Suzuki Grand Vitara JB416 / JB420. Manual — part 102

1D-76 Engine Mechanical: For J20 Engine

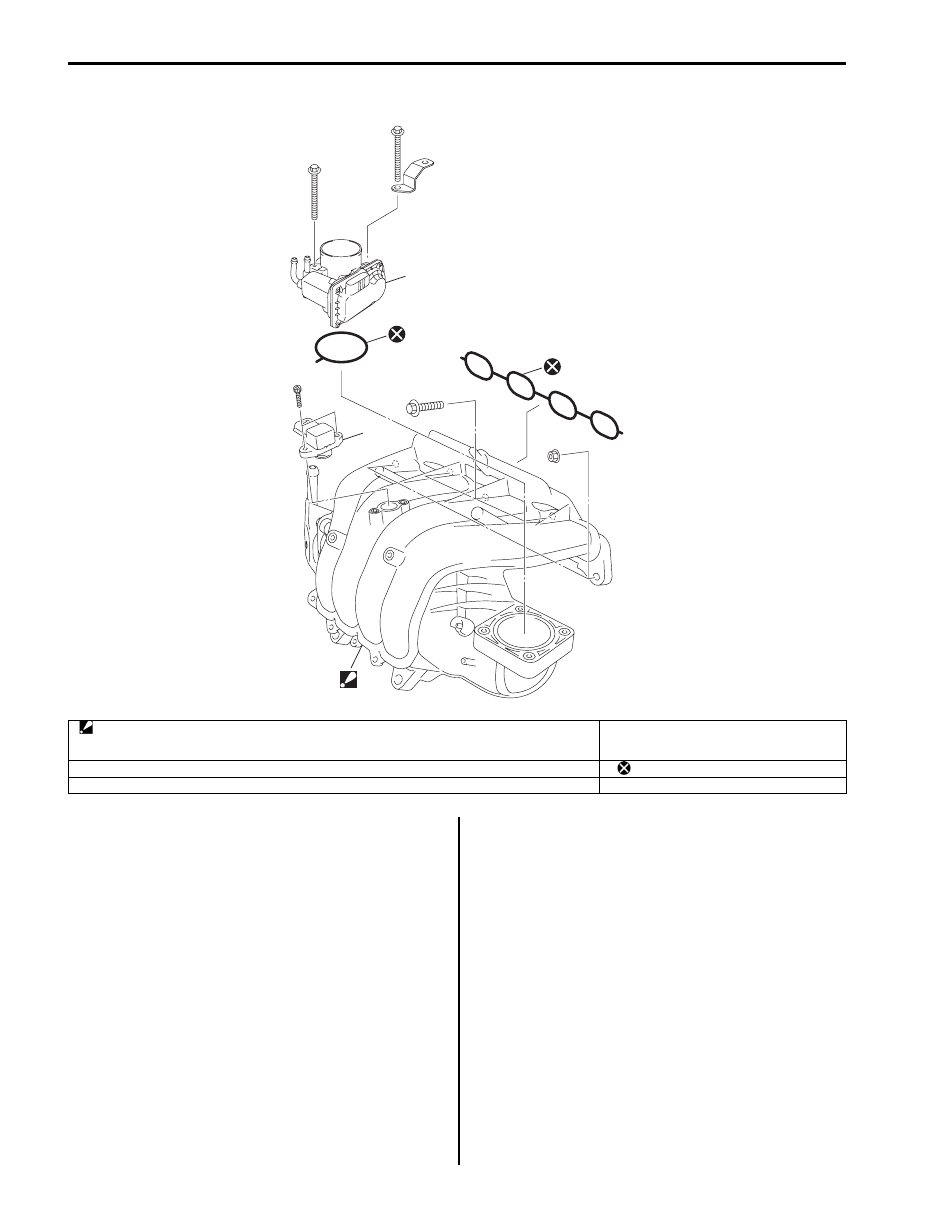

Throttle Body and Intake Manifold Components

S5JB0A1426007

Throttle Body On-Vehicle Inspection

S5JB0A1426045

Check electric throttle body assembly referring to

“Throttle Valve Operation Check” and “Electric Throttle

Body Assembly Operation Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Electric Throttle Body Assembly Removal and

Installation

S5JB0A1426046

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining

2

4

3

2

1

I5JB0A142005-01

1. Intake manifold

: Never disassemble intake manifold. Disassembly will spoil its original performance. If faulty condition is

found, replace it with new one.

4. Electric throttle body assembly

2. O-ring

: Do not reuse.

3. MAP sensor

Engine Mechanical: For J20 Engine 1D-77

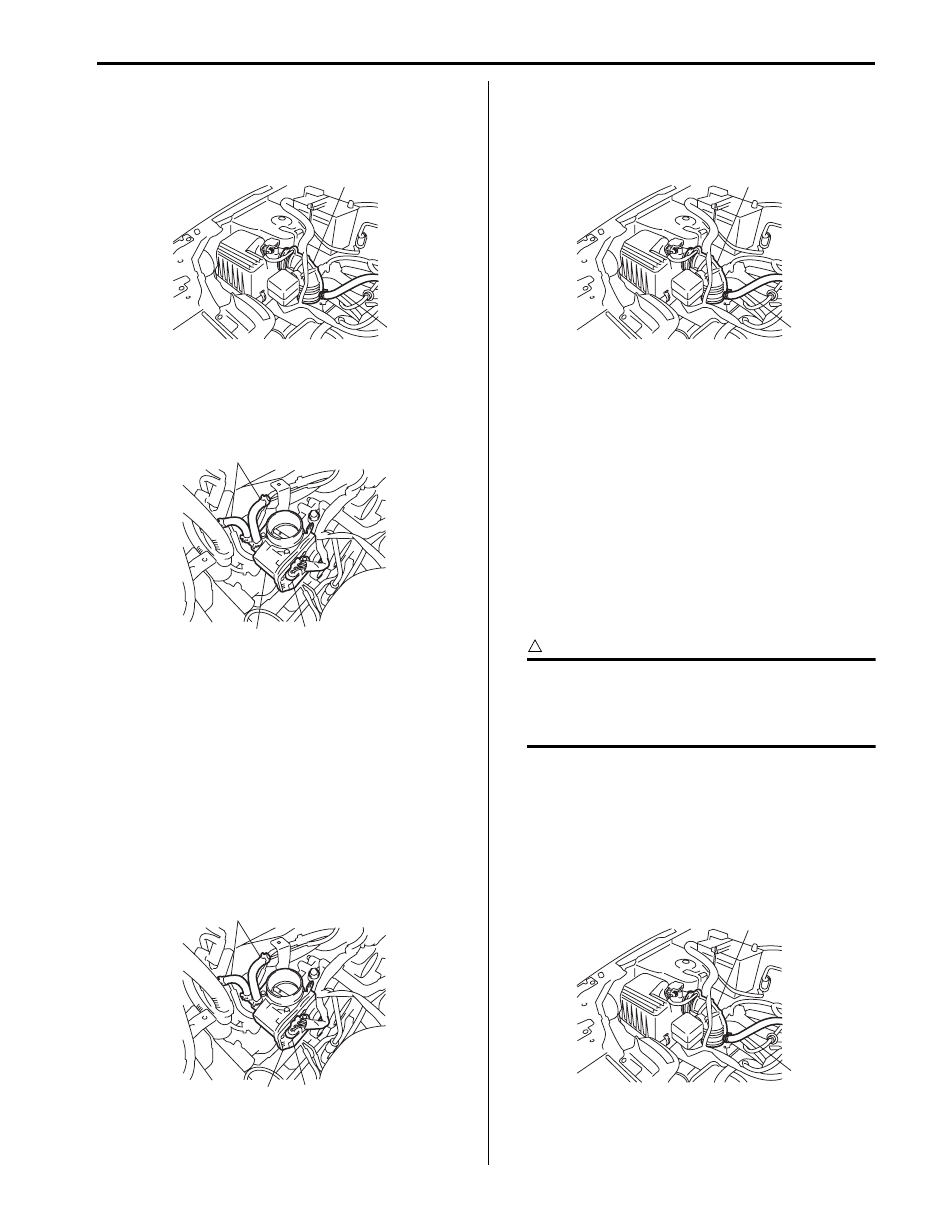

3) Disconnect breather hose (1) from air cleaner outlet

hose (2).

4) Disconnect air cleaner outlet hose (2) from air

cleaner case and electric throttle body assembly.

5) Disconnect engine coolant hoses (1) from electric

throttle body assembly (2).

6) Disconnect connector (3) from electric throttle body

assembly.

7) Remove electric throttle body assembly from intake

manifold.

Installation

1) Clean mating surfaces, and install new throttle body

gasket to intake manifold.

2) Install electric throttle body assembly (1) to intake

manifold.

3) Connect connector (2) to electric throttle body

assembly securely.

4) Connect engine coolant hoses (3) to electric throttle

body assembly (1).

5) Connect air cleaner outlet hose (1) to air cleaner

case and electric throttle body assembly.

6) Connect breather hose (2) to air cleaner outlet hose

(1).

7) Refill coolant referring to “Cooling System Flush and

8) Connect negative cable at battery.

9) Perform calibration of electric throttle body assembly

referring to “Electric Throttle Body System

Calibration in Section 1C” if replaced.

Throttle Body Cleaning

S5JB0A1426010

Clean electric throttle body assembly referring to

“Throttle Valve Operation Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

Intake Manifold Removal and Installation

S5JB0A1426012

CAUTION

!

Never disassemble intake manifold.

Disassembly will spoil its original

performance. If faulty condition is found,

replace it with new one.

Removal

1) Disconnect negative cable at battery.

2) Drain cooling system referring to “Cooling System

3) Remove engine cover.

4) Remove air cleaner outlet hose (1) and breather

hose (2).

2

1

I5JB0A142006-01

1

2

3

I5JB0A142007-01

3

1

2

I5JB0A142008-01

1

2

I5JB0A142009-01

1

2

I5JB0A142009-01

1D-78 Engine Mechanical: For J20 Engine

5) Remove electric throttle body assembly referring to

“Electric Throttle Body Assembly Removal and

Installation: For J20 Engine”.

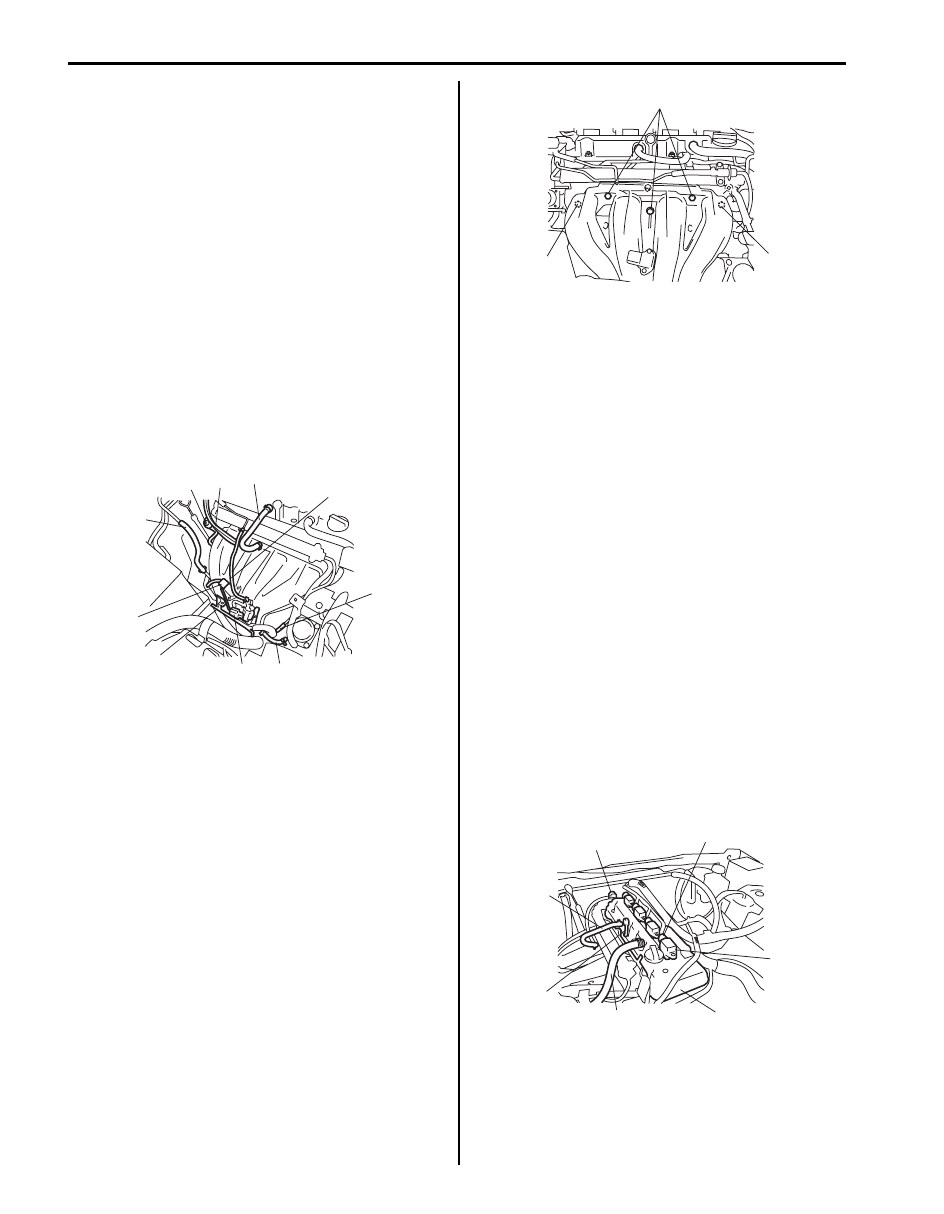

6) Disconnect the following electric lead wires:

• EVAP canister purge valve coupler (1)

• MAP sensor coupler (2)

7) Disconnect the following hoses:

• Brake booster hose (3) from intake manifold

• PCV hose (4) from PCV valve

• Fuel pressure regulator vacuum hose (5) from

intake manifold

• Vacuum hose (6) from EVAP canister purge valve

• Vacuum hose (7) from vacuum tank

• EVAP canister purge hose (8) from EVAP canister

purge valve

8) Remove EGR pipe bolt (9) from EGR pipe.

9) Remove EVAP canister purge valve bracket (10)

form intake manifold.

10) Remove water pump and generator drive belt

referring to “Water Pump and Generator Drive Belt

Removal and Installation (For J20 Engine) in Section

1J”.

11) With hose connected, detach P/S pump referring to

“P/S Pump Removal and Installation for J20 Engine

Model in Section 6C”.

12) Remove intake manifold and O-ring from cylinder

head.

Installation

Reverse removal procedure for installation noting the

followings.

• Use new intake manifold O-ring.

• Use new EGR pipe gasket.

• Install intake manifold bolt (2) and nut (1) as shown in

figure.

• Check to ensure that all removed parts are back in

place.

Reinstall any necessary parts which have not been

reinstalled.

• Adjust water pump and generator drive belt referring

to “Water Pump and Generator Drive Belt On-Vehicle

Inspection (For J20 Engine) in Section 1J”.

• Refill cooling system referring to “Cooling System

Flush and Refill in Section 1F”.

• Upon completion of installation, turn ignition switch

ON but engine OFF and check for fuel leaks.

• Finally, start engine and check for engine coolant

leaks.

Cylinder Head Cover Removal and Installation

S5JB0A1426013

Removal

1) Disconnect negative cable at battery.

2) Remove engine cover.

3) Disconnect ignition coil couplers (1).

4) Remove ignition coils (4).

5) Remove oil level gauge (6).

6) Disconnect CMP sensor coupler (5) from cylinder

head cover.

7) Disconnect breather hose (2) and PCV hose (3) from

cylinder head cover (7).

4

7

9

3

2

10

1

6

5

8

I5JB0A142010-01

2

1

1

I5JB0A142011-01

1

4

7

5

3

6

2

I5JB0A142012-02

Engine Mechanical: For J20 Engine 1D-79

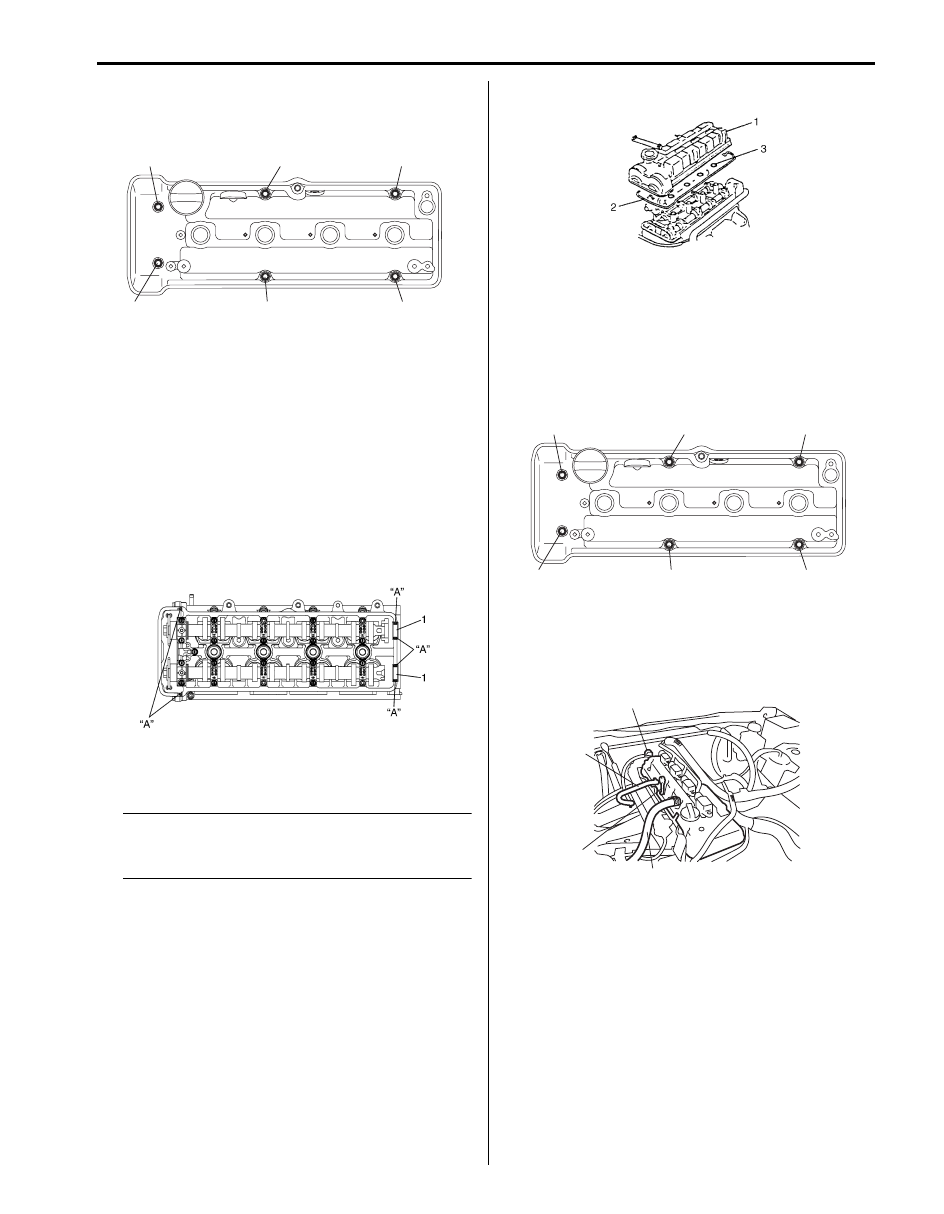

8) Remove PCV valve from cylinder head cover.

9) Remove cylinder head cover nuts in such order as

indicated in the figure.

Installation

1) Install PCV valve to cylinder head cover referring to

“EGR Valve Removal and Installation in Section 1B”.

2) Remove oil, old sealant and dust from sealing

surfaces on cylinder head and cover.

3) Install new cylinder head side seals (1) to cylinder

head.

4) Apply sealant “A” to cylinder head sealing surface

area as shown in figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

5) Install new O-rings (3) and new cylinder head cover

gasket (2) to cylinder head cover (1).

NOTE

Be sure to check each of these parts for

deterioration or any damage before

installation and replace if found defective.

6) Install cylinder head cover to cylinder head.

7) Tighten cylinder head cover nuts in such order as

indicated in the figure a little at a time till they are

tightened to specified torque.

• Use new seal washers.

Tightening torque

Cylinder head cover nut (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

8) Install oil level gauge (1).

9) Connect CMP sensor coupler (4).

10) Connect breather hose (2) and PCV hose (3) to

cylinder head cover.

11) Install ignition coils referring to “Ignition Coil

Assembly (Including ignitor) Removal and

Installation in Section 1H”.

12) Install engine cover.

13) Connect negative cable at battery.

“2”

“6”

“4”

“3”

“5”

“1”

I5JB0A142013-01

I5JB0A142067-01

I5JB0A142068-02

“5”, (a)

“1”, (a)

“3”, (a)

“4”, (a)

“2”, (a)

“6”, (a)

I5JB0A142014-01

4

3

1

2

I5JB0A142015-01

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст