Suzuki Grand Vitara JB416 / JB420. Manual — part 4

00-13 Precautions:

Repair Instructions

Electrical Circuit Inspection Procedure

S5JB0A0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perform careful check, starting with

items which are easier to check.

1) Disconnect negative cable from battery

2) Check each connector at both ends of the circuit

being checked for loose connection. Also check lock

condition of connector if equipped with connector

lock.

3) Using a test male terminal, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each terminal is locked in the

connector fully.

4) Using continuity check or voltage check the following

procedure, check the wire harness for open circuit

and poor connection with its terminals. Locate

abnormality, if any.

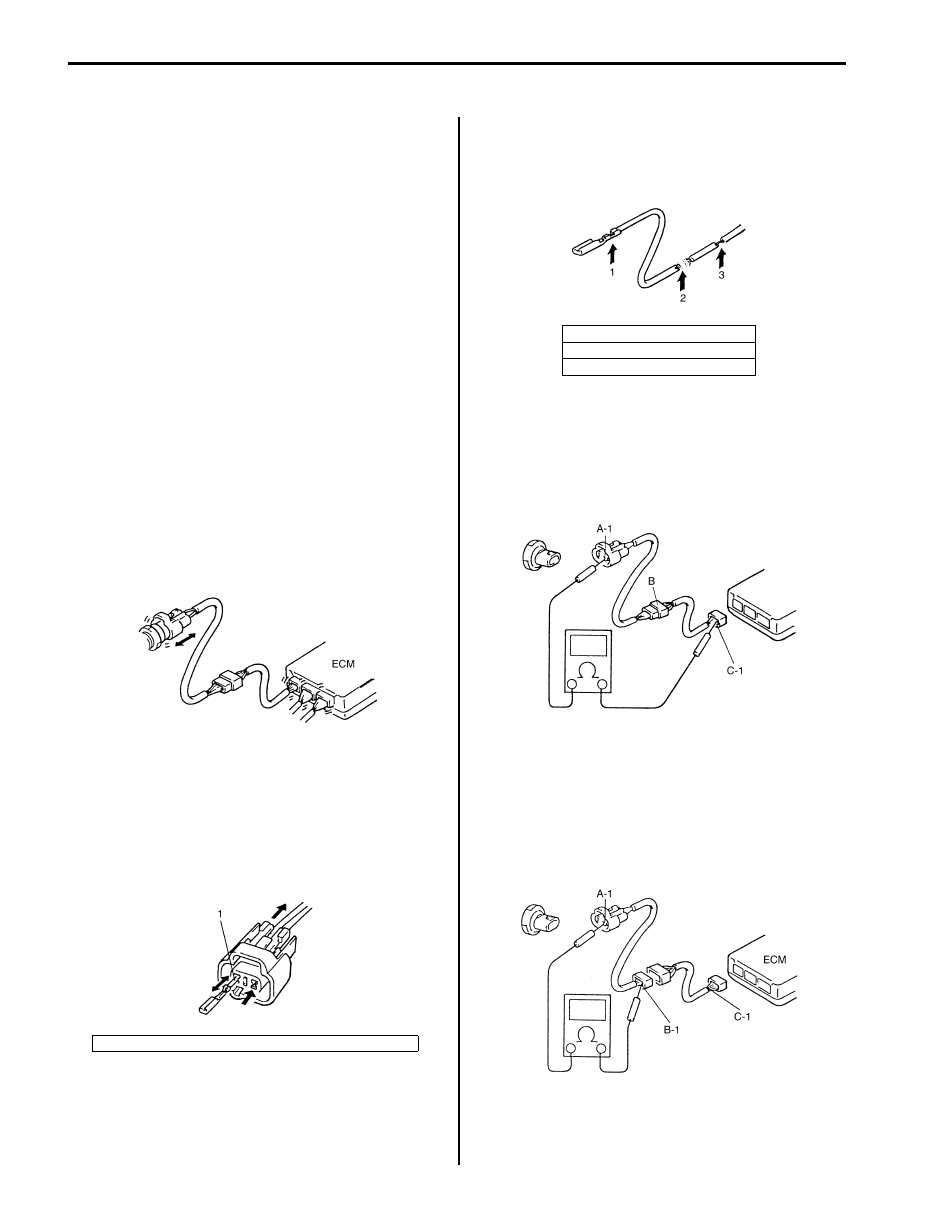

Continuity Check

1) Measure resistance between connector terminals at

both ends of the circuit being checked (between “A-

1” and “C-1” in the figure). If no continuity is indicated

(infinity or over limit), that means that the circuit is

open between terminals “A-1” and “C-1”.

2) Disconnect the connector included in the circuit

(connector-B in the figure) and measure resistance

between terminals “A-1” and “B-1”.

If no continuity is indicated, that means that the

circuit is open between terminals “A-1” and “B-1”. If

continuity is indicated, there is an open circuit

between terminals “B-1” and “C-1” or an abnormality

in connector-B.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

1. Looseness of crimping

2. Open

3. Thin wire (single strand of wire)

I2RH01010051-01

I2RH01010052-01

I2RH01010053-01

Precautions: 00-14

Voltage Check

If voltage is supplied to the circuit being checked, voltage

check can be used as circuit check.

1) With all connectors connected and voltage applied to

the circuit being checked, measure voltage between

each terminal and body ground.

a) If measurements were taken as shown in the

figure and results were as listed in the following,

it means that the circuit is open between

terminals “B-1” and “A-1”.

Voltage between each terminal and body

ground

“C-1” and body ground: Approx. 5 V

“B-1” and body ground: Approx. 5 V

“A-1” and body ground: 0 V

b) Also, if measured values were as listed in the

following, it means that there is a resistance

(abnormality) of such level that corresponds to

the voltage drop in the circuit between terminals

“A-1” and “B-1”.

Voltage between

“C-1” and body ground: Approx. 5 V

“B-1” and body ground: Approx. 5 V

“A-1” and body ground: Approx. 3 V

“A-1” and “B-1”: 2V voltage drop

Short Circuit Check (Wire Harness to Ground)

1) Disconnect negative cable at battery.

2) Disconnect connectors at both ends of the circuit to

be checked.

NOTE

If the circuit to be checked is connected to

other parts (1), disconnect all connectors of

those parts.

Otherwise, diagnosis will be misled.

3) Measure resistance between terminal at one end of

circuit (“A-1” terminal in the figure) and body ground.

If continuity is indicated, it means that there is a short

to ground between terminals “A-1” and “C-1” of the

circuit.

4) Disconnect the connector included in circuit

(connector B) and measure resistance between “A-

1” and body ground.

If continuity is indicated, it means that the circuit is

shorted to the ground between terminals “A-1” and

“B-1”.

I5RH01000005-01

1. To other parts

1. To other parts

I5RH01000006-01

I2RH01010056-01

00-15 Precautions:

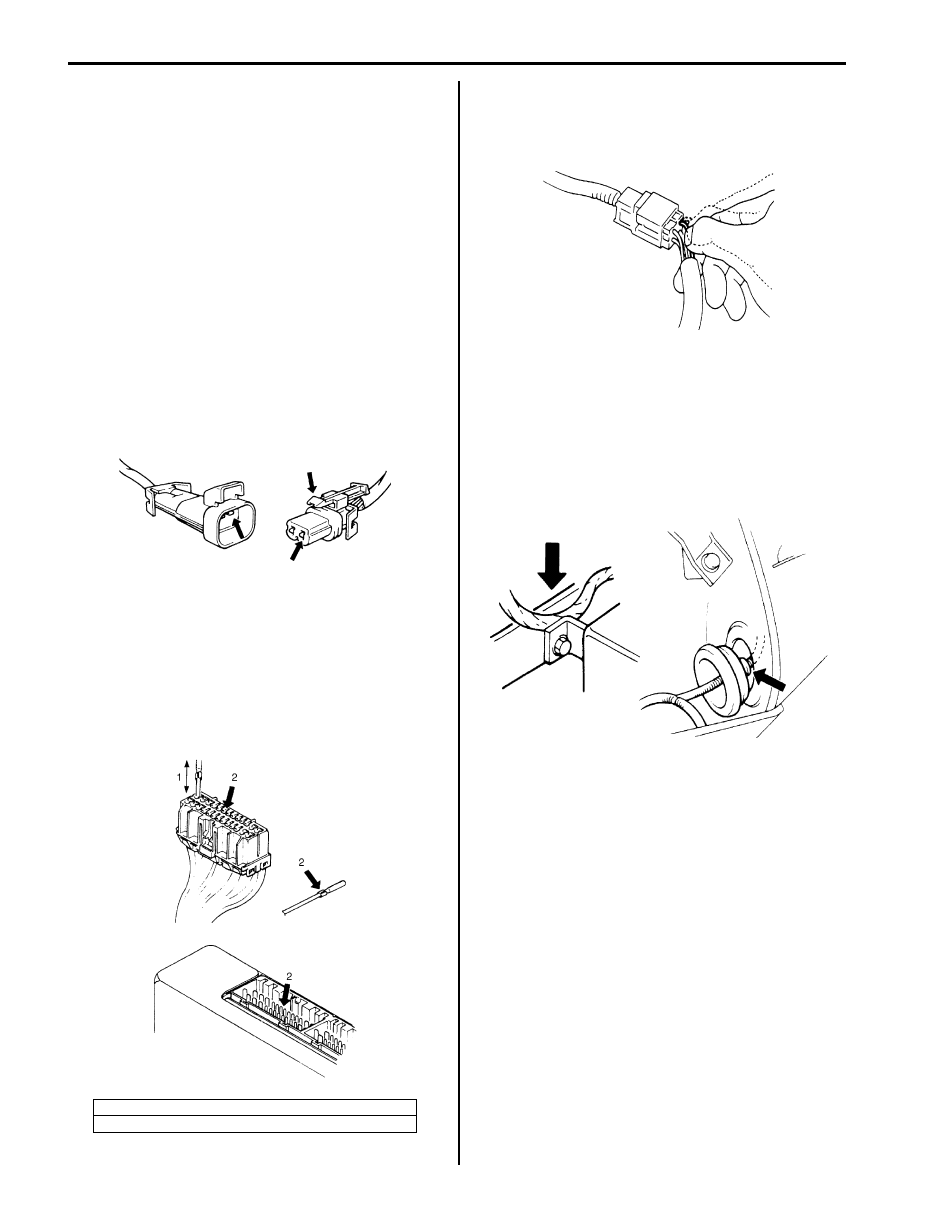

Intermittent and Poor Connection Inspection

S5JB0A0006002

Most intermittent are caused by faulty electrical

connections or wiring, although a sticking relay or

solenoid can occasionally be at fault. When checking it

for proper connection, perform careful check of suspect

circuits for:

• Poor mating of connector halves, or terminals not fully

seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must

be clean and free of any foreign material which could

impede proper terminal contact. However, cleaning

the terminal with a sand paper or the like is prohibited.

• Damaged connector body, exposing the terminals to

moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

• Improperly formed or damaged terminals.

Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal.

If contact tension is not enough, reform it to increase

contact tension or replace.

• Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace.

• Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wiring broken inside the insulation. This condition

could cause continuity check to show a good circuit,

but if only 1 or 2 strands of a multi-strand-type wire

are intact, resistance could be far too high.

If any abnormality is found, repair or replace.

1. Check contact tension by inserting and removing just once.

2. Check each terminal for bend and proper alignment.

I2RH01010057-01

I5RH01000007-01

I2RH01010059-01

I2RH01010060-01

Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information . . . . . . . . 0A-1

General Description . . . . . . . . . . . .0A-1

Abbreviations . . . . . . . . . . . . . .. 0A-1

Symbols . . . . . . . . . . . . . . . .. 0A-2

Wire Color Symbols . . . . . . . . . . . 0A-3

Fastener Information. . . . . . . . . . ... 0A-3

Vehicle Lifting Points. . . . . . . . . . ... 0A-5

Engine Supporting Points . . . . . . . . ... 0A-7

Vehicle Identification Number . . . . . . . . 0A-7

Engine Identification Number. . . . . . . .. 0A-7

Transmission Identification Number. . . . . 0A-7

Component Location . . . . . . . . . . ...0A-8

Warning, Caution and Information Label

Location . . . . . . . . . . . . . . . 0A-8

Maintenance and Lubrication. . . . . 0B-1

Precautions. . . . . . . . . . . . . . ...0B-1

Precautions for Maintenance and Lubrication. . 0B-1

Scheduled Maintenance . . . . . . . . . ..0B-1

Maintenance Schedule under Normal Driving

Conditions . . . . . . . . . . . . . . . 0B-1

Maintenance Recommended under Severe

Driving Conditions. . . . . . . . . . . . 0B-2

Repair Instructions . . . . . . . . . . . ..0B-4

Engine Accessory Drive Belt Inspection . . . . 0B-4

Engine Accessory Drive Belt Replacement. . . 0B-4

Valve Lash (Clearance) Inspection . . . . . . 0B-4

Engine Oil and Filter Change. . . . . . . .. 0B-5

Engine Coolant Change. . . . . . . . . .. 0B-6

Exhaust system Inspection . . . . . . . . . 0B-7

Spark Plugs Replacement . . . . . . . . .. 0B-7

Air Cleaner Filter Inspection. . . . . . . . 0B-7

Air Cleaner Filter Replacement . . . . . . ... 0B-7

Fuel Lines and Connections Inspection . . . .. 0B-7

Fuel Filter Replacement. . . . . . . . . .. 0B-7

Fuel Tank Inspection. . . . . . . . . . ... 0B-7

Crankcase Ventilation Hoses and

Connections Inspection (Vehicle without A/F

Sensor). . . . . . . . . . . . . . . ..0B-7

PCV Valve Inspection . . . . . . . . . . .0B-7

Fuel Evaporative Emission Control System

Inspection. . . . . . . . . . . . . . ..0B-8

Brake Discs and Pads Inspection . . . . . ...0B-8

Brake Drums and Shoes Inspection. . . . . 0B-8

Brake Hoses and Pipes Inspection . . . . . .0B-8

Brake Fluid Change . . . . . . . . . . . 0B-9

Parking Brake Lever and Cable Inspection. . .0B-9

Clutch Fluid Inspection. . . . . . . . . . 0B-9

Tire / Wheel Inspection and Rotation . . . . ..0B-9

Wheel Discs Inspection. . . . . . . . . .0B-10

Wheel Bearing Inspection . . . . . . . . .0B-10

Suspension System Inspection . . . . . . .0B-10

Steering System Inspection . . . . . . . ..0B-10

Propeller Shafts and Drive Shafts Inspection. 0B-11

Manual Transmission Oil Inspection . . . . .0B-11

Manual Transmission Oil Change . . . . . .0B-12

Automatic Transmission Fluid Inspection. . ..0B-12

Automatic Transmission Fluid Change . . . .0B-12

Automatic Transmission Fluid Cooler Hose

Inspection. . . . . . . . . . . . . . 0B-12

Change. . . . . . . . . . . . . . . 0B-12

Specifications. . . . . . . . . . . . . .0B-15

Tightening Torque Specifications. . . . . ..0B-15

Special Tools and Equipment . . . . . . ...0B-15

Recommended Fluids and Lubricants. . . ...0B-15

Special Tool . . . . . . . . . . . . . ..0B-15

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст