BMW 3 (E46). Manual — part 82

quick tests.

Disconnecting the battery may

erase fault code(s) stored in

memory. Check for fault codes

prior to disconnecting the battery

cables.

Wait at least 40 seconds after

turning off the ignition before

removing the engine control

module (ECM) connector. If the

connector is removed before this

time, residual power in the system

relay may damage the control

module.

Cleanliness is essential when

working on an open fuel system.

Thoroughly clean fuel line

connections and surrounding

areas before loosening. Avoid

moving the car. Only install clean

parts.

Fuel system cleaners and other

chemical additives other than

those specifically recommended

by BMW may damage the catalytic

converter, the oxygen sensor or

other fuel supply components.

130-2

Electrical Checks and

Component Testing

Troubleshooting and fault diagnosis on

OBD II cars is best performed using an

electronic scan tool. However, it may

be necessary to perform basic tests of

the engine management main

components, fuel system or wiring.

CAUTION!

The tests in this section may set

fault codes (DTCs) in the ECM

and illuminate the MIL. After all

testing tests is completed,

access and clear DTC fault

memory using a BMW

compatible scan tool. See

OBD On Board Diagnostics

at

the back of this manual.

Only use a digital multimeter for

electrical tests.

Relay positions can vary. Be

sure to confirm relay position by

identifying the wiring in the

socket using the wiring

diagrams found at the rear of

this manual.

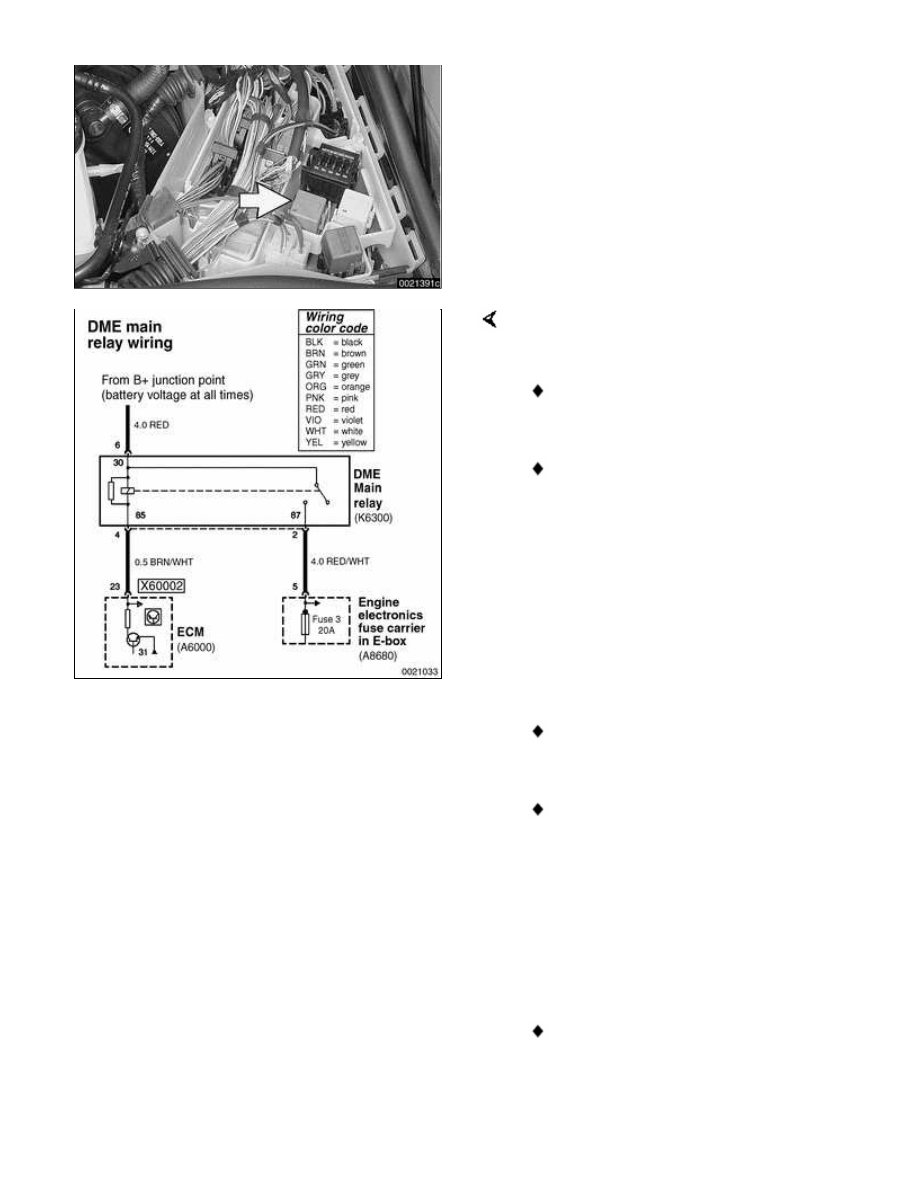

DME main relay, testing

The DME main relay is energized via

the engine control module (ECM) and

supplies battery positive (B+) power to

many of the engine management

components and subsystems. If this

relay is faulty, the engine will not start.

With ignition off, remove main relay

(arrow) in electronics box (E-box) at

left rear of engine compartment.

Check for voltage at terminal 6 of main

relay socket (30- red wire).

If battery voltage is present

continue testing.

If battery voltage is not present,

check large red wire in relay

socket. See Electrical Wiring

Diagrams.

-

Reinstall relay and turn ignition

on. Gain access to underside of

relay socket and check for ground

at terminal 4 (85- brown/white

wire).

If ground is present continue

testing.

If ground is not present, signal

from ECM (connector X60002, pin

23) is missing. Check wire

between ECM and relay.

-

With ignition on and relay

installed, check for battery voltage

at terminal 2 (87- red/white wire).

If battery voltage is present, relay

has energized and is functioning

correctly.

If battery voltage is not present

and all earlier tests are OK, relay

is faulty and should be replaced.

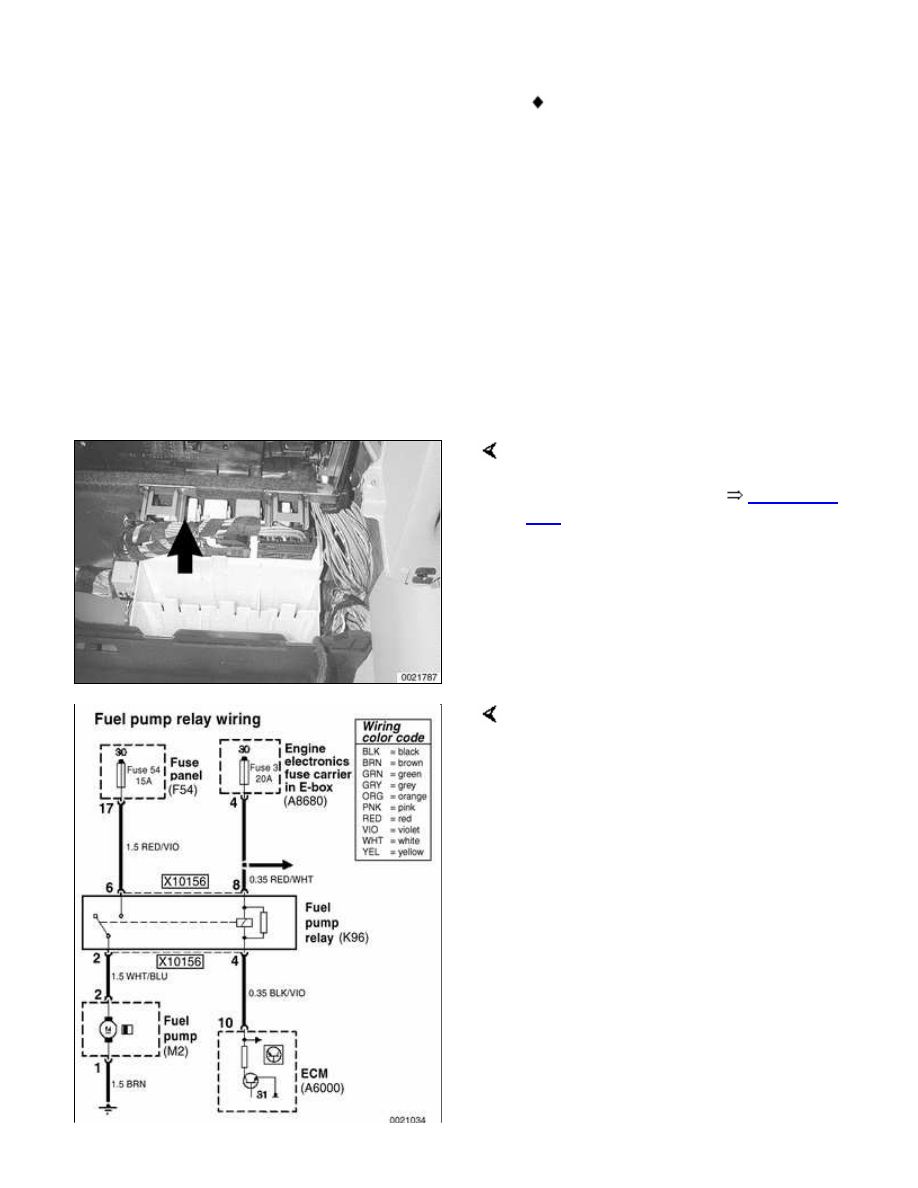

Fuel pump relay, testing

The ECM energizes the fuel pump

relay by providing the coil side of the

relay with ground. During starting, the

fuel pump runs as long as the ignition

switch is in the start position and

continues to run once the engine

starts. If the relay is faulty the fuel

pump will not run.

Fuel pump relay (arrow) is located

behind glove compartment. Remove

glove compartment. See

513 Interior

Trim

.

-

Remove fuel pump relay from

socket.

With ignition in START position, check

for battery voltage at relay connector

(X10156) terminals 6 and 8 (red/violet

andred/white wires).

CAUTION!

Ensure that manual transmission

vehicles are not in gear, and

automatic transmission vehicles are

in Park or Neutral prior to operating

ignition in START position.

-

With ignition in START position,

use digital multimeter to check for

ground at terminal 4 (black/violet

wire).

Note:

Нет комментариевНе стесняйтесь поделиться с нами вашим ценным мнением.

Текст