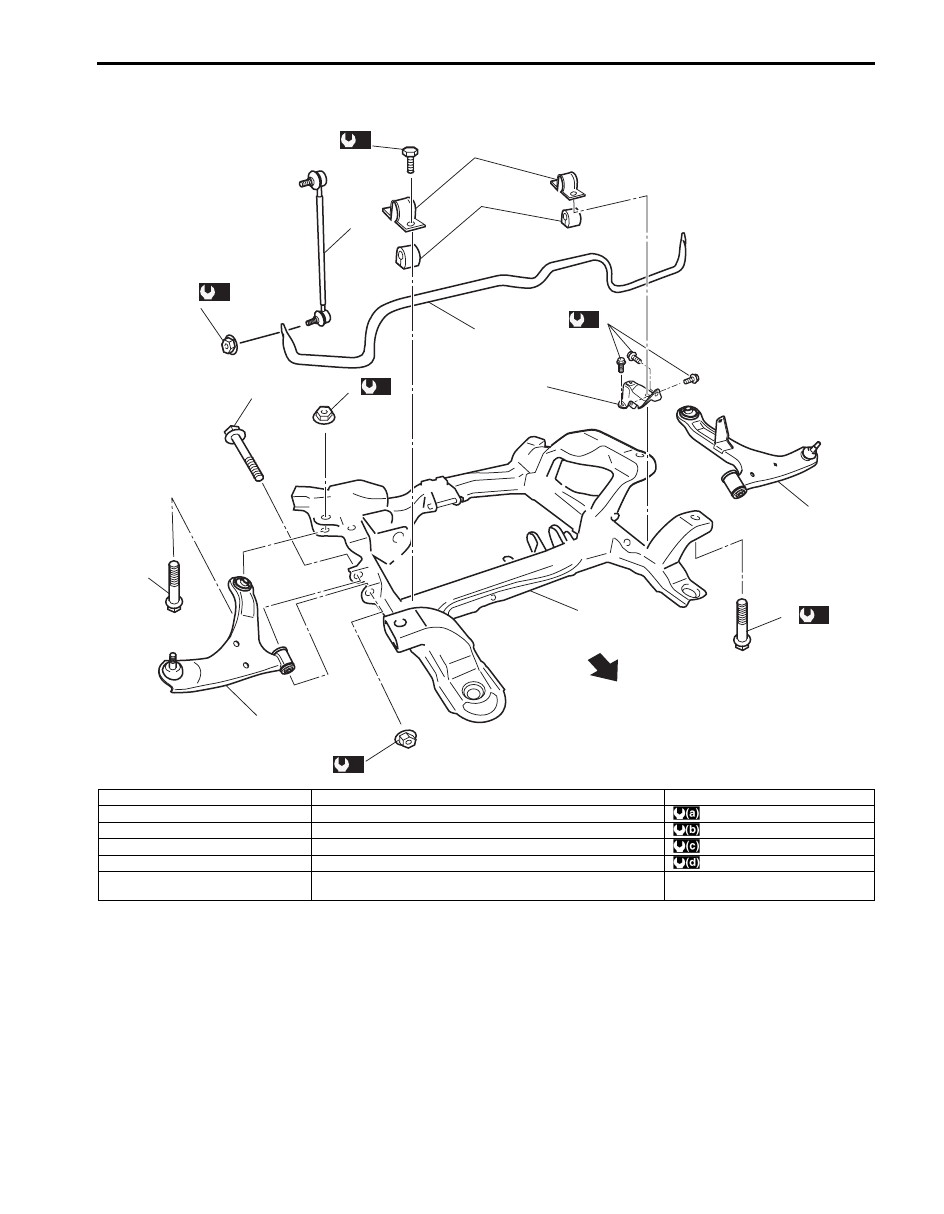

Front Suspension Frame, Stabilizer Bar and/or Bushings Components

S5JB0A2206014

10

7

3

2

5

1

8

8

7

(a)

4

6

(b)

9

(b)

9

11

(b)

F

(c)

(d)

12

I5JB0A220040-02

F: Forward

6. Stabilizer joint nut

12. Stabilizer mount

1. Stabilizer bar

7. Suspension control arm

: 50 N

⋅m (5.0 kgf-m, 36.5 lb-ft)

2. Stabilizer bushing

8. Control arm mounting bolt

: 135 N

⋅m (13.5 kgf-m, 98.0 lb-ft)

3. Stabilizer mounting bracket

9. Control arm nut

: 60 N

⋅m (6.0 kgf-m, 43.5lb-ft)

4. Stabilizer bar mounting bracket bolt

10. Suspension frame

: 55 N

⋅m (5.5 kgf-m, 40.0 lb-ft)

5. Stabilizer joint

11. Suspension frame mounting bolt

: If reuse bolt, apply engine oil to thread, bearing and trunk surface.

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст